SRT SC12E User manual

Stripe Removal Technologies

(SRT)

1-877-205-6053

www.striperemovaltechnologies.com

Thank you and congratulations on your decision to purchase Stripe Removal Technologies

Surface Preparation Equipment! We are confident that you will be satisfied with your

purchase and that you will receive many years of quality use and production.

Our goal is nothing short of excellence in providing the finest surface preparation equipment

and service that can be found on the market today. This pursuit of excellence is founded upon

our 20 years in selling and servicing surface preparation equipment. The staffs at SRT are

dedicated to providing exceptional service and are the cornerstone by which the SRT

superior product line is built.

When you need timely service, support or replacement parts, SRT is there with regional

warehouses, same day shipping of parts and machines or delivery right to your jobsite. Sales

and service staff are available from 5:00 AM to 5:00 PM (PST) for jobsite consulting, trouble

shooting or for shipping orders.

On behalf of the entire Stripe Removal Technologies Team, thank you for your valued

business and we look forward to servicing your surface preparation needs.

Sincerely,

Stripe Removal Technologies

Jim Weder

President

Stripe Removal Technologies Equipment Safety Policy Statement

Stripe Removal Technologies (SRT) is adamant that safety is the highest priority for both our employees

and customers. When considering set-up and operation of any piece of equipment supplied,

manufactured, distributed, rented or serviced by Stripe Removal Technologies, the safety and protection

of people should always be the top priority.

All customers and employees should follow all of OSHA and local safety standards, requirements and

regulations.

The use of the following safety equipments are both recommended and required when operating any piece

of equipment supplied, manufactured, distributed, rented or serviced by Stripe Removal Technologies.

OSHA approved/certified eye protection (safety glasses).

OSHA approved/certified hearing and ear protection.

OSHA approved/certified foot protection (steel toed boots).

OSHA approved/certified respirator or breathing device.

OSHA approved head protection (hard hat).

Proper protective work gloves.

Proper protective clothing limiting skin exposure.

(The list is not meant to be all inclusive, please exercise sound judgments during operation)

The work area must always have proper ventilation to minimize the health and safety risks of propane and

gasoline emissions and airborne dust.

All SRT Equipments are engineered, designed and provided with dust control shrouds and vacuum ports.

It is strongly recommended that an approved dust containment system be connected to and used in

conjunction with all SRT equipment during operational use. SRT supplies, distributes, rents and services

dust control systems with HEPA filtration.

Extreme caution must be exercised at all times when electrical power is considered. All SRT

employees are prohibited from working on or hard wiring our equipments to any power source that

has not been provided by SRT. Any such work must be performed by a certified electrical

technician. No SRT employee is permitted or authorized to work on, operate or connect to our

equipment or equipment belonging to our customers to an electrical source that is not within OSHA

approved specifications. There are no exceptions to this policy! SRT also strongly recommends that

only certified electricians be permitted to deal with or manipulate electrical power sources within

our customers’ facilities or on their job-sites.

Finally, we at Stripe Removal Technologies cannot stress enough the importance of following

general safety practices, the utilization of appropriate safety equipment and the application of

common sense when operating equipment supplied, manufactured, distributed, rented or serviced

by SRT both on the job-site and in the field.

Table of Contents

Important Information.....................................................................................................................................8

Safety Communication.................................................................................................................................... 9

General Instructions.......................................................................................................................................9

(PPE) Personal Protection Equipment......................................................................................................... 10

General Operation.........................................................................................................................................10

Before Starting the Machine.........................................................................................................................11

Electrical Powered Equipment.....................................................................................................................11

Poisonous Exhaust........................................................................................................................................12

Dust Warning...............................................................................................................................................14

Dry Grinding................................................................................................................................................14

Maintenance....................................................................................................................................................15

Engine Air Filter..........................................................................................................................................15

Operating Procedures for SC12E (GAS)......................................................................................................17

Start-Up......................................................................................................................................................16

Drive Motor/Engine:..................................................................................................................................16

Cutter/Drum Configuration........................................................................................................................16

Working with the Scarifier:........................................................................................................................16

Changing the cutter drum:..........................................................................................................................17

Dust Control:..............................................................................................................................................17

Cutter and Flail Shaft Recommendations....................................................................................................18

Parts for Honda Engine – Gas.......................................................................................................................20

Parts for Chassis.............................................................................................................................................22

Parts for Tensioning Pulley; Belt Guard......................................................................................................24

Parts for Housing; Front Wheel; Dust Shield..............................................................................................26

Parts for Hex Drive Shaft...............................................................................................................................28

Parts for Drum................................................................................................................................................30

Parts for Depth Adjuster................................................................................................................................32

Parts for Axle..................................................................................................................................................36

Parts for Spring Assembly.............................................................................................................................38

Stripe Removal Technologies Scarifier SC12E User Manual

Important Information

DO NOT OPERATE THIS EQUIPMENT WITHIN AN ENCLOSED AREA. The

exhaust from the internal combustion engine contains carbon monoxide, an odorless and

deadly poison. If using equipment indoors, proper and adequate ventilation is required. An

approved OSHA air-monitoring system must be in place at all times. Avoid inhalation of

exhaust gas.

Carbon monoxide gas is toxic. Breathing it can cause unconsciousness and may KILL you.

Avoid any areas or actions that expose you to carbon monoxide.

Do to the use of the equipment; suitable protective clothing must be worn or bodily harm

may occur. The machine operator must wear eye protection, gloves, earplugs and non-slip

safety shoes.

When doing work that causes dust, wear an appropriate respiratory mask that will protect

you from the type of dust you are working in.

Before operation please read about this topic and other important safety information that is

contained within the enclosed Engine Owners Manual.

Stripe Removal Technologies © 2006 All Rights Reserved

Stripe Removal Technologies Scarifier SC12E User Manual

READ AND UNDERSTAND BEFORE

ATTEMPTING TO OPERATE THIS EQUIPMENT

Safety Communication

Safety Instructions are preceded by a graphic alert symbol of

DANGER, WARNING, or CAUTION

Imminent hazard which, if not avoided, will result in death or serious

injury.

injury.

Imminent hazar ded, can res ult in d eath or serious d which, if not avoi

Hazards wh ich, if not avoided, could result in s erious injury and or

damage to the equipment.

General Instructions

Maintain the machine in safe operating condition with all guards in place and secure all

mechanical fasteners tight

Ensure all controls in working order and the machine is configured for the job application.

Be sure all safety decals can be clearly read and understood. Replace damaged or missing

decals immediately.

Equipment should only be operated by trained personnel in good physical condition and

mental health.

Never operate this machine while under the influence of drugs, alcohol or when taking

medications that impair the senses or reactions, or when excessively tired or under stress.

Avoid deck inserts, pipes, columns, openings, electrical outlets, or any objects protruding

from slab surface.

Maintain a safe operating distance to other personnel. It is the operators’ responsibility to

keep other people (workers, pedestrians, bystanders, etc.) at a safe distance during

operation.

Block off the work area in all directions. Failure to do so may result in others being injured

by flying debris or exposing them to harmful dust and noise.

Stripe Removal Technologies © 2006 All Rights Reserved

Stripe Removal Technologies Scarifier SC12E User Manual

For the oper ator’s safety and the saf ety of ot hers, always keep all guards in place during

operation.

Never let equipment run unattended.

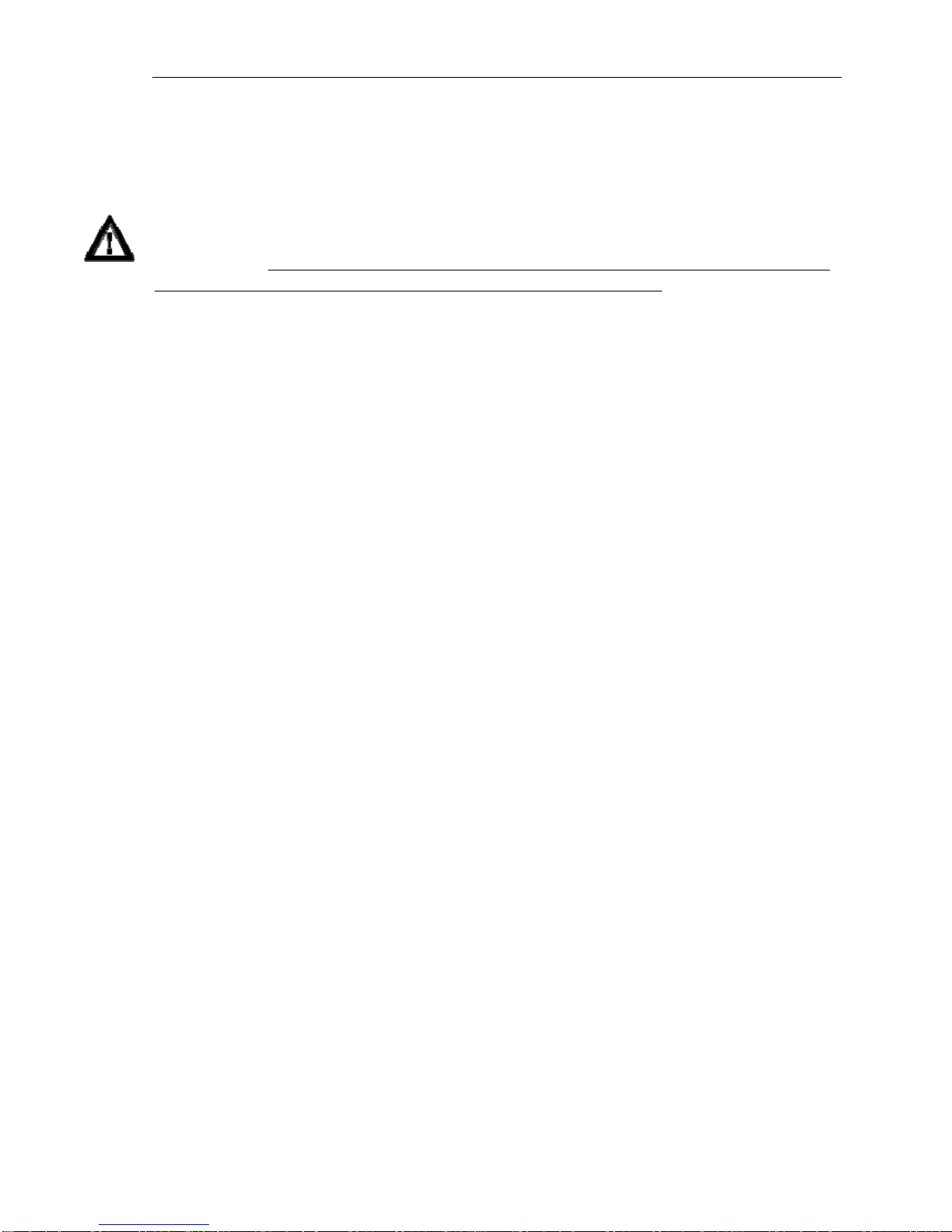

(PPE) Personal Protection Equipment

Proper safety attire must be worn when operating this machinery.

es when conditions require.

e

e

ate clothin

worn.

lt in dismemberment or death.

The operator m ust wear approved safety equip ment appropriate for the job

such as hard hat and safety sho

Ear protection m ust be wor s when t his machine is in use. During

normal use, sound levels exc

n at all tim

eed 92dB.

Eye protection must be wor s when this machine is in use. Use only

ANSI approved safety glasses to help prevent eye injury.

n at all tim

Operator must wear appropri g and footwear. Steel toe safety shoes

should be

Do not wea r loose clothing or jewelr y that can get tangled or caught in

moving parts. Keep body parts and loos e clothing away from moving parts.

Failure to do so could resu

General Operation

Stop motor/engine when adjusting or servic ing this equip ment. Maintain a saf e operating

distance from flammable materials.

Sparks from the cutting-action of this machine can ignite flammable materials or vapors.

Check motor rotation.

DO NOT use if drum rotation is incorrect - have a qualified electrician make the necessary

change in the main control panel or motor connection box.

Stripe Removal Technologies © 2006 All Rights Reserved

Stripe Removal Technologies Scarifier SC12E User Manual

Before Starting the Machine

Perform a visual in spection of the entire m achine and all daily m aintenance according to

the Maintenance Schedule.

Locate and be familiar with all engine/motor and operating controls.

For Gasolin e m odels, obtain th e Engine Manufacturer’s Owner’s Manual. Read it and

understand it before continuing. Follow the engine manual for break-in instructions.

Use the correct cutters for the job. Be sure cutter drum is ba lanced, the num ber, size and

type of cutter wheels are correct.

Be sure all fasteners are tight and secure, check for sign s of m etal cracking or fatigue,

inspect for damage to electrical wiring, damage to fuel lines, check bearings, etc.

Be sure all guards are in place.

Inspect work area to determ ine the presence an d location of deck inserts, pipes, colum ns

and objects protruding from the slab surface so that they may be avoided during operation.

Safety warnings and guidelines do not by themselves eliminate danger.

They are not given as substitutes for proper accident prevention and good judgment.

Electrical Powered Equipment

For Electric Models - Electric motors must be properly grounded at all

times. Check the outlet box to be sure the electrical service is properly

grounded. Be sure adequate power is available. Insufficient power will cause a

motor to overheat and burn out.

Use only grounded extension cords correctly sized for the current draw and voltage drop

(amp rating and length). Never use frayed, damaged, taped or under rated extension cords.

Electrical shock could result in death or serious injury to the operator

and damage to the equipment.

Extreme care must be taken when operating electric models with water present: Ensure

power cord is properly grounded, is attached to a Ground-Fault-Interrupter (GFI) outlet,

and is undamaged.

Check all electrical cables - be sure connections are tight and cable is continuous and in

good condition. Be sure cable is correctly rated for both the operating current and voltage

of this equipment.

Stripe Removal Technologies © 2006 All Rights Reserved

Stripe Removal Technologies Scarifier SC12E User Manual

Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. Check with qualified electrician or service person if there is any doubt as to whether

the outlet is properly grounded. Adhere to all local codes and ordinances.

NOTE: In the event of a malfunction or breakdown, grounding provides a path of least

resistance for the electric current to dissipate. The motor is equipped with a grounded plug

and must be connected to an outlet that is properly installed and properly grounded. DO

NOT modify the plug provided on the motor. If the plug does not fit the outlet have a

qualified electrician install the proper receptacle.

Switch motor OFF before disconnecting power.

Do not disconnect power by pulling cord. To disconnect, grasp the plug, not the cord.

Unplug power cord at the machine when not in use and before servicing.

Starting the Engine/Motor for Electric Models

Be sure the “OFF” button is depressed on the motor starter box.

Hook up the correct voltage/phase electrical power source by plugging into the connector

provided. If the cord does not mate with the connector, consult a qualified licensed

electrician before continuing.

Verify that the electrical current being supplied is the proper voltage and phase required to

run the equipment.

Poisonous Exhaust

Gasoline and Propane Powered Models

DO NOT operate any gasoline/propane powered equipment without adequate ventilation.

Carbon monoxide is an invisible, odorless gas that can kill.

NEVER REFUEL A HOT ENGINE OR AN ENGINE WHILE IT IS RUNNING.

Only refuel a cool “stopped” engine in a well-ventilated area. Properly clean any spilled

fuel before starting the engine.

Gasoline is extremely flammable and poisonous. It should only be dispensed in

well ventilated areas, and with a cool engine.

Propane is extremely flammable.

Stripe Removal Technologies © 2006 All Rights Reserved

Stripe Removal Technologies Scarifier SC12E User Manual

Engine exhaust from this product contains chemicals known to cause cancer, birth

defects or other reproductive harm.

Small gasoline engines produce high concentrations of carbon monoxide

(CO). Gasoline or propane powered equipment should not be used in

enclosed or partially enclosed areas. Symptoms of CO poisoning include,

headache, nausea, weakness, dizziness, visual problems and loss of

consciousness. If symptoms occur get into fresh air and seek medical attention

mediately.

nual and follow the

irections for starting the engine and allow the engine to warm up.

ne

ould the gasoline model. Be sure propane tank is positioned

orrectly.

urn on main fuel valve at propane tank.

heck all connections for tightness and leaks.

sult a qualified

P-gas service person or STRIPE REMOVAL TECHNOLOGIES directly.

EVER check for propane leaks using an open flame. Instead, use a leak-testing solution.

propane fumes to escape in a closed area; propane is heavier than air and

ill “settle.”

t this propane powered equipment, open the main fuel valve located on the propane

nk.

pen the throttle wide open and start the engine.

ays turn off the main fuel valve on the propane tank when equipment is not

eing used.

cturer’s Owner’s Manual for maintenance information

pecific to the engine/motor used.

im

Gasoline Models - Consult the Engine Manufacturer’s Owner’s Ma

d

Propane Models - Propane models use a vapor withdrawal system. Operate the propa

engine much like you w

c

T

C

If you detect an odor, IMMEDIATELY shut off the main fuel valve and con

L

N

NEVER allow

w

To star

ta

O

NOTE: Alw

b

Refer to the Engine/Motor Manufa

s

Stripe Removal Technologies © 2006 All Rights Reserved

Stripe Removal Technologies Scarifier SC12E User Manual

Dust Warning

Some dust created by grinding and other construction activities

contains chemicals known to cause cancer, birth defects, or other

reproductive harm.

Some examples of these chemicals are:

•Lead from lead-based paints

•Crystalline silica from concrete and other masonry products

Your risk of exposure to these chemicals varies depending on how often you do this type of

work.

To reduce your risk work in a well ventilated area, use a dust control system,

such as an industrial-style vacuum, and wear approved personal safety

equipment, such as a dust/particle respirator designed to filter out microscopic

particles.

Dry Grinding

Dry Grinding creates a large volume of airborne dust. For health reasons, the operator

should wear an applicable respirator. The dust may contain chemicals known to cause

serious illnesses, including Silicosis - a fatal disease of the lungs.

Check the chemical properties of the material to be removed and follow all EPA/OSHA

regulations.

An Industrial vacuum, capable of handling high volume of fine dust, should be used when

dry grinding with this machine. If the material being used is hazardous or contains Silica -

the vacuum unit should be capable of removing Silica and hazardous particles of less than

3 microns and if necessary, have the capability to be equipped with a HEPA filter.

Most standard drum type units use a paper bag filter. The dust created during grinding is

extremely fine and will clog the filter bag of these units and eventually damage the

vacuums motor. In addition, damage to the engine could occur.

The collected debris and filters should be disposed of according to procedures that comply

with current EPA/OSHA standards

Serious injury or death could occur if this machine is used improperly.

Stripe Removal Technologies © 2006 All Rights Reserved

Stripe Removal Technologies Scarifier SC12E User Manual

Maintenance

Proper belt tension must be maintained to transmit the engine/motor power to the cutting

drum. An over tensioned belt will shorten belt and bearing life.

A damaged, stretched or excessively worn belt should be replaced.

Check oil level before operation. Change engine oil and filter according to engine

manufacturers recommendations.

Engine Air Filter

Important! Clean air filter element daily

Inspect the air filter for excess dust, dirt or damage before the engine is operated. More

often if operating in an extremely dusty environment.

Operating the engine with a damaged or dirty air filter, or without an air filter, will allow

dirt to enter the engine causing premature engine wear which is not covered under the

engine manufacturer’s warranty.

Follow the engine manufacturer’s procedures for keeping filters in good condition.

Never work on or under equipment without first securing the equipment to prevent it from

moving or falling.

Always work on a flat and level surface.

Remove spark plug lead on gasoline/propane engine models or disconnect the supply

voltage connector on electric models before performing any maintenance.

Disconnect the power cord at the machine.

Stripe Removal Technologies © 2006 All Rights Reserved

Stripe Removal Technologies Scarifier SC12E User Manual

Operating Procedures for SC12E (GAS)

Start-Up

•Add oil and gasoline to the machine.

•Move the fuel valve lever to the ON position.

•Move the choke lever to the CLOSED position (cold engine).

•Move the throttle lever 1/3 of the way toward the FAST position.

•Turn the engine switch to the ON position.

•Operate the starter by lightly pulling the starter grip until you feel resistance, then

pull briskly.

•Gently return the starter grip.

•Lower drum and begin grinding.

•Read the following additional information before operating your scarifier.

Caution: Never tilt the unit back on the handle. Oil will flow into the cylinder head

and could severely damage the motor and void the warranty.

Drive Motor/Engine:

The internal combustion engines are supplied without fuel or motor oil. Therefore, be sure

to fill them as instructed in the manufacturer’s manual. If the motor suddenly stops, the oil

could be to low or it may have been overfilled.

Caution: Start the motor ONLY when the cutter drum assembly is in the raised position.

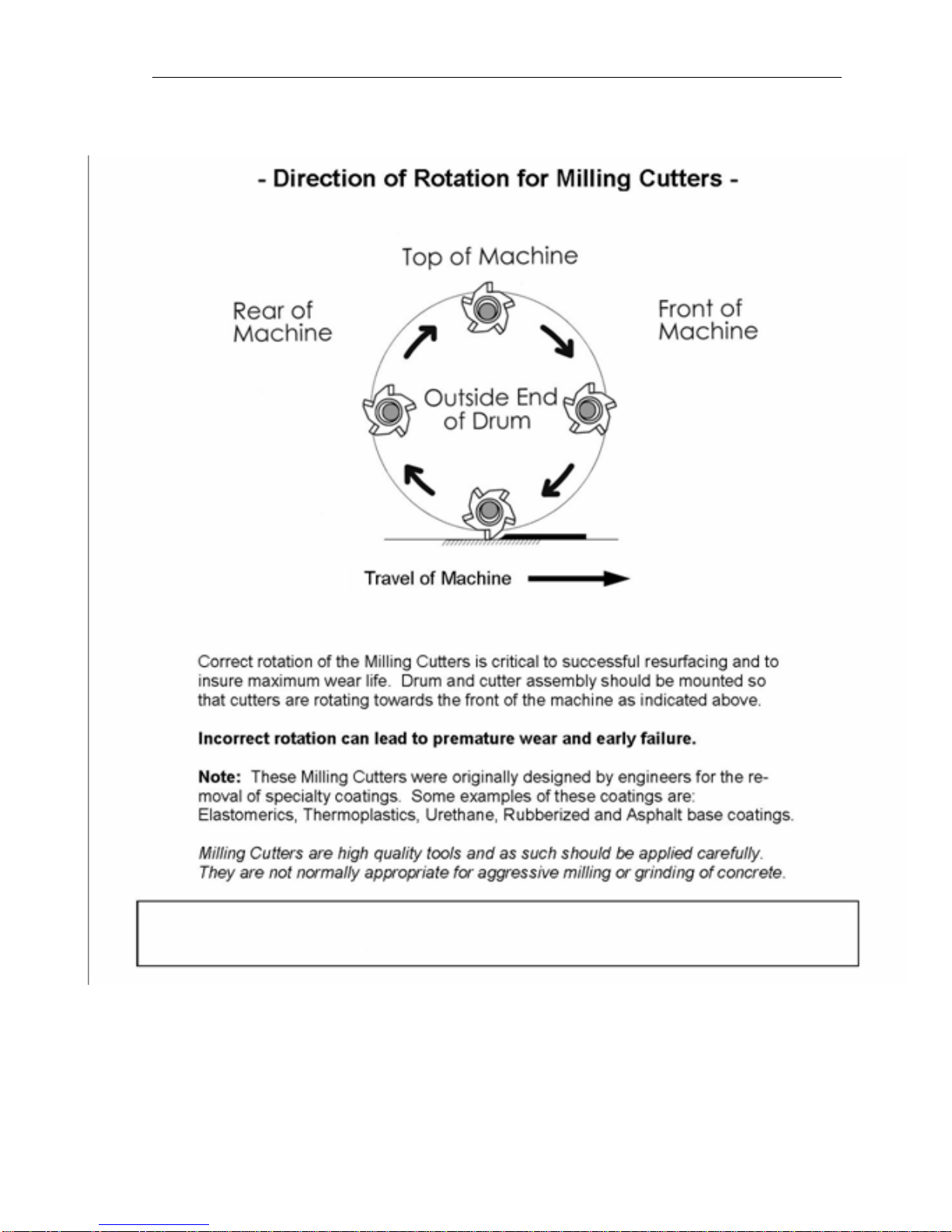

Cutter/Drum Configuration

Check to make sure that the drum is configured with the cutters we recommend for the

application in question. When working with special milling cutters, be extra careful about

the correct direction of drum rotation and correct cutter installation. Never tip the machine

on its back to look at the cutters. This can be done quickly and easily by removing the

endplate. When putting the endplate back on the machine, make certain to check the

tightening torque of cover nuts.

Caution: To avoid bearing damage, repeat this check of the cover nuts from time to time!

Working with the Scarifier:

To engage the drum, lift the black handle up and proceed in forward motion with the lever.

Once the drum engages, you can go lower for more aggressive cutting or back up for

lighter scarifying. For fine-tuning of the adjustment depth, turn the black dial clockwise

until the desired adjustment is reached.

Caution: Do not lower the black handle too deep. This will NOT increase productivity.

When the depth is set correctly, the machine will run smoothly.

Stripe Removal Technologies © 2006 All Rights Reserved

Stripe Removal Technologies Scarifier SC12E User Manual

To stop scarifying, lift the black handle up and proceed in a backward motion until the

lever is in the uppermost position

Changing the cutter drum:

Always be sure to switch off the machine before removing the endplate. This will prevent

any flying debris from injuring the worker. Remove the cover nuts from the endplate, and

then remove the endplate to expose the cutter drum assembly.

Dust Control:

Should dust control be of concern, please contact Stripe Removal Technologies to inquire

about our powerful dust control vacuums. The SC12E can be used with an optional 2”

vacuum connection.

If you need further assistance, please call our toll free number 1-877-2056053.

Stripe Removal Technologies © 2006 All Rights Reserved

Stripe Removal Technologies Scarifier SC12E User Manual

Cutter and Flail Shaft Recommendations

- The above flail shafts are showing excessive wear. These shafts should have been

replaced much earlier.

To a great extent, economical use of cutter drums depends upon proper maintenance. Changing flail

shafts before they become excessively worn and begin to oval out the shaft holes can significantly

increase the life of the drum. If you run a machine with badly worn flail shafts you can easily

destroy a drum in just a few hours. These shafts are only surface hardened in order to maintain their

internal strength. This is why it is important to replace them as soon as the grooves are 1/5 of an

inch or 5mm deep.

Changing the shafts early provides the following advantages:

•The drum shaft holes will not wear as fast thus increasing drum life.

•Breakage of shafts can be avoided, thus saving a great deal of downtime refitting the

machine.

Recommendations:

•When working with five, six, eight or 12 point Tungsten Carbide tipped cutters or special

milling cutters, replace the shafts every fifteen to twenty hours of operation.

•When working with steel cutters change the shafts every time new cutters are installed.

•Change the entire cutter/drum assembly after 3 sets of cutters have been used up, if not

sooner.

Stripe Removal Technologies © 2006 All Rights Reserved

Stripe Removal Technologies Scarifier SC12E User Manual Stripe Removal Technologies Scarifier SC12E User Manual

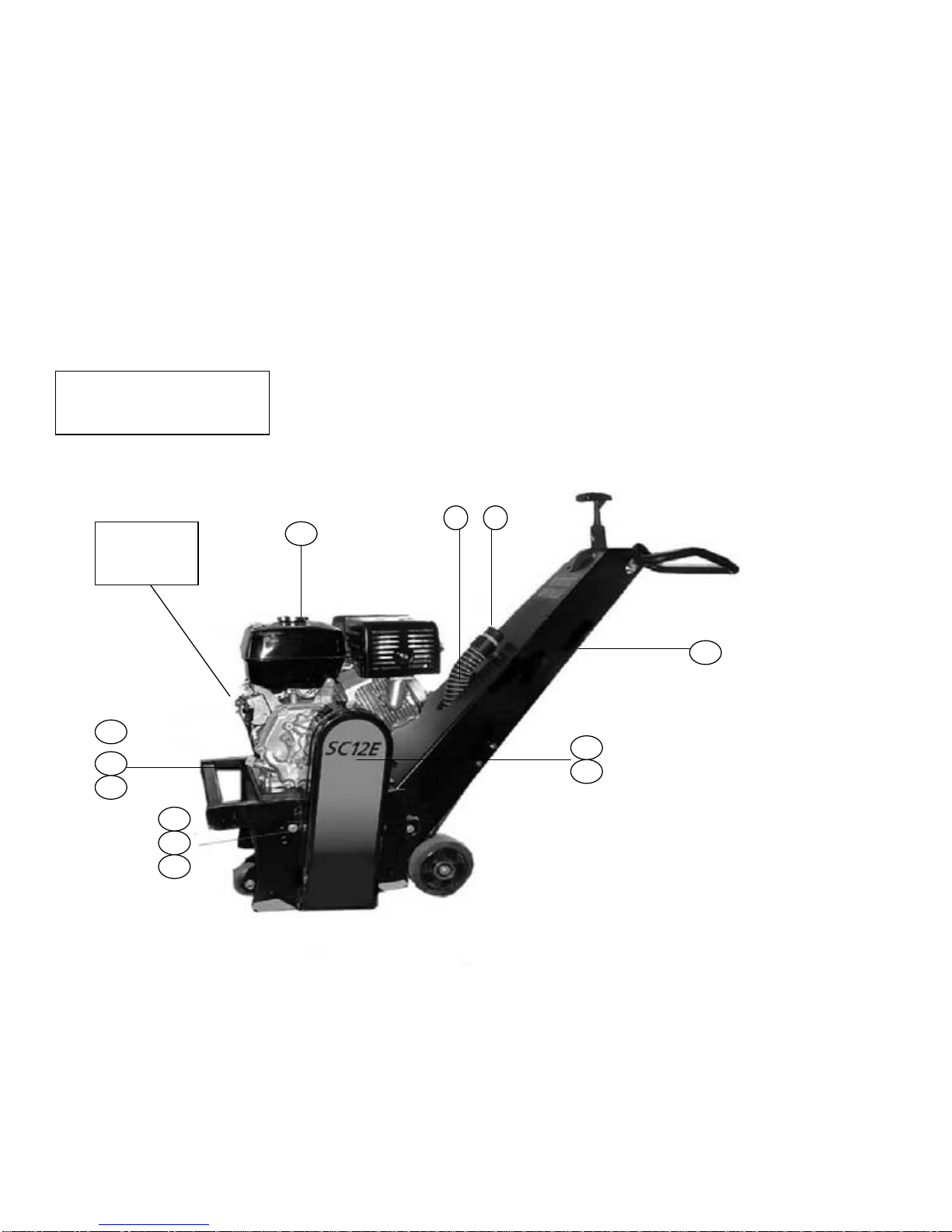

Stripe Removal Technologies © 2006 All Rights Reserved

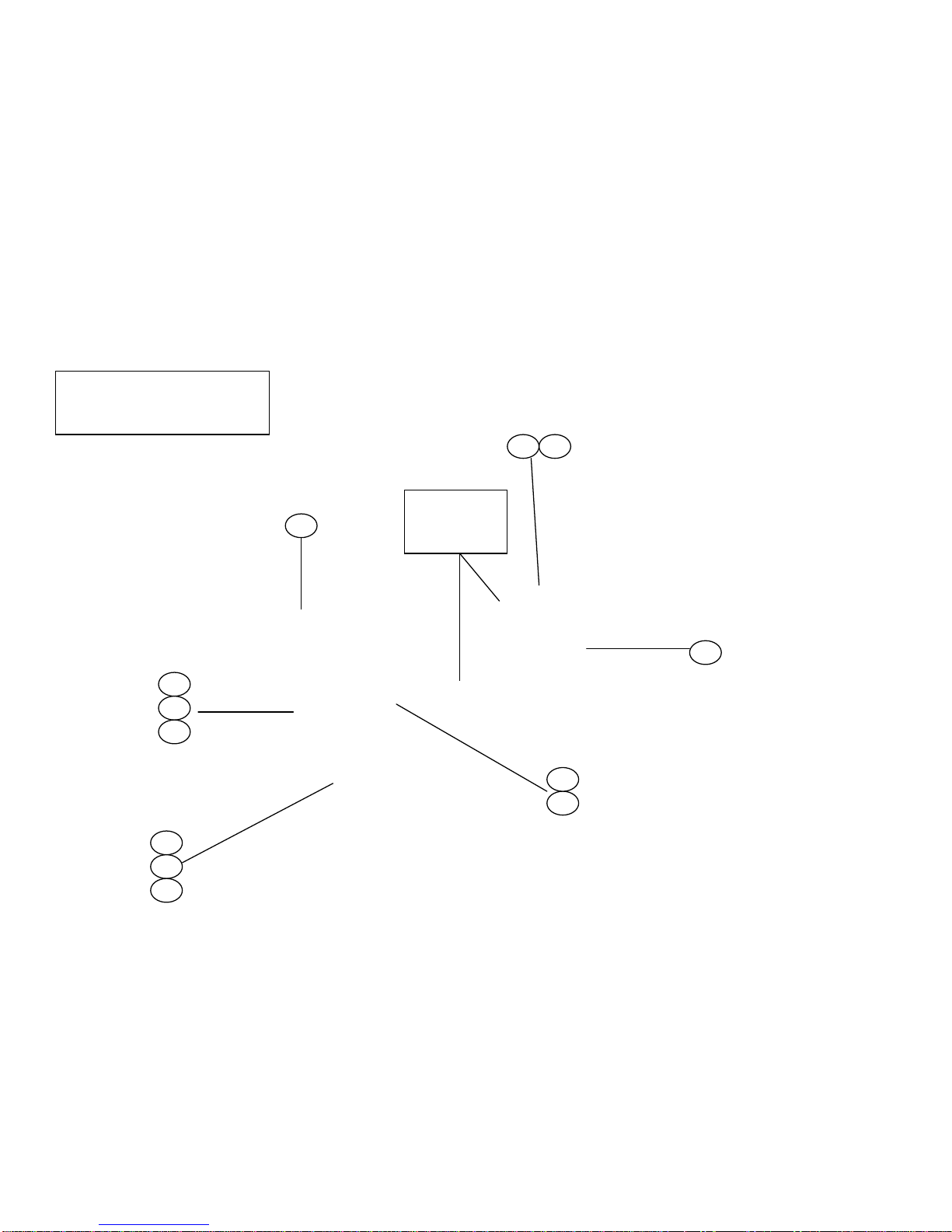

1

2

3

5

6

5

6

4

Dead man

Switch

& Wiring

SC12E gas

8 7

17

16

SC12E User Manual

SASE Company, Inc © 2006 All Rights Reserved

18

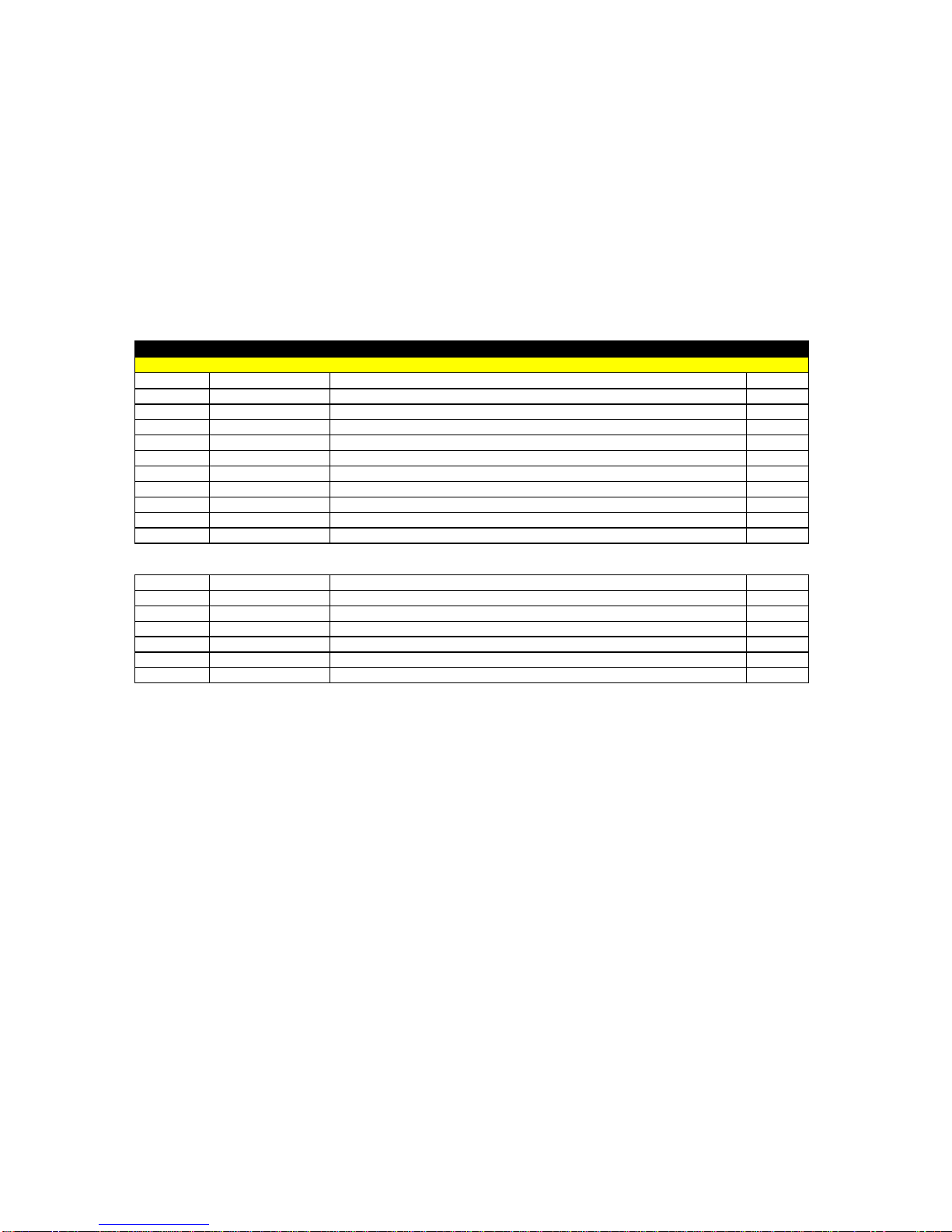

Item No Part No Description Quantity

1 HON.GX390 13 HP ENGINE GX390 VA 30 S 1

2 SC.12.000 Black SC12E Scarifier Chassis w/ Drum 1

3 NB.10.113 M10X35 Hex Screw 4

4 NB.10.137 M10X20 Hex Screw 2

5 NB.30.110 M10 Flat Washer 6

6 NB.30.210 M10 Lock Washer 6

7 VAC.8A02261 2 inch Inlet Bull Cap 100 1

8 VAC.HS2.00TR7 Vacuum Hose 2 ft

16 SC.12.156 PULLEY, UPPER FOR GAS ENGINE 1

17 SC.12.117 BELT, TOOTHED FOR GAS ENGINE 1

Deadman Switch & Wiring

9 795.00.12 11" x 0.125" Black Zip Tie 2

10 795.00.19 Emergency Stop Tether Switch 1

11 795.00.20 16-14 AWG Bullet Connector Blue Nylon 1

12 795.00.21 22-18 AWG Ring-1/4" Stud Red Nylon 1

13 795.00.22 22-18 AWG Butt Connector Red Vinyl 2

14 795.00.23 3/8" HEAT SHRINK TUBING BLACK 4 in

15 AIW.16X2CRD Power Cord 16/2 4 ft

SC12E GAS

SC.12.020

SC12E User Manual

SASE Company, Inc © 2006 All Rights Reserved

19

SC12E 230V

Three Phase

10

1

4

7

8

5

6

9

3

2

Dead man

Switch

& Wiring

1211

SC12E User Manual

SASE Company, Inc © 2006 All Rights Reserved

20

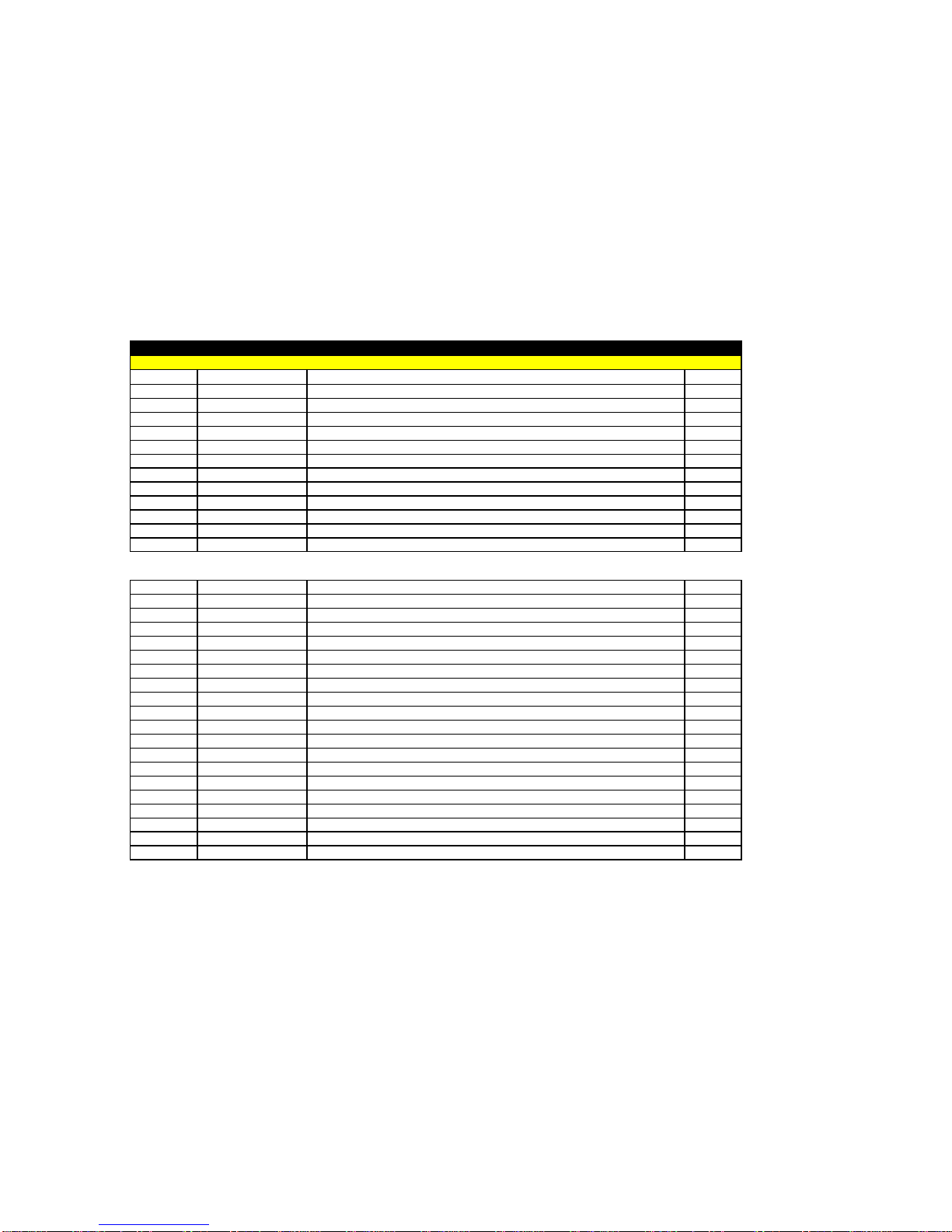

Item No Part No Description Quantity

1 SC.12.000 SCARIFIER, BLACK SC12E CHASSIS W/ DRUM 1

2 SC.12.117 BELT, TOOTHED 1040 VA 30 S SC12E GAS 1

3 SC.12.154 PULLEY, ELECTRIC W/O TAPER BUSHING VA30S SC12E 1

4 NB.10.107 SCREW, HEX HEAD M12 X 25 ZINC 4

5 NB.10.126 SCREW, HEX M10 X 16 ZINC 2

6 NB.30.110 WASHER, FLAT M10 ZINC 2

7 NB.30.130 WASHER, LOCK M12 ZINC 4

8 NB.30.134 WASHER, FLAT M12 ZINC 4

9 NB.30.210 WASHER, LOCK M10 ZINC 2

10 ZZ.KM121T MOTOR, ELECTRIC VA 30 S/FR 300 3 PH 1

11 VAC.8A02261 CAP, 2 INCH INLET BULL 100 1

12 VAC.HS2.00TR7 HOSE, VACUUM FOR SC10E 2.0" ID BY THE FOOT 2 ft

Deadman Switch & Wiring

13 655.22.G1 BUSHING, GRIP VA 30 ELECTRIC 1

14 795.00.04 CONDUIT, 3/4" LIQUIDTIGHT FLEXIBLE NON-METALLIC PER FOOT 2 ft

15 795.00.05 3/4" L/T BULLET CONNECTOR LT75P 1

16 795.00.06 3/4" W/R BLACK SLRN21 1

17 795.00.07 1/2-IN BLACK CORD GRIP SLN13 1

18 795.00.08 3/4-IN 45 BULLET L/T CONNECTOR 1

19 795.00.10 18 GAUGE WIRE NUT YELLOW 3

20 795.00.11 20 GAUGE WIRE NUT ORANGE 3

21 795.00.62 REDUCING WASHER 1-1/4" X 3/4" 2

22 AIW.10X4CRD CORD, POWER 10/4 6 ft

23 MCC.27.25A SWITCH, 25 AMP 1

24 MCC.27.KAZ BOX, SWITCH ENCLOSURE FOR 25A SWITCH 1

25 MCC.27AA220 MODULE, SHUNT RELAY 220V FOR 25A SWITCH 1

26 NB.19.101 8-32 X 3/4 Pan Head Screw 2

27 NB.20.133 8-32 Nyloc Nut 2

28 795.00.12 ZIP TIE BLK 11" X 0.125" 2

29 795.00.19 SWITCH, EMERGENCY STOP TETHER WITH CORD 1

30 795.00.22 22-18 AWG BUTT CONNECTOR RED VINYL 2

31 795.00.23 3/8" HEAT SHRINK TUBING BLACK 4 in

32 AIW.16X2CRD CORD, POWER 16/2 2 ft

SC12E 230V Three Phase

SC.12.040

Table of contents