•Neveroperatewiththeguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly,and

functioningproperty.

•Donotexceedtheratedoperatingcapacityofthe

machine,asthemachinemaybecomeunstablewhichmay

resultinlossofcontrol.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Neverleavethemachinerunningunattended.Always

stoptheengine,settheparkingbrake,andremovethe

keybeforeleaving.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Checkforoverheadclearances(i.e.branches,doorways,

electricalwires)beforedrivingunderanyobjectsanddo

notcontactthem.

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthemachine

backsupduringoperationiftheoperatorisnotattentive

tothesurroundings.Onlyoperatetheunitinareaswhere

thereissufcientclearancefortheoperatortosafely

maneuvertheproduct.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

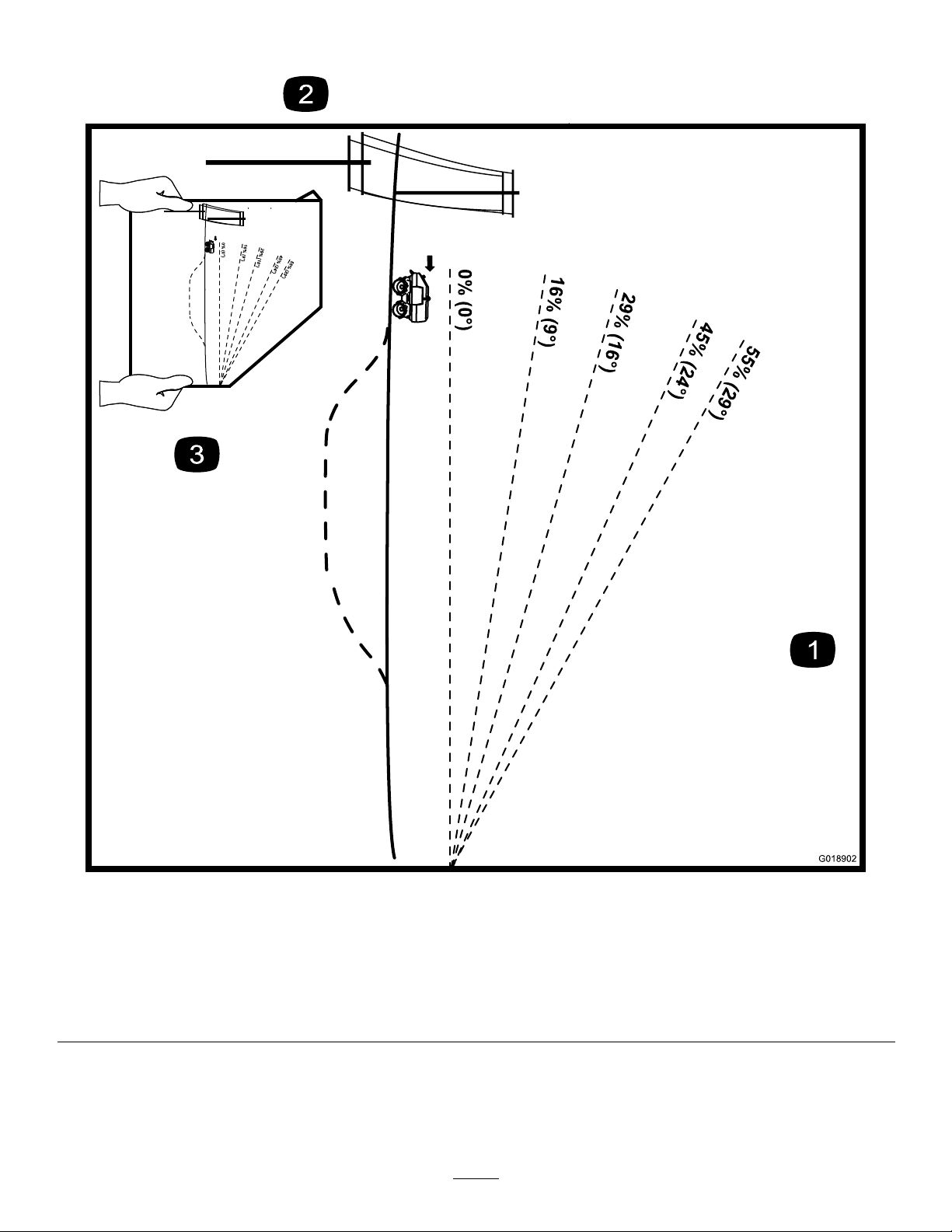

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Allslopesrequireextracaution.

•Donotparkthemachineonahillsideorslope.

•Ifpossible,avoiddrivingthemachineacrossaslope.

Whencrossingaslopeisnecessary,drivethemachine

straightuptheslope,acrossthetop,andthenstraight

downtheslope.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotoperatethemachineonhillsidesorslopes

exceedingtheanglesrecommendedinStabilityData

(page6).SeealsotheSlopeChart(page7)andTiltChart

(page8).

•Neveroperatethemachinewiththevibrationfunction

On,andmovingupordownagradethatisgreaterthan

45percent(24°).

•Neveroperatethemachinewiththevibrationfunction

Off,andmovingupordownagradethatisgreaterthan

55percent(29°).

•Neveroperatethemachinewiththevibrationfunction

Off,andmovingacrossthesideofahillwithagradethat

isgreaterthan18percent(10°).

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

workarea.Watchforholes,ruts,orbumps,asuneven

terraincouldoverturnthemachine.Tallgrasscanhide

obstacles.

•UseonlyToro-approvedattachments.Attachmentscan

changethestabilityandtheoperatingcharacteristics

ofthemachine.Warrantymaybevoidedifusedwith

unapprovedattachments.

•Avoidstartingorstoppingonaslope.Ifthemachine

losestraction,ensurethatthevibrationfunctionisturned

totheOffpositionandproceedslowly,straightdown

theslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly.

•Donotoperateneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifadrumgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Donotoperateonwetgrass.Reducedtractioncould

causesliding.

MaintenanceandStorage

•Parkthemachineonalevelsurface,settheparking

brake,stoptheengine,andremovethekey.Waitforall

movementtostopbeforeadjusting,cleaning,orrepairing.

•Cleandebrisfromthedrives,mufer,andengineto

helppreventres.Cleanupfuel,oil,andhydraulicuid

spillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentsofthemachine

whenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

last.Reconnectpositiverstandnegativelast.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

5