SSI A20829 User manual

Single Gas H2(Hydrogen)

Sensor Modules

With Optional O2Input

OPERATIONS MANUAL

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH45249

513-772-0060

Fax: 513-772-9466

www.supersystems.com

PN: A20829

PN: A20830

Super Systems Inc.

Page 2 of 38

Super Systems Inc.

USA Office

Corporate Headquarters:

7205 Edington Drive

Shipping Address:

7245 Edington Drive

Cincinnati, OH 45249

Phone: (513) 772-0060

http://www.supersystems.com

Super Systems Europe

Unit E, TyburnTrading Estate,

Ashold Farm Road, Birmingham

B249QG

UNITED KINGDOM

Phone: +44 (0) 121 306 5180

http://www.supersystemseurope.com

Super Systems México

SistemasSuperioresIntegrales S de RL de CV

Acceso IV No. 31 Int. H Parque Industrial

Benito Juarez

C.P. 76120 Querétaro, Qro.

Phone: +52 442 210 2459

http://www.supersystems.com.mx

Super Systems China

No. 369XianXia Road

Room 703

Shanghai, CHINA

200336

Phone: +86 21 5206 5701/2

http://www.supersystems.cn

Super Systems India Pvt. Ltd.

A-26 Mezzanine Floor, FIEE Complex,

OkhlaIndl. Area, Phase –2

New Delhi, India 110 020

Phone: +91 11 41050097

http://www.supersystemsindia.com

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 3 of 38

Page 3 of 51

Table of Contents

Introduction..................................................................................................................................... 4

Specifications.................................................................................................................................. 4

Connections Diagram ..................................................................................................................... 5

A20829 ......................................................................................................................................... 5

A20830 ......................................................................................................................................... 6

Connection Ports & Function ...................................................................................................... 6

Mounting ......................................................................................................................................... 7

A20829 ......................................................................................................................................... 7

A20830 ......................................................................................................................................... 8

Modbus............................................................................................................................................ 8

A20829 ......................................................................................................................................... 8

A20830 ......................................................................................................................................... 9

Modbus Registers ..........................................................................................................................10

Initial Network Configuration ........................................................................................................18

nLocateIP Method ......................................................................................................................18

Control Interface via Web Browser................................................................................................20

Main............................................................................................................................................21

Instrument Information..............................................................................................................21

Sensor Information ....................................................................................................................22

Instrument Configuration...........................................................................................................23

Output Configuration..................................................................................................................23

Output Calibration ......................................................................................................................25

Sensor Calibration......................................................................................................................26

A20829 ....................................................................................................................................26

A20830 ....................................................................................................................................28

Input Configuration ....................................................................................................................30

Zero & Span Calibration: ........................................................................................................30

TC Trim ...................................................................................................................................30

CJ Trim ...................................................................................................................................31

Alarms........................................................................................................................................31

SSI Configuration .......................................................................................................................32

Read/Write Registers.................................................................................................................33

Network Configuration...............................................................................................................34

Replacement Parts ........................................................................................................................35

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 4 of 38

Page 4 of 51

Warranty.........................................................................................................................................36

Appendix A: DIP Switch Setting Examples.....................................................................................37

Revision History .............................................................................................................................38

Introduction

SSi provides hydrogen gas analysis technology for use in heat treating and other industrial

environments. This manual covers the two H2versions of Single Gas Sensor Module (SGSM).

The in-situ H2sensor (A20829) is designed to mount directly to a vertical pipe on a furnace,

while the flow-through sensor (A20830) is designed to be mounted on DIN rail. For compliance

with electrical connection standards, the in-situ H2sensor functions are routed to a 10-Position

plug and an included connection cable. The connections for the DIN mounted flow-through

sensor are on terminal blocks located on the face of the sensor.

The primary function of each of these sensors is to measure H2, but each of them has the ability

to measure Oxygen (O2) with the addition of an external O2sensor (see details below). Note that

the Lambda O2sensor requires 12 VDC power.

Specifications

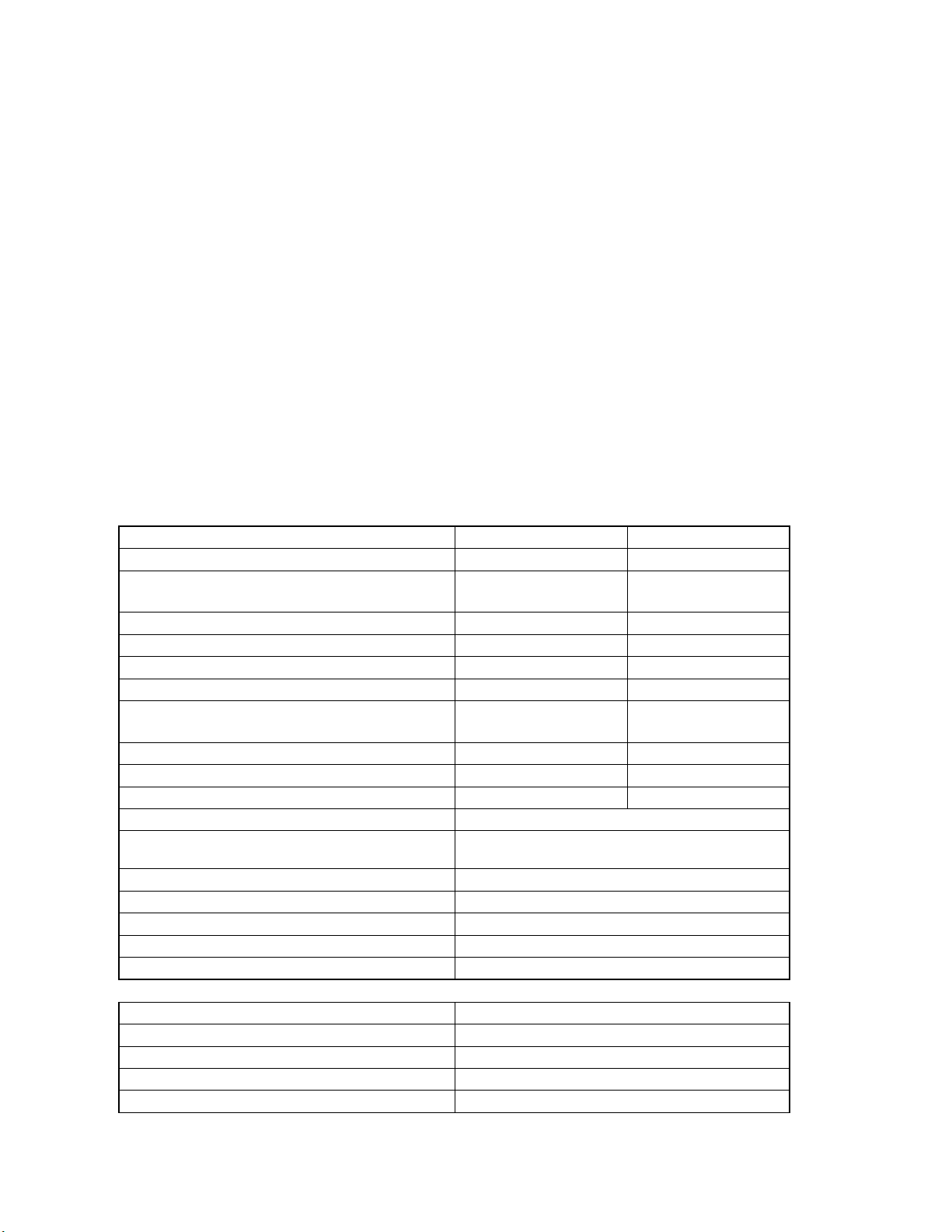

Specifications

In-Situ H2

Din Rail Mount H2

Part Number

A20829

A20830

24VDC (10-30VDC Acceptable) Power

Input

Yes

Yes

Analog Outputs (4-20mA or 0-5VDC)

2

2

Ethernet

1

1

USB Host port

0

1

USB Client port

0

1

RS485 Communications Ports (modbus

RTU)

1

2

Communications Port for HMI

0

1

Wiring Method

Cable (included)

Direct

Inputs for Optional Oxygen Sensor

Yes

Yes

Measurement Range

0 –100% of gas concentration

Accuracy

±1% of full scale (±0.1% of gas concentration,

based on 100%)

Resolution

0.1%

Response Time (to 90% of Reading)

0 - 6 seconds

Maximum Operating Temperature

122 °F (50 °C)

Field Calibration

Via web interface

Measurement Method

Thermal Conductivity

Specifications

Optional Oxygen Sensor

Part Number

31435

Measurement Range

0 - 21%

Accuracy

±0.1%

Measurement Method

Lambda Zirconia

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 5 of 38

Page 5 of 51

Connections Diagram

The following diagrams show the connections for the two versions of the SGSM.

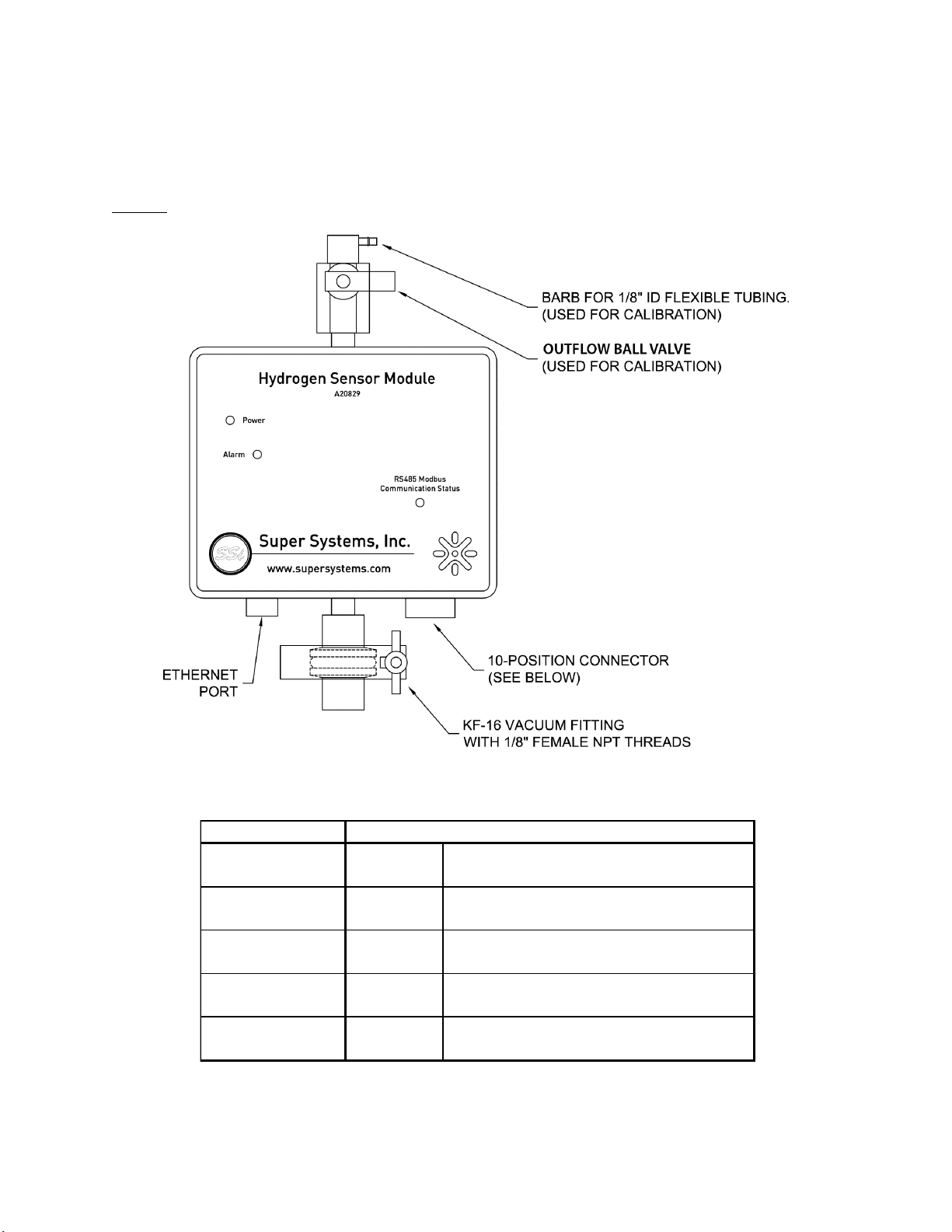

A20829

Figure 1 - Connections diagram for A20829

.

Wire Color

Red +VDC Power supply (24VDC @ 750 mA)**

Black -VDC

Green/Black Stripe +RS485 Communications signal

Red/Black Stripe -RS485 provided by modbus over serial

White/Black Stripe +O2 O2 input for lambda probe

Orange/Black Stripe

-O2 when used as H2/O2 sensor

Orange + mA Analog output #1

Blue - mA (4-20 mA)

Green + mA Analog Output #2

White - mA (4-20 mA)

Function

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 6 of 38

Page 6 of 51

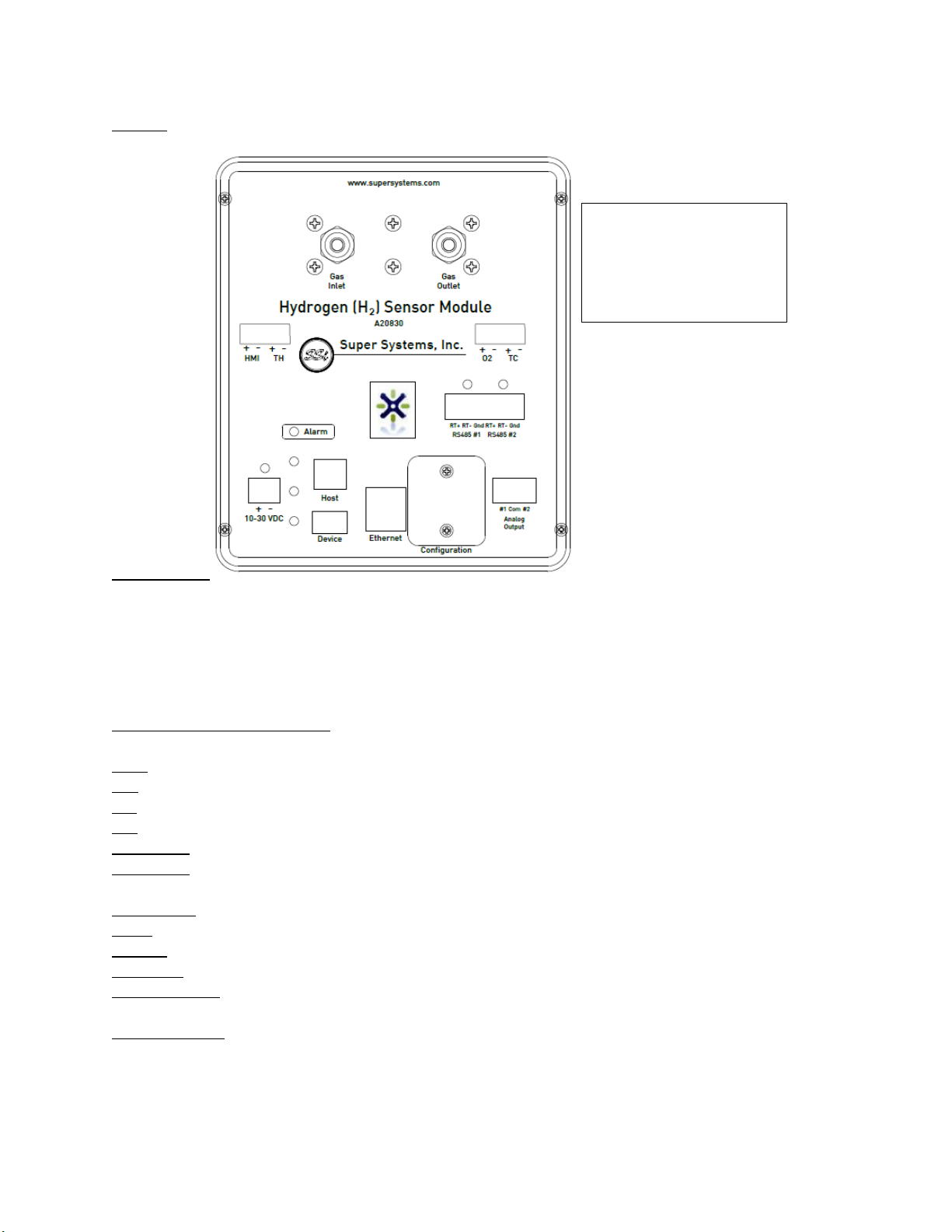

A20830

Figure 2 - Connections diagram for A20830

**Note that both the A20829 and A20830 will accept 10 –30 VDC power. They are commonly

powered using a 24 VDC supply. When a Lambda O2sensor is required, consider using a 12 VDC

supply for both the SGSM and the Lambda sensor. SSi offers a 12 VDC supply for this option.

Connection Ports & Function

HMI: This is the connection for an HMI.

TH: This connection port is N/A for this product.

O2: This is the port for the Lambda O2analog sensor.

TC: This connection port is N/A for this product.

RS485 #1: This is a communications port used for when this device is the Client.

RS485 #2: This is a communications port used for when this device is the Host to another

device.

10-30 VDC: This is the port to supply power to the SGSM.

Host: This is the USB Host port.

Device: This is the USB Client port.

Ethernet: This is the Ethernet port.

Configuration: This is where dip switch settings can be changed for the Modbus

communications address.

Analog Output: These ports are for analog output #1 and #2.

All connection points

are located on the front

of the unit and labeled

with the connection

type and polarity.

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 7 of 38

Page 7 of 51

Mounting

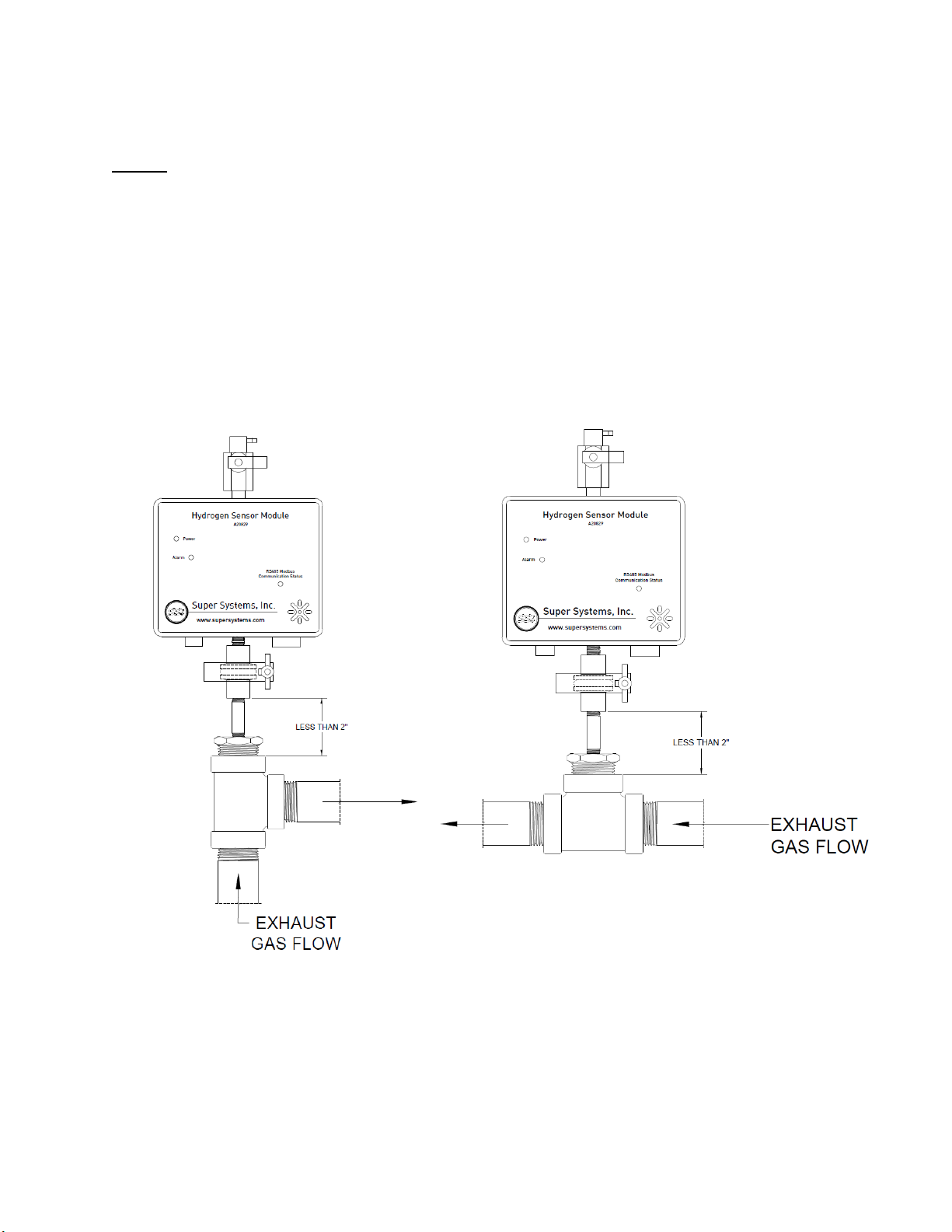

A20829

SSi recommends that the in-situ H2sensor (A20829) be mounted to the exhaust piping as close

to the furnace as possible. Many contaminants solidify when cooled and can cause irreversible

damage to the sensor over time. Heat from the gases will help to prevent the formation of

contaminants in the sensor.

The unit should be mounted right side up so that the lettering on the front of the unit can be

read. The length of pipe between the main exhaust and the bottom of the KF fittings should be

minimized and must be

less than 2”

or the unit’s response and accuracy may be negatively

affected. The best location on the exhaust piping is at an elbow where the exhaust line might be

vertically plumbed out of the furnace lid. See illustrations.

Figure 3–Mounting/Plumbingdiagram for A20829

Other mounting locations are possible, but must be tested and verified prior to using for

measurement and control of the furnace atmosphere. Contact SSi if there are questions about

the mounting location.

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 8 of 38

Page 8 of 51

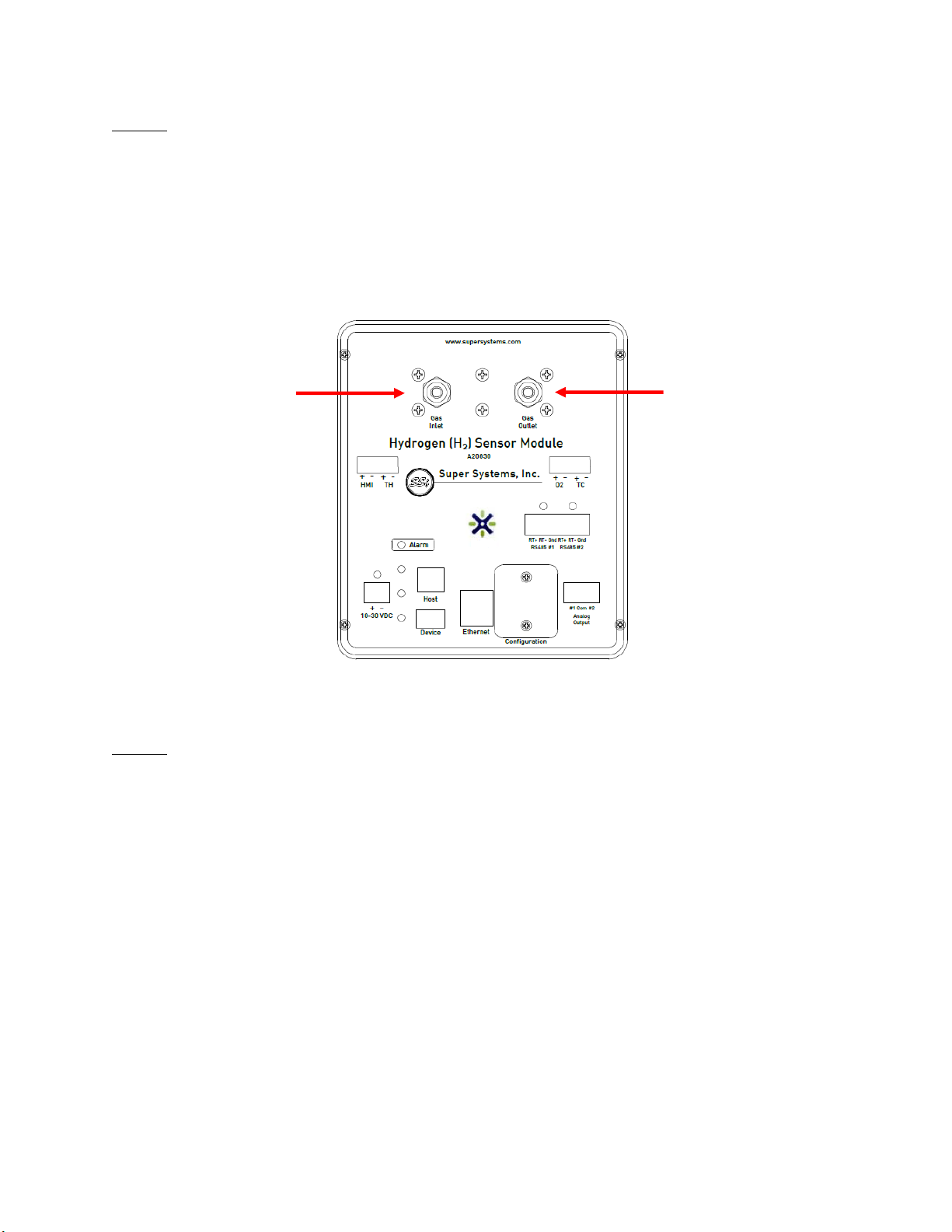

A20830

The flow-through sensor (A20830) requires gas flow past the sensor. The unit has specific inlet

and outlet ports, which are labeled on the unit and shown in the figure below.

The unit comes with 1/8” FNPT threaded ports in which two stainless steel compression fittings

have been plumbed. The compression fittings are sized to handle ¼” OD tubing.

This unit is designed to be mounted to 35 mm DIN rail.

Figure 4 –Connections diagram for A20830

Modbus

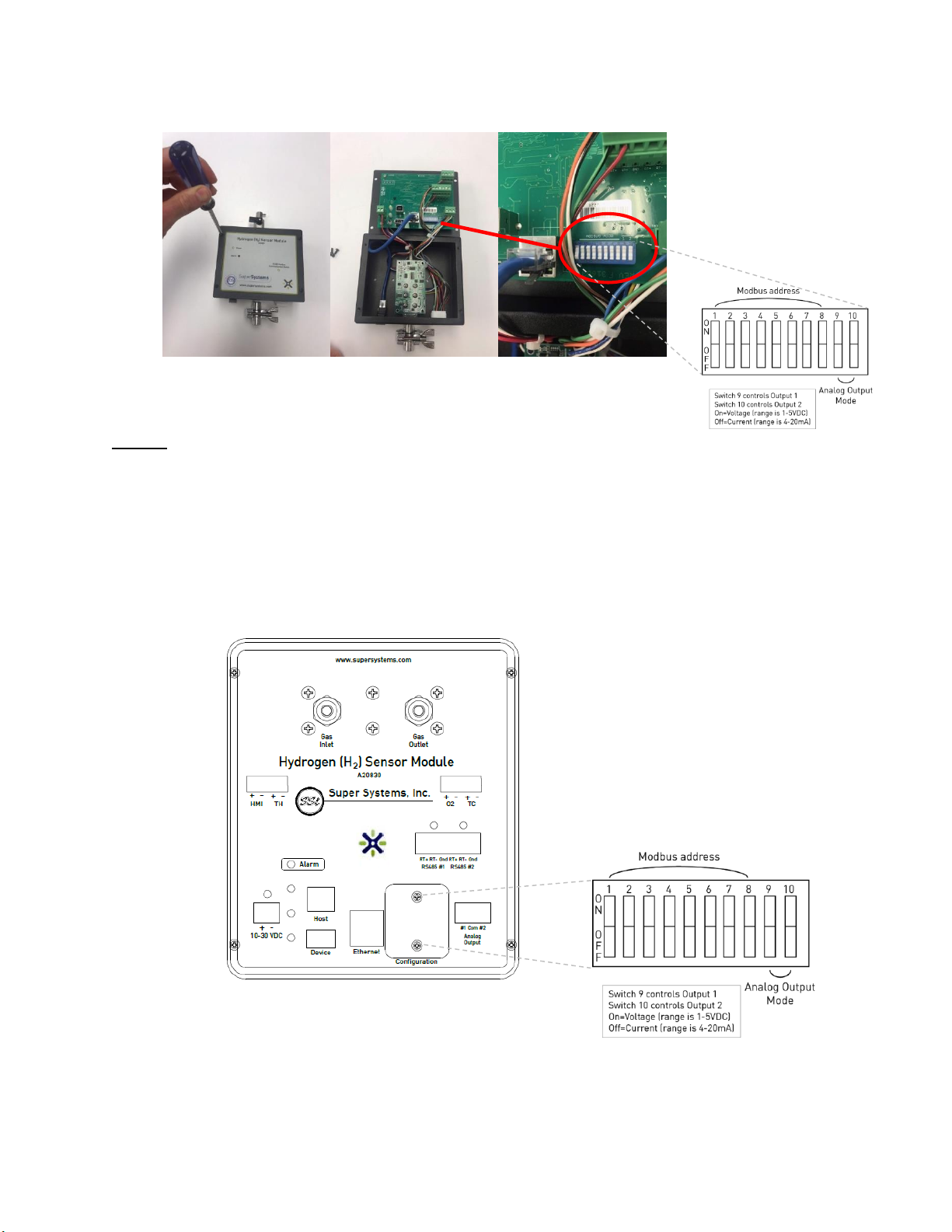

A20829

The in-situ H2sensor has DIP switches located inside of the enclosure for setting the Modbus

address. The Modbus address is set to 1 by default. Photos below show where the DIP switches

are located inside of the enclosure. The DIP switch settings for each address are given in

Appendix A.

To gain access to the DIP switches:

1. Verify that the unit is not powered. Unplug the power connector to remove power.

2. Remove the four (4) 6-32 screws to remove the front cover plate.

3. Carefully, pull the cover plate off of the enclosure. The cover plate has a circuit board

attached to it, which is connected to the enclosure via several wires. Be careful not to

damage the wires or circuit boards.

4. The DIP switches are located on the circuit board mounted to the back of the cover plate.

5. Move the DIP switches accordingly for the Modbus address listed in Appendix A.

6. When reassembling the unit, be careful of wire locations. Some wires may need to be

positioned to the side or behind circuit boards in the enclosure in order to get the cover

plate on the enclosure properly.

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 9 of 38

Page 9 of 51

Figure 5 –Modbus DIP switch location for A20829

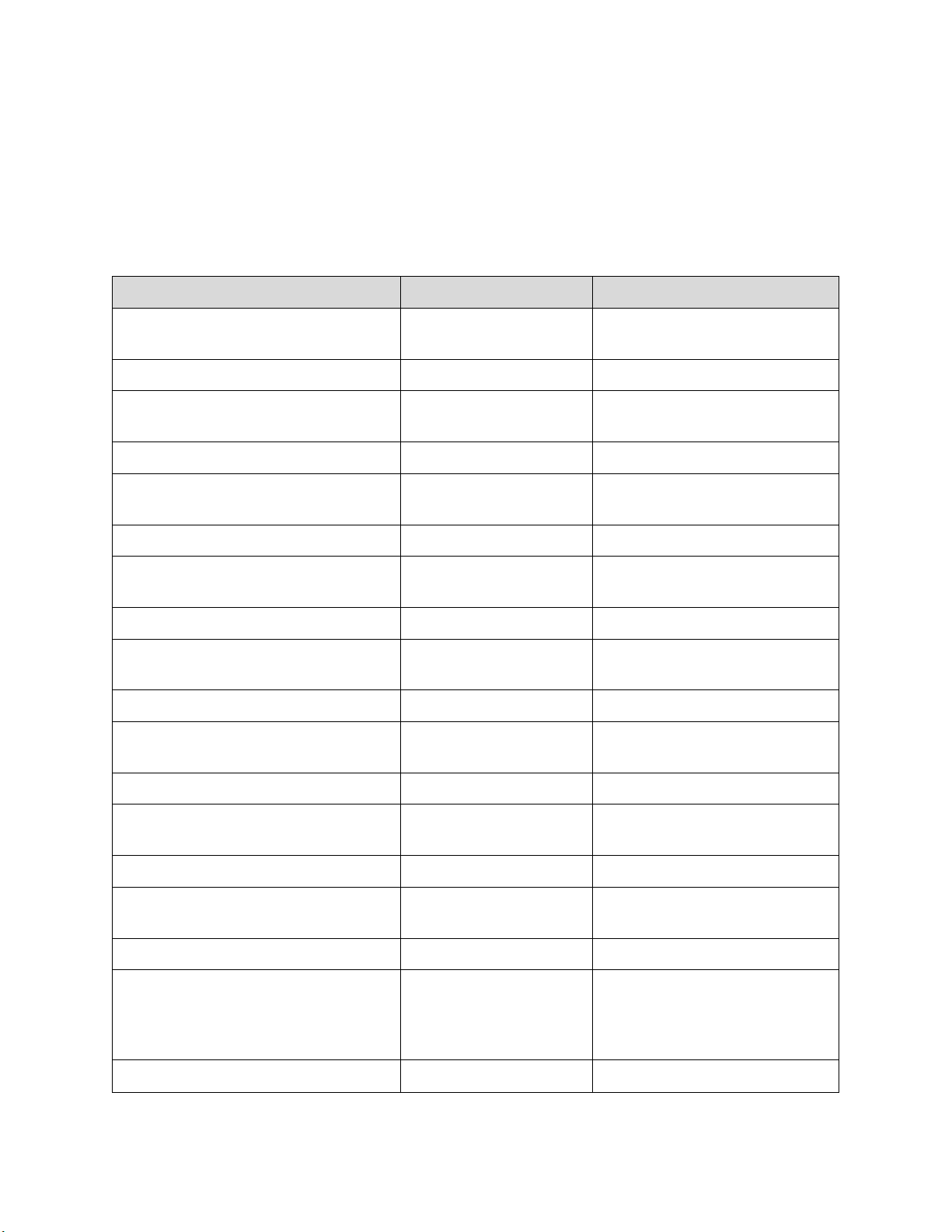

A20830

The DIP switches are accessible from the front of the unit without having to remove the cover

plate.

1. Verify that the unit is not powered. Unplug the power connector to remove power.

2. Remove the two (2) 6-32 screws from the access plate labeled, “Configuration.” This

will expose the DIP switches.

3. Move the DIP switches accordingly for the Modbus address listed in Appendix A.

4. Secure the cover plate with the two screws.

Figure 6–Modbus DIP switch location for A20830

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 10 of 38

Page 10 of 51

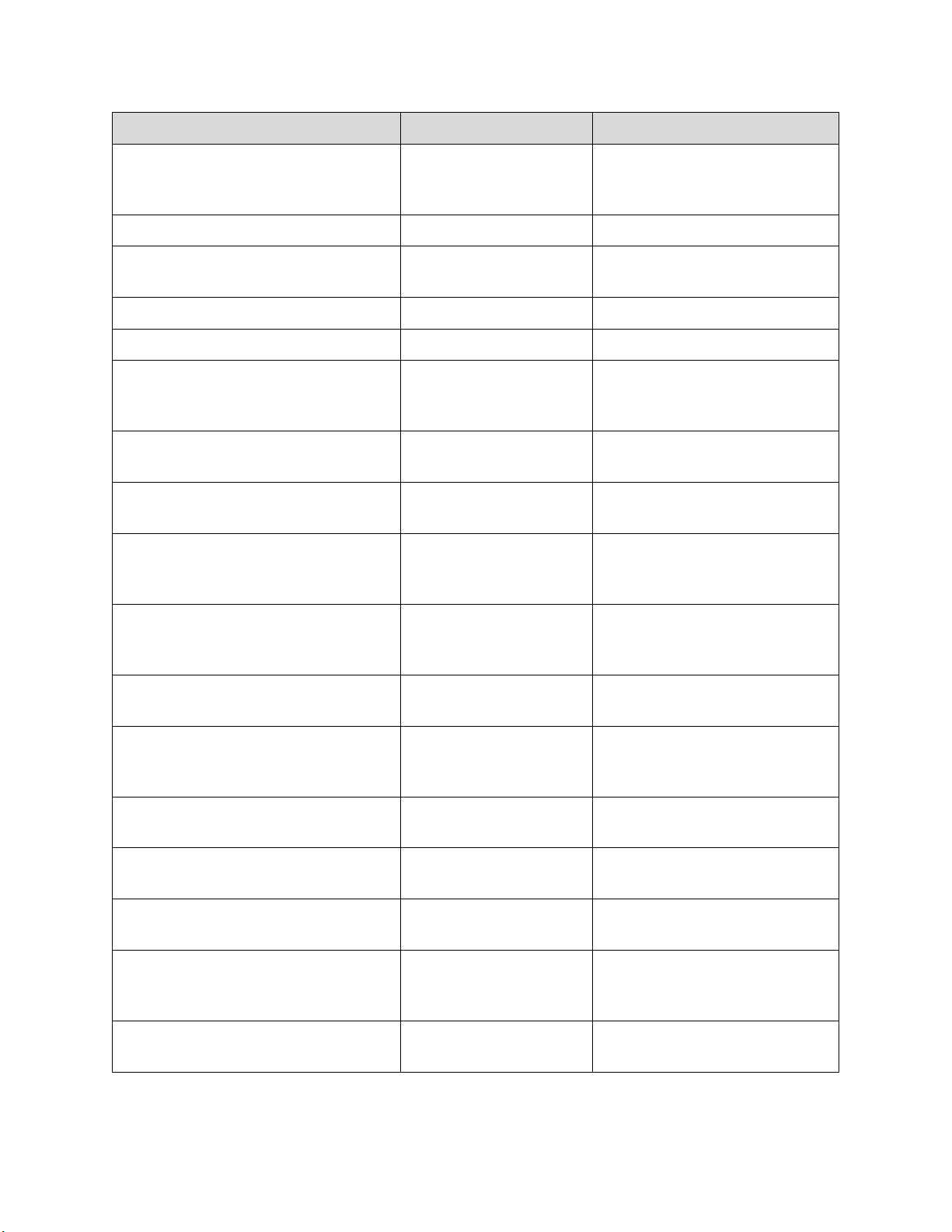

Modbus Registers

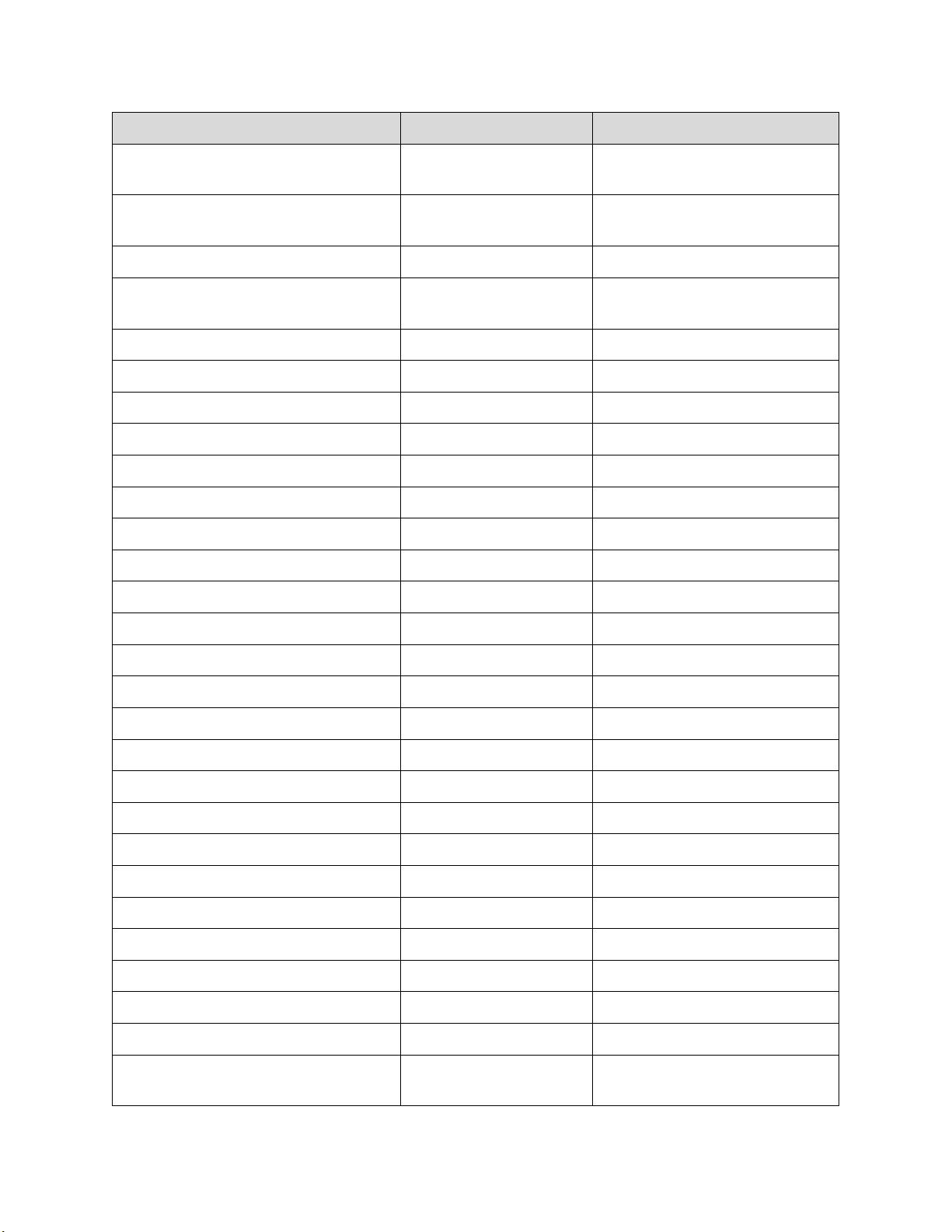

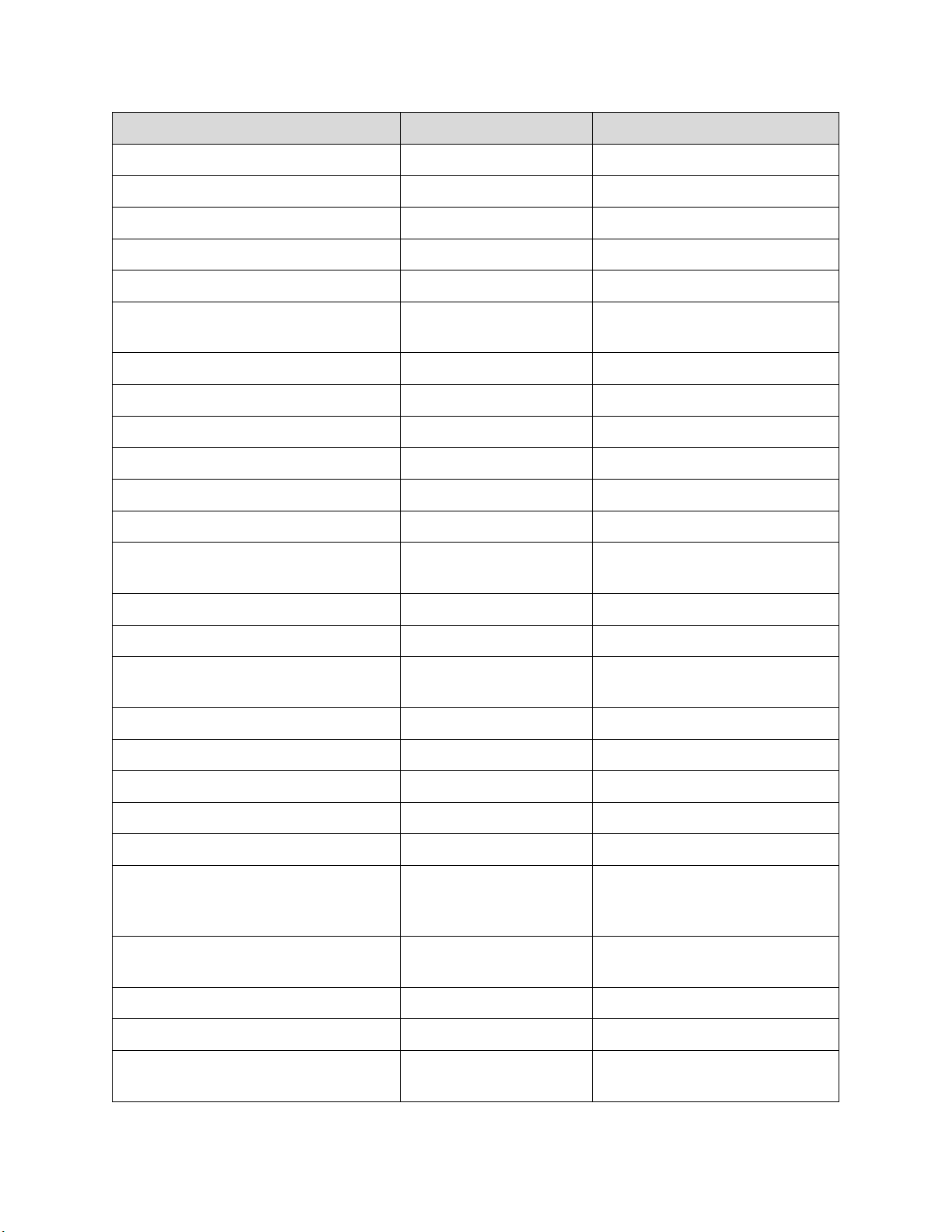

The following table shows the Modbus registers for the SGSM. The name of the register,

address location, and description are provided.

NOTE: The gas percentage (multiplied by 10000) is located in register 1205.

Register Name

Register Location

Description

VERSION_NUMBER

0

current version number of the

firmware

UART_1_MODE

1

0 = slave, 1 = Sensor Driver

VERSION_NUMBER

0

Current version number of the

firmware

UART_1_MODE

1

0 = slave, 1 = Sensor Driver

UART_1_BAUD_RATE

2

Baud Rate:

0=1200,...,5=19200,...10=115200.

UART_2_MODE

3

0 = slave, 1 = Sensor Driver

UART_2_BAUD_RATE

4

Baud Rate:

0=1200,...,5=19200,...10=115200.

UART_3_MODE

5

0 = slave, 1 = Sensor Driver

UART_3_BAUD_RATE

6

Baud Rate:

0=1200,...,5=19200,...10=115200.

UART_4_MODE

7

0 = slave, 1 = Sensor Driver

UART_4_BAUD_RATE

8

Baud Rate:

0=1200,...,5=19200,...10=115200.

UART_5_MODE

9

0 = slave, 1 = Sensor Driver

UART_5_BAUD_RATE

10

Baud Rate:

0=1200,...,5=19200,...10=115200.

PV_VARIABLE

11

Actual process variable.

BOARD_ADDR

14

Board modbus address

(important for slave only)

MODEL_NUM

15

MODEL number Map as reg 900

SET_FACT_DEF

16

23205 = Full Defaults, 23206 =

H2 Defaults, 23207 = Loop 1

Defaults, 23208 = Loop 2

Defaults

DEGREE_REG

17

0 = °F, 1 = °C, 2 = °R, 3 = K

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 11 of 38

Page 11 of 51

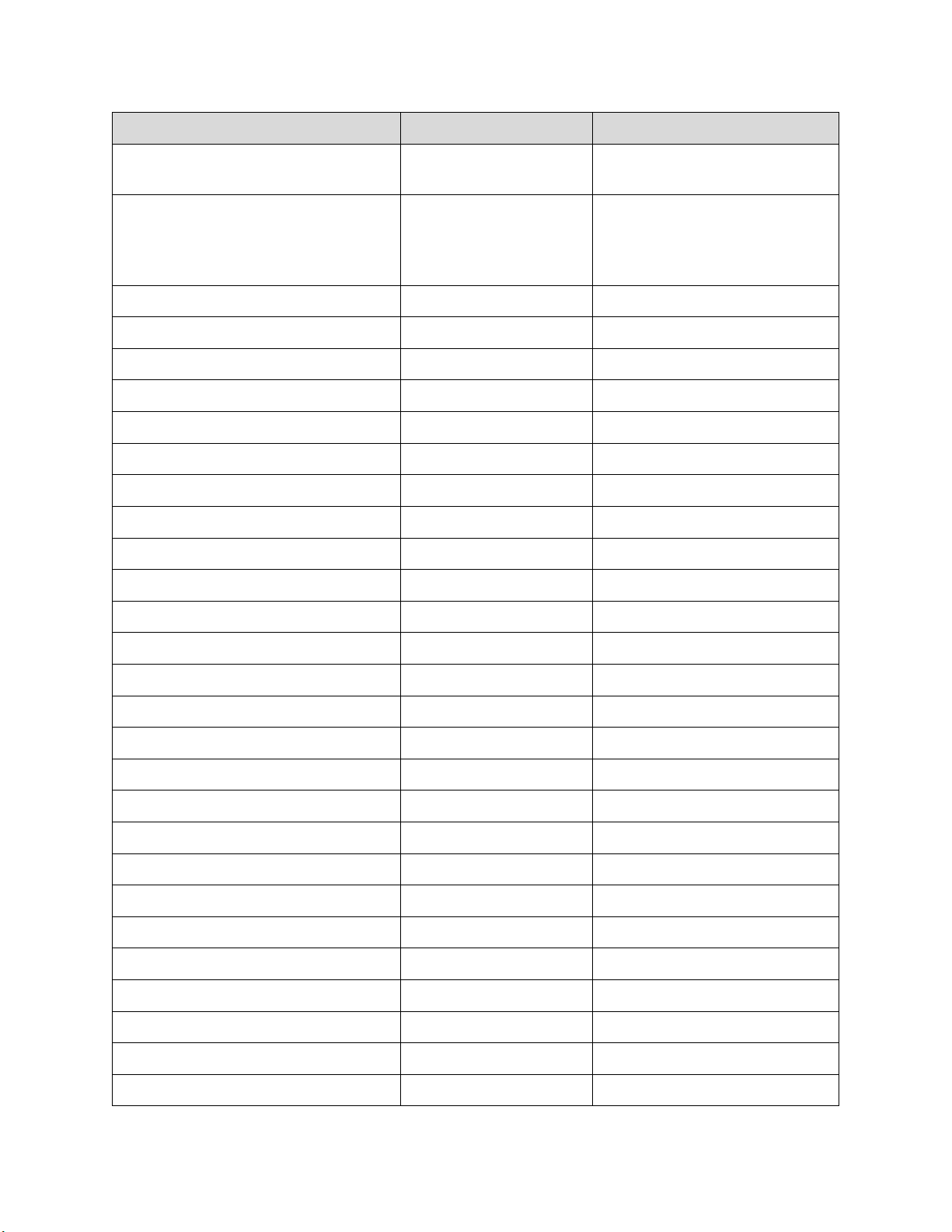

Register Name

Register Location

Description

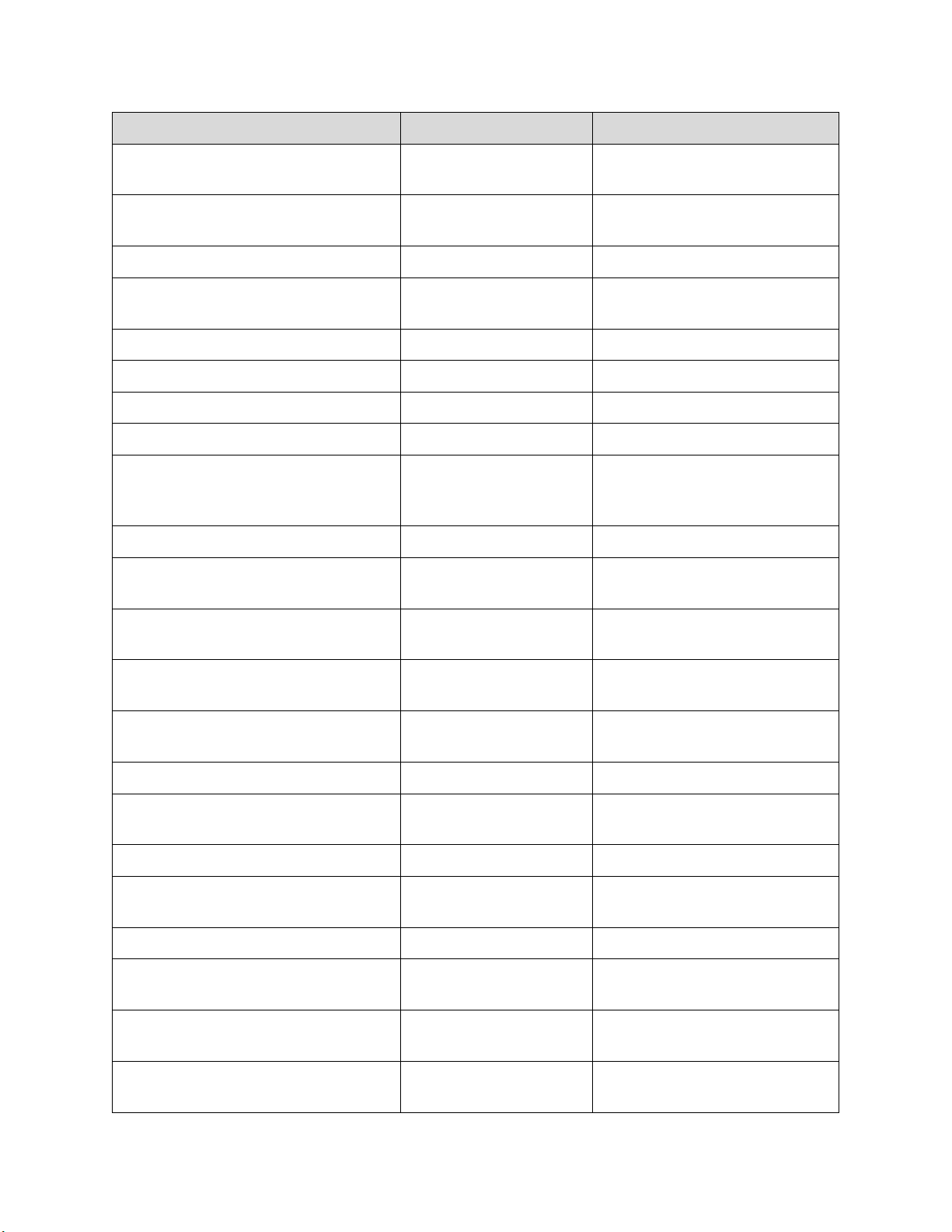

CUR_LOOP_CAL_REG

18

Calibration state. 0 = normal, 1

= prep zero, 2 = store zero, 3 =

prep span, 4 = store span

CUR_LOOP_CAL_CHN

19

Calibration channel

CUR_LOOP_CAL_VAL

20

Cal value. 20.12 mA would be

20120

CUR_LOOP_TARGET_VALUE

22

Actual request value

CUR_LOOP_ZERO_TO_TWENTY

24

0-20 mA enable

CUR_LOOP_SOURCE

26

0 = H2, 1 = DA, 2 = NH3, 3 = KN,

4 = External, 5 = Standard Kn, 6

= NDIR gas

CUR_LOOP_ZERO

28

Zero value. This value equates

to either 4 mA or 0 mA

CUR_LOOP_SPAN

30

Span value. This value equates

to either 20 mA

CUR_LOOP_MANUAL

32

If manual mode is set, then this

register controls (0-20000)

INST_PV_MODE

34

0 = H2, 1 = DA, 2 = NH3, 3 = KN,

4 = Standard Kn, 5 = NDIR single

gas

H2_SELECTION

36

0 = Single gas OEM, 1 = In-Situ

Sensor

DISP_OPT

37

Display option bitmap: bit 0 =

H2, 1 = DA, 2 = NH3, 3 = Super

KN, 4 = Standard KN

EEPROM_WRITER_COUNT

38

Counts how many times the

EEPROM has been written

CUR_LOOP_OUTPUT_CNTS

39

Counts being output for each

current loop.

MB_LO_ALARM_BITMAP

96

First of two words containing

the low threshold alarm bit map

MB_HI_ALARM_BITMAP

98

First of two words containing

the high threshold alarm bit

map

MB_ALARM_1_LOWER_LIMIT

100

Lower Limit for a given type

(first of 30)

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 12 of 38

Page 12 of 51

Register Name

Register Location

Description

MB_ALARM_1_UPPER_LIMIT

130

Upper Limit for a given type

(first of 30)

MB_ALARM_1_ACTION

160

Action for a given type (first of

30)

SER_NUM_REG

444

actual mapping from Advantech

MB_SET_TIME_WRITE

506

1 = SNTP server write, 2 =

manual write

MB_SET_TM_YEAR

507

set year

MB_SET_TM_MON

508

set month

MB_SET_TM_MDAY

509

set day of month

MB_SET_TM_WDAY

510

set day of week, 0 = Sunday

MB_SET_TM_HOUR

511

set hour

MB_SET_TM_MIN

512

set minute

MB_SET_TM_SEC

513

set second

MB_TM_YEAR

514

year

MB_TM_MON

515

month

MB_TM_MDAY

516

day of month

MB_TM_WDAY

517

day of week, 0 = Sunday

MB_TM_HOUR

518

hour

MB_TM_MIN

519

minute

MB_TM_SEC

520

second

MB_TM_LEAP

521

1 = leap year, 0 = otherwise

MB_COMP_TIME_YEAR

580

compile year

MB_COMP_TIME_MON

581

compile month

MB_COMP_TIME_MDAY

582

compile day of month

MB_COMP_TIME_WDAY

583

compile day of week, 0 = Sunday

MB_COMP_TIME_HOUR

584

compile hour

MB_COMP_TIME_MIN

585

compile minute

MB_COMP_TIME_SEC

586

compile second

MODEL_NUM_OLD

900

MODEL number

RESET_FACT_DEFAULTS

909

Resets everything to factory

settings

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 13 of 38

Page 13 of 51

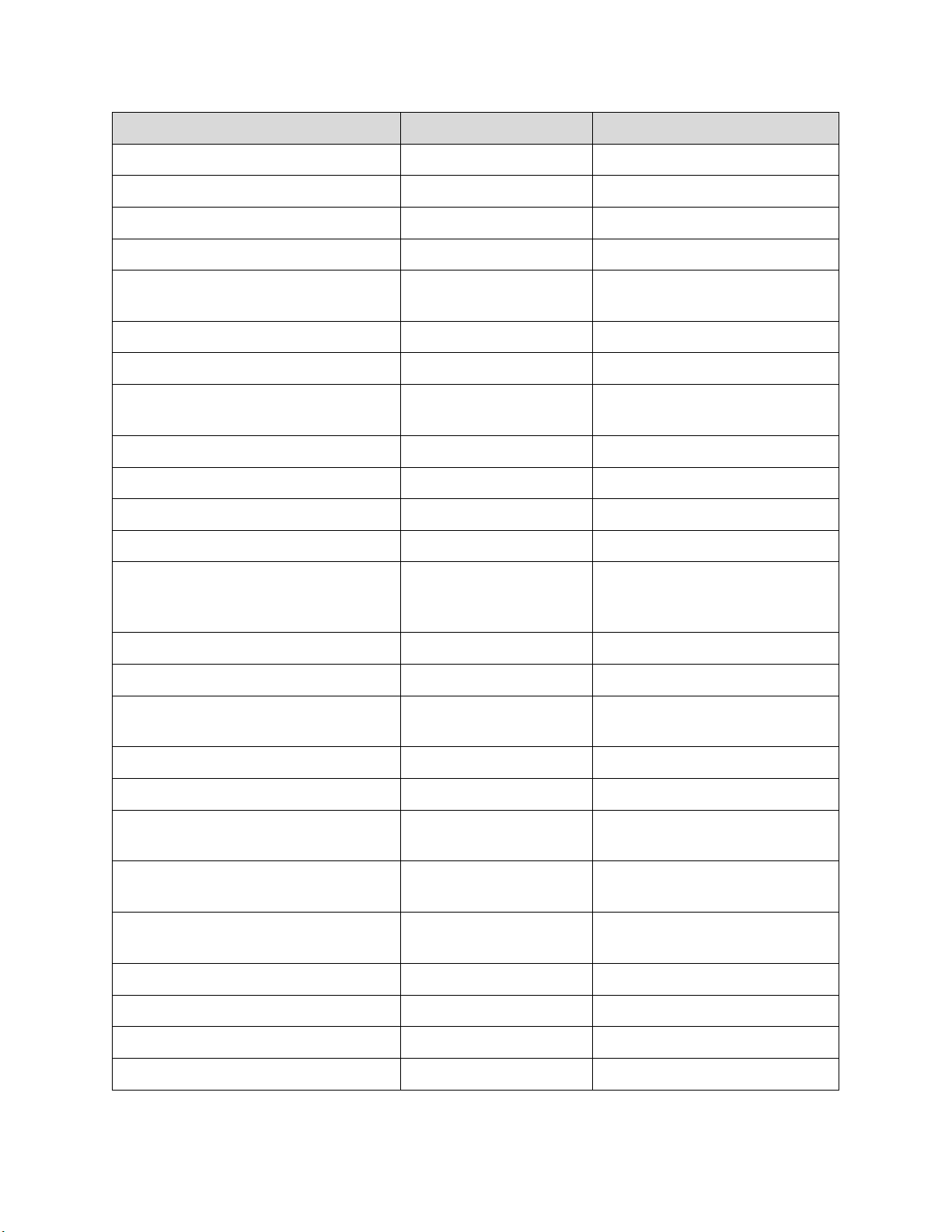

Register Name

Register Location

Description

WEBPAGE_ACCESS_CODE

910

Settable register that allows

access to the webpages

SECOND_TIMER_VALUE

911

First of two bytes, memcpy'd 32

bit unsigned integer that

increments every second

forever

MB_IP_ADDR

914

IP Address

MB_IP_MASK

918

Subnet Mask

MB_IP_GTWY

922

Gateway

0

930

Max Round robin time (ms)

RESET_ROUND_ROBIN

931

Resets the round robin time

SENSOR_APP_RR_TIME

932

Round robin time (ms)

SENSOR_APP_RR_TIME_MAX

933

Max Round robin time (ms)

DIGIO_RR_TIME

934

Round robin time (ms)

DIGIO_RR_TIME_MAX

935

Max Round robin time (ms)

UART_1_PARITY

940

0 = 8N1, 1 = 8E1, 2 = 8N2

UART_2_PARITY

941

0 = 8N1, 1 = 8E1, 2 = 8N2

UART_3_PARITY

942

0 = 8N1, 1 = 8E1, 2 = 8N2

UART_4_PARITY

943

0 = 8N1, 1 = 8E1, 2 = 8N2

UART_5_PARITY

944

0 = 8N1, 1 = 8E1, 2 = 8N2

UART_1_MB_ADD_DELAY

955

Additional Intermessage delay

UART_2_MB_ADD_DELAY

956

Additional Intermessage delay

UART_3_MB_ADD_DELAY

957

Additional Intermessage delay

UART_4_MB_ADD_DELAY

958

Additional Intermessage delay

UART_5_MB_ADD_DELAY

959

Additional Intermessage delay

UART_1_MB_ADD_TO

960

Additional Timeout delay

UART_2_MB_ADD_TO

961

Additional Timeout delay

UART_3_MB_ADD_TO

962

Additional Timeout delay

UART_4_MB_ADD_TO

963

Additional Timeout delay

UART_5_MB_ADD_TO

964

Additional Timeout delay

SENSOR_COMM_STATUS_REG

1100

H2O2 comm status (0-16)

SENSOR_N2_FLOW

1101

N2 flow

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 14 of 38

Page 14 of 51

Register Name

Register Location

Description

SENSOR_NH3_FLOW

1102

NH3 flow

SENSOR_DA_FLOW

1103

DA flow

SENSOR_H2_FLOW

1104

H2 Flow

SENSOR_PV_MODE

1105

Process variable (0 = H2, 1 = DA,

2 = NH3, 3 = Kn, 4 = Standard

Kn)

SENSOR_INPUT_TYPE_REG

1106

Input for voltage inputs

SENSOR_MIN_H2

1108

minimum H2 value

SENSOR_CO2_PRESENT

1109

concentration of CO2 present.

Important for H2 measurement

only

SENSOR_PV_REMOVE_NEGATIVE

1110

Makes any negative number

zero

SENSOR_GEN_QUEUE_ENABLE

1150

Allows for a generic write

SENSOR_GEN_QUEUE_START

1151

Start of write. E.g., register 45.

SENSOR_GEN_QUEUE_ADDRESS

1152

Address of board to write to.

SENSOR_GEN_QUEUE_NUM_WORDS

1153

Number of words to write down

up. Up to 30

SENSOR_GEN_QUEUE_BLOCK

1154

write up to 30 words

SENSOR_READ_REGISTERS

1200

just designates where to start

writing

MB_READ_VERSION_NUMBER

1200

current version number of the

firmware

MB_READ_PELLISTOR_AVDD

1201

A/D analog voltage supply

MB_READ_PELLISTOR_EXCV

1202

Pellistor bridge excitation

voltage

MB_READ_PELLISTOR_VDC

1203

Pellistor voltage

MB_READ_PELLISTOR_NA

1204

Pellistor Normalized

Absorbance

MB_READ_PERC_H2

1205

H2 x 10000

MB_READ_PER_H2_MANT

1206

H2 mantissa

MB_READ_PER_H2_EXP

1207

H2 exponent

MB_READ_PER_DA

1208

DA value

MB_READ_PER_NH3

1209

NH3 value

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 15 of 38

Page 15 of 51

Register Name

Register Location

Description

MB_READ_PER_SUPER_KN

1210

Super Kn

MB_READ_STANDARD_KN

1211

Standard KN

MB_READ_PROC_VAR

1212

Process variable

MB_READ_GAS_TEMP

1213

Gas temperature

MB_READ_BOARD_ADDR

1214

Board modbus address

(important for slave only)

MB_READ_MODEL_NUM

1215

MODEL number Map as reg 900

MB_READ_SET_FACT_DEF

1216

23205 = Full Defaults

MB_READ_DEGREE_REG

1217

Sets the unit used to display

temperature.

MB_READ_N2_FLOW

1218

N2 flow

MB_READ_NH3_FLOW

1219

NH3 flow

MB_READ_DA_FLOW

1220

DA flow

MB_READ_H2_FLOW

1221

H2 Flow

MB_READ_PV_MODE

1222

Process variable (0 = H2, 1 = DA,

2 = NH3, 3 = Kn, 4 = Standard

Kn)

MB_READ_INPUT_TYPE_REG

1223

Input for voltage inputs

MB_READ_MIN_H2

1225

minimum H2 value

MB_READ_CO2_PRESENT

1226

Amount of CO2 present up to

10%.

MB_READ_PV_REMOVE_NEG

1227

Remove negative number

MB_READ_SET_TAPS_REG

1228

Sets the digital trim pot

MB_READ_UART_1_BAUD_RATE

1229

Baud Rate:

0=1200,...,5=19200,...10=115200.

MB_READ_UART_2_BAUD_RATE

1230

Baud Rate:

0=1200,...,5=19200,...10=115200.

MB_READ_PV_FP

1231

Process variable in floating

point

MB_READ_PELLISTOR_DIAG

1233

Pellistor Diagnostics

MB_READ_AMBIENT_TEMP

1234

Ambient temperature

MB_READ_CJ_TEMP_REG

1235

Cold junction temperature

MB_READ_AD_RAW_VDC

1237

Raw VDC

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 16 of 38

Page 16 of 51

Register Name

Register Location

Description

MB_READ_GAIN_REG

1239

Gain

MB_READ_AD_SCALED_VDC

1241

Scaled VDC

MB_READ_TC_PROC_VAR

1243

TC process variable

MB_READ_PERC_O2

1245

Based on Nernst equation

MB_READ_PERC_O_DP

1246

decimal point for O2

MB_READ_PERC_O2_FP

1247

floating point value for O2 (w

registers)

MB_READ_LAMBDA_TEMP

1249

Typically 800F

MB_READ_LAMBDA_CNV_MV_EN

1250

Convert mV to probe mV

MB_READ_AMB_PRESSURE_REG

1251

Ambient pressure (absolute)

MB_READ_GAS_PRESSURE_REG

1252

Gas pressure (absolute)

MB_READ_NDIR_GAS_SELECTION

1253

[0-7]. TBD

MB_READ_NDIR_GAS_VPP

1254

Peak-peak voltages

MB_READ_NDIR_GAS_VPP_SF

1258

Peak-peak voltages. No

high/low values

MB_READ_NDIR_GAS_VPP_FIR

1262

Peak-peak voltages FIR filtered

MB_READ_NDIR_GAS_NA

1266

Gas Normalized absorbance

MB_READ_NDIR_GAS_NA_TC

1269

Gas Normalized absorbance,

temperature compensated

MB_READ_NDIR_GAS_CONC

1272

Gas concentration

MB_READ_NDIR_GAS_CONC_DP

1275

Gas concentration decimal point

MB_READ_NDIR_GAS_CONC_FP

1278

Gas concentration floating point

MB_READ_CAL_ENABLE_REG

1284

enables a calibration

MB_READ_CAL_REQUEST_REG

1285

CJ cal or zero/span voltage cal

MB_READ_CAL_RANGE_REG

1286

Calibration Range register. Sets

the voltage gain for a

calibration.

MB_READ_CAL_CHANNELS_REG

1287

bitmap of channels to be

calibrated

MB_READ_CAL_VALUE_REG

1288

Calibration value

MB_READ_CAL_TIMER_REG

1293

First of 5 calibration timers

MB_READ_CAL_PROGRESS_REG

1294

0 = no calibration, 1 =

calibration in progress

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 17 of 38

Page 17 of 51

Register Name

Register Location

Description

MB_READ_CAL_ERROR_REG

1295

First of 5 calibration error

calculations

MB_READ_ZERO_VOLT_CAL

1300

volts at zero (for NDIR cell, 100

= ref, 101 gas)

MB_READ_ZERO_TEMP_CAL

1302

temperature at zero

MB_READ_SPAN_VOLT_CAL

1303

volts at span (for NDIR cell, 103

= ref, 104 gas)

MB_READ_SPAN_TEMP_CAL

1305

temperature at span

MB_READ_SPAN_TARG_CAL

1306

Target value at span

MB_READ_MAX_ROUND_ROBIN

1307

Max Round robin time (ms)

MB_READ_MAX_ROUND_ROBIN_US

1308

Max Round robin time (us)

MB_READ_EEPROM_WRITER_COUNT

1309

Counts the number of times

EEPROM has been written (not

saved)

MB_READ_SPAN_MULTIPLIER

1310

Shows the span multiplier

MB_DIGIO_OUTPUT_SET

1600

Bitmap that sets the output of a

digital I/O card

MB_DIGIO_COMM_STATUS_REG

1601

Communication status for

digital I/O card

MB_DIGIO_VERSION_NUMBER

1610

current version number of the

firmware

MB_DIGIO_UART_1_MODE

1611

Determines mode: modbus

slave = 0, modbus master = 1

MB_DIGIO_UART_1_BAUD_RATE

1612

Baud Rate.

MB_DIGIO_UART_2_MODE

1613

Determines mode: modbus

slave = 0, modbus master = 1

MB_DIGIO_UART_2_BAUD_RATE

1614

Baud Rate.

MB_DIGIO_BOARD_ADDR

1615

Board modbus address

(important for slave only)

MB_DIGIO_MODEL_NUM

1616

MODEL number Map as reg 900

MB_DIGIO_RESET_FACT_DEFAULTS

1618

SFD 23205 sets factory defaults

Map as reg 909

MB_DIGIO_UART_3_MODE

1619

Determines mode: modbus

slave = 0, modbus master = 1

MB_DIGIO_UART_3_BAUD_RATE

1620

Baud Rate. 0=1200 ,...,

10=115200

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 18 of 38

Page 18 of 51

Register Name

Register Location

Description

MB_DIGIO_SER_NUM_0

1621

Start of Serial number

MB_DIGIO_SER_NUM_1

1622

serial number 1

MB_DIGIO_SER_NUM_2

1623

serial number 2

MB_DIGIO_SER_NUM_3

1624

serial number 3

MB_DIGIO_SER_NUM_4

1625

serial number 4

MB_DIGIO_SER_NUM_5

1626

serial number 5

MB_DIGIO_SER_NUM_6

1627

serial number 6

MB_DIGIO_SER_NUM_7

1628

serial number 7

MB_DIGIO_SER_NUM_8

1629

serial number 8

MB_DIGIO_SER_NUM_9

1630

serial number 9

MB_DIGIO_EVENT_IN_CP

1636

Copy of Event Input

MB_DIGIO_EVENT_OUT_ACT_CP

1637

Actual Output

MB_DIGIO_EVENT_OUT_SP_CP

1638

Copy of Output setpoint

SENSOR_SUB_SERIAL_NUM

1700

serial number of sensor board

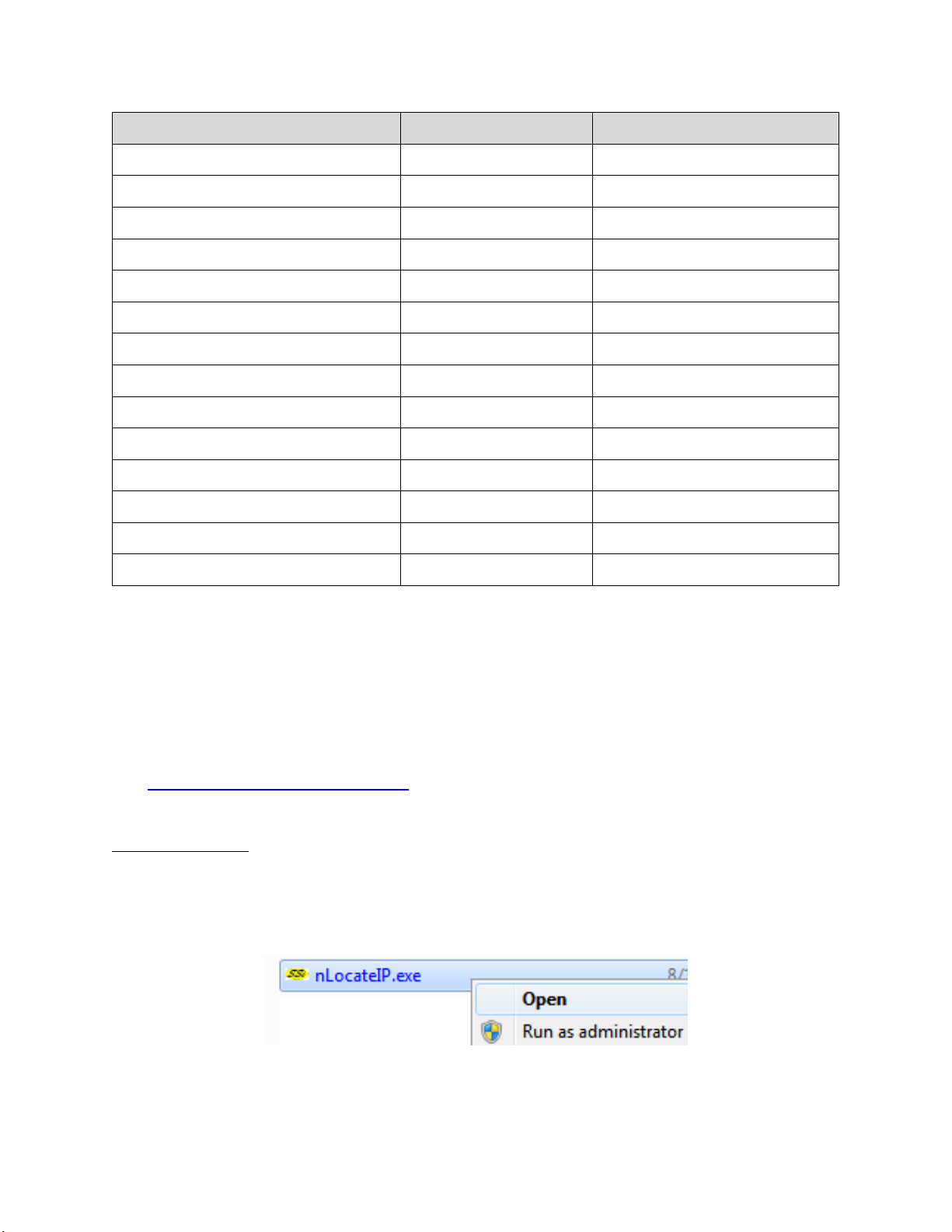

Initial Network Configuration

This section is intended for use by persons familiar with Ethernet network setup. The SGSM has

a static IP Address so that the web interface can be accessed easily. The default IP Address of

the sensor is 192.168.1.200.

If the default IP Address does not allow you to connect to this device through the web browser

(see Control Interface via Web Browser section), the IP Address of the sensor can be found by

using SSi’s

nLocateIP

software. This method is described in the following subsection.

nLocateIP Method

Once the unit is connected to the network, you should be able to locate it using SSi’s

nLocateIP

software. This program is available from SSi. To use it in locating the unit on the network, follow

these steps on a Windows-based PC:

1. Ensure that the unit is connected to the network.

2. Open the nLocateIP program

3. Once the program opens, click the Search button. The program will begin searching for SSi

devices connected to the network.

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 19 of 38

Page 19 of 51

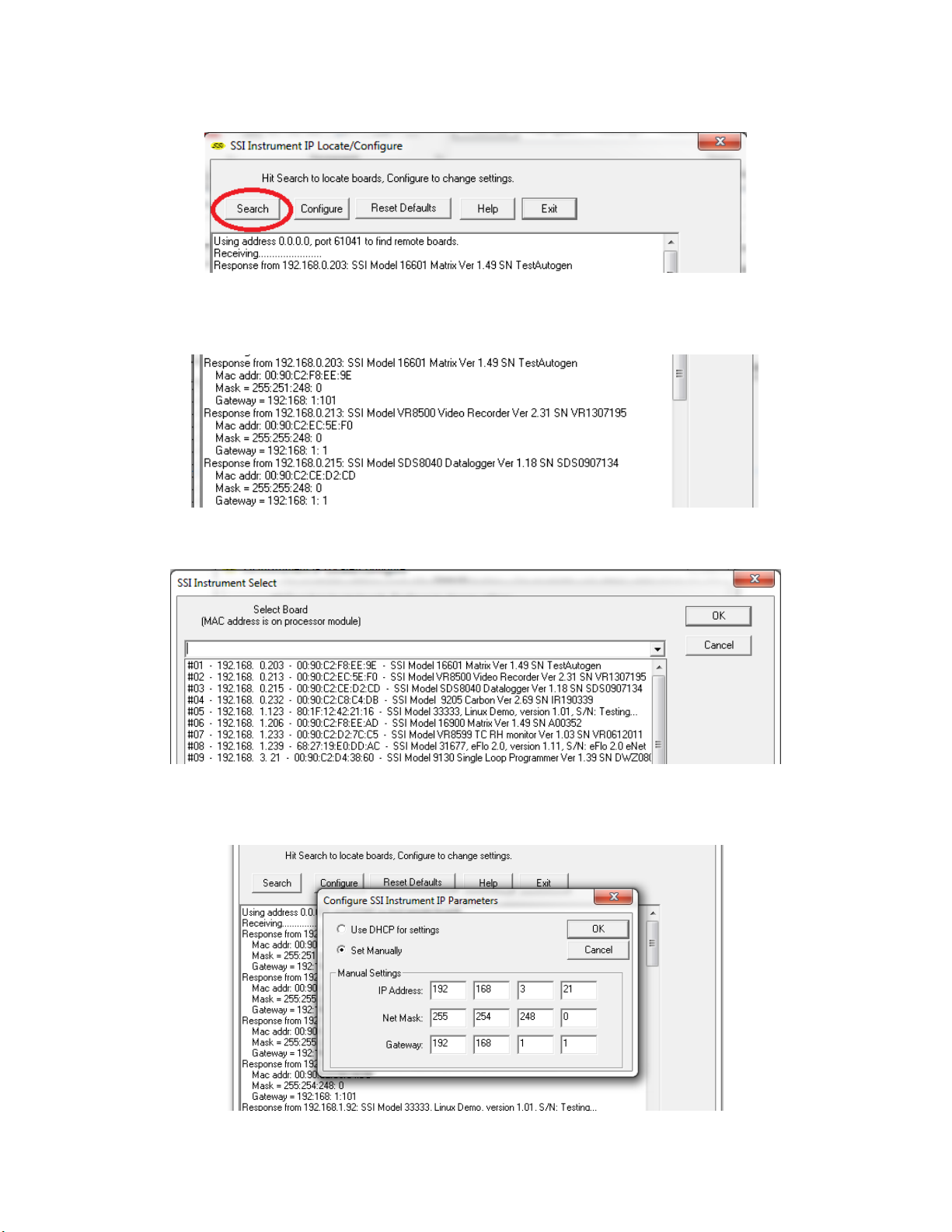

4. Look for identifying text in the list of instruments. It includes the type of instrument and

serial number. It also provides the IP Address information for the sensor.

5. Click the Configure button and choose the sensor to change its IP Address settings.

6. Click on the device description to highlight it and click the OK button. This will display the

device’s IP settings, which can be changed to match the network to which it’s connected.

Single Gas Sensor Module (SGSM)

Operations Manual

Super Systems Inc.

Page 20 of 38

Page 20 of 51

The sensor’s IP Address settings will be changed immediately to allow it to communicate. If you

are unable to find the unit in the list of devices, it is possible that a network setting (such as

subnet mask) may be different, the unit may be connected to a different network, or the unit

may not be powered on. SSi recommends consulting an IT engineer or network administrator. If

needed, call SSi at (513) 772-0060.

Control Interface via Web Browser

The SGSM can be controlled using a web browser on your computer. The web browser connects

to the unit through an Ethernet connection. The computer you are using and the unit need to be

on the same network with the same subnet mask. Contact your IT administrator if you have

network setup questions.

Enter the IP Address into the search bar of the web browser.

Access Password:

Contact SSi at (513) 772-0060 for more information on the password used to

access secured options.

Note that the interface pages shown below are for the H2 option.

This manual suits for next models

2

Table of contents