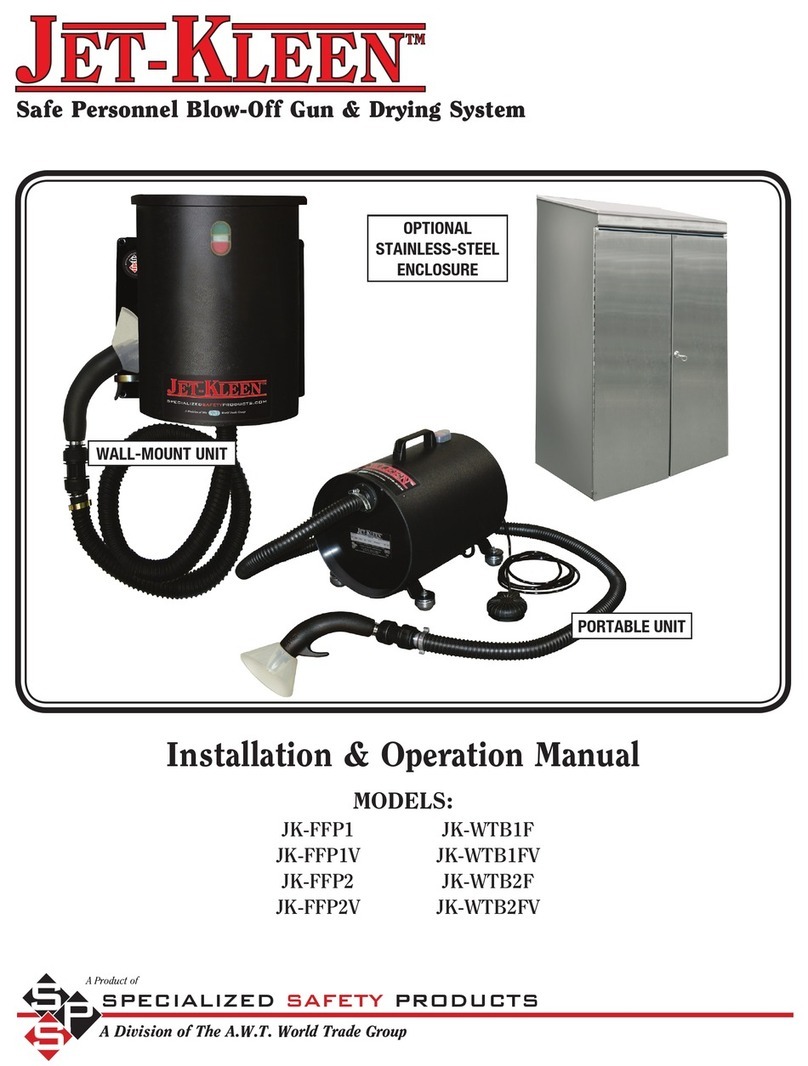

SSP Jet-Kleen JKL-115 User manual

Safe Personnel Blow-Off & Drying System

Installation & Operation Manual

MODELS:

JKL-115

JKL-240

Overview & Features ...............................3

Receiving & Unpacking .............................4

Receiving ......................................4

Unpacking .....................................4

Safety Precautions ................................4

Owner Responsibilities ...........................4

General Safety ..................................4

Electrical Safety .................................5

Installation & Setup ..............................5

Nozzle Assembly Attachment ......................5

Nozzle Assembly Detachment ......................5

Optional Wall-Mount Bracket .................... 5

Air Filter Replacement ...........................6

Technical Information ..............................6

Models and Specifications ....................... 6

Electrical Specifications ..........................6

Government Regulations .........................6

PSI Specifications ...............................6

Velocity .......................................6

Noise Level .....................................6

Space Requirements .............................6

Shipping Requirements ..........................6

Replacement Parts .................................7

Replacement Parts Photos ..........................7

Warranty ........................................ 8

SPECIALIZED SAFETY PRODUCTS

A Division of The A.W.T. World Trade Group

Chicago, IL 60641 USA

p

S

S

Thank you for choosing the Jet-Kleen Limited Safe Personnel Blow-Off & Drying

System for safe and efficient personnel blow-off and drying and cleaning of equip-

ment and components. The Jet-Kleen Limited is a safer, more economical alterna-

tive to compressed air.

This Installation & Operation Manual will help you to achieve optimal perfor-

mance with your Jet-Kleen Limited by guiding you through the proper steps for

setup, operation, and maintenance of the unit. The manual also includes impor-

tant information on safety precautions, technical specifications, options and acces-

sories, and replacement parts.

Should any questions arise, our experienced technical support staff is available

to assist you. Just call us at 773.777.7100, 8am to 5pm, Central Standard Time,

Monday through Friday.

We welcome the opportunity to meet your safety equipment and supplies needs

on an ongoing basis, with the quality products and outstanding service our cus-

tomers have come to rely on from SPECIALIZED SAFETY PRODUCTS.

We look forward to serving you again in the near future.

Sincerely,

Michael Green

Table of ConTenTs

SPECIALIZED SAFETY PRODUCTS A Division of The A.W.T. World Trade Group

4321 N. Knox Ave., Chicago, IL 60641 USA 773.777.7100 • Fax:773.777.0909

[email protected] www.specializedsafetyproducts.com

Jet-Kleentm 2 Installation & Operation Manual

p

S

S

A Product of

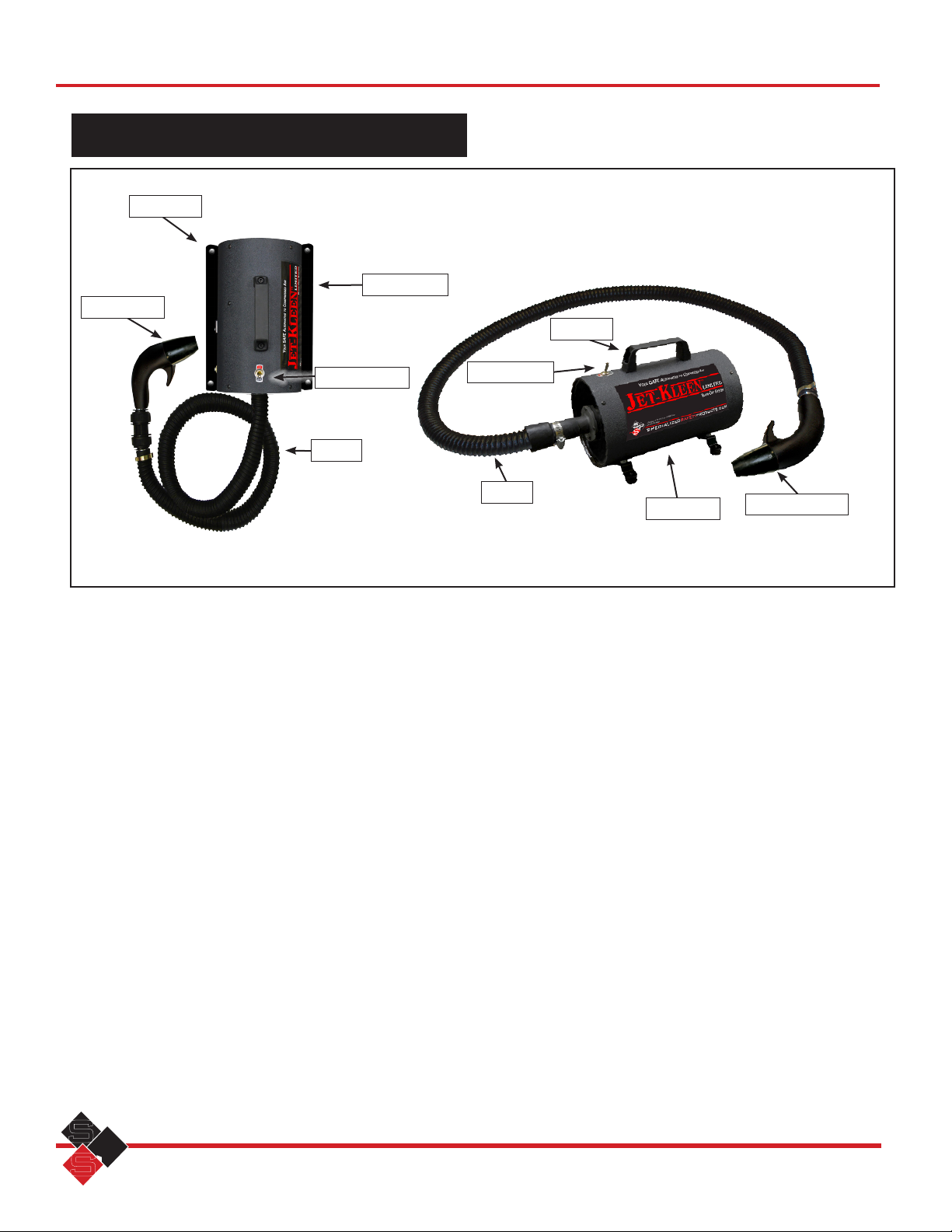

Figure 1. Jet-Kleen units and major components.

overview & feaTures

Blower unit

Handle

Hose

STANDARD FEATURES

All Models

• 1.9 PSI

• Velocity: 22,000' per minute

• Noise level below 78dB

• CSA, CE, and U.L. approved motor components

• Removes dust, fibers, water, powders and more

• Can be safely directed at the body

• Heavy-duty construction

• Industrial technology for durability

• Advanced technology air flow system

• Virtually maintenance-free

OPTIONS AND ACCESSORIES

• Wall-Mount Bracket

• Quick Disconnect Swivel Connector

• Ergonomic Pliable Plastic Chip Guard

• Pliable Plastic Nozzle Replacement

• Chip Guard

On/off switch

Gun assembly

On/Off switch

Hose

Wall mount

Blower unit

Handle assembly

SPECIALIZED SAFETY PRODUCTS A Division of The A.W.T. World Trade Group

4321 N. Knox Ave., Chicago, IL 60641 USA 773.777.7100 • Fax:773.777.0909

[email protected] www.specializedsafetyproducts.com

Jet-Kleentm 3 Installation & Operation Manual

p

S

S

A Product of

reCeiving & unpaCking

RECEIVING

Immediately upon receipt of your Jet-Kleen Limited, check

the crate and all packaging materials for shipping dam-

age. The unit must be thoroughly examined upon arrival to

ensure that there is no damage by the freight carrier.

Notify the carrier and Specialized Safety Products promptly

of any damage or shortage, either visible or concealed, and

request an inspection. Failure to follow these instructions

may result in the carrier’s refusal to accept responsibility for

any damages or shortages. Do not discard or destroy the crate

or any packaging materials.

Claims for damages usually must be submitted to the freight

carrier within three (3) days. If the Jet-Kleen Limited is

damaged, it should not be unpacked or set up prior to an

inspection by the carrier’s representative. Specialized Safety

Products is not responsible for any damage claims which

are not honored by the freight carrier. In the event that

shipping damage occurs, we suggest that photos be taken to

document the damages at the time of delivery.

UNPACKING

After you have inspected the packaging materials for shipping

damage, you may proceed to unpack the Jet-Kleen Limited.

1. Carefully unpack the Jet-Kleen Limited, taking precau-

tions not to damage the unit and any other enclosed

components

2. Check the Jet-Kleen Limited and all components for

indications of shipping damage, as described in the

RECEIVING section of this manual.

3. Carefully set the Jet-Kleen Limited in position at the

desired location in your facility.

safeTy preCauTions

OWNER RESPONSIBILITIES

To ensure the safe and trouble-free installation and opera-

tion of this equipment, the operator(s) must have a thorough

understanding of the contents of this manual. Therefore, it

is the responsibility of the Equipment Owner to ensure that

every operator of this equipment:

1. Read, understand, and observe the procedures recom-

mended in the Receiving and Uncrating sections of this

manual prior to uncrating.

2. Read and understand the Safety Precautions, Operation,

and Maintenance sections prior to operation.

3. Read, understand, and observe the General Safety and

Electrical Safety Guidelines prior to operation.

4. Observe fundamental regulations pertaining to workers’

protection and accident prevention.

5. Observe additional and supplementary rules and

regulations in effect at the your place of business.

Once trained, equipment operators should be continually

evaluated to ensure that they understand and are adhering to

safety guidelines and operating procedures.

GENERAL SAFETY

1. The On/Off switch for the unit is located on the cylindri-

cal enclosure at the end furthest from the blower hose.

The switch toggles between OFF and ON.

2. Be sure the portable unit stands level its four feet.

3. Do not remove any guarding or the flexible hose at any

time. Do not allow objects to pass through the guard

while the fan is rotating.

4. Always switch the unit off at the main electrical sup-

ply and remove the plug before cleaning the Jet-Kleen

Limited. Do not use a pressure washer or steam washer

to clean the unit.

5. Eye protection should be worn at all times while

operating the unit.

6. Do not aim the Jet-Kleen Limited at the eyes or ears.

CAUTION

Please read all information regarding safety

precautions. Failure to follow these procedures

may void your warranty.

SPECIALIZED SAFETY PRODUCTS A Division of The A.W.T. World Trade Group

4321 N. Knox Ave., Chicago, IL 60641 USA 773.777.7100 • Fax:773.777.0909

[email protected] www.specializedsafetyproducts.com

Jet-Kleentm 4 Installation & Operation Manual

p

S

S

A Product of

ELECTRICAL SAFETY

1. The unit should be connected to an electrical supply that

is surge protected and in compliance with local codes.

2. The unit is fitted with a standard three-prong plug with a

15A circuit breaker.

3. Ensure that the correct supply voltage is available before

switching on the unit.

4. Ensure the voltage being used corresponds with the volt-

age on the machine parts. The standard motors are 115V,

1Ph, 50/60Hz and 240V, 1Ph, 50/60Hz

5. Check the AC cable for nicks and cuts (regularly inspect

the cable to ensure it is in good condition).

6. Do not pull the portable unit by the electrical cable or

the hose.

7. Only qualified personnel may access electrical system.

8. There are no serviceable parts in the fan unit.

REPLACEMENT PARTS

This unit was designed, engineered, and built with operator

safety and optimum performance as primary objectives.

Substitution of non-OEM parts may jeopardize safety, void

any warranties, and adversely impact performance.

After you have unpacked the Jet-Kleen Limited and familiar-

ized yourself with this manual, you may proceed to instal-

lation and setup of the unit. Set up the portable Jet-Kleen

Limited where you intend to use it, making sure there is an

available electric supply and adequate clearance.

The Jet-Kleen Limited should be placed so that the four feet

are in contact with a level or flat surface.

The Jet-Kleen Limited should be plugged into an appropriate

grounded outlet. Turn the switch to ON to operate the Jet-

Kleen Limited. Turn switch to off when finished.

Nozzle Assembly Attachment

To attach the nozzle assembly, follow these simple instruc-

tions:

1. Leave the locking ring open (unscrewed) as shown

in Figure 2. If the locking ring is in the closed posi-

tion, rotate the locking ring on the swivel connector

(Figure 2) counterclockwise 180° until it clicks.

2. Push the new nozzle assembly firmly into place.

3. Close the locking ring by rotating it 180° back to its

original position.

Nozzle Assembly Detachment

To detach the nozzle assembly:

1. Rotate the locking ring on the swivel connector (Figure

2) counterclockwise 180° until it clicks.

2. Depress the quick release ring.

3. Pull the quick-release fitting toward the hose away from

the gun assembly.

4. Twist and pull out the gun assembly.

Follow similar procedures when replacing the

hose by using the locking ring and quick-release

fitting on the hose end of the swivel connector.

Optional Wall-Mount Bracket

To install the Optional Wall-Mount Bracket to your Jet-Kleen

Limited unit:

1. Remove the four rubber feet from the Jet-Kleen Limited

using an Allen wrench.

2. Leave the mounting hardware attached to the Jet-Kleen

Limited unit as this will be used to attach the wall-

mount bracket.

3. Attach the Optional Wall Mount Bracket to the mounting

hardware using the four flathead screws provided with

the bracket.

4. Secure using a flathead screwdriver.

The Jet-Kleen Limited may now be wall-mounted in a loca-

tion of your choice using appropriately-rated fasteners.

Figure 2. With locking ring unscrewed (as pictured) depress quick release ring

then pull quick-release fitting toward hose.

Locking ringQuick-release fitting

Handle

assembly

insTallaTion & seTup

Swivel connector

IMPORTANT

TO PREVENT OVERHEATING AND POSSIBLE PERMANENT DAM-

AGE TO THE UNIT, DO NOT RUN THE JET-KLEEN LIMITED CONTINU-

OUSLY FOR MORE THAN THREE HOURS.

SPECIALIZED SAFETY PRODUCTS A Division of The A.W.T. World Trade Group

4321 N. Knox Ave., Chicago, IL 60641 USA 773.777.7100 • Fax:773.777.0909

[email protected] www.specializedsafetyproducts.com

Jet-Kleentm 5 Installation & Operation Manual

p

S

S

A Product of

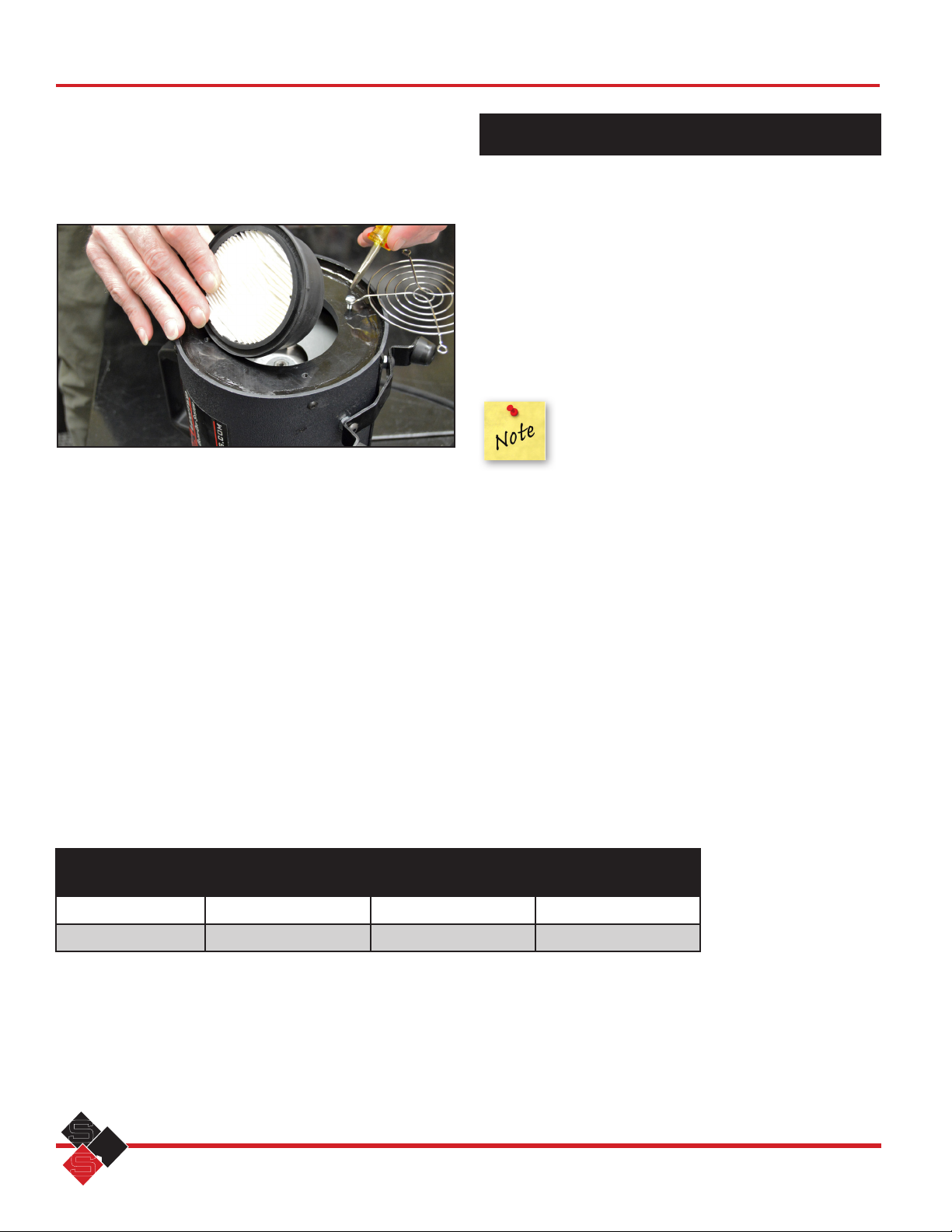

Air Filter Replacement

The air filter is located on the non-hose end of the portable

Jet-Kleen Limited unit. The filter is accessed by removing the

filter guard, which is secured with four screws. Simply pull

out the used filter and insert a new one (Figure 3).

Replacing the filter is recommended at least every six

months, although your specific application and operating

conditions may warrant much more frequent filter replace-

ment.

Replacement filters for the entire Jet-Kleen series are avail-

able from Specialized Safety Products.

IMPORTANT: To prevent overheating and possible perma-

nent damage to the unit, DO NOT run the Jet-Kleen Limited

continuously for more than three hours.

TeChniCal informaTion

CATALOG

NUMBER

HOSE ELECTRICAL

SPECIFICATIONS

WEIGHT

JKL-115 96" (244cm) 115V, 1Ph, 50/60Hz 18.6 lbs. (8.4kg)

JKL-240 96" (244cm) 240V, 1Ph, 50/60Hz 18.6 lbs. (8.4kg)

MODELS AND SPECIFICATIONS

Output pressure greater than 3 PSI is legally

prohibited in Europe. In the US, we conform to

OSHA Standard number 1910.242(B).

GOVERNMENT REGULATIONS

The Jet-Kleen Limited has been designed in accordance

with the following directives:

EN55014-1 EMC Directive (Emissions)

EN55014-2 EMC Directive (Immunity)

EN60335-2-69 Low Voltage (Electrical Safety Testing)

EN61000-3-2 EMC - Limits for harmonic current emissions

EN61000-3-3 EMC - Limits of voltage changes, fluctua-

tions and flicker in public low-voltage

supply systems

PSI SPECIFICATIONS

1.9 PSI

VELOCITY

22,000' per minute

NOISE LEVEL

Below 78dB (A)

SPACE REQUIREMENTS

• Weight: 18.6 lbs. (8.4kg)

• Dimensions: 16.6"L x 11.3"W x 13.7"H (42.2cm

x 28.7cm x 34.8cm)

SHIPPING REQUIREMENTS

• Weight: 23 lbs. (8.4kg)

• Dimensions: 23"L x 16"W x 17"H (58.4cm x 40.6cm x

43.2cm)

Figure 3. Changing the air filter.

SPECIALIZED SAFETY PRODUCTS A Division of The A.W.T. World Trade Group

4321 N. Knox Ave., Chicago, IL 60641 USA 773.777.7100 • Fax:773.777.0909

[email protected] www.specializedsafetyproducts.com

Jet-Kleentm 6 Installation & Operation Manual

p

S

S

A Product of

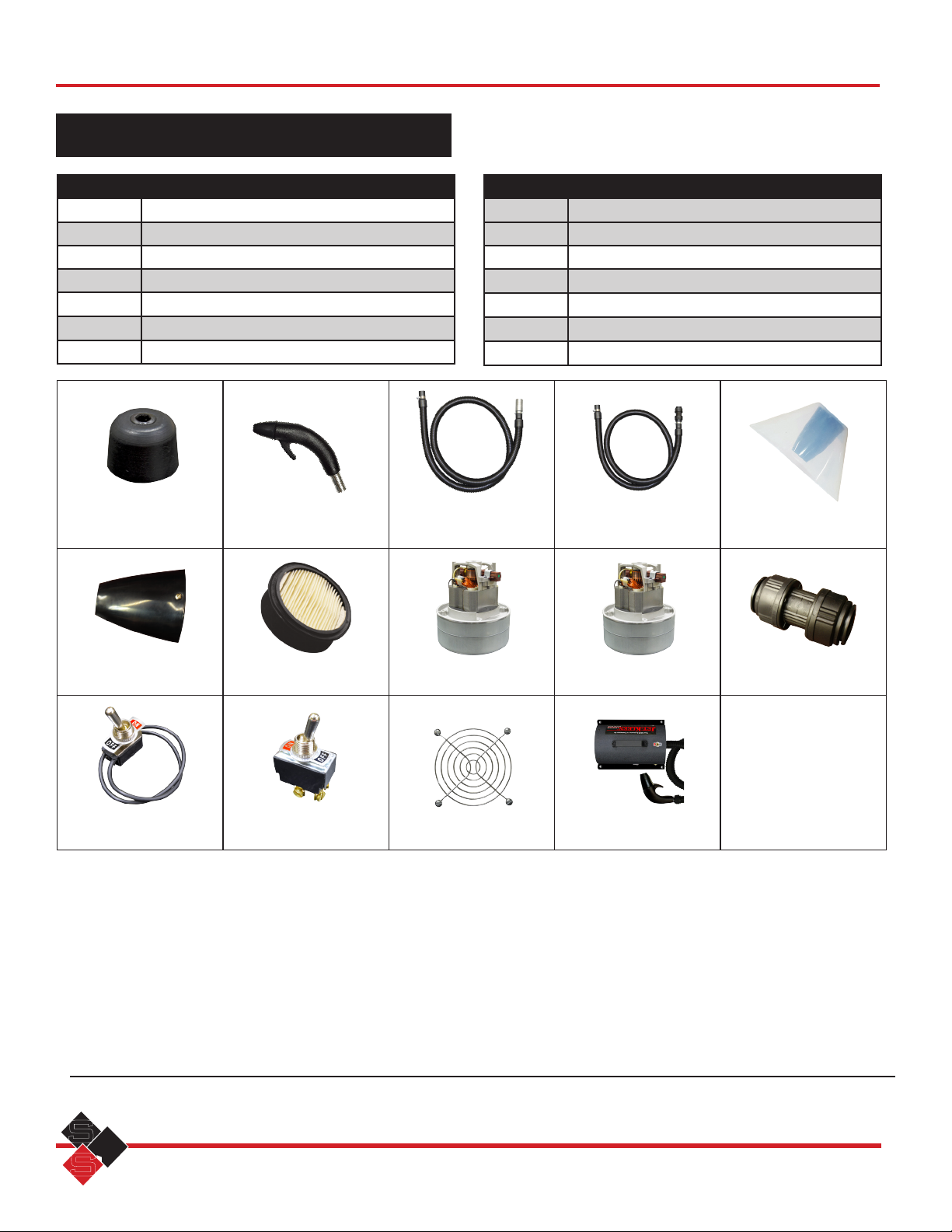

replaCemenT parTs

JKL-RF

Rubber Feet for

Jet-Kleen Limited

JKL-GA

Complete Handle Assembly

JK-NO included

JKL-FMH

Portable Hose

(96"/244 cm)

JKL-FMHS

Portable Hose with

Adapter for Swivel Connection

(96"/244 cm)

JK-CG

Chip Guard

JK-NO

Nozzle JK-FE

Filter Assembly

JKL-VM

Vacuum Motor 115V

JKL-VM-240

Vacuum Motor 240V

JK-SC

Swivel Connector

JKL-OS

On/Off Switch

JKL-OS-240

On/Off Switch 240V JKL-FG

Filter Guard

JKL-WMB

Wall Bracket

CATALOG # DESCRIPTION

JKL-RF Rubber Feet (Set of 4)

JKL-GA Complete Handle Assembly (JK-NO Included)

JKL-FMH Hose Without Adapter for Swivel Connector

JKL-FMHS Hose With Adapter for Swivel Connector

JK-NO Nozzle

JK-FE Filter

JKL-VM Vacuum Motor 115V

CATALOG # DESCRIPTION

JKL-VM-240 Vacuum Motor 240V

JKL-OS On/Off Switch

JKL-OS-240 On/Off Switch 240V

JKL-FG Filter Guard

JK-CG Chip Guard

JKL-WMB Wall Bracket

JK-SC Swivel Connector

SPECIALIZED SAFETY PRODUCTS A Division of The A.W.T. World Trade Group

4321 N. Knox Ave., Chicago, IL 60641 USA 773.777.7100 • Fax:773.777.0909

[email protected] www.specializedsafetyproducts.com

Jet-Kleentm 7 Installation & Operation Manual

p

S

S

A Product of

LIMITED WARRANTY

Specialized Safety Products/A.W.T. equipment is warranted against defects in workmanship and materials

for a period of one (1) year or 2,500 hours running time from the shipping date of the equipment from A.W.T.

World Trade, Chicago, IL 60641. Warranties are not included for any product or machine invoice that remains

unpaid according to the conditions of the Sales Agreement/Quotation.

This limited warranty does not cover failure of parts or components resulting from misuse or lack of mainte-

nance.

Specialized Safety Products/A.W.T. is not responsible for installation or replacement of any defective part or

its replacement. Service labor, travel cost and sustenance charges are the responsibility of the customer on all

defective parts. Removal or installation, if requested, is billed at prevailing service rates.

Any part determined to be defective, in workmanship and material, under this limited warranty period will

be repaired or replaced, at our option, without charge, when returned within 30 days from the date the Return

Authorization was issued. Specialized Safety Products/A.W.T. is not obligated to cover any freight costs.

Customers must obtain a return authorization number from our Customer Service Department or service man-

ager before returning any defective part. The consumer must return parts via prepaid postage or prepaid freight

to the following address:

A.W.T. World Trade Inc.

4321 N. Knox Ave.

Chicago, IL 60641 USA

Consequential damages, lost time, material loss, inconvenience, or any other contingent liabilities are expressly

not covered by this warranty. We specifically make no other warranties, expressed or implied, other than the above

Limited Warranty.

SPECIALIZED SAFETY PRODUCTS A Division of The A.W.T. World Trade Group

4321 N. Knox Ave., Chicago, IL 60641 USA 773.777.7100 • Fax:773.777.0909

[email protected] www.specializedsafetyproducts.com

Jet-Kleentm 8 Installation & Operation Manual

p

S

S

A Product of

©2018 Specialized Safety Products. No part of this literature may be reproduced without written permission. Specifications subject to change without notice. #MAN-AWT-JETKLN 04/18

This manual suits for next models

1

Table of contents

Other SSP Vacuum Cleaner manuals