Siedle Group

Novotechnik

Messwertaufnehmer OHG

MAP300_400_en_01.doc

10

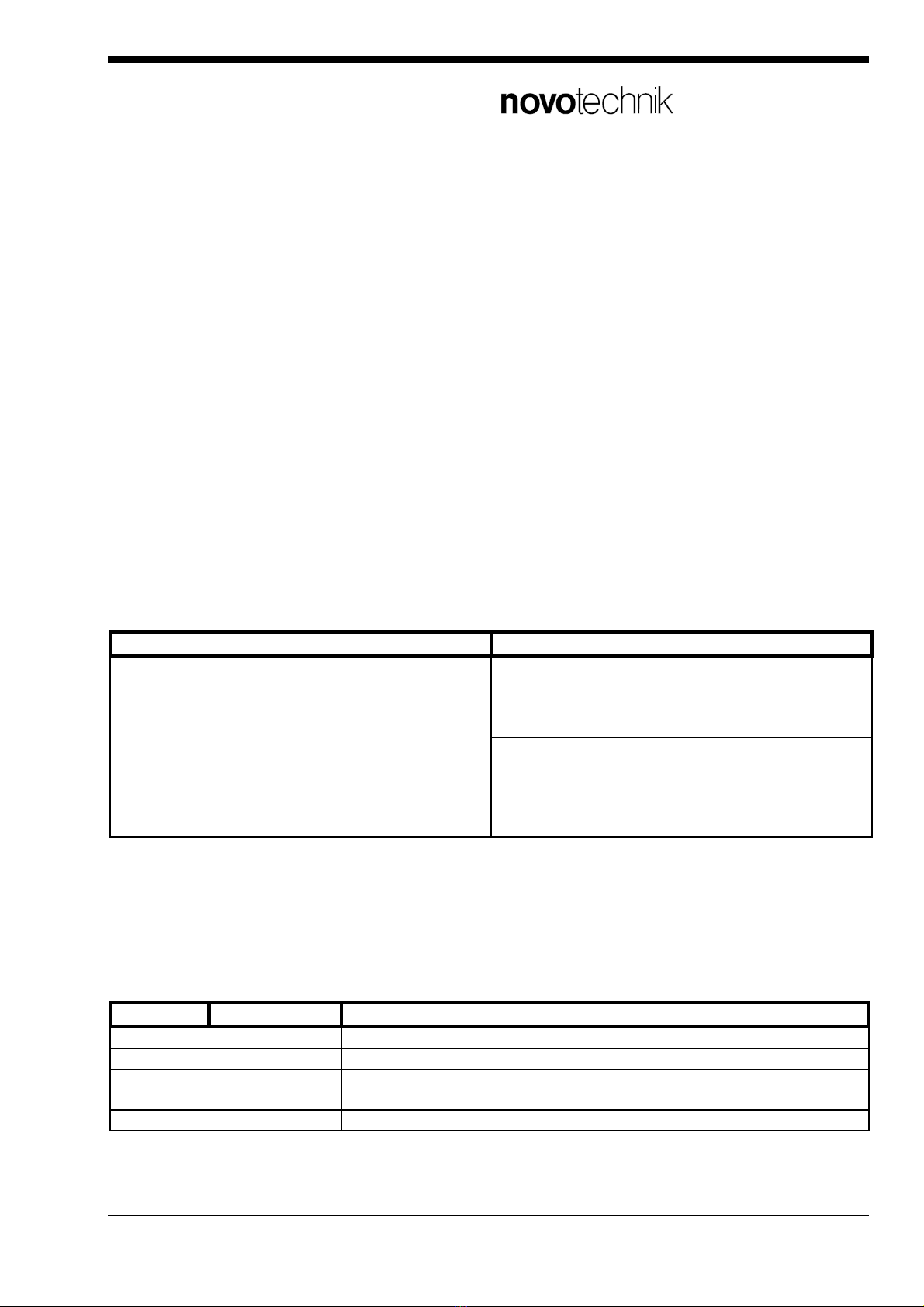

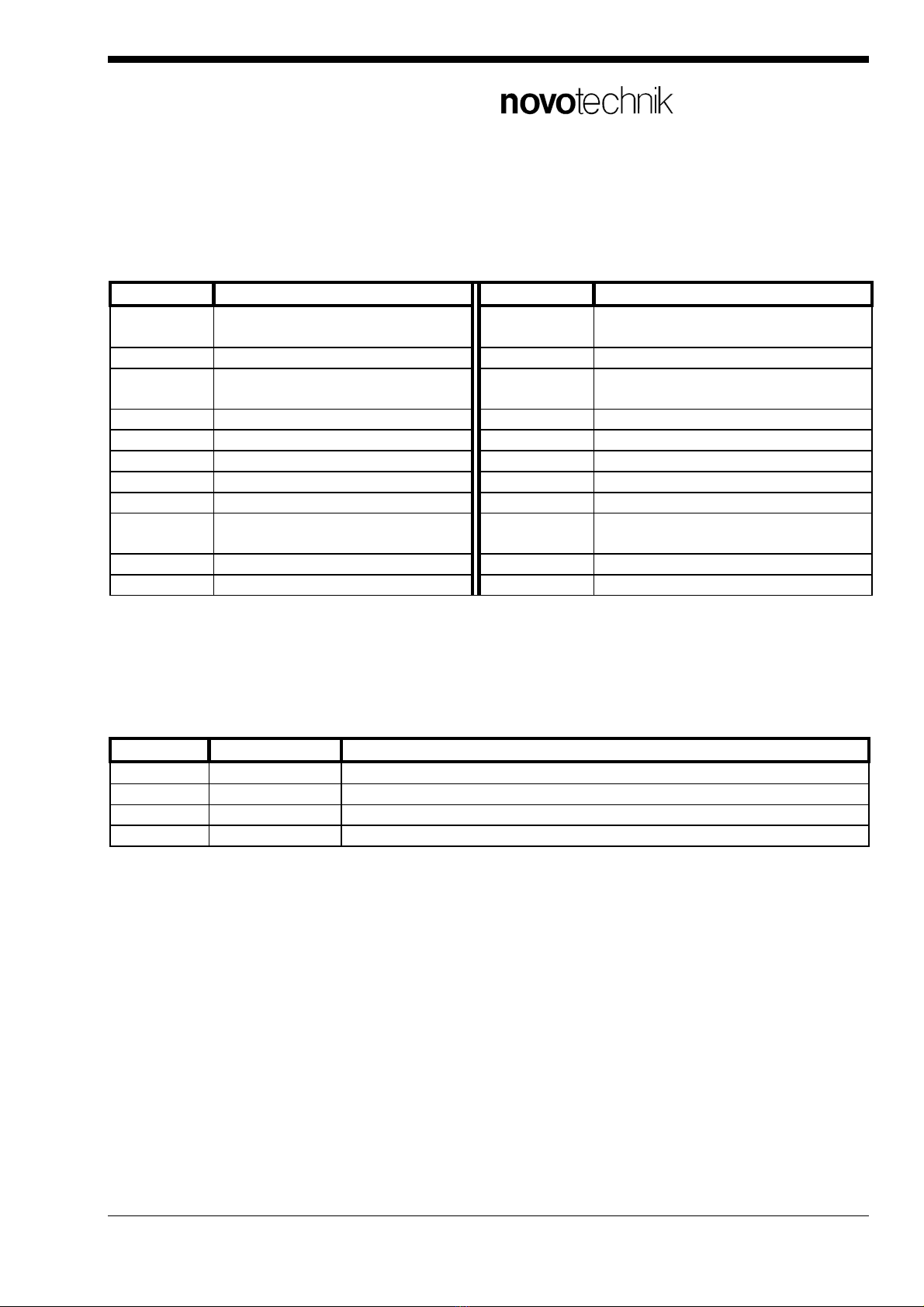

Selection possibilities of the input functions for all inputs:

display function display function

1 taring function (static)

notice the detailed description !

c BCD-inquiry

2 taring function reset d HEX-inquiry

3 storage function: display + com-

parator (Hold)

E print start, measurement value

4 storage function: comparator F display dark function

5 storage function: display G closed-circuit output function

6 programming block H, J, L print start, progr. text (16 signs)

7 SEL-key block N limit value acceptance

8 keyboard block o print start: like „E“, but continuous

9 peakdetector: positiv P print start: like „E“, but with

<CR><LF>

A peakdetector: negativ q taring function (dynamic)

b peakdetector: difference - no function

After calling up program routine [2], the control inputs can be selected by pressing the SP>-key.

The position, which is to be changed, flashes. The input functions can be changed by pressing the

-keys.

Example: display q E 9 A

input display function

IN1 q taring function (dynamic)

IN2 E print start, measurement value

IN3 9 peakdetector: positiv

IN4 A peakdetector: negativ

3.2.1 Taring function

The taring function resets the display value at an optional position and can be externally controlled.

After activation, only the deviation from the stored taring value is displayed. The taring function can

also be reset externally, if a control input is programmed for the function "taring function reset". In

the FUNC menu, the taring value can be additionally set to zero or any optional value.

a) Taring function (dynamic) Input function „q“ > New function ! <

The taring value is stored in the internal dynamic RAM. The taring value is activ until the

supply voltage is connected. After a power fail the taring value is reset to zero. It is recom-

mended to use this function because there is no limitation on storage cycles.

b) Taring function (static) Input function „1“ > Important ! <

The taring value is stored in the internal static EEPROM. Do not use this function for fre-

quently taring cycles. Use this function only for rare cycles, when it is absolutly necessary to

protect the actual taring value against power fails. At frequently storage cycles it is possible

that storage errors will affect because of the limited and unknown storage capacity of the in-