SST Automation GT100-IE-MPI User manual

EtherNet MPI Adapter

GT100-IE-MPI

User Manual

V 2.0

SST Automation

Email: [email protected]

www.SSTAutomation.com

WWW.SSTAUTOMATION.COM

Important Information

Warning

The data and examples in this manual cannot be copied without authorization. SST Automation reserves the right

to upgrade the product without notifying users.

The product has many applications. The users must make sure that all operations and results are in accordance

with the safety of relevant fields, and the safety includes laws, rules, codes and standards.

Copyright

Copyright © 2022 by SST Automation. All rights reserved.

Trademark

is the registered trade mark of SST Automation.

Technical Support Contact Information

www.sstautomation.com

E-mail: support@sstautomation.com

WWW.SSTAUTOMATION.COM

Catalog

1 Product Overview ......................................................................................................................................................1

1.1 Product Function ............................................................................................................................................ 1

1.2 Product Features ............................................................................................................................................. 1

1.3 Technical Specifications .................................................................................................................................1

1.4 Related Products .............................................................................................................................................2

1.5 Revision History .............................................................................................................................................2

2 Hardware Descriptions .............................................................................................................................................. 3

2.1 Product Appearance ........................................................................................................................................3

2.2 Indicators ........................................................................................................................................................ 4

2.3 Interface ..........................................................................................................................................................4

2.3.1 Power Interface ................................................................................................................................... 4

2.3.2 Ethernet Interface ................................................................................................................................ 5

2.3.3 S7 Bus Interface .................................................................................................................................. 5

2.3.4 Reset Button ........................................................................................................................................ 6

3 Hardware Installation ................................................................................................................................................ 7

3.1 Mechanical Dimension ...................................................................................................................................7

3.2 Installation Method ........................................................................................................................................ 7

4 Quick Start Guide ...................................................................................................................................................... 8

5 Configuration Instructions .........................................................................................................................................9

5.1 Configuration Interface Description .............................................................................................................. 9

5.2 Home .............................................................................................................................................................. 9

5.3 Parameter Settings ........................................................................................................................................10

5.3.1 Basic Settings .................................................................................................................................... 10

5.3.2 Serial Interface Settings .................................................................................................................... 11

5.3.3 Ethernet Interface Settings ................................................................................................................ 11

5.4 Download ..................................................................................................................................................... 12

6. Portal Programming ............................................................................................................................................. 13

6.1 System Requirement .................................................................................................................................... 13

6.2 Programming ................................................................................................................................................ 13

7. Use Case ................................................................................................................................................................. 20

www.SSTAutomation.com

1

1 Product Overview

1.1 Product Function

The GT100-IE-MPI is an adapter which is used for Ethernet communication of Siemens SIMATIC S7 series PLC

(including S7-200, S7-300, S7-400), Siemens CNC (840D, 840DSL, etc). It supports data monitoring.

1.2 Product Features

Supports multi-master communication, the expansion port can be connected to touch screen or other masters.

Baud rate adaptive.

Automatically query the master station address and display the address list.

It can be directly installed on the PPI/MPI/PROFIBUS DP communication port of PLC without external

power supply.

Supports Siemens S7 Ethernet communication drivers, including MicroWIN, STEP7, WinCC, SIMATIC

NET, KEPServerEX, etc.

Supports 16 Ethernet TCP/IP connections, allowing 16 PCs to collect PLC data at the same time.

1.3 Technical Specifications

[1] DB9 communication port:

Interface type: TIA/EIA RS-485 compatible, ESD: ±15KV, up to 32 nodes.

Protocol supported: Siemens S7 bus multi-master protocol, supports PPI, MPI and PROFIBUS DP.

Baud rate (bps): 9600, 19200, 45450, 93750, 187500, 500K, 1.5M.

[2] Ethernet port:

Network port type: a 10M/100M adaptive network port.

Protocol supported: S7TCP, 16 TCP/IP connections.

[3] Power: 24 VDC (11~30 VDC), 100mA(24VDC).

www.SSTAutomation.com

2

[4] Operating temperature: 32℉~140℉(0℃ ~ 60℃). Humidity: 5%~90% (non-condensing).

[5] Dimensions (W*H*D): 0.67 in *2.56 in *1.29 in (17mm*65mm*33mm).

[6] Installation: Siemens S7 PLC DB9 communication port plug.

[7] Protection Level: IP20.

1.4 Related Products

The related products include: GT200-DP-RS, GT200-PN-RS and GT200-PN-3RS, etc.

To get more information about related products, please visit SSTCOMM website: www.sstautomation.com.

1.5 Revision History

Revision

Date

Chapter

Description

V2.0

03/20/2021

ALL

New release

www.SSTAutomation.com

3

2 Hardware Descriptions

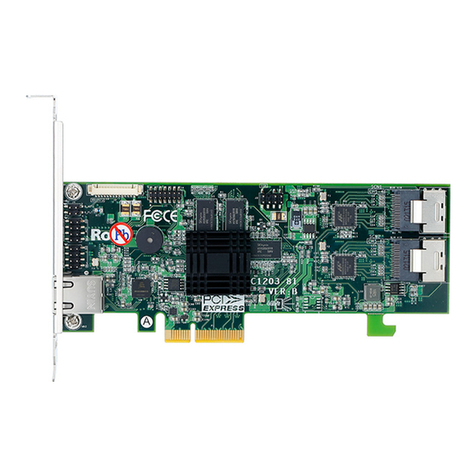

2.1 Product Appearance

Notes: This picture is for reference only. The product appearance is subject to the actual product.

Extended S7 Bus Interface

S7 Bus Interface

Indicators

Optional Power Interface

Ethernet Interface

www.SSTAutomation.com

4

2.2 Indicators

Indicator

State

State description

Troubleshooting

PWR

ON

Supply of power is normal

N/A

OFF, Flashing

Supply of power is abnormal

Check the power supply

BUS

ON

The baud rate is correct and the gateway

is functioning normally

N/A

Flashing (for 1

seconds)

The same station address exists on the

S7 bus

Modify the station address of the

module through the web page

Flashes twice at 1Hz

after a few seconds

interval

Baud rate is not detected

Check the PLC communication port

OFF

Gateway or indicator failure

Contact technical support

Flashing

Communication response frequency

N/A

Link

ON

Network is connected

N/A

OFF

Gateway or network failure

Check local and remote network

connections

Active

Flashing

Communication is normal with remote

devices

N/A

OFF

No communication

N/A

ON, not flashing

quickly

Ethernet failure

Contact technical support

2.3 Interface

2.3.1 Power Interface

The power interface is an optional interface. It’s not recommended to use it. The gateway can get power when

connecting PLC using S7 bus interface. If PLC itself cannot provide power, you can connect power interface to

power it.

Pin

Function

1

+24V

2

GND

www.SSTAutomation.com

5

2.3.2 Ethernet Interface

The Ethernet interface uses an RJ-45 connector. Its pin (standard Ethernet signal) is defined as below:

2.3.3 S7 Bus Interface

1) S7 bus interface X1

X1 interface is DB9 male port, which can be directly inserted into the communication port (PPI port, MPI port or

PROFIBUS DP port) of S7 series PLC. The pin definition of the communication port is the same as that of the

PLC, among which pin 3 is the B line of RS485, pin 8 is the A line of RS485, and pin 5 is the logic ground. Pin 7

is the positive of the 24VDC power supply of the PLC, and pin 2 is the ground of the 24VDC power supply. The

24VDC power supply of pin 2/7 is used as the default power supply input. The baud rates supported by the X1

interface include: 9.6K, 19.2K, 45.45K, 93.75K, 187.5K, 500K and 1.5Mbps.

5

1

RS485_A (Pin 8)

GND (Pin 5)

RS485_B (Pin 3)

Pin

Description

S1

TXD+, Transmit Data+

S2

TXD-, Transmit Data-

S3

RXD+, Receive Data+

S4

Bi-directional Data+

S5

Bi-directional Data-

S6

RXD-, Receive Data-

S7

Bi-directional Data+

S8

Bi-directional Data-

Pin

Function

2

GND of 24VDC

3

RS485, B

5

GND

7

24VDC

8

RS485, A

www.SSTAutomation.com

6

2) Extended S7 bus interface X2

The X2 interface is a DB9 female port, which is used to connect Siemens communication equipment (such as

Siemens touch screen, CP5611 communication card, etc.). The supported baud rates include 9.6K, 19.2K, and

187.5K.

2.3.4 Reset Button

The reset button is used to restore the gateway to factory settings. Long press the button for 5 seconds and release

the button when the BUS indicator is solid green. The default IP is 192.168.1.188. Visit 192.168.1.188 in web

browser to configure the gateway.

www.SSTAutomation.com

7

3 Hardware Installation

3.1 Mechanical Dimension

Size (width * height * depth):

0.67 in *2.56 in *1.29 in (17mm*65mm*33mm)

3.2 Installation Method

Using Siemens S7 PLC DB9 communication port plug.

www.SSTAutomation.com

8

4 Quick Start Guide

Basic steps when configuring G100-IE-MPI :

1. Wiring:See also Chapter2.3 Interface.

(1)Plug the S7 bus Ethernet interface to Siemens PLC PPI, MPI or PROFIBUS DP communication port.

(2)Connect the network port of the gateway to the PC with a network cable for downloading the

configuration.

(3)Power on the PLC, check whether the gateway is power on.

2. Build your configuration using web browser after connecting the gateway with network cable.

If the gateway cannot be searched,please note:

The network factory setting of GT100-IE-MPI is 192.168.1.188. Please check whether the computer and

gateway are in the same network segment.

Please test the network connection first. Please refer to the note "How to Use the Ping Command"

located on our Support page on the sstautomation.com website.

If you press and hold the Reset button for 5 seconds, the gateway will restore the default configuration,

and the IP address will be fixed to192.168.1.188.

3. Fill in 192.168.1.188 in your web browser and starting the configuration of the gateway. For more

configuration details, please refer to Chapter 5.

www.SSTAutomation.com

9

5 Configuration Instructions

5.1 Configuration Interface Description

After connecting the gateway using network cable, you can fill in http://192.168.1.188/ to start configuration of

GT100-IE-MPI.

When you first visit the web configuration page, the interface is as below.

The default password is admin.

5.2 Home

There is the basic info and diagnostics for your reference.

www.SSTAutomation.com

10

5.3 Parameter Settings

5.3.1 Basic Settings

Click the "Parameter Settings" on the left and you will the configuration interface, as shown below:

Device name: Enter the name of the device to which the bridge is connected.

Password: Change the login password of the web configuration page.

Confirm password: Input the password again.

www.SSTAutomation.com

11

5.3.2 Serial Interface Settings

Protocol mode: Select the protocol mode of PLC. If you want to conect the PPI of S7-200 PLC, please select PPI.

If the PLC is S7-300 or S7-400, please select MPI M/S. If you want to connect PROFIBUS DP port, please select

PROFIBUS.

Bridge adapter address: The default is 0,which cannot conflict with other station address on the bus.

Bus highest address: The default is 31. No need to change.

Gap factor: The default is 10. No need to change.

X1 baudrate: Select the baudrate you want to use with PLC. X1 port connects to PLC,the baudrate can be set to

be automatic or fixed baudrate.

X2 baudrate: Select the baudrate you want to use with PLC. X2 port connects to PLC,the baudrate can be set to

be automatic or fixed baudrate.

5.3.3 Ethernet Interface Settings

IP Address: Set the IP address of the GT100-IE-MPI.

Subnet Mask: Subnet mask is 255.255.255.0 by default.

Gateway: The default address is 192.168.1.1.

S7TCP taget address by slot: When the status is ON,S7TCP target address is set by slot

S7TCP taget address: The default is 2,valid when the status of S7TCP target address by slot is OFF.

Open TCP Port: The default is 1099.

www.SSTAutomation.com

12

5.4 Download

When parameter settings are done, please click Download button to download the configuration to the

GT100-IE-MPI.

The web page will show the following hint when you click the Download button. Then the configuration will take

effect.

www.SSTAutomation.com

13

6. Portal Programming

6.1 System Requirement

If you want to use GT100-IE-MPI to do programming on Portal or STEP7, you should install Portal software

firstly.

6.2 Programming

You should refer to the following instructions to finish the programming.

1. New a project.

2. Double click "Add new device".

3. Unfold the "Controllers" and unfold the "CPU" under "SIMATIC S7 300", select the actual PLC model you

want to connect, click "OK".

www.SSTAutomation.com

14

4. Double click "MPI address", configure it and click "Add new subnet".

www.SSTAutomation.com

15

5. It will generate "MPI_1" network, the "Address” should be the same with MPI address of PLC. The default is 2.

6. Then "Add new device", select "PC station" under "PC general" of "PC systems", click OK.

www.SSTAutomation.com

16

7. Select "Communications modules"->"PROFIBUS"->"CP5611(A2), drag it to the No.1 slot of PC station.

8. Double click "CP5611A2_A" and start configuring. Choose "MPI" for Interface type. Choose "MPI_1" for

Subnet, "Address" keeps 3 (Prevents address duplication with other MPI stations).

www.SSTAutomation.com

17

9. Select "Communications modules"->"PROFINET/Ethernet"->"IE general", drag it to the No.2 slot.

10. Double click "IE general_1" and start configuring. Click "Add new subnet" and it will automatically generate

"PN/IE", fill in the IP address and Subnet mask of the GT100-IE-MPI (for example, it is 192.168.1.188).

Table of contents

Other SST Automation Adapter manuals