SST 5029 User manual

MODEL5029 4-20 mA ANALOG INPUT MODULES

DESCRIPTION

TheSST Model 5029 Analog Input Modulesareusedto monitorany processvariable

that can be converted to the industry standard 4-20 Ma output signal. The analog

input on the module is completely isolated, so that it can be fed from a transmitter

that is referenced to + DC, -DC, ground, or floating. Because this is a current loop,

other devices, such as a PLC input or a data acquisition system, may be connected

into the same loop without affecting the Model 5029 indications. A 24 VDCoutput,

derived from the redundant NOVA-5000 system power supplies, is provided for

powering the 4-20 mA transmitter associated w ith the field sensor. The module

features a digital readout indicating the relative level of the sensed signal, plus two

alarm indicating circuits with adjustable alarm levels. Field wiring to the transmitter

is continuously supervised, and the module automatically performs a self-check

routine at regular intervals.

!NOTE: The information in this section applies to all modules in this series.

These modules are all electrically identical, regardless of the actual

variable being sensed. The only difference between the various models is

the legend at the top of the nameplate (pressure, temperature, Halon

weight, etc.), and the maximum level displayed on the digital readout.

Application Caution

The Analog Input Module interfaces

process management functions to

the NOVA-5000 Control System.

An alarm condition on the analog

module does not indicate a fire con-

dition. The outputs of the analog

module must not be used to ac-

tivate any fire alarm signal devices.

The analog modules should activate

separate and distinct signals from

the fire system.

LOGIC DIAGRAM

Figure 5029-1 shows, in simplified

form, the internal logic in the

Analog Input Module, and indicates

the terminal number assigned with

each.

Figure 5029-1 Logic Diagram

DESCRIPTION MODEL 5029 4-20 mA ANALOG INPUT MODULES

DESIGN MANUAL December, 1994 5029-1

INPUT/OUTPUT CONNECTIONS

Figure 5029-2 shows the physical arrangement of the 16 terminals associated with

the Analog Input Module. Each of the available signals is described below.

Alarm Relay Outputs — terminals 1 through 6

These are NOVA-5000 Standard Relay Outputs that operate whenever the signal

level detected exceeds the alarm levels programmed into the module. The normally

open (NO) and normally closed (NC) contacts will be in that state with no alarm

detected. The relays A1 or A2 will transfer when an alarm condition occurs, and

may optionally be set to latch until the zone is reset by pushing the reset pushbutton

on the module or the main system reset pushbutton. These outputs will not be

activated if the isolate switch on the module is in the isolated position.

Alarm Lamp Outputs — terminals 7 and 8

These are Standard Alarm Lamp Outputs activated by the Alarm state of the

appropriate level. They exactly follow the state of the front panel alarm lamps, i.e.

flash on initial detection of an alarm, steady when acknowledged, and switched off

by reset. These outputs are activated by Lamp Test, and are not inhibited by Isolate.

Alarm Solid State Outputs — terminals 9 and 10

These are Standard Logic Outputs activated at the alarm level settings A1 and A2.

They operate simultaneously with the alarm relay outputs, and will not be activated

if the Model 5029 Module is in the Isolate condition.

Sensor Power Status — terminal 11

This is a Standard Logic Output activated by the sensor power control circuits in the

module. The module includes a source of 24 volts DC operating power for the sensor

transmitter, as described below. The Detector Power Status Output is energized

whenever power is being supplied tothetransmitter.

In case of excessive current draw, such as a short

circuit condition on the power wire, the detector

power supply feed from the module is shut down,

and this output will be deenergized.

Sensor 24 VDC Transmitter Power — terminal 14

Because the actual signal output from any sensor is

very low,anelectronic circuit, typically referredto as

a “transmitter”, is required to amplify the sensor

signal to the 4-20 mA level required by the module.

This output is a source of 24 volt DC operating

power for the sensor transmitter. Transmitter power

should always betaken from this source, rather than

directly from a 24 VDC power supply, because this

source utilizes the redundant power feeds to the

module. It is rated at 500 mA, and will be shut down Figure 5029-2

INPUT/OUTPUTCONNECTIONS MODEL 5029 4-20 mA ANALOG INPUT MODULES

DESIGN MANUAL December, 1994 5029-2

if a short-circuit or excessive current draw condition is detected in the loop. This

output is also interrupted when the module is reset; this feature is provided to permit

the use of “intelligent” sensor transmitters that have latching circuits when an alarm

is detected.

Sensor 4-20 mA Input — terminals 15 and 16

This is the sensing input which is connected into the 4-20 mA loop. It is completely

isolated from the NOVA-5000 circuits (floating), so that any other 4-20 mA input

may be included on the loop, whether grounded or not. When the module is active,

the voltage drop across these terminals is less than 0.2 volts at 20 mA, and will

increase to not more than 0.8 volts w ith the module unpowered or failed. A 1 amp

silicon diode may be installed across these terminals if you need to prevent

interruption of the 4-20 mA loop when a module is unplugged. This input is rated to

withstand any voltage up to 120 V AC or DC with respect to ground.

Typical Wiring Diagram

Figures 5029-3 and 5029-4 show the approved connections for the Model 5029

series modules. All installations should be made in conformance with these draw-

ings.

Fig. 5029-3 Typical Wiring Diagram, 4-Wire Transmitters

Figure 5029-4 Typical Wiring Diagram, 2-Wire Transmitters

INPUT/OUTPUTCONNECTIONS MODEL 5029 4-20 mA ANALOG INPUT MODULES

DESIGN MANUAL December, 1994 5029-3

MODULE SETUP INSTRUCTIONS

All NOVA-5000 modules are completely tested and calibrated at the factory before

shipment. The following adjustments are the only ones necessary before installing

the module.

Setting alarms for Latching/Non-Latching operation

There are two “DIP” switch assemblies on the module, marked SW2 and SW3. SW2

controls the action of Alarm 1 (A1), and SW3 controls Alarm 2 (A2).

Switch section 1 on SW2 or SW3, Latch Enable, permits the Module to operate as

a trip detector (e.g. to trip and hold an alarm) or as a level switching amplifier (e.g.

to control a fill valve associated with a level detector). SW2 controls the latching for

alarm A1 and SW3 controls A2.

When the switch is ON or CLOSED, the alarm is set up to be

latching

, and the

following actions will occur when the input current exceeds the appropriate trip

threshold:

• the red “A1” or “A2” lamp on the front panel will start to flash

• the alarm lamp output of the module will start to flash

• the appropriate alarm solid state output will be activated

• the appropriate alarm relay contacts will transfer

If the input current falls below the threshold, the latching function will cause the

above listed outputs to remain as indicated until the module is reset. Note, however,

that the digital display will continue to indicate the actual value of the variable being

sensed.

When the switch is OFF or OPEN, the alarm is set to be

non-latching

. The same

actions as above occur when the input current exceeds the threshold, but if it

subsequently reduces below the threshold again:

• if the red “A1” or “A2” lamp and the lamp output is flashing, they will

continue to flash until acknowledged; if they had been previously acknow-

ledged, they will extinguish immediately

• the alarm relay and solid state outputs will return to their normal conditions

Setting alarm level trip points

Switch sections 2 through 8 on SW2 set the threshold level or trip point at which

alarm A1 will be energized. SW3 performs the same function for A2. The trip levels

associated with each switch section depends on the full scale range of the module.

These settings are as follows:

Switch No. 2345678

FullScale=100 6432168421

FullScale=50 32168421

Full Scale= 20 12.8 6.4 3.2 1.6 0.8 0.4 0.2

MODULESETUPINSTRUCTIONS MODEL 5029 4-20 mA ANALOG INPUT MODULES

DESIGN MANUAL December, 1994 5029-4

The value listed in the table above is selected when the switch is ON or CLOSED,

and closing multiple switches will cause the values to add. For instance, closing

switches 3 and 5 will cause the alarm to trip at 40 on a 100 scale module, because

32 + 8 = 40. Note, however, that this setting will cause the alarm to trip at 20 on

a 50 scale module, or at 8 on a 20 scale module.

The full scale range for any Model 5029 module is set by programming in the

module’s ASIC chip. You can determine this scale range by checking the SST part

number marked on the identification label. The numbers following the dash in the

part number correspond to the full scale range. Thus a part number 35029-100

indicatesafull scalerangeof 100, whilepart number35029-20 indicates afull scale

range of 20.

!If the alarm threshold is set to a number greater than the full scale range,

the Module will signal a self-check fault, as one of the self-check functions

is to seethat both threshold detectors function correctly. If only one alarm

level is required, both thresholds must be set to this same value to satisfy

the self-check requirement.

Module keying

Beforeinstalling eachModel 5029 analog moduleinto thewired slot in themounting

rack, be sure that the snap in covers have been installed at keying locations 2 and

10 of the rack keying strip. See “Module Keying Instructions” in the mounting rack

section of this manual for complete details.

!Installation of the keying system is very important. A module can be

permanently damaged if it is plugged into a slot which is wired for a

different type of module.

Modules may be inserted into or unplugged from the rack at any time, even with the

power on. This will not damage the modules nor generate any false alarms, but will

of course generate a fault alarm.

OPERATING INSTRUCTIONS

General

The Model 5029 Analog Input modules have been designed to monitor the signals

generated by any process parameters which can be converted into the industry

standard 4-20 mA signal. The Model 5029 incorporates a sensitive isolated input

circuit which can be wired into a current loop with such a low voltage drop (not

greater than 0.5 V) that it has negligible effect on the transmitter or any other

indicating equipment in the loop. The value of the process parameter is displayed on

a 2-digit numeric display, and the module incorporates two independent trips which

can be set to operate anywhere within the normal (i.e. 4 to 20 mA) range of input

current. Diagnostic messages are displayed for currents outside this range, and for

extreme cases, faults are signalled by the module.

The module has an automatic self-check routine which is run every 8 minutes. The

input is disconnected from the loop, and connected to an internal ramp generator in

order to check the analog measurement section and the trips.

OPERATINGINSTRUCTIONS MODEL 5029 4-20 mA ANALOG INPUT MODULES

DESIGN MANUAL December, 1994 5029-5

Alarms and faults are indicated as follows:

• When an alarm or fault indication is first detected, the relevant indicator lamp

flashes. Most systems are wired so that an audible alarm sounds at the same

time. If the alarm acknowledge button is depressed, any flashing indication

becomes steady, and this action will silence the audible alarm on most

systems.

When the cause of an alarm or fault is removed, the indication generally operates as

follows:

• If the indication is flashing, it remains flashing until it is acknowledged or the

zone is reset, when it will extinguish.

• If the indication is steady, it will extinguish immediately.

Some faults and alarms are latched so that they can only be cleared by resetting the

module.

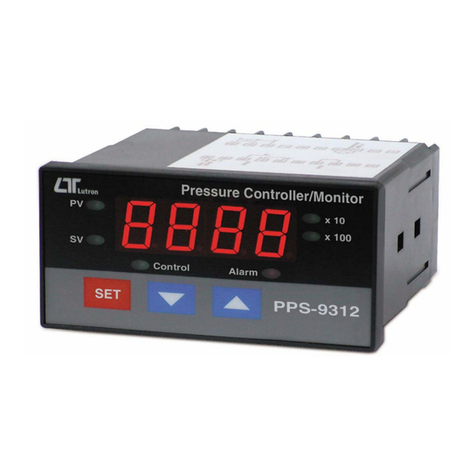

Power lamps (green and yellow)

The two lamps at the top of the panel indicate the status of the power supply to the

module. A green lamp indicates that both of the dual 24 volt power feeds are within

specification. If the yellow lamp is on or flashing, an out-of-tolerance power

condition or power failureis indicated. Probablecause is a blown fuseon themodule.

When a power fault is detected, the main channel fault lamp on the module will also

be illuminated. In the unlikely event of failure of the control integrated circuit in the

module, a fault will be signalled by opening the Fault Loop. Depending on the failure

mode, other indications may or may not be given. Whatever the failure mode, the

green Power lamp will extinguish.

System designers should ensure that opening the Fault Loop alone will operate the

System Fault alarms.

Alarm lamps (red)

These lamps will normally be off. When an Alarm is detected

(i.e. the input current rises above the preset threshold for that

alarm), the appropriate lamp will flash, and the appropriate

module alarm outputs will be activated. The alarm lamp will

continue to flash until either the system alarm pushbutton is

depressed, or the module is reset. If the alarm has been

configured to be non-latching, an acknowledged alarm will

extinguish as soon as the input level goes below the

programmed alarm trip threshold. For latching alarms, the

module must be reset, either from the system reset pushbut-

ton or from the front panel pushbutton to reset the alarm state

to normal.

Numeric Display

The 2-digit numeric display provides a digital readout of the

variable being monitored. The reading is scaled so that the

4-20 mA signal reads out in a suitable variable range. Because

this display is intended to indicate the severity of an alarm,

rather than for use as a normal process monitor, it is turned Figure 5029-5 Front

Panel

OPERATINGINSTRUCTIONS MODEL 5029 4-20 mA ANALOG INPUT MODULES

DESIGN MANUAL December, 1994 5029-6

off when the input signal is near normal. If the full scale capability of the module is

100, thedisplay will start at 3. For 50 scale modules, display starts at 2; for 20 scale

modules, 1.

Outside the normal range of operating current the following indications are dis-

played:

Su . . . . . . . . . . . . . . . . .Start Up

Displayed for 15 seconds ar power up and after reset button is pushed. Start

up time delay to allow time for sensor to stabalize.

Oc . . . . . . . . . . . . . . .Open Circuit

This indicates that there is no current coming into the input. Probable cause is

an open circuit on the wiring between the 4-20 mA transmitter and the module.

Ur . . . . . . . . . . . . . . .Under Range

This indicates a current considerably below the normal range. The circuit

probably needs to be recalibrated.

Or . . . . . . . . . . . . . . . Over Range

This indicates a current above 20 mA. This probably indicates a failure in the

sensor.

Sc . . . . . . . . . . . . . . .Short Circuit

Indicates that excessive current was delivered to the module from the sensor

transmitter. Probable cause is a short circuit on the wires between the module

and transmitter, or a short circuit between one of the wires and ground. This

condition shuts down the transmitter power output on the module. You must

press reset to restore.

Check Lamps (green and yellow)

The green lamp will illuminate when the module is carrying out its self-check routine.

A self-check is initiated immediately anytime the RESET button on the module or the

SYSTEM RESET bus is activated. Thereafter, the self-check is automatically

reinitiated every 8 minutes.

The GREEN CHK lamp blinks while the self-check is in progress. In the self-check

mode, the input circuit inside the module is switched to an internally-generated ramp,

and the numeric display indicates values over its entire range. As each alarm

threshold is crossed, the appropriate Alarm lamp will illuminate. If the two alarm

thresholds are not crossed during the check, the YELLOW CHK lamp will flash to

indicate a failure in the module, and a System Fault will be signalled. This Fault can

be accepted and reset in the usual way.

During the self-check routine, the ALARM RELAY and ALARM SOLID STATE OUT-

PUTS do not change state. If they were in alarm when the test starts, they will

remain energized during the test; if there were no alarms at the start of the test,

alarm outputs will not be energized. Only the alarm lamps on the module, or on an

external mimic panel, will be illuminated during the test. Theself-check routine takes

20 SECONDS to complete.

The status of the alarm LED’s on the front panel prior to the start of the routine is

saved to memory, and restored to the front panel indicators at the end of the test.

As noted above, the external outputs from the moduledo not change during the test.

OPERATINGINSTRUCTIONS MODEL 5029 4-20 mA ANALOG INPUT MODULES

DESIGN MANUAL December, 1994 5029-7

Isolate Lamp (yellow)

This lamp indicates that the Isolate switch is in the Isolate (up) position.

Isolate Switch

This switch is recessed behind the panel and requires a small screwdriver to operate

it. The switch is used to prevent system alarm outputs from occurring during routine

calibration and maintenance of the module and sensor. When it is switched to its

active (upper) position the following actions occur:

• The yellow Isolate lamp is illuminated

• A pulse is transmitted on the Isolate Pulse bus

• The Isolate Loop is open-circuited

• The alarm outputs from the module are disabled.

When the switch is returned to its normal (lower) position, an internal reset is

generated so that any alarm condition created during testing within the module is

cleared, thus preventing unwanted external alarms.

Fault Lamp (yellow)

This lamp will be illuminated when any fault condition is detected as follows:

• Open or short circuit on detection input

• Self-check failure

On initial detection of the fault the following actions occur:

• The Fault lamp starts to flash

• The Fault Pulse bus is activated for 100 to 150 milliseconds

• The Fault Loop is open-circuited.

The fault lamp will continue to flash until the acknowledge or reset pushbuttons are

depressed.

Shutdown Lamp (yellow)

This lamp indicates that the 24 volt power supply to the sensor transmitter has been

shut down, due to excessive current draw. This will also cause a module fault to be

signalled. The Shutdown condition is latched, and must be cleared by a Reset either

from the system reset pushbutton or from the front panel pushbutton.

Reset Pushbutton

This pushbutton performs the following actions:

• Alarm and Fault status, whether acknowledged or not, is canceled

• The Sensor transmitter power supply line is shut down while the button is

pressed, then restarted

• The Sensor Power Status output is deactivated while the button is depressed

• A local lamp test occurs, i.e. all the lamps on the module are illuminated and

the Alarm Lamp outputs are energized.

When the module is reset using an external system reset pushbutton, the same

action as listed above occurs, except that the lamp test will not be performed.

OPERATINGINSTRUCTIONS MODEL 5029 4-20 mA ANALOG INPUT MODULES

DESIGN MANUAL December, 1994 5029-8

CALIBRATION

The module is shipped with the zero and span pre-set so that an input of 4.0 mA

corresponds to a reading of “0" and 20.0 mA corresponds to full scale on the digital

readout. These modules are extremely stable, and should not need adjustment from

year to year unless used with detector equipment which has no span and zero

adjustment within itself.

!Recommendation:

Wherever possible, zero and span should be adjusted at the sensor

transmitter, so that the signal levels transmitted to the module will always

vary between 4.0 and 20.0 mA. These modules also include fixed

threshold levels for detecting an open or short circuit fault on the 4-20 mA

input. If the normal values are out of this 4-20 mA range, detection

thresholds for faults would be incorrect.

Should recalibration be necessary, adjust the calibrating trim pots. RV1, near the

edge of the circuit board, is the zero adjustment; RV2 adjusts the span. The

recommended method of adjustment is by using a precision current calibrator. The

system wiring will need to be disconnected from terminals 15 (+ ) and 16 (-) of the

back plane and the calibrator connected in place. The moduleshould be set to Isolate

mode (the Isolate switch on the front panel in the upper position). This will cause

the digital display to be permanently on, so that values near zero can be read. With

thecalibratorset to4.0 mA, adjust zeropot RV1 to thepoint wherethedisplay reads

“0” on the display. Note that as you vary RV1 around the zero point, the negative

sign to the left of the zero goes on and off. Adjust the pot to the point where the

negative sign just extinguishes. Now set the calibrator for an output of 19.84 mA.

Adjust span pot RV2 and note that the maximum number you can display on the

readout is one less than the full scale range (i.e. 99 for a 100 scale range). When

you exceed this number the display changes to “Or” (Over range). Observe the two

positions on the pot over which the maximum number is displayed, and set the span

pot RV2 to be half way between these two positions. The two controls are

interactive to a small degree, so repeat as necessary until adjustments make no

further changes.

Alternatively, where there is no zero and span adjustment in the detector, the

detector manufacturer’s calibration procedure must be followed, using RV1 as the

zero and RV2 as the span adjustments.

Note that when the Isolate switch is returned to its “Normal” (down) position, the

numeric display is blank for input currents close to the “zero” (i.e. 4 mA) value. This

feature is provided so that, when several modules are used, those displaying

detection values will stand out more readily from those in normal ranges.

CALIBRATION MODEL 5029 4-20 mA ANALOG INPUT MODULES

DESIGN MANUAL December, 1994 5029-9

Blank Page

Table of contents