Stübbe NIS Series Installation instructions

Level switch

Original operating manual Series

NIS

Version BA-2022.10.26 EN

Print-No. 302 499

TR MA DE Rev001

STÜBBE GmbH & Co. KG

Hollwieser Straße 5

32602 Vlotho

Germany

Phone: +49 (0) 5733-799-0

Fax: +49 (0) 5733-799-5000

E-mail: co[email protected]

Internet: www.stuebbe.com

Subject to technical modifications.

Read carefully before use.

Save for future use.

Table of contents

Table of contents

1 About this document ............................... 3

1.1 Target groups ................................. 3

1.2 Other applicable documents ................ 3

1.3 Warnings and symbols ....................... 3

2 General safety instructions ....................... 4

2.1 Intended use .................................. 4

2.2 General safety instructions .................. 4

2.2.1 Obligations of the operating company ...... 4

2.2.2 Obligations of personnel ..................... 4

2.3 Hazardous media ............................ 4

3 Layout and Function ............................... 5

3.1 Type plate ..................................... 5

3.2 Description .................................... 5

3.3 Assembly ..................................... 5

4 Transport, Storage and Disposal ................. 5

4.1 Unpacking and inspection on delivery .. .. .. 5

4.2 Transportation ................................ 5

4.3 Storage ....................................... 5

4.4 Disposal ....................................... 6

5 Installation and connection ....................... 6

5.1 Preparations for installation ................. 6

5.1.1 Check operating conditions ................. 6

5.1.2 Preparation of the vessel .................... 6

5.2 Preparation of the device .................... 6

5.2.1 Connecting the immersion tubes ........... 6

5.2.2 Setting the switching points ................. 7

5.2.3 Application examples for the variants NIS 1

to NIS 4 ....................................... 7

5.3 Install device .................................. 8

5.4 Electrical connection of device .............. 8

6 Commissioning ..................................... 8

7 Maintenance ......................................... 9

7.1 Servicing ...................................... 9

7.2 Maintenance .................................. 9

7.2.1 Removing the device ........................ 9

7.2.2 Replacement parts and return .............. 9

8 Troubleshooting .................................... 10

9 Appendix ............................................. 10

9.1 Technical data, operating limits and

weights ........................................ 10

9.2 Connection diagram ......................... 10

9.3 Dimensions ................................... 11

9.4 Accessories ................................... 11

9.4.1 Mounting flange .............................. 11

9.4.2 mounting plate ................................ 11

List of figures

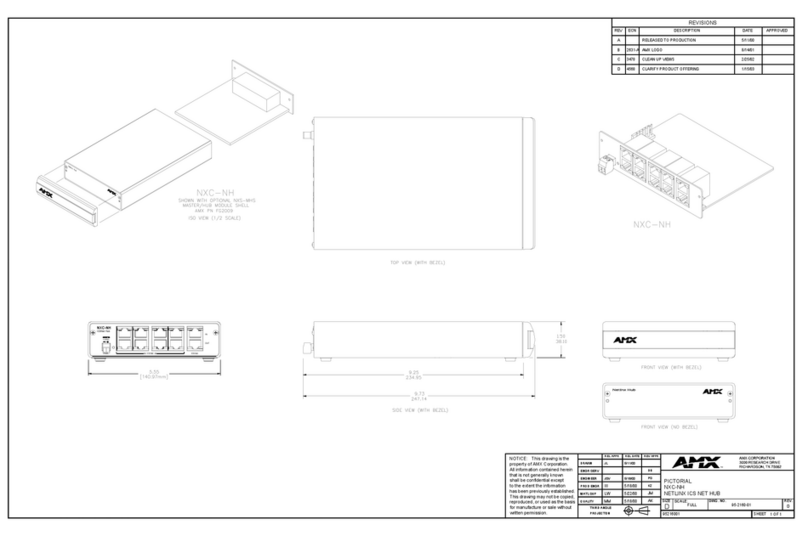

Fig. 1 Type plate .................................... 5

Fig. 2 Assembly (example: NIS 4) ................. 5

Fig. 3 Connecting the immersion tubes ............ 6

Fig. 4 Setting the switching points ................. 7

Fig. 5 Switching point for NIS 1 .................... 7

Fig. 6 Switching points for NIS 2 ................... 7

Fig. 7 Switching points for NIS 3 ................... 8

Fig. 8 Switching points for NIS 4 ................... 8

Fig. 9 Electrical connection of device .............. 8

Fig. 10 Connection diagram ......................... 10

Fig. 11 Dimensions ................................... 11

Fig. 12 Mounting flange .............................. 11

Fig. 13 mounting plate ................................ 11

List of tables

Tab. 1 Other application documents, purpose and

where found .................................. 3

Tab. 2 Warnings and symbols ....................... 3

Tab. 3 Servicing activities ........................... 9

Tab. 4 Troubleshooting .............................. 10

2 NIS BA-2022.10.26 EN 302 499

About this document

1 About this document

This manual:

• is part of the equipment

• applies to all series referred to

• describes safe and proper operation during all operating

phases

1.1 Target groups

Operating company

• Responsibilities:

– Always keep this manual accessible where the device

is used on the system.

– Ensure that employees read and observe this docu-

ment, particularly the safety instructions and warnings,

and the documents which also apply.

– Observe any additional country-specific rules and reg-

ulations that relate to the system.

Qualified personnel, fitter

• Mechanics qualification:

– Qualified employees with additional training for fitting

the respective pipework

• Electrical qualification:

– Qualified electrician

• Transport qualification:

– Qualified transport specialist

• Responsibility:

– Read, observe and follow this manual and the other

applicable documents, especially all safety instructions

and warnings.

1.2 Other applicable documents

To download:

Resistance Guide

Chemical resistance of the materials

used

www.stuebbe.com/pdf/300051.pdf

To download:

NIS data sheet

Technical specifications, conditions of

operation

www.stuebbe.com/pdf/302505.pdf

To download:

CE declaration of conformity

Conformity with standards

www.stuebbe.com/pdf/300773.pdf

Tab. 1 Other application documents, purpose

and where found

1.3 Warnings and symbols

Symbol Meaning

• Immediate acute risk

• Death, serious bodily harm

• Potentially acute risk

• Death, serious bodily harm

• Potentially hazardous situation

• Minor injury

• Potentially hazardous situation

• Material damage

Safety warning sign

Take note of all information

highlighted by the safety warning

sign and follow the instructions to

avoid injury or death.

Instruction

1., 2., ... Multiple-step instructions

Precondition

→Cross reference

Information, notes

Tab. 2 Warnings and symbols

302 499 BA-2022.10.26 EN NIS 3

General safety instructions

2 General safety instructions

The manufacturer accepts no liability for damages caused

by disregarding any of the documentation.

2.1 Intended use

The device is used to monitor liquid levels in unpressurized

vesselsandopenpits. Thedeviceisalsousedasasignal

transmitter when the level rises above or falls below a specified

level.

• Only use the device with suitable media

(→ resistance lists).

• Adhere to the operating limits (→ Data sheet).

• Not for use as an overfill protection device for WHG §19

purposes. The devise is not a safety system.

Avoidance of obvious misuse (examples)

• Do not use the device in a position inverted from the cor-

rect installation orientation (correct installation orientation:

perpendicular, from top to bottom).

• Vent the immersion tubes regularly. If the immersion tubes

are not vented, shifts in the switching points may occur due

to the propensity of the pumped media to absorb air.

• Do not adjust the pressure adjustment screws on the

diaphragm pressure switches. The pressure setting

screws are correctly preset by the manufacturer. Adjusting

the pressure setting screws may cause in the switching

points to be shifted.

2.2 General safety instructions

Observe the following regulations before carrying out any

work.

2.2.1 Obligations of the operating company

Safety-conscious operation

• Only operate the device if it is in perfect technical condition

and only use it as intended, staying aware of safety and

risks, and in adherence to the instructions in this manual.

• Ensure that the following safety aspects are observed and

monitored:

– Intended use

– Statutory or other safety and accident-prevention reg-

ulations

– Safety regulations governing the handling of haz-

ardous substances

– Applicable standards and guidelines in the country

where the pump is operated

• Make personal protective equipment available.

Qualified personnel

• Make sure all personnel tasked with work on the device

have read and understood this manual and all other appli-

cable documents, especially the safety, maintenance and

repair information, before they start any work.

• Organize responsibilities, areas of competence and the

supervision of personnel.

• The following work should be carried out by specialist tech-

nicians only:

– Installation, repair and maintenance work

– Work on the electrical system

• Make sure that trainee personnel only work on the device

under supervision of specialist technicians.

2.2.2 Obligations of personnel

Only complete work on the device if the following requirements

are met:

• System is empty

• System has been flushed

• System is depressurized

• System has cooled down

• System is secured against being switched back on again

• Do not make any modifications to the device

2.3 Hazardous media

• When handling hazardous media, observe the safety reg-

ulations for the handling of hazardous substances.

• Use personal protective equipment when carrying out any

work on the device.

• Collect leaking pumped liquid and residues in a safe man-

ner and dispose of in accordance with environmental reg-

ulations.

4 NIS BA-2022.10.26 EN 302 499

Transport, Storage and Disposal

3 Layout and Function

3.1 Type plate

NIS 4

Schaltleistung

Id.No.

130748

1304-05371

1

2

3

4

-100 mA/24 VAC | -30mA/24 VDC

Material PVC-U

Fig. 1 Type plate

1Devicetype

2 Switching capacity

3 Material

4 ID number

3.2 Description

Thedevicemonitorsliquidlevelsinunpressurizedvesselsand

open pits. The sensor does not require an additional power

supply and actuates a potential-free switching contact when

the level rises above or falls below the specified level.

• Depending on the variant, the device carries 1 to 4

diaphragm pressure switches/immersion tubes

• The switching behavior depends on the air pressure/fluid

level in the immersion tube:

– The switch is set to „On“ when the air pressure rises

by max. 10 mbar / level difference rises by more than

100 mm H2O

– The switch is set to „Off“ when the air pressure falls

by max. 5 mbar / level difference falls by more than

50 mm H2O

3.3 Assembly

1

2

3

Fig. 2 Assembly (example: NIS 4)

1 Housing

2 Diaphragm pressure switch (concealed)

3 Immersion tube

4 Transport, Storage and

Disposal

4.1 Unpacking and inspection on delivery

1. Unpack the device when received and inspect it for trans-

port damage and completeness.

2. Check that the information on the type plate agrees with

the order/design data.

3. Report any transport damage to the manufacturer immedi-

ately.

4. If fitted immediately: Dispose of packaging material

according to local regulations.

– If fitted at a later point: leave device in its original pack-

aging.

4.2 Transportation

Device should preferably be transported in the original

packaging.

4.3 Storage

NOTE

Material damage due to inappropriate storage!

Store the device properly.

1. Make sure the storage room meets the following condi-

tions:

–Dry

– Frost-free

– Vibration-free

– Not in direct sunlight

– Storage temperature +10 °C to +60 °C

2. Device should preferably be stored in the original packag-

ing.

302 499 BA-2022.10.26 EN NIS 5

Installation and connection

4.4 Disposal

Plastic parts can be contaminated by poisonous or radioac-

tive media to such an extent that cleaning will not be suffi-

cient.

WARNING

Risk of poisoning and environmental damage from

medium!

Use personal protective equipment when carrying out any

work on the device.

Prior to the disposal of the device: Neutralize residues of

medium in the device.

1. Remove electronic parts and dispose of in accordance with

local regulations.

2. Dispose of plastic parts in accordance with local regula-

tions.

5 Installation and connection

5.1 Preparations for installation

5.1.1 Check operating conditions

1. Ensure the required operating conditions are met:

– Resistance of body and seal material to the medium

(→ resistance lists).

– Media temperature (→ Data sheet).

– Operating pressure (→ Data sheet).

2. Consult with the manufacturer regarding any other use of

the device.

5.1.2 Preparation of the vessel

The device can be installed in closed, pressureless and

open containers.

The device can be installed by means of a threaded

insert on the lower part of the housing or by means of

a suitable mounting device, e.g. mounting flange or

mounting plate (→ 9.4 Accessories, Page 11).

1. Check that the vessel provides sufficient immersion depth.

2. Align the vessel correctly, ensuring the following points are

satisfied:

– Vertical mounting position of the device

– Sufficient space for installation, electrical connection

and maintenance (→ 9.3 Dimensions, Page 11).

5.2 Preparation of the device

5.2.1 Connecting the immersion tubes

Connection types:

– PVC socket end for solvent welding

– PP fusion socket end

43 mm

1

3

2

Fig. 3 Connecting the immersion tubes

1 diaphragm pressure switch

2 Bottom section of casing

3 Immersion tube

The device installation is complete.

Depending on the type of connection, glue or weld the

immersion tube (3) to the lower part of the housing (2).

Only the manufacturer may perform welding of the variants

NIS 2 to NIS 4 in PP, because a special tool is required for

welding the tubes at the pitch of 43 mm.

6 NIS BA-2022.10.26 EN 302 499

Installation and connection

5.2.2 Setting the switching points

Fig. 4 Setting the switching points

Max Max. filling level

Min Min. filling level

pr Switching point for discharging

ps Switching point for filling

The device installation is complete.

The immersion tubes are connected.

Tool: Power drill, 8 mm drill bit

1. Check the fill levels of the vessel and select the switching

point accordingly.

2. Cut the immersion tubes to length as required.

3. Drillan8mmholeintotheimmersiontube100mmbelow

the selected switching point. Ensure the necessary spac-

ingof≥150mmfromthedrilledholetothelowerpartof

the housing.

5.2.3 Application examples for the variants

NIS 1 to NIS 4

NIS 1

Max

Fig. 5 Switching point for NIS 1

L1 switches the pump off when the maximum fill level (Max) is

reached.

NIS 2

Max

Min

Fig. 6 Switching points for NIS 2

L1 switchesthesubmersiblepumponwhenthemaximumfill

level is reached. L2 switches the submersible pump off when

the minimum fill level is reached.

On the vessel, the shut-off valve is opened at (Max) fill level

and closed at (Min) fill level.

302 499 BA-2022.10.26 EN NIS 7

Commissioning

NIS 3

1

2

3

Fig. 7 Switching points for NIS 3

L1 outputs a warning signal when the fill level 1is reached.

L2 switchesthepumponwhenthefilllevel2is reached.

L3 switches the pump off when the fill level 3is reached.

NIS 4

1

2

3

4

Fig. 8 Switching points for NIS 4

L1 outputs a warning signal when the fill level 1is reached.

L2 switches both pumps on when the fill level 2is reached.

L3 switchesonepumponwhenthefilllevel3is reached.

L4 switches both pumps off when the fill level 4is reached.

5.3 Install device

WARNING

Risk of injury and poisoning due to medium spraying out!

Use personal protective equipment when carrying out any

work on the fitting.

The device installation is complete.

The device is prepared.

Screw in the threaded inserts so that the device when

mounted in the container is perpendicular to the surface

of the media.

5.4 Electrical connection of device

2

3

4

1

5

Fig. 9 Electrical connection of device

1 Plug 4 diaphragm pressure

switch

2Top part of the housing 5Cable gland

3Screw

The unit must be installed properly.

Power supply must be switched off and secured against

being switched back on again.

1. Removetheplug(1).

2. Undo screw (3).

3. Remove the top part of the housing (2).

4. Guide connection cable through the cable gland (5) and

connect it to the diaphragm pressure switch (4):

– Electrical data (→ Data sheet).

– Connection diagram (→ 9.2 Connection diagram,

Page 10).

5. Tighten the cable gland securely.

6. Tighten the top part of the housing.

6 Commissioning

The device is installed and connected.

Switch on power supply.

Depending on the actual filling level, the device will now

trigger a switching operation.

8 NIS BA-2022.10.26 EN 302 499

Maintenance

7 Maintenance

WARNING

Risk of injury and poisoning due to hazardous media and

improper operating procedure!

Use personal protective equipment when carrying out any

work on the device.

Disconnect the power supply and secure it against being

switched back on again.

Block the infeed of media to the vessel / the device.

Safely collect the media and dispose of it in accordance

with environmental regulations.

7.1 Servicing

Interval Action

The interval

is defined by

the operating

company

Check the switching function. If the

switching points have shifted

– Take the device out of the vessel

and vent the immersion tubes.

– Install device.

As necessary Clean device with a damp cloth.

Six-monthly Perform a visual and functional check:

– Normal operating conditions

unchanged

– No leaks

Tab. 3 Servicing activities

Perform maintenance tasks according to the table.

7.2 Maintenance

7.2.1 Removing the device

System is empty.

System has been flushed.

System is depressurized.

System has cooled down.

System must be secured against being switched back on

again.

1. Unplug connection cable.

2. Take the device out of the vessel.

3. Decontaminate device if required.

7.2.2 Replacement parts and return

1. Have the following information ready to hand when order-

ing

spare parts (→ 3.1 Type plate, Page 5 ).

–Devicetype

– ID number

– Nominal pressure and diameter

– Connection and gasket material

2. Please complete and enclose the document of compliance

for returns

(→ www.stuebbe.com/en/service/download).

3. Use only spare parts from STÜBBE.

302 499 BA-2022.10.26 EN NIS 9

Appendix

8 Troubleshooting

WARNING

Risk of injury and poisoning due to hazardous media liq-

uids!

Use personal protective equipment when carrying out any

work on the device.

Error Possible cause Corrective action

The hole for communication between

the housing and the diaphragm pressure

switch is clogged or is missing

Clean the hole or drill it.

Switching pressure in the immersion tube

too low (< 10 mbar or < 100 mm)

Ensure that the hole giving access to the switching

point bore is at least 100 mm below the switching

point level.

Air in the immersion tube has been

absorbed by the medium

Vent the immersion tubes.

Device does not trip

No pressure build-up can be achieved in

theimmersiontube

Replace the defective diaphragm pressure switch.

The device fails to switch

any consumer

Electrical connection faulty Check the power supply and if necessary change

the terminal assignment.

Tab. 4 Troubleshooting

9 Appendix

9.1 Technical data, operating limits

and weights

The particulars are described on the data sheet (→ Data

sheet).

9.2 Connection diagram

2

3

1

P

Fig. 10 Connection diagram

1COM

2NC

3NO

P Pressure in the immersion tube

10 NIS BA-2022.10.26 EN 302 499

Appendix

9.3 Dimensions

M6

PG16

43

Ø32

Fig. 11 Dimensions

B PVC-U = 105

PP = 103.5

9.4 Accessories

9.4.1 Mounting flange

180

220

B

Fig. 12 Mounting flange

B PVC-U = 105

PP = 103.5

9.4.2 mounting plate

80

135

6,5

B

Fig. 13 mounting plate

B PVC-U = 105

PP = 103.5

302 499 BA-2022.10.26 EN NIS 11

This manual suits for next models

4

Table of contents

Other Stübbe Switch manuals