St. Croix PRESCOTT EXL Configuration guide

Prescott Series

Operation & Maintenance

Manual

Table of Contents

ST. CROIX FEATURES.......................................................................................2

INSTALLATION.................................................................................................. 3

PREVENTING CHIMNEY FIRES .....................................................................3

SATISFACTORY PERFORMANCE................................................................. 3

APPROVED FUELS .............................................................................................3

Pellets, Cherry Pits & Pellet /Corn mix...................................................3

OPERATING INSTRUCTIONS......................................................................... 4

Control Board Features.............................................................................4

Thermostat Function – How does it work?.............................................5

Pre-Lighting Instructions..........................................................................6

Lighting Your Stove ................................................................................. 6

Shutting the Stove off ............................................................................... 6

Diagnostic Features....................................................................................6

Safety Features...........................................................................................7

Combustion Air Damper ..........................................................................8

Flame Pattern Characteristics..................................................................8

MAINTAINING THE STOVE ............................................................................9

Daily Maintenance ........................................................................... 10-11

Periodic Maintenance ...................................................................... 11-12

Yearly Maintenance ......................................................................... 13-14

SAFE OPERATION........................................................................................... 15

TROUBLESHOOTING AND FAQ............................................................ 16-20

PARTS LAYOUT ..........................................................................................21-22

WARRANTY....................................................................................................... 23

608

Prescott Series Operations Manual

Page 8

THERMOSTAT

WIRE

TERMINAL

DAMPER

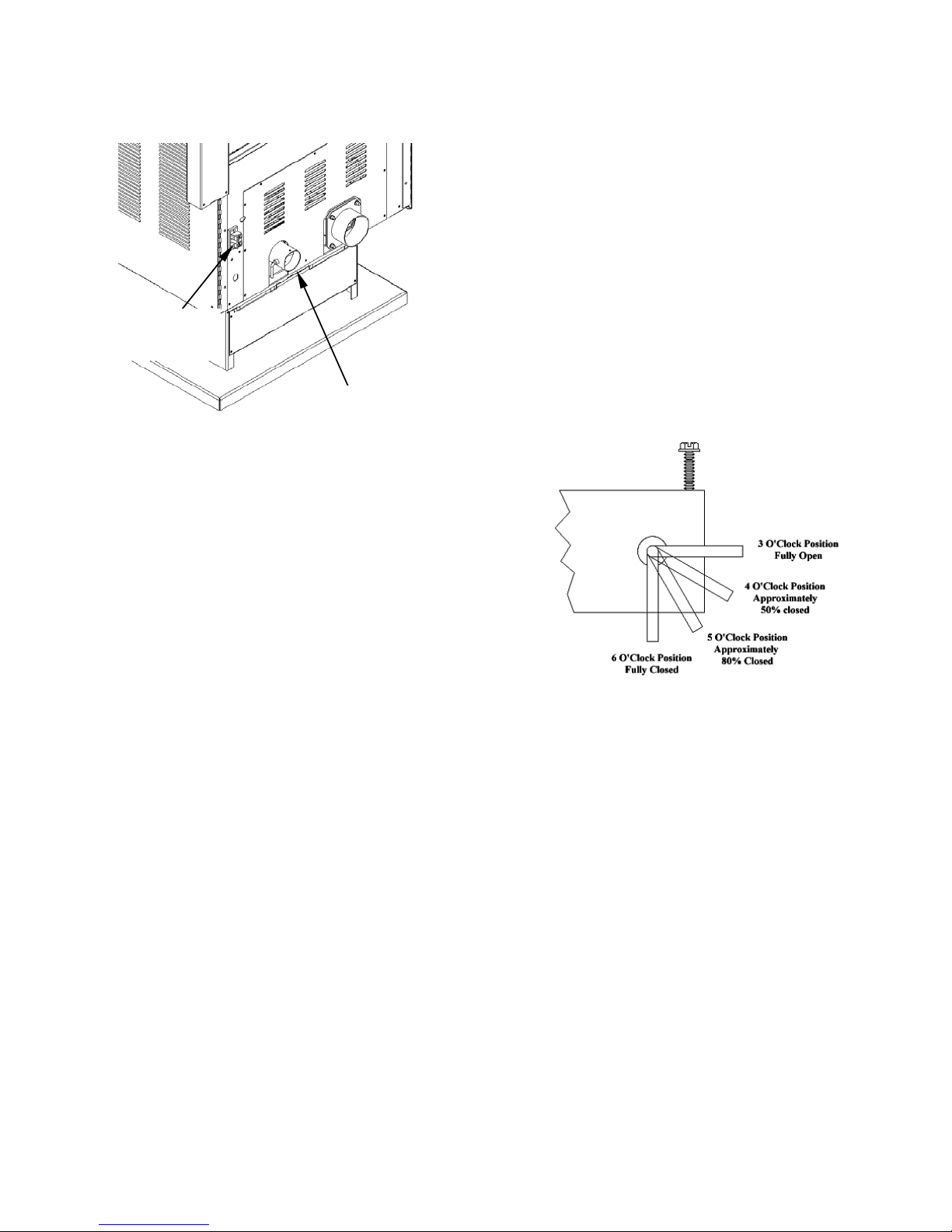

Combustion Air Damper

Figure 3

Damper Adjustment

When burning pellets make sure to check for

the formation of creosote in the unit and

venting system. Constantly running the stove

on a low setting with too much combustion air

may cause creosote to form. Burn pot

temperatures can be “too cool” when burning

on low with too much draft.

Adjusting the Damper may take a little time and

patience, but only needs to be done once. After

the damper has been adjusted to the venting

system in your home, the control board will do

the rest.

The purpose of this damper is to adjust

combustion airflow to match the characteristic of

each specific air inlet and chimney configuration.

There is a setscrew in the damper (shown in

Figure 4) and the damper has been preset at the

factory. This setting will most likely work for

90% of the most common installations. Long

horizontal runs might need the damper opened.

Tall vertical runs might need the damper to be

closed a little, etc. To adjust the damper, use the

setscrew to make the adjustments. To make an

adjustment turn the screw ½ turn clockwise to

open the damper or ½ turn counter clockwise to

close the damper. Remember to use the damper

handle to bring the damper up to the screw. The

damper will not close by itself. After making an

adjustment wait at least 15 minutes to see how

the burn pot reacts to the change. Adjusting the

damper during the break in period is very

important (See “Preventing Chimney Fires” on

page 2). Break-in requires the burning of 15 bags of

pellets or continuous burn for two weeks. If during

the initial break-in period you experience difficulty

keeping the stove burning or there appears to be an

excessive amount of burning pellets being evacuated

from the burn grate, it may be necessary to close the

damper some more. Once the damper is fine tuned

for settings 1, 2, 3 and 4 the stove will run fine

without having to make a change to the damper

setting unless the stove is run on 5 for extended

periods of time. It is normal for ash and some sparks

to be continually evacuated from the burn grate. This

is how the grate continuously cleans itself. The

equivalent of a teacup of unburned pellets a day in

the ash pan is considered normal.

Figure 4

Flame Pattern Characteristics

Correct Flame Pattern -

Bright yellowish-white

flame with a brisk movement, having sharp pointed

end tips extending up towards the Heat Exchange

Tubes while forming a fan-like shape. Small

amounts of ash and some live sparks being blown

out from the Burn Pot area is considered normal

operation.

Incorrect Flame Pattern -

Dark orangish-brown

flame with a lazy movement, having black smoky

end tips curling up and over the Heat Exchange

Tubes while forming a fireball-like shape. Some Ash

or Live Sparks not being blown out from the Burn

Pot area is considered abnormal operation.

Extremely black soot forming on the ceramic glass

surface is a sign of very poor combustion (not

enough combustion air) and should not be

overlooked. At the other end of the spectrum; an

Prescott Series Operations Manual

Page 9

extremely brisk flame which blows large pieces

of live coal out from the Burn Pot area and causes

stubborn shiny black build-up on the glass (too

much combustion air) is also considered

undesirable.

If you experience problems

adjusting the stove during the Break-In

Period, contact your dealer.

MAINTAINING THE STOVE - The stove

requires a minimum amount of daily

maintenance. Required maintenance depends

largely upon the quality of pellet fuel burned and

the rate of burn. The amount of daily

maintenance will increase if fuel quality

decreases and/or the burning rate of pellets

increases.

NOTE: FAILURE TO KEEP YOUR STOVE

CLEAN, AS DESCRIBED IN THIS

MANUAL, COULD RESULT IN POOR

OPERATION, INEFFICIENT FUEL

USAGE AND A POSSIBLE SAFETY

HAZARD! IT IS YOUR RESPONSIBILITY

TO DETERMINE NEEDED MAINTE-

NANCE FREQUENCY.

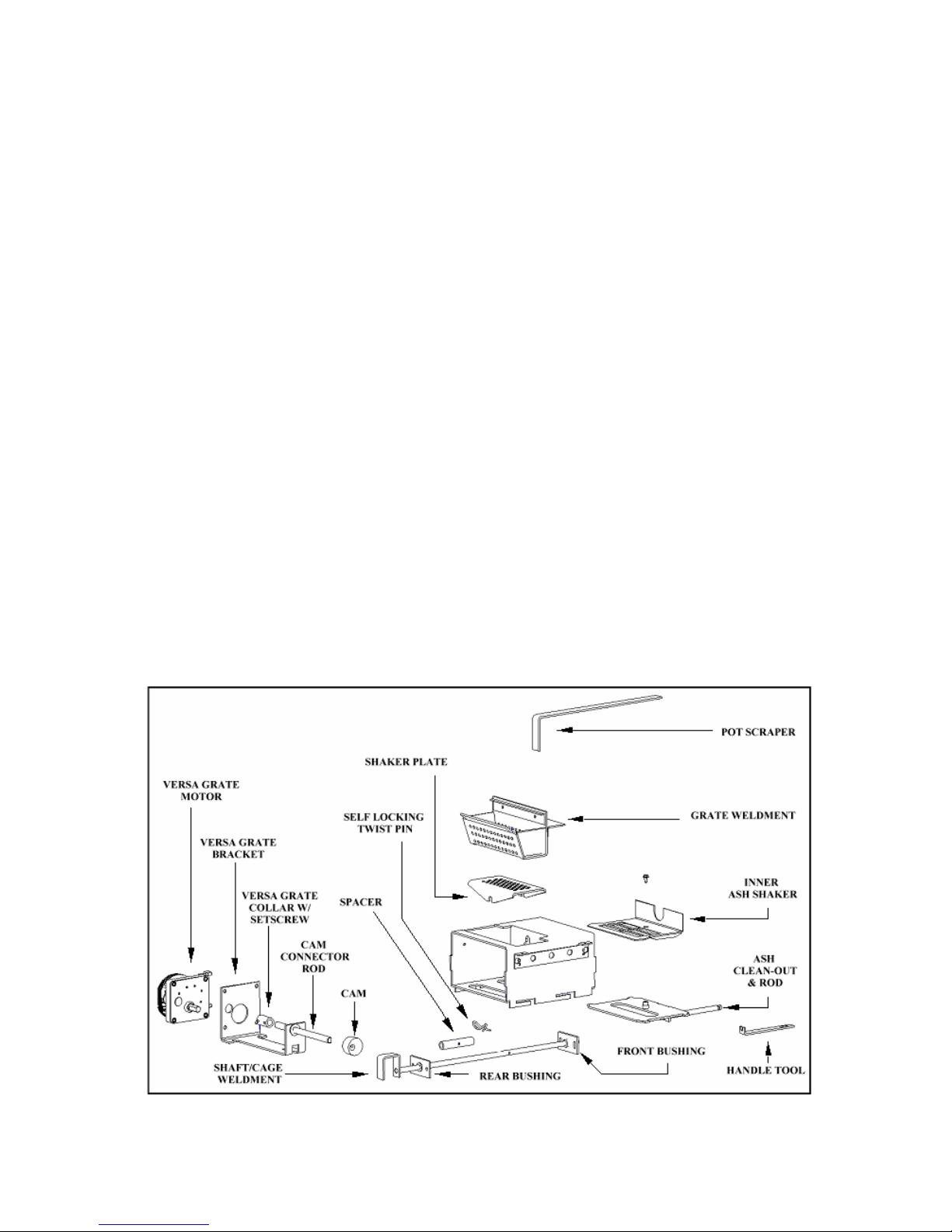

The Versa Grate System (see Figure 5 below).

The benefit of this feature is that the stove can

operate for longer periods of time, with most

fuels, without the grate requiring cleaning. If the

flame becomes dark orange, is accompanied by

black smoke or burns with a lazy motion - it’s time

to clean the grate When you first operate your

stove or whenever you change fuels check to

determine needed cleaning frequency.

First, let’s become familiar with the burn system in

a St. Croix Pellet stove. Remember, cleaning

frequency may change dramatically from one fuel to

another. Pellets with high ash content or that have

increased amounts of impurities or high moisture

content. Every St. Croix Pellet stove model will

have the same system as shown in figure 5 below.

There is a 2-piece burnpot. The top Part is called the

“Grate Weldment”. This sits on top of the “Shaker

Plate”. This in turn sits on top of the “Shaft/Cage

Weldment” and is held in place with the “Spacer”

& “Self Locking Twist pin”. The Shaft/Cage

weldment is moved towards the front of the stove

and then towards the back of the stove by the

“Cam” that is connected to the “Versa Grate

Motor”. This motion is constant, while the stove is

in operation. The only parts that may need to be

removed for cleaning purposes during the Daily or

Periodic Maintenance are the “Grate weldment” and

the “Shaker Plate”. This is to check the holes in the

burnpot system to see if they are plugged.

Figure 5

Prescott Series Operations Manual

Page 10

POT

SCRAPER

ASH

CLEANOUT

ROD

ASH PANROD PULL TOOL

Daily Maintenance

1. Check Grate Weldment and Shaker Plate (See

figure 5) to determine if holes are plugged. Clean

as needed. With proper precautions the grate may

be partially cleaned while the stove is hot. Follow

these steps:

CAUTION: THE

DOOR AND FRONT PART

OF THE STOVE WILL BE HOT. DO NOT

TOUCH ANY PART OF THE STOVE THAT

IS HOT!

a. Wear a leather glove that covers the lower arm.

b. Turn the Stove to Heat Level 1 and allow the

flame to burn down to a low burn.

c. Open the firebox door slowly to prevent

drawing ash or odors into the room.

d. Use the “scraper” provided to move the

burning pellets to one side of the grate, leaving

the ash in the bottom of the grate. (See Fig 5 & 6)

e. Rake the ash & clinkers out over the grate into

the ash pan.

f. Rake the burning pellets across the bottom of

the grate.

g. Close the door.

h. Re-select the desired heat setting.

CAUTION: NEVER ADD FIRE STARTER

TO A HOT STOVE.

Figure 6

2. Remove ash buildup under the grate bottom daily

or as frequently as needed. Clean the ashes out from

under the burn pot by pulling the Ash Cleanout Rod

in and out several times (see Fig. 6) Use the Rod

Pull Tool with the Ash Cleanout Rod. This tool is

hanging on a screw on the back of the stove; this

provides a convenient location to keep the tool in

reach and prevent it from getting lost.

CAUTION: The Ash Cleanout Rod must be

pushed all the way in during operation of the

unit. Failure to keep this area clean could result

in a safety hazard.

3. Check ash pan (See Fig. 6) to determine emptying

frequency needed. NOTE: Do not use a vacuum

cleaner for this purpose. Hot coals may cause your

vacuum filter to catch fire. Place ashes in a metal

container with a tight fitting lid. The closed

container of ashes should be placed on a

noncombustible floor or on the ground, well away

from all combustible materials, pending final

disposal. If the ashes are disposed of by burial in soil

or otherwise locally dispersed, they should be

retained in the closed container for at least two days

until all cinders have thoroughly cooled.

4. Once or twice daily pull the Heat Exchange Tube

Scraper, (See stove layout on page 2) out and back to

clean heat exchange tubes. Failure to operate the

tube scraper daily may result in poor combustion and

loss of heat output. This should be done when the

stove is cool or operating on the low temperature

setting. Use the Rod Pull Tool shown in Figure 6

with the Tube Scraper Rod.

5. The rate of burn and the quality of fuel will

determine how often the window needs cleaning.

Prolonged burning at a slow burn rate will result in

the need for more frequent window cleaning.

Burning poor fuel also increases the need to clean

the window. Cooling the stove and wiping the

window daily with a cloth or paper towel will

normally keep the window from accumulating

difficult to clean residue. Use of a glass cleaner

ONLY permitted when the stove is cold. Tip: Dip

the damp towel in the ashes to remove stubborn

buildup on the glass.

CAUTION: Do not slam the door. Do not

operate the stove with a broken or cracked

glass. Replace only with heat resistant

ceramic glass supplied by the manufacturer.

Prescott Series Operations Manual

Page 11

REMOVE DECORATIVE

GRILL (LEFT SIDE SHOWN)

REMOVE SHIPPING

SCREW & DISCARD

ASH CLEAN-OUT

COVER (LEFT

SIDE SHOWN)

6. Burn the stove at the HI fuel setting for at least

20 to 30 minutes each day. This helps keep the

window, ceraboard and firebox area clean. A

daily high burn also aids in maintaining the

overall efficiency and performance of the stove.

Periodic Maintenance

CAUTION:

Periodic maintenance should only

be done while the stove is shut off and cold.

1. Empty the ash pan when it appears full. This

may range from 1 to 2 weeks in the Prescott

EXP model. The Prescott EXL model has a

much smaller ashpan and should be checked

at least twice a week. The frequency of

cleaning the ash pan will depend on the

quality and amount of pellets being used.

Carefully check to make sure the ash pan

door is tightly closed after each opening.

2. The Prescott models have 3 Exhaust

Cleanout/Ash Trap covers, 2 of which are

located below the rear brick panel and a 3

rd

Clean Out is located behind the Ash Pan.

Remove covers and clean regularly. (See

stoves shown in Figure 7) Be sure to clean

both sides.

Use scraper shown in figure 5 & 6 to scrape

ash into ash pan. Use a vacuum (cold stove

only) to thoroughly clean these areas.

IT IS CRITICAL THAT YOU KEEP ASH CLEAN

OUTS CLEAN FOR SATISFACTORY

PERFORMANCE.

Frequency of cleaning Ash Traps depends on the

amount of fuel being burnt and the quality of the

pellets. Fuel with low ash content is recommended.

Failure to clean the ash traps can cause the stove

to become plugged with fly ash and could result

in a Safety Hazard.

THE LOCATION OF THE THIRD CLEAN-OUT/ASH

TRAP BEHIND THE ASH PAN IN A PRESCOTT EXP

THE LOCATION OF THE THIRD CLEAN-OUT/ASH

TRAP BEHIND THE ASH PAN IN A PRESCOTT EXL

Figure 7

Prescott Series Operations Manual

Page 12

3. Clean burn grate holes at least weekly. Remove

the burn grate and use a small metal object to

clean out plugged holes. (

See fig. 5 on page 9.)

4. Remove the baffle and clean the ashes that

accumulate on a regular basis.

Frequency of cleaning depends on amount of fuel

being burnt and the quality of the pellets. Fuel

with low ash content is recommended.

Failure to clean the baffle can cause the stove

to become plugged with fly ash and could

result in a Safety Hazard.

To remove the baffle (See Figure 8), lift the back

of the baffle up to clear the inner back of the

stove and slide towards the front of the stove. The

baffle will slide out of the keyhole slots and drop

down. When putting the baffle back in the stove,

make sure the screws are in the keyhole slots

and the back of the baffle is lifted up over the

inner back.

4. Periodic cleaning of the exhaust system is

required. Under certain conditions creosote

buildup may occur rapidly. Low quality

pellets and poor installations require more

frequent chimney cleanings. See Page 3

“Preventing Chimney Fires”. The products

of combustion will also contain small

particles of fly ash. The fly ash will collect

in the exhaust vent and restrict the flow of

the flue gases. Judge the frequency of

cleaning by checking the amount of ash that

accumulates in the elbows or tee’s of the

exhaust system. Ask the dealer for suggested

frequency of cleaning, equipment needed

and procedures for cleaning. Check the

exhaust system at least once every two

months during the heating season.

Periodically inspect the condition of the rope

gasket around the door, window and ash door.

Replace as needed.

Figure 8

Prescott Series Operations Manual

Page 13

Yearly Maintenance

Yearly maintenance is designed to assure safe

operation, prolong the life of the stove and help

preserve its aesthetic appeal.

1. Spring Shutdown. After the last burn in the

spring, cool the stove. Remove all pellets

from the hopper and the auger. Thoroughly

clean the burn grate, burn grate box, ash pan

and ash traps behind the ash pan. (To locate

the ash traps see Figure 7 on page 11)

NOTE: UNPLUG THE STOVE. Open the side

panels of the stove. Carefully clean or vacuum

any sawdust, cobwebs and household dust.

Carefully vacuum around the fan motors. If

electrical wires become disconnected call your

dealer for service.

2. The exhaust system should be thoroughly

cleaned at least annually. Call your dealer for

this service.

3. The motor/fan area behind the firebox and under

the hopper should be vacuumed annually.

4. The Exhaust and Room fans should be removed

and cleaned annually. Call dealer for this

service. Annual oiling of the motors is not

needed. (See fig. 8)

Figure 9

Note: The Vacuum Switch may be removed to allow easier access to the combustion fan

This manual suits for next models

1

Other St. Croix Pellet Stove manuals

Popular Pellet Stove manuals by other brands

Timberwolf

Timberwolf TPS35 Installation and operating instructions

Eco Spar

Eco Spar AURIGA 23 kW Manual for installation and operation

Mareli Systems

Mareli Systems PS 10 Assembly and exploitation manual

Enviro

Enviro WINDSOR owner's manual

calimax

calimax Solida operating instructions

SMG

SMG ComfortBilt HP21 Operator's manual