Staco Energy FirstLine P User manual

003-2551 REV B

FirstLine P

FirstLine P 924

BATTERY CABINET

USER MANUAL

i | Page

No reproduction of any part of this manual, even partial, is permitted without the authorization of Staco

Energy Products Company. The Staco Energy Products Company reserves the right to modify the

product described herein, in order to improve it, at any time and without notice.

301 Gaddis Boulevard • Dayton, Ohio 45403

U.S. Toll Free 866-261-1191

(937) 253-1191 • Fax: (937) 253-1723

Web site: www.stacoenergy.com

Thank you for choosing our product.

ii | Page

Safety Warnings

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions for FirstLine P Battery Cabinets that should be followed

during installation and maintenance of the battery cabinet. Please read all instructions before operating

the BATTERY CABINET and save this manual for future reference.

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

a. Do not use outdoors.

b. Do not route wiring across or near hot surfaces.

c. Do not install near gas or electric heaters.

d. Use caution when servicing batteries. Battery acid can cause burns to skin and eyes. If acid is

spilled on skin or in eyes, flush acid with fresh water and contact a physician immediately.

e. Unit should be installed where it will not readily be subjected to tampering by unauthorized

personnel.

f. The use of accessory equipment not recommended by the manufacturer may cause an unsafe

condition.

g. Do not use this battery cabinet for other than intended use.

This battery cabinet has been designed and manufactured in accordance with the standards for

the product, for normal use and for all uses that may reasonably be expected. It may under no

circumstances be used for any purposes other than those envisaged, or in any other ways than

those described in this manual. Any interventions should be carried out in accordance with the

criteria and the time-frames described in this manual.

WARNING

A battery can present a risk of electrical shock and high short circuit current. The following

precautions should be observed when working on batteries:

1) Remove watches, rings, or other metal objects.

2) Use tools with insulated handles.

3) Wear rubber gloves and boots.

4) Do not lay tools or metal parts on top of batteries.

5) Disconnect charging source prior to connecting or disconnecting battery terminals.

6) Determine if the battery is inadvertently grounded. If inadvertently grounded, remove

source of ground. Contact with any part of a grounded battery can result in electrical

shock. The likelihood of such shock will be reduced if such grounds are removed during

installation and maintenance

Staco Energy is highly specialized in the development and production of battery cabinets. The

battery cabinets of this series are high quality products, carefully designed and manufactured to

ensure optimum performance.

iii | Page

This Battery Cabinet contains LETHAL VOLTAGES. All repairs and service should be

performed by AUTHORIZED SERVICE PERSONNEL ONLY. There are NO USER

SERVICEABLE PARTS inside the Battery Cabinet.

To reduce the risk of fire or electric shock, install This Battery Cabinet in a temperature and

humidity controlled, indoor environment, free of conductive contaminants. Do not operate

near water or excessive humidity (95% maximum).

WARNING

This Battery Cabinet contains its own energy source (batteries). Hazardous voltage may be

present even when the battery cabinet is not connected to a power source

Batteries can present a risk of electrical shock or burn from high short circuit current.

Observe proper precautions. Servicing should be performed by qualified service personnel

knowledgeable of batteries and required precautions. Keep unauthorized personnel away

from batteries.

There is a risk of explosion if batteries are replaced by an incorrect type. Replace with same

type and rating only. See Table 10

Proper disposal of batteries is required. Refer to your local codes for disposal requirements.

Never dispose of batteries in a fire

WARNING

This product contains Valve Regulated Sealed Acid Batteries.

These batteries contain lead, a neurotoxin, and sulfuric acid, a corrosive. Additionally, the

energy stored in the batteries can present a shock hazard and a burn hazard. Batteries

should only be serviced by trained personnel. Appropriate safety precautions must be

observed, including eye protection and skin protection. Contact with electrolyte requires

flushing with a generous amount of clean water. Seek medical attention immediately

following contact with electrolyte. Unwanted batteries must be recycled and should never be

discarded.

WARNING

Do not dispose of battery or batteries in a fire. The battery may explode.

Do not open or mutilate the battery or batteries. Released electrolyte is harmful to the skin

and eyes. It may be toxic.

DANGER

WARNING

iv | Page

Emergency Interventions

The following information is of a general nature.

First aid interventions

Company regulations and traditional procedures should be followed for any first aid intervention that may

be required.

Firefighting measures

1. Do not use water to put out a fire, but only fire extinguishers that are suitable for use with

electrical and electronic equipment.

2. If exposed to heat or fire, some products may release toxic fumes into the atmosphere. Always

use a respirator when extinguishing a fire.

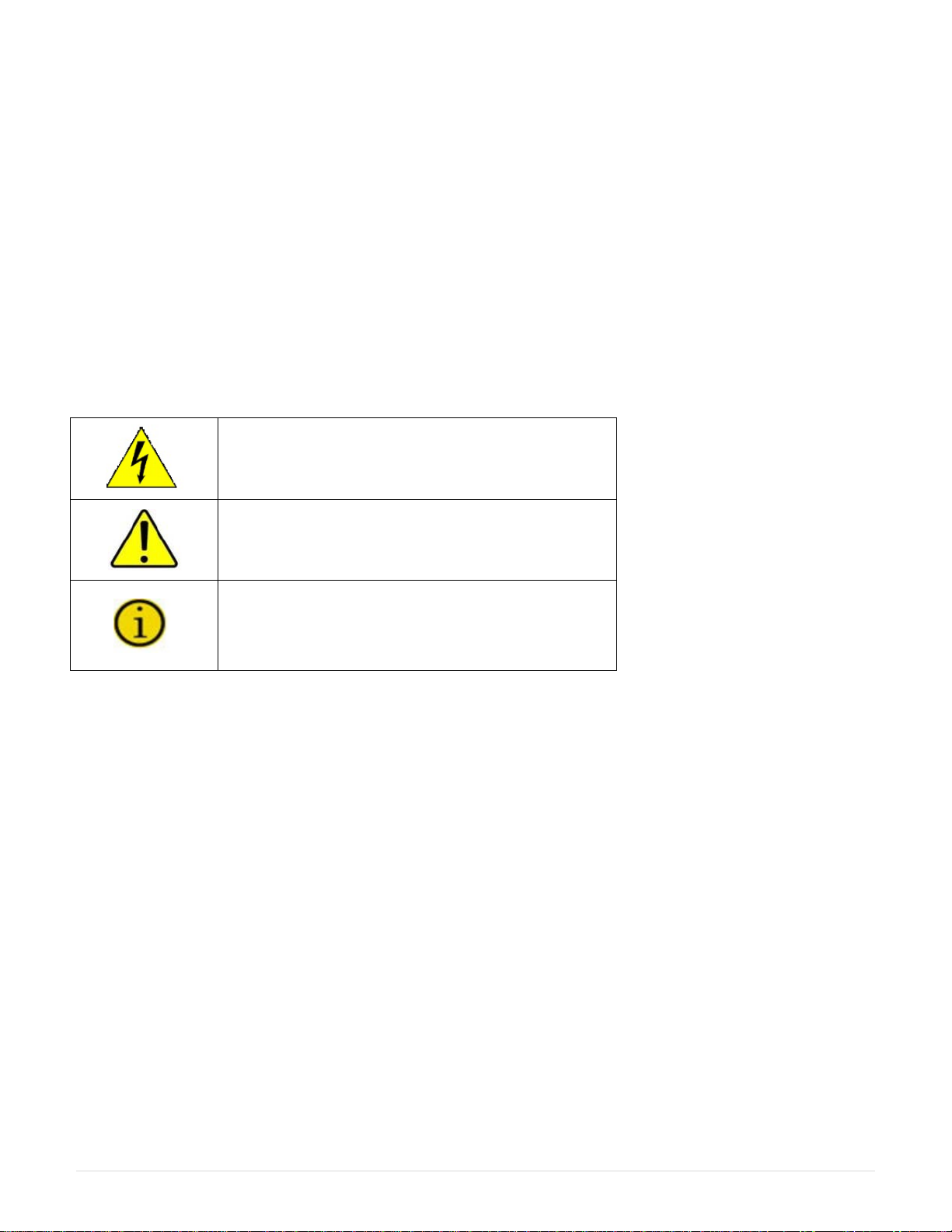

Symbols used in the Manual

In this manual, some operations are shown by graphic symbols to alert the reader to the dangerous

nature of the operations:

Danger / Risk of Electric Shock

This symbol indicates possibility of serious injury

or substantial damage to the unit, unless

adequate precautions are taken.

Warning

This symbol indicates important information which

must be understood and any stated precautions

taken

Note

Protective Equipment

No maintenance operations shall be carried out on the unit without wearing the Personal Protective

Equipment (PPE). Personnel involved in the installation or maintenance of the unit must be properly

clothed.

General Precautions

This manual contains detailed instructions for the use, installation and start-up of the Battery Cabinet.

Read the manual carefully before installation. For information on using the Battery Cabinet, the manual

should be kept close at hand and consulted before carrying out any operation on the Battery Cabinet.

v | Page

Table of Contents

Safety Warnings..................................................................................................................................... ii

Emergency Interventions ..................................................................................................................... iv

First aid interventions ...........................................................................................................................iv

Firefighting measures...........................................................................................................................iv

Symbols used in the Manual................................................................................................................ iv

Protective Equipment........................................................................................................................... iv

General Precautions............................................................................................................................. iv

1 Battery Cabinet Setup......................................................................................................................... 1

1.1 Storage...........................................................................................................................................1

1.2 Inspecting the Equipment...............................................................................................................1

1.3 Floor Loading ................................................................................................................................. 2

1.4 Clearances..................................................................................................................................... 2

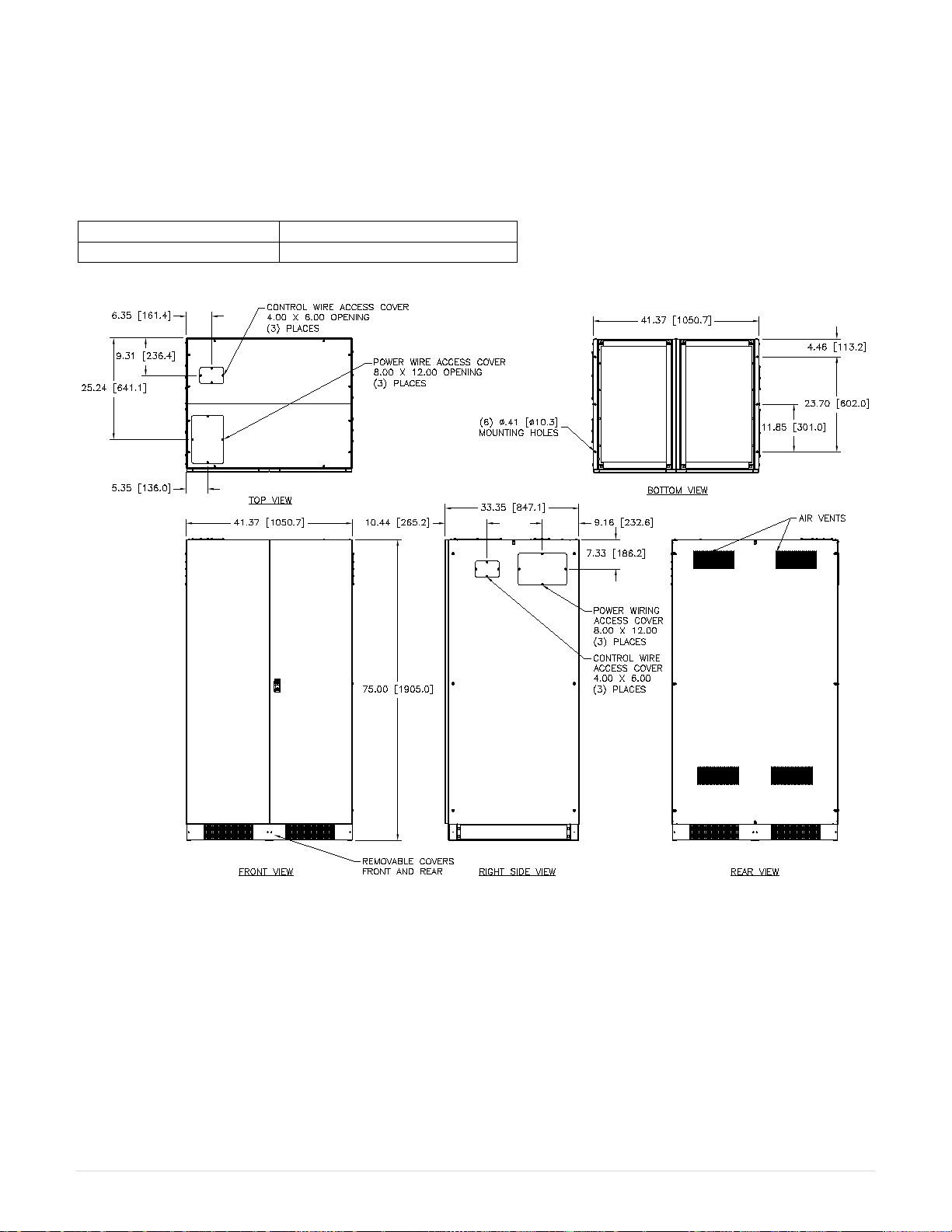

1.5 Dimensions..................................................................................................................................... 2

2 Installation...........................................................................................................................................3

2.1 Unpacking ......................................................................................................................................3

2.2 Electrical Installation.......................................................................................................................4

2.2.1 Wiring Preparation...................................................................................................................5

2.2.2 Connecting To the Firstline Battery Cabinet............................................................................. 5

2.3 Circuit Breaker Interface.................................................................................................................6

3 Operation............................................................................................................................................. 9

4 UL924 Emergency Lighting Systems ................................................................................................ 9

5 Battery Removal, Installation, and Service..................................................................................... 10

6 Maintenance...................................................................................................................................... 11

7 Specifications.................................................................................................................................... 13

Figures

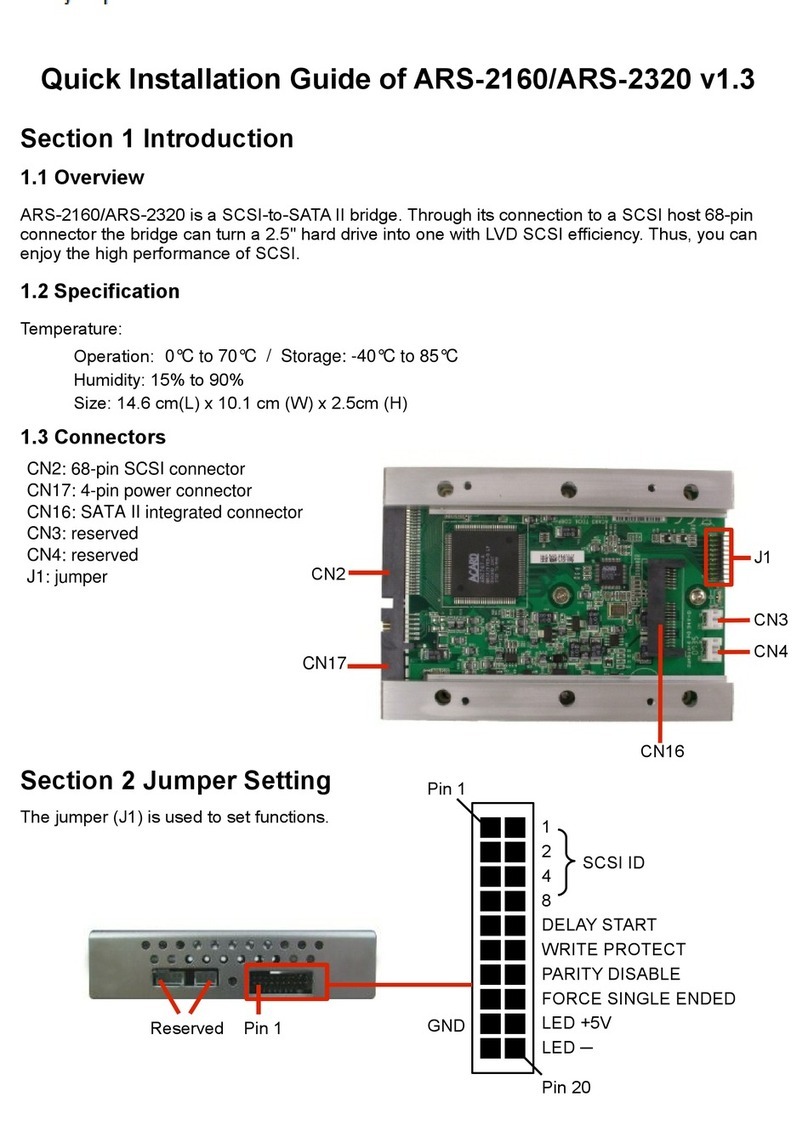

Figure 1 – Battery Storage Duration........................................................................................................1

Figure 2 – FirstLine P Battery Cabinet Layout......................................................................................... 2

Figure 3 - Pallet Mounting Hardware....................................................................................................... 3

Figure 4 – Electrical Connections............................................................................................................ 4

Figure 5 - Circuit Breaker Interface Board Assembly Location................................................................. 7

Figure 6 - Circuit Breaker Interface Board Assembly............................................................................... 7

Figure 7 - UPS REPO Connections......................................................................................................... 7

Figure 8 - Battery Cabinet to the UPS Remote Emergency Power Off (REPO) Switch Interface............. 8

Figure 9- Battery Layout....................................................................................................................... 10

Figure 10 - Cabinets Schematic............................................................................................................ 12

Tables

Table 1 – Battery Models approved for UL924......................................................................................... 9

Table 2 – UL924 Approved Systems ....................................................................................................... 9

Table 3 – Battery Replacement Quantities............................................................................................. 11

Table 4 – Recommended Replacement Intervals .................................................................................. 11

Table 5 – Factory Breaker & Fuse settings............................................................................................ 13

Table 6 - Input / Output Cable Size and Torques................................................................................... 13

Table 7 - Ground Cable Size and Torques ............................................................................................ 13

Table 8 - Circuit Breaker Interface Board Cable Size and Torques........................................................ 13

Table 9 - Model Floor Loadings............................................................................................................. 13

Table 10 – Battery Models..................................................................................................................... 13

1 | Page

1 Battery Cabinet Setup

1.1 Storage

The batteries in your Staco system were shipped from the factory fully charged. If you plan to place the

batteries in storage for any period of time prior to installation and startup then the following precaution

should be followed.

Batteries placed in storage will age. How fast they will age depends on the storage temperature. The

batteries are rated for storage over a temperature range of -15o C to 40o C (5o F to 104o F). The amount

of time the batteries may be stored without recharge varies greatly with storage temperature. Please

consult the following Figure 1. If the batteries are allowed to sit in storage for an excessive period of

time before recharging then they are subject to irreversible damage.

Figure 1– Battery Storage Duration

Once the batteries are placed into service and fully charged, the useful life of the batteries will be

reduced if they are subjected to high temperatures. The operating temperature range of -15o C to 40o C

(5o F to 104o F) must not be exceeded for even short periods of time. Batteries operating continuously at

or near 40o C will experience a shorter useful life than batteries operating continuously at 25o C. Battery

life will be further shortened if the batteries are allowed to fully discharge and then left in that condition for

extended periods of time. As soon as the load is removed from the battery it will continue to age at a

higher rate than a fully charged battery. The longer the battery remains discharged the greater the risk of

irreversible damage.

Allowing the batteries to become damaged due to; a) operation or storage outside the rated

temperature range, b) storage for extended periods of time without recharge per the Figure 1

above, or c) sitting for a period of time in a discharged state will void the battery warranty.

1.2 Inspecting the Equipment

If any equipment has been damaged during shipment, keep the shipping and packing materials for the

carrier or place of purchase and file a claim for shipping damage. If you discover damage after

acceptance, file a claim for concealed damage.

To file a claim for shipping damage or concealed damage: 1) File with the carrier within 15 days of

receipt of the equipment, 2) Send a copy of the damage claim within 15 days to your service

representative.

2 | Page

1.3 Floor Loading

When planning the installation, consider the battery cabinet weight for floor loading. The strength of the

installation surface must be adequate for point and distributed loading. The approximate weights are

shown in Table 9.

1.4 Clearances

The following clearances are recommended for the FirstLine P Battery Cabinet.

From Front of Cabinet

36” (91.4 cm) working space

From Back of Cabinet

0” (0 cm)

1.5 Dimensions

Figure 2– FirstLine P Battery Cabinet Layout

3 | Page

2 Installation

2.1 Unpacking

The following tools are required for unloading the cabinet(s):

Wrenches for 3/8” lag bolts.

Forklift or pallet jack

Phillips screwdriver

WARNING

The Battery Cabinets are heavy (see Table 9). Unloading the cabinets requires at least two

people to safely remove the cabinets from the pallet.

To remove the battery cabinet from the ship pallet:

1. Make sure the forklift is rated for the cabinet weight.

2. Make sure the path traveled has sufficient support for the combined weight of the forklift and the

battery cabinet.

3. Make sure forks are at maximum separation.

4. Use a very strong ratchet strap (or similar device) of sufficient strength to tie the upper part of the

cabinet to the forklift tower before moving.

5. Keep people out of the fall zone. If the cabinet topples over, stand clear.

6. With a Phillip’s screwdriver, remove the four kick panels. These will be remounted when the

cabinet is in place.

7. Remove all banding, wrapping and foam protection.

8. Remove the six 3/8” lag bolts securing the cabinet to the pallet. (See Figure 3)

Figure 3- Pallet Mounting Hardware

9. Lift the cabinet with a forklift one to two inches (1”-2” [2.5-5cm]) above the pallet.

10. Slide the pallet completely away from the raised cabinet.

11. Carefully move the cabinet to the desired location and slowly lower the cabinet to the floor or

other appropriate flat surface.

12. Remount the four kick panels

4 | Page

2.2 Electrical Installation

The FirstLine P Battery Cabinet has the following power connections:

2-pole (positive, negative) terminal block and ground connection for battery power input and output.

Each pole has compression lug holes. One connection goes to the UPS or to the next Battery Cabinet

closer to the UPS. The second connection goes to the input of the next Battery Cabinet, if supplied.

In order to completely isolate the battery cabinet for maintenance, a DC disconnect switch or DC breaker

should be installed between the battery cabinet and UPS.

Figure 4– Electrical Connections

WARNING

Only qualified service personnel (such as a licensed electrician) should perform the UPS

installation and initial startup. Risk of electrical shock.

WARNING

!

USE COPPER

CONDUCTORS ONLY

CAUTION!

FORUSE IN A CONTROLLED ENVIRONMENT.REFER

TOHA NDBOOK F OR ENVIRONMENTAL

CONDITIONS.

ATTENTION:

Pouruti lisation en atmosphèrecontrolée.

Consulte r la noti ce te chnique pour les

conditions dumilieu.

DO NOT DISCONNECT

UNDER LOAD

Donot clos e the circuit breakeruntil

the displ ay of the UP S nolonger shows:

Wait: DO NOT connect the BATTERY

Closingth e breaker before t his may damage the

UPSor blow fuses in the bat tery cabinet.

WARNING!

BATTERY

CIRCUIT BREAKER

5 | Page

2.2.1 Wiring Preparation

To begin wiring the UPS:

1. Verify that the electrical connections to the installation site have been properly installed.

2. Wire the FirstLine UPS per the User’s Manual.

3. Switch off utility power to the distribution point where the UPS is connected. Be absolutely sure there

is no power.

4. Open the front door of the Battery Cabinet

5. Switch the circuit breaker to the “Off” position.

6. Remove the terminal access cover on the breaker on the right (load side) (see Figure 4).

7. Conduit landing plates are located toward the on the top cover, side panels, and base to

accommodate bottom wire entry to the cabinet (see Figure 2). Remove plates and drill or punch

hole to fit conduit bushing with Greenlee punch or similar device. Make certain that the bushing will

be clear in the opening in the base. Mount bushing to plate and tighten to manufacturer’s

recommendations.

8. Replace the plates and mount conduit.

2.2.2 Connecting To the Firstline Battery Cabinet

1. Check that the circuit breakers are in the “Off” or open position.

2. Inspect battery trays for signs of damage. Verify that all terminal connections are sound.

3. With wire sized per the Table 6, connect one wire to the terminal block pole marked positive (+)

and one wire to the terminal block pole marked negative (-).

4. Connect the ground wire to the 1/4-20 ground stud with a ring terminal or pressure lug by

removing and replacing the top nut and washers.

5. Before working within the UPS cabinet, verify that the UPS has no power applied. Refer to the

UPS manual. Repeat procedures 3 and 4 to the FirstLine P UPS Battery connector located in the

right side of the UPS. We recommend that the wires be marked as to which is positive (+) and

negative (-) to ensure that the wires are not accidentally crossed.

6. If a second battery cabinet is present, repeat the procedure to install wires connecting the

terminals on the second cabinet to the unused terminals (of each pole of the terminal block) on

the first cabinet.

7. If additional cabinets are present, continue this process until all cabinets are connected.

DANGER

Never connect the positive to the negative. Severe damage and injury could result.

8. Connect the Circuit Breaker Interface per Section 5 if it is desired to implement the remote

emergency power off function.

9. Close front doors to cabinet.

6 | Page

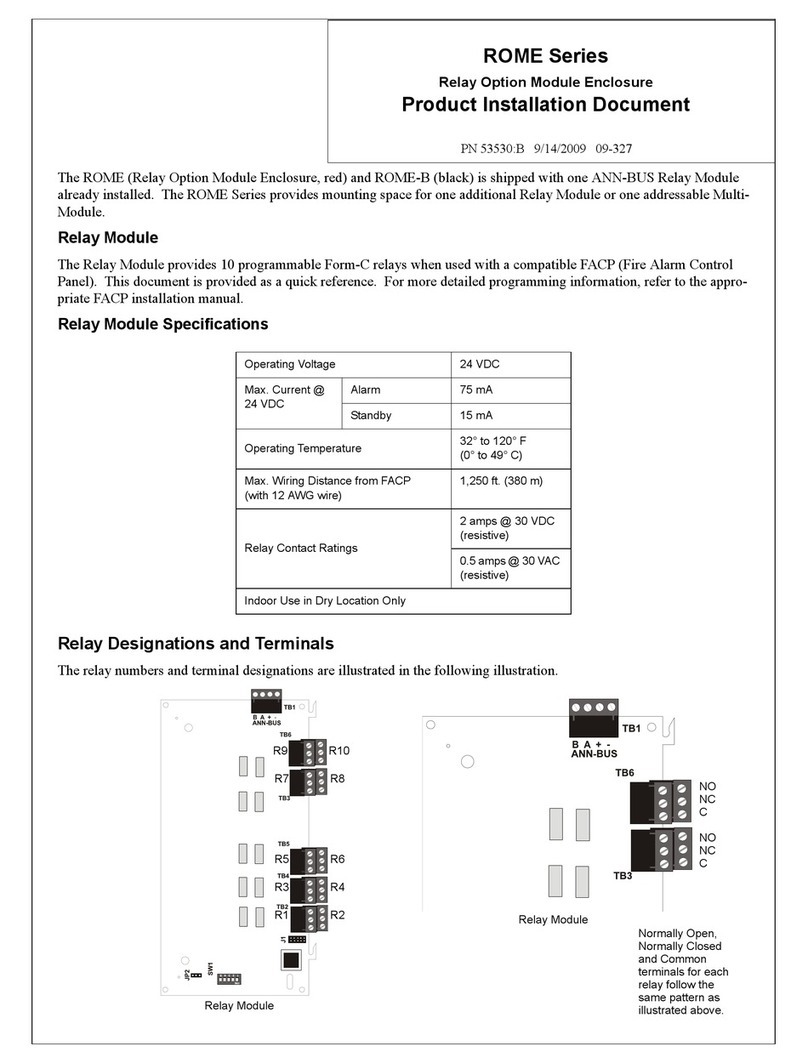

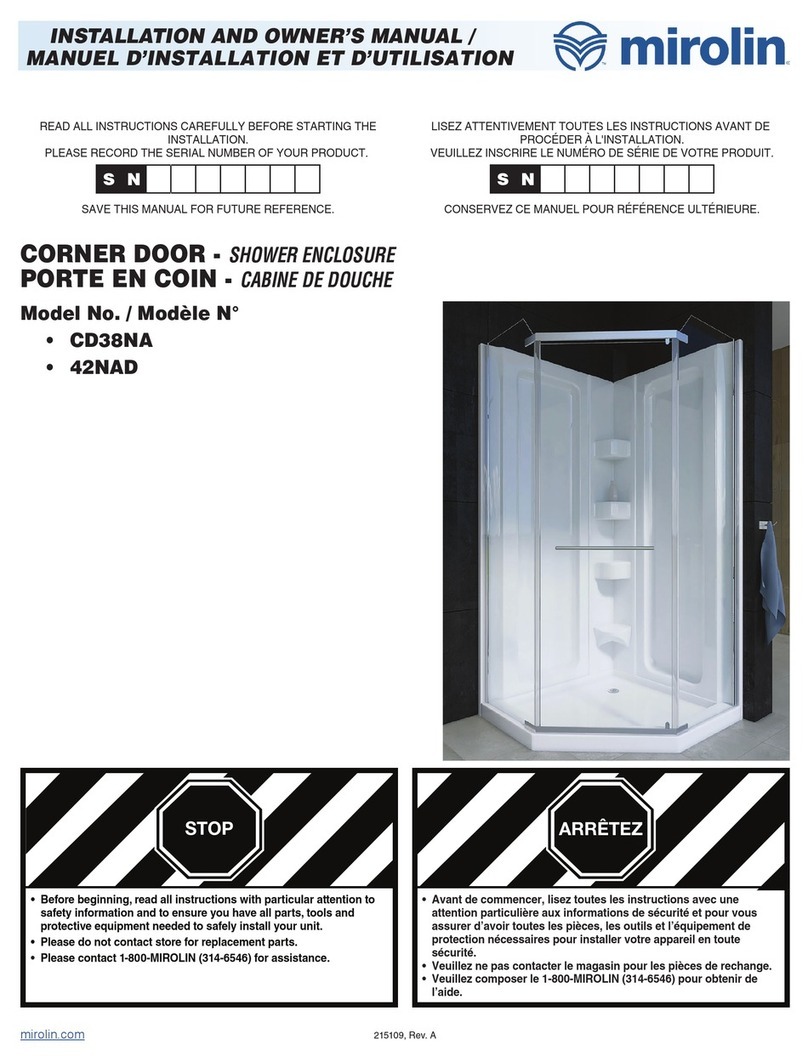

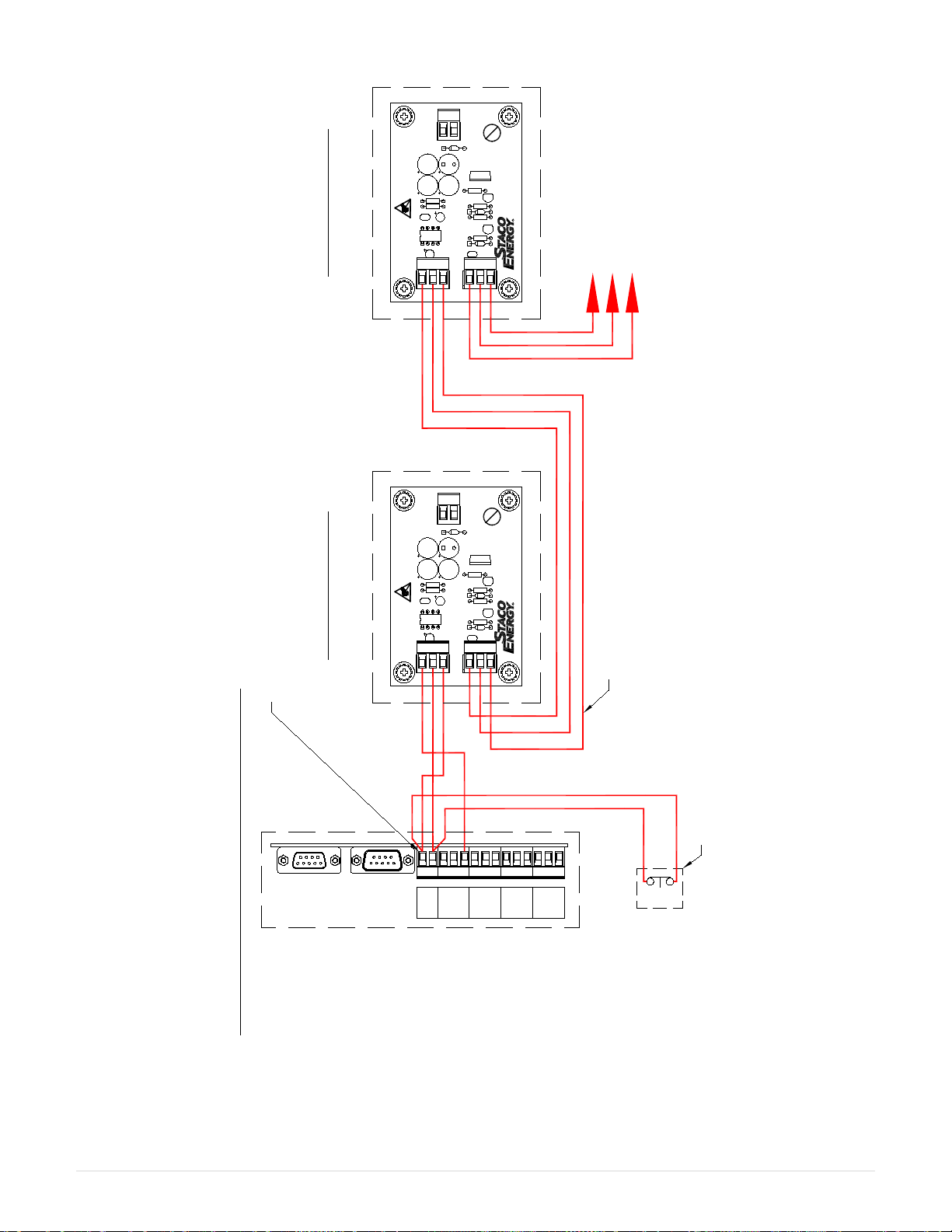

2.3 Circuit Breaker Interface

Figure 5shows the location of the circuit breaker interface terminal blocks in the Battery Cabinet.

The circuit breaker interface must be connected to the UPS if it is desired to have the Battery Cabinet

circuit breaker trip when the Remote Emergency Power Off (REPO) signal is applied to the UPS.

Additional Battery Cabinets must connect to the pass-through connection provided for this function (see

Figure 8).

If it is not desired to have the Battery Cabinet Breaker trip on REPO activation, then these connections

can be omitted.

This function requires 3 wires between the battery cabinet and the UPS. The wires can be part of a

jacketed cable assembly or they can be three individual wires. Local codes may require that the wires be

run in a conduit. In any case, these low voltage signal wires must be kept physically separated from the

power wiring between the Battery Cabinet and the UPS.

Refer to the section in the UPS manual "REMOTE COMMANDS, ALARMS AND EPO" for the location of

the Terminal Block in the UPS where the Battery Cabinet signals are to be connected. The UPS is

factory-fitted with a shorting jumper between terminals 13 and 14. This jumper must be removed for the

REPO function to be enabled (See Figure 7).

The terminal blocks TB1 and TB2 are pluggable connectors for ease of wiring. Carefully pull each

terminal block loose from the circuit breaker interface board to wire as instructed below and plug them

back into place. A small flat screwdriver is required to tighten each wire in place; tighten as specified in

Table 8.

From TB1 in the Battery Cabinet, connect a wire from terminal 1 to terminal 10 in the UPS. Connect a

second wire from TB1 terminal 2 to terminal 13 in the UPS. Connect a third wire from TB1 terminal 3 to

terminal 14 in the UPS.

If a second Battery Cabinet is to be connected in parallel with the first, three control wires need to

connect TB1 in the second cabinet to TB2 in the first, terminal 1 to terminal 1, terminal 2 to terminal 2,

terminal 3 to terminal 3. If additional cabinets are present, this same procedure applies.

Finally, the UPS will not operate unless a normally closed REPO switch is connected across terminals 13

and 14 at the UPS. Refer to the wiring diagram, Figure 8. Note that terminals 2 and 3 in the battery

cabinet are wired in parallel with terminals 13 and 14 of the UPS. If desired, the REPO switch can be

connected to terminals 2 and 3 of TB2 instead of 13 and 14 of the UPS.

Usually, this normally closed contact is part of a push-button switch. If multiple switches are desired, the

multiple normally closed contacts must be wired in series such that the operation of any switch causes

the connection across the REPO terminals to be opened. Wiring of this switch circuit should be run in

metal or metal shielded conduit for maximum protection. Damage to or interference with this circuit can

cause the UPS to trip off.

During commissioning of the UPS installation, the REPO system should be tested. Start the UPS. When

the UPS display no longer states "Wait: DO NOT connect the BATTERY", close the breaker on each of

the battery cabinets. Operate the REPO switch and verify that the UPS shuts down and that all of the

battery cabinet breakers trip.

NOTE: Wires to the circuit breaker interface board must not enter the UPS or Battery Cabinet

through the same port as the input/output or battery power wires. Wires to the battery cabinet

must enter through the removable cover over the circuit breaker interface board.

7 | Page

Figure 5- Circuit Breaker Interface Board Assembly Location

Figure 6- Circuit Breaker Interface Board Assembly

Figure 7- UPS REPO Connections

U1 TB3

TB2

TB1

R7

R6

R5

R4

R1 R2

Q2

Q1

Q3

D4

D3

D2

C8

C3 C6

C5

C4

C2

C1

SENSITIVE DEVICE

ELECTROSTATIC

ATTENTION

1 2 3

1 2

1 2 3

R

PRODUCTS CO.

FLU-P SHUNT TRIP BOARD

ASSY NO.: 825-0593-LF

Pb

8 | Page

Figure 8- Battery Cabinet to the UPS Remote Emergency Power Off (REPO) Switch Interface

141312114321 5 6 7 8 109

REMOTE COMMANDS AND ALARMS CONNECTIONS

ON FRONT OF UPS BEHIND DOOR

NORMALLY CLOSED

REPO SWITCH

BYPASS

FAULT BATT.

ON BATT.

LOW EPO

INV.

OFF

U1 TB3

TB2

TB1

R7

R6R5R4

R1 R2

Q2

Q1

Q3

D4D3

D2

C8

C3 C6

C5C4

C2

C1

SENSITIVE DEVICE

ELECTROSTATIC

ATTENTION

123

1 2

1 2 3

R

PRODUCTS CO.

BATTERY CABINET #1

CIRCUIT BREAKER INTERFACE BOARD

IN REAR OF CABINET

U1 TB3

TB2

TB1

R7

R6R5R4

R1 R2

Q2

Q1

Q3

D4D3

D2

C8

C3 C6

C5C4

C2

C1

SENSITIVE DEVICE

ELECTROSTATIC

ATTENTION

123

1 2

1 2 3

R

PRODUCTS CO.

BATTERY CABINET #2

CIRCUIT BREAKER INTERFACE BOARD

IN REAR OF CABINET

TO BATTERY CABINET #3

IF PRESENT

ALL WIRING IS INSTALLER PROVIDED

AND SHOULD BE WELL PROTECTED.

WIRE SHOULD BE 1,5 mm² MAXIMIUM

TO 0,34 mm² MINIMUM INSULATED COPPER.

REPO MAY BE WIRED AS SHOWN OR TO TB2 TERMINALS

2 AND 3 OF THE BATTERY CABINET INTERFACE BOARD.

REMOVE AND DISCARD JUMPER

AT TERMINALS 13 AND 14.

FLU-P SHUNT TRIP BOARD

ASSY NO.: 825-0593-LF

Pb

FLU-P SHUNT TRIP BOARD

ASSY NO.: 825-0593-LF

Pb

9 | Page

3 Operation

Refer to the UPS manual for operating instructions. Please note that the breaker in the battery cabinet

must not be operated until the UPS has started and the display no longer shows the message: "Wait: DO

NOT connect the BATTERY". If the breaker has been improperly operated, a qualified service person

needs to check for blown fuses or other damage.

If the UPS is stopped (turned off), the breaker may be left in the closed position for a short period of time.

The safety circuits in the UPS represent a slight current drain on the battery that can lead to severe

depletion of charge, if the battery remains connected to a non-operating UPS. This can lead to battery

damage over the course of several days.

It is recommended to disconnect the batteries if the UPS is to remain off for any significant period of time.

Also, it is not safe to work within the UPS unless all of the batteries are disconnected.

4 UL924 Emergency Lighting Systems

The Staco Battery cabinet can be used as part of an approved UL924 Emergency Lighting system.

Table 1– Battery Models approved for UL924

MODEL

CSB

FIAMM

FLU-P-BAT-540-1

HRL 12540W

12FLX540

Table 2– UL924 Approved Systems

Staco UL924

Model # kW Staco UPS

Model # # of Battery

Cabinets required

FLU-P-924-58

58.5kW

FLU-065

2

FLU-P-924-72

72kW

FLU-080

3

FLU-P-924-90

90kW

FLU-100

3

FLU-P-924-112

112.5kW

FLU-125

4

FLU-P-924-144

144kW

FLU-160

5

FLU-P-T-924-144

144kW

FLU-160-T

5

FLU-P-924-180

180kW

FLU-200

6

FLU-P-T-924-180

180kW

FLU-200-T

6

FLU-P-924-225

225kW

FLU-250

8

FLU-P-T-924-225

225kW

FLU-250-T

8

10 | Page

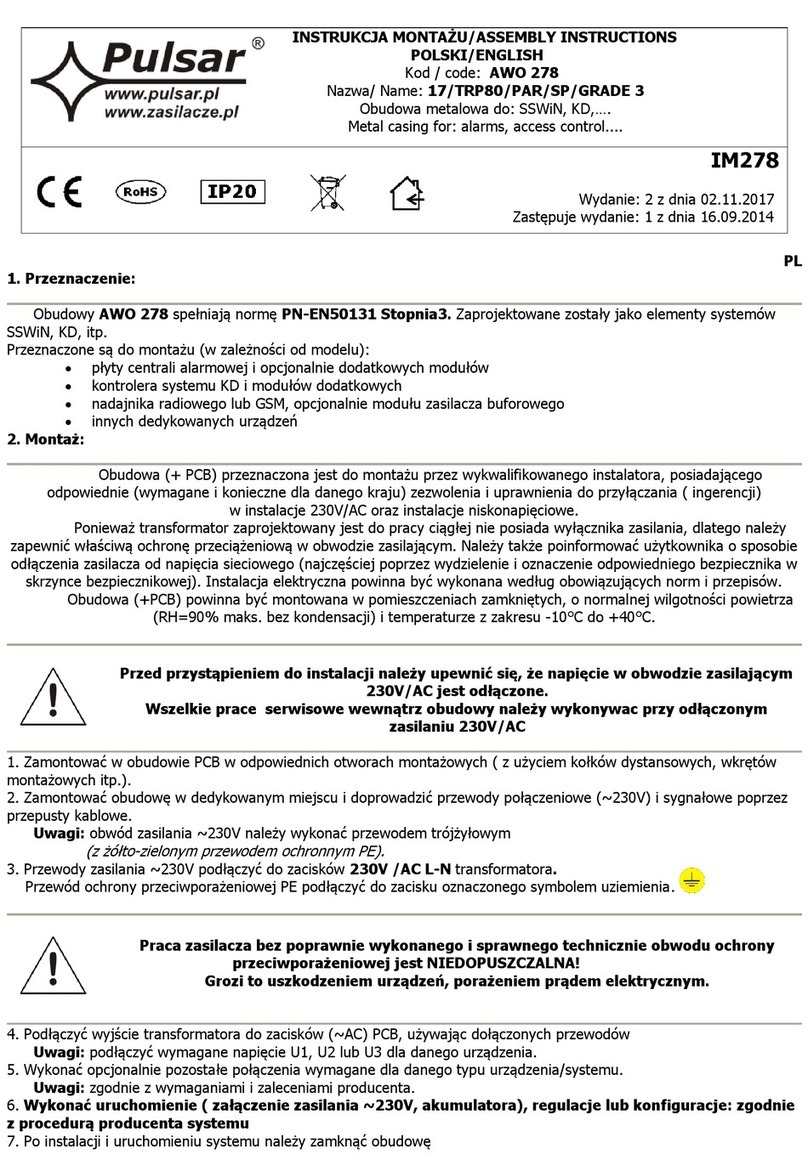

5 Battery Removal, Installation, and Service

Servicing of batteries should be performed or supervised by personnel knowledgeable of batteries and

the required precautions. Keep unauthorized personnel away from batteries. Always wear eye protection

and have eye wash near at hand. Never work on any connections that have not been disconnected from

all other sources of voltage. Parallel connected battery cabinets require that all battery strings in all

battery cabinets be disconnected before working within any particular cabinet.

Before servicing batteries, the UPS should be turned off, power should be removed from the UPS input,

and all battery breakers should be open. If a Maintenance Bypass Switch (MBS) is present, power to the

load can be maintained during service. Refer to the instructions for the MBS to put the system in bypass

mode before removing power from the UPS.

If it is necessary to remove the cables from the batteries, the connections should be marked in a way that

no confusion will exist when it is time to reconnect the cables (see Figure 10).

Figure 9- Battery Layout

If batteries are being replaced, only use the same manufacturer and battery type and rating as the

battery removed - see Table 10. When the bus bars connecting the batteries are removed, be careful to

avoid dropping bolts or shifting the bus bars so that they might short across adjacent battery terminals.

We recommend using a piece of electrical insulating paper (for example, “Nomex”) as a temporary shield

between the bus bars during service.

If the batteries are to be removed, always remove the highest batteries first. The battery are very heavy

and it will be necessary to use a lifting device to support the batteries as they are removed.

11 | Page

6 Maintenance

The FirstLine P Battery Cabinet is designed to be virtually user maintenance free, requiring only the

occasional wipe with a damp cloth or non-abrasive cleaner.

Spare parts kits are available for the FirstLine Battery Cabinet series, please contact Staco Energy

Products Co. service center for details.

For maximum availability of the UPS, the batteries should be replaced as part of a comprehensive

preventive maintenance program:

Table 3– Battery Replacement Quantities

REPLACEMENT BATTERY

Cabinet Model

Quantity Required

FLU-P-BAT-200-1

40

FLU-P-BAT-200-2

80

FLU-P-BAT-390-1

40

FLU-P-BAT-540-1

40

Table 4– Recommended Replacement Intervals

RECOMMENDED REPLACEMENT INTERVALS

Batteries

2 to 5 years

This product contains Valve Regulated Sealed Lead Acid Batteries.

These batteries contain lead, a neurotoxin, and sulfuric acid, a corrosive. Additionally, the energy stored

in the batteries can present a shock hazard and a burn hazard. Batteries should only be serviced by

trained personnel. Appropriate safety precautions must be observed, including eye protection and skin

protection. Contact with electrolyte requires flushing with generous amounts of clean water. Seek

medical attention immediately following contact with electrolyte. Unwanted batteries must be recycled

and should never be discarded.

The functional lifetime of batteries is significantly affected by the temperature at which they are stored

and operated. Ideally, batteries should be used in a 21º C (70º F) environment. For every 8.3º C (15º F)

increase in temperature, the life expectancy of a battery will be halved.

Exposure to temperatures in excess of 32º C (90º F) should be limited to no more than 30 days per year.

Under no circumstances should the battery be exposed to temperatures over 40º C (104º F) which can

lead to thermal runaway, a condition that damages the battery. Thermal runaway can cause batteries to

swell. If the battery cases burst, the hazardous contents may be exposed.

Maintaining proper ambient temperature usually requires installing the product in a temperature

controlled space. Equipment rooms without cooling systems do not generally maintain the proper

conditions for good battery life.

See Staco’s website for warranty details:

http://www.stacoenergy.com/support/literature-download-center.html

12 | Page

Figure 10 – Typical Cabinets Schematic

13 | Page

7 Specifications

Table 5– Factory Breaker & Fuse settings

MODEL

Breaker

Fuse

FLU-P-BAT-200-1

200

200

FLU-P-BAT-200-2

300

(2) 150

FLU-P-BAT-390-1

400

400

FLU-P-BAT-540-1

600

600

FLU-P-BAT-620-1

600

600

I1: Set to max

I3: set to max

Table 6- Input / Output Cable Size and Torques

Wire Size

Torque

Hardware

(2) 350kcmil

380 lb-in

Compression lug

NOTE 1: It is recommended to use 75°C copper wire.

NOTE 2: Recommended cable sized based on THW cables at 30°C ambient (NEC Table 310.16). If different

cables are used or installed at higher ambient, the cable size need to be reviewed.

NOTE 3: Any external battery wires use reinforced insulation or double insulated wire.

Table 7- Ground Cable Size and Torques

Min Wire Size

Torque

Hardware

#1 AWG

80-90 lb-in

¼-20 screw

Table 8- Circuit Breaker Interface Board Cable Size and Torques

Wire Size

Torque

Hardware

# 22-12 AWG

4.4 lb-in

¼-20 screw

Table 9- Model Floor Loadings

MODEL

Weight (lbs)

Point Loading

FLU-P-BAT-200-1

1, 950

19.2 lb/in2

FLU-P-BAT-200-2

3, 500

34.5 lb/in2

FLU-P-BAT-390-1

3, 300

32.5 lb/in2

FLU-P-BAT-540-1

4, 400

43.4 lb/in2

Table 10 – Battery Models

MODEL

CSB

FIAMM

FLU-P-BAT-200-1

HRL 12200W

12FLX200

FLU-P-BAT-200-2

HRL 12200W

12FLX200

FLU-P-BAT-390-1

HRL 12390W

12FLX400

FLU-P-BAT-540-1

HRL 12540W

12FLX540

Other manuals for FirstLine P

3

This manual suits for next models

1

Table of contents