Stahl SH 3 Manual

Wire Rope Hoists

_

Operating and Maintenance Instructions

SH

BASH_02_1.FM

2

Fundamental information

You have purchased a product manufactured by STAHL CraneSystems GmbH.

This wire rope hoist has been constructed in compliance with the applicable

standards and regulations.

Inspect hoist for damage caused in transit immediately upon delivery.

Report damage caused in transit and after consulting the manufacturer/supplier

repair or have repaired before installation and commissioning.

Do not install or commission a damaged hoist!

- Assembly

- installation

- commissioning

-tests

- maintenance and elimination of faults

may only be carried out by a qualified person

Terms employed

User

Whoever uses and employs the wire rope hoist or has it operated by suitable trained

personnel is considered to be the user (employer/company).

Trained personnel

Trained personnel are persons who have been instructed and trained in the duties

with which they are entrusted and the risks which may arise from incorrect

behaviour, have been advised on the necessary protective devices, precautions,

applicable regulations, accident prevention regulations and prevailing conditions

and have proven their ability.

Skilled electrician

A skilled electrician possesses knowledge and experience on electrical equipment

arising from specialist training and, with knowledge of the applicable standards and

regulations, is able to assess the work with which he is entrusted and detect and

avoid possible risks.

Definition of a qualified person (specialist):

A qualified person is one with the necessary qualification, based on theoretical and

practical knowledge of hoists, for the required activities as listed in the operating

instructions.

The person must be in a position to assess the safety of the installation in

conjunction with the application. Persons with the authority to undertake certain

maintenance work on our products include service engineers of manufacturer and

trained fitters with the corresponding certification.

Seminars:

Comprehensive understanding of material handling products is a prerequisite for the

correct use of equipment. Competent and practically oriented, we impart the special-

ist knowledge required for the correct use, monitoring and care of your installation.

Ask for our seminar programme → you will find information on it on the last page.

01.08

BASH_02_1.FM

Contents

3

1 Safety instructions 1.1 Symbols ........................................................................................................................... 4

1.2 Operating instructions .................................................................................................. 4

1.3 Use for intended purpose............................................................................................. 5

1.4 Safety-conscious operation......................................................................................... 5

1.5 Organisational safety precautions.............................................................................. 5

1.6 General regulations....................................................................................................... 6

1.7 Installation, commissioning, maintenance and repairs .......................................... 6

1.8 Warranty.......................................................................................................................... 6

1.9 Periodic tests.................................................................................................................. 6

1.10 After sales service.........................................................................................................6

2

Getting to know the wire rope hoist

..................................................................................................................................................... 7

3 Installation 3.1 Stationary wire rope hoist............................................................................................ 8

3.2 Fleet angles..................................................................................................................... 9

3.3 Trolleys/crabs ...............................................................................................................11

3.3.1 KE-S monorail trolley................................................................................................... 11

3.3.2 UE-S4 monorail trolley ................................................................................................ 13

3.3.3 UE-S776 monorail trolley ............................................................................................ 14

3.4 DKE-S articulated trolley ............................................................................................ 16

3.5 Double rail crab............................................................................................................ 19

3.6 Travel limit switches.................................................................................................... 20

3.7 Electrical equipment ................................................................................................... 21

3.8 Hoists with frequency converter............................................................................... 23

3.9 Reeving rope.................................................................................................................24

4 Commissioning 4.1 Commissioning ............................................................................................................. 29

5 Operation 5.1 Duties of crane operator ............................................................................................ 30

5.2 Operating control pendant ......................................................................................... 31

5.3 Emergency stop ........................................................................................................... 31

6 Inspection and maintenance ................................................................................................................................................... 32

6.1 Inspection intervals..................................................................................................... 32

6.2 Maintenance intervals................................................................................................ 33

6.3 RSM hoist motor brake ............................................................................................... 34

6.4 Travel motor brake....................................................................................................... 34

6.5 Hoist limit switch versions ......................................................................................... 35

6.6 Hoist limit switch on standard crane - version I..................................................... 36

6.7 Hoist limit switch on standard crane - version II ................................................... 39

6.8 Hoist limit switch on radio-controlled crane - version III ..................................... 42

6.9 Crane test...................................................................................................................... 47

6.11 Rope drive ..................................................................................................................... 48

6.12 Trolley/crab................................................................................................................... 53

6.13 Remaining service life................................................................................................. 54

6.14 General overhaul ......................................................................................................... 54

7 Fault-finding 7.1 What is to be done if? ................................................................................................. 55

8 Technical data 8.1 FEM classification ....................................................................................................... 58

8.2 Conditions of use ......................................................................................................... 58

8.3 Hoist ............................................................................................................................... 59

8.4 Cable cross sections and lengths of supply cables............................................... 62

8.5 Tightening torques for screws................................................................................... 63

8.6 Lubricants...................................................................................................................... 64

8.7 Lubricants for travel drive .......................................................................................... 64

8.8 Sound pressure level .................................................................................................. 65

8.9 Circuit diagrams........................................................................................................... 65

9 Wearing parts 9.1 Serial number ............................................................................................................... 66

9.2 Hoist ............................................................................................................................... 66

10 General information 10.1 Seminars........................................................................................................................ 67

Subject to technical alterations; errors and printing errors excepted.

10.08

BASH_02_1.FM

1 Safety instructions

4

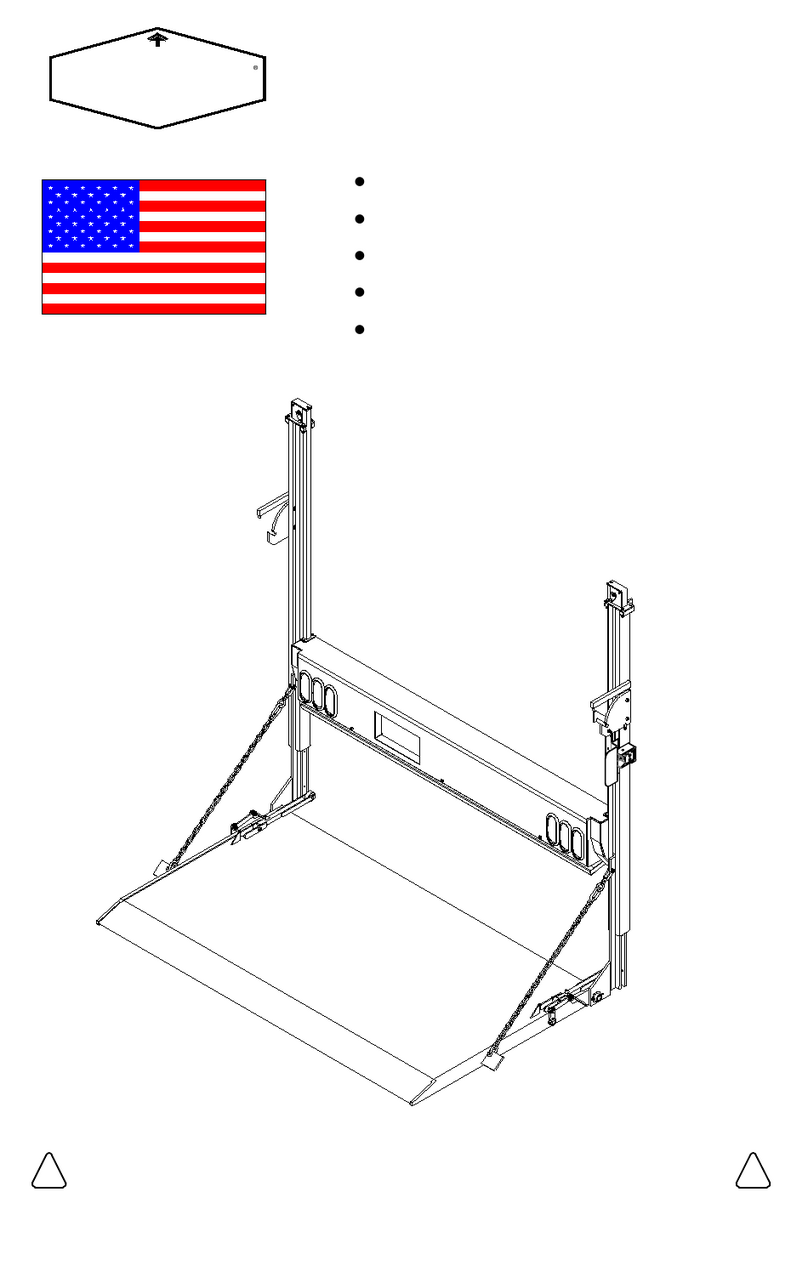

1.1 Symbols Transport

The wire rope hoist is delivered on a special pallet. This enables the hoist to be

loaded and unloaded safely with a fork-lift truck. If the wire rope hoist is to be

transported suspended, it must be attached by the suspension lugs provided, see

sketch.

Safety at work

This symbol marks all information on safety at work where risks to life and limb are

entailed.

Warning of electrical voltage

Covers such as hoods and caps which are marked with this symbol may only be

opened by "qualified persons or suitably instructed personnel".

Warning of suspended load

It is forbidden for persons to stand under suspended loads. This entails risks to life

and limb!

Safety in operation

Information marked with this symbol must be observed to avoid damage to the wire

rope hoist or the goods transported.

1.2 Operating instructions Read carefully and observe the operating instructions.

In these operating instructions, these symbols mark particularly important infor-

mation on risks and safety in operation.

07.04

BASH_02_1.FM

1 Safety instructions

510.08

1.3 Use for intended purpose • Wire rope hoists are intended for lifting freely movable and guided loads that

cannot tilt. Depending on their design, they are for stationary or mobile use. If

loads are to be towed horizontally, or in the case of guided loads, automatic opera-

tion, continual deadweight or constantly repeated hoisting motions, the individual

application must be assessed. Please contact the manufacturer in case of doubt.

• Any fundamental alterations and modifications to the wire rope hoist, such as e.g

welding on load-bearing components, structural alterations to load-bearing com-

ponents, alteration of drives, alteration of speeds and motor outputs, replacing

trolleys, etc. must be authorised by the manufacturer, otherwise the declaration of

conformity will be invalidated.

• Also any work on or additions to the control must be authorised by the manufactu-

rer. The manufacturer cannot accept any liability for malfunctioning after unautho-

rised work on the control.

Not permitted:

• Exceeding the safe working load

• Transporting persons

• Pulling loads at an angle

• Pulling loads loose

• Pulling or towing loads if the wire rope hoist has not been especially designed for

this application.

• Manipulating the overload cut-off, apart from corrections as described on page 57.

• Operating the hoist with slack rope.

• If the hoist forms "part of a machine," the person placing it on the market must

ensure that the hoist meets the specific regulations of the application

1.4 Safety-conscious operation SH wire rope hoists are constructed according to the state of the art and equipped

with an overload cut-off. In spite of this, dangers may arise from incorrect use or use

for an unintended purpose.

• The user is responsible for ensuring that work is carried out with safety in mind

and avoiding risks, see page 2.

• Read the operating instructions before starting to work with the wire rope hoist.

• Do not lift any loads heavier than the rated load.

• Standing under a suspended load is forbidden. Danger to life and limb!

• Observe the "Duties of crane operator", see page 30.

• Before starting work, find out where the EMERGENCY STOP button is (usually in

the control pendant).

•Donot put your hand between edges which might pinch or cut.

• Do not use the emergency limit switch (ultimate limit switch for highest and lowest

hook position) as an operational limit switch.

• Report damage and defects to the wire rope hoist (abnormal noises, impaired

braking function, deformations, ...) to the person responsible immediately. Do not

use the wire rope hoist until the faults have been eliminated.

• Do not remove information plates from the wire rope hoist. Replace illegible or

damaged plates.

• Have hoist inspected by the relevant authority before commissioning.

1.5

Organisational safety precautions

• Only direct persons to operate the hoist if they have been trained or instructed in

its use. Observe the legal minimum age!

• At regular intervals, check that work is being caried out in a safety-conscious

manner.

• Observe the intervals specified for periodic tests. File the test reports in the test log

book.

• Store the operating instructions within easy reach where the wire rope hoist is

operated.

BASH_02_1.FM

1 Safety instructions

6

1.6 General regulations • Safety regulations and accident prevention regulations.

• National regulations

1.7 Installation, commissioning,

maintenance and repairs

• Installation, commissioning, maintenance and repairs may be carried out by quali-

fied persons only, see page 2.

• We recommend having installation carried out by personnel engaged by the

manufacturer.

• Do not carry out any alterations or modifications.

• Additional fitments must be approved by the manufacturer.

(During welding work, electrode and ground must be in contact with the same

component!)

• Use only original spare parts for repairs.

If the wire rope hoist is constantly operated out of doors and exposed to the

elements without protection, we recommend fitting a small roof or at least "parking"

the hoist under a roof.

1.8 Warranty • The warranty will become invalid if these operating instructions are not observed

for installation, operation, inspection and maintenance.

• Repairs and elimination of faults within the scope of the warranty may only be per-

formed by qualified personnel (see page 2) after the manufacturer/supplier has

been consulted and has given his approval.

The warranty will become invalid if the hoist is modified or original spare parts not

used.

1.9 Periodic tests Hoists and cranes must be inspected by a qualified person see page 2 at least once

a year. The results of the test must be recorded and filed in the test log book.

The remaining service life of the hoist acc. to FEM 9.755 must also be established

during this inspection.

The periodic tests must be adapted to the hoist’s use. Intensive use entails shorter

maintenance intervals.

All tests must be initiated by the user, see page 2.

1.10After sales service With the purchase of this wire rope hoist, you have decided on a high-quality piece

of lifting equipment. Our after sales service will give you advice on its correct use.

You will find information on our after sales service on the back cover.

In order to maintain the safety and constant availability of your wire rope hoist, we

recommend concluding a maintenance agreement on the basis of which we will

undertake the "periodic tests" on your behalf.

Repairs will be carried out professionally and quickly by our trained personnel.

09.07

BASH_02_1.FM

2 Seilzug kennen lernen

7

The modular concept of our series of wire rope hoists permits a multitude of

variations on the basis of series components.

Our certified quality assurance system to DIN ISO 9001/EN 29001 guarantees

consistently high quality.

If you have any questions, for example on hoists modified to customers’ specific

applications, please contact one of our branches or subsidiaries. We will be pleased

to advise you!

1 Panel box with connection parts

2 Gear limit switch

3 Gear

4 Mounting point for safety brake (SH4 - SH6)

5 Rope drum

6 Rope guide with rope tensioning spring

7 Clamps for rope attachment

8 Rope drum bearing

9 End cover

10 Motor

11 Brake

12 Fan

13 Fan cover

14 Stationary wire rope hoist, hoist for installation

15 Wire rope hoist with "short headroom" monorail trolley

16 Wire rope hoist with "standard headroom" monorail trolley

17 Wire rope hoist with "articulated" monorail trolley

18 Wire rope hoist with double rail crab

14

15

18

16 17

09.07

BASH_02_1.FM

3 Installation

8

3.1 Stationary wire rope hoist Possible fixing positions and rope lead-off

Feet "at bottom," and "at top" are possible for designs with bottom hook block (rope

lead-off vertically downwards).

The SH wire rope hoist with 1/1 and 2/2 rope lead-off can be installed in various posi-

tions. The fleet angles possible can be seen from the sketches on pages 9 and 10.

If possible, install the hoist in the preferred installation position ***, see page 9.

• Use the fixing elements specified, see sketches and tables.

• Take care that no distortion arises from unevenness, etc.

(see sketch, max. 0.5°, max. 2mm)

• The customer's substructure must take up the torque MTfrom the rope drum. It

must therefore be torsion resistant.

• If the rope lead-off is not vertical, the shearing forces arising must be taken up by a

support bar.

• For tightening torques, see page 63

3.1.1 Feet at bottom

3.1.2 Feet at top

MT(Rope drum torque)

SH 3: MT= 0.5 x F x 126 mm

SH 4: MT= 0.5 x F x 167 mm

SH 5: MT= 0.5 x F x 219 mm

SH 6 : MT = 0.5 x F x 356 mm

Standard reevings

1/1 2/1 4/1 4/2-1

2/2-1 8/2-1

SH 3 SH 4 SH 5 SH6 / SHR6 SH 6

2/1, 4/1, 4/2-1 1/1

SH3 SH4 SH5 SH6 1/1

*1 Tractive force at rope drum

*2 Lock washer (Schnorr)

10.08

BASH_02_1.FM

3 Installation

9

3.2 Fleet angles

3.2.1 Feet at bottom

3.2.2 Feet at top

1/1, 2/2

SH 3 SH 4 SH5 SH6

α14°5°8°8°

α2 23° 13° 20° 18°

α3 27° 30° 30° 30°

α4 74° 73° 76° 80°

α5 30° 30° 30° 25°

α6 113° 103° 110° 108°

α7 83° 81° 60° 60°

α8 11 12° 18° 20°

α9 24° 26° 30° 12°

α10 7° 7° 8° 8°

α12 90° 90° 90° -

SH 3

SH 4

SH 5

SH 6

1/1, 2/2

SH3SH4SH5SH6

α14°5°8°8°

α2 23° 13° 20° 18°

α3 27° 30° 30° 12°

α4 74° 73° 76° 80°

α5 16° 17° 14° -

α6 34° 32° 36° -

α7 74° 73° 76° -

α12 90° 90° 90° 8°

α13 90° 90° 90° 30°

SH 3

SH 4

SH 5

SH 6

α

α

α

α

α

α

α

α

α

*** Preferred installation position

*1 Standard

*2 By turning rope guide

*4 By turning rope guide and grease pan; version G, H not possible for SH 6

07.04

BASH_02_1.FM

3 Installation

10

3.2.3 Fleet angles

The rope guide must be adjusted to the fleet angle. Observe also the radial rope exit

angle γ.

3.2.4 Angles of installation

• Instal the wire rope hoist within the permissible range of angles. Hoists with rope

drives with bottom hook blocks must always be installed horizontal to their

longitudinal axis.

• The max. permissible rope exit angle acc. to standard is 4° for non-twist-free wire

ropes, 1.5° for twist-free wire ropes. However even at these angles a reduction in

service life is to be expected.

• The wire rope must not touch the rope guide or structural elements.

Type

γ

SH 3 53°

SH 4 60°

SH 5 53°

SH 6 53°

γ°

07.04

BASH_02_1.FM

3 Installation

11

3.3 Trolleys/crabs

3.3.1Monorail trolley (KE-S33 - 76) with SH 3, SH 4, SH 5, SHR 6, SH 6 wire rope hoists

• Check flange width "B" and clearance "c" against table 1 and set trolley to beam

width if necessary.

Caution! If the flange width is altered (by customer), it may be necessary to alter

the counterweight to prevent the trolley canting. Please have it checked by our

after-sales service.

Installation if end of runway is freely accessible

• Slide trolley onto end of runway and check play f/2.

Installation if end of runway is not accessible

• Unscrew nuts (2) on threaded bolts (1) and slide trolley side cheek (3) outwards by

approx. "x" mm or until dimension "B+y" is reached (table 1).

• Push hoist side of trolley onto lower flange of runway beam and secure against

slipping.

• Push trolley side cheek (3) towards the runway beam on support bolt (4).

• Adjust dimension "c" with nuts (2), tighten nuts (2).

• Check track gauge "c" and play "f/2".

• Tighten nuts (2) with torque spanner.

• For tightening torques see table 1.

Drive shaft for travel drive (trolleys KE-S33 - KE-S65)

• Fit drive shaft in mounting position X3 or X4 depending on flange width (B) of

runway beam and length (L) of drive shaft (D).

• Fit circlips (S).

• See sketch and table 2.

Table 1

Hoist ØD Trolley cf/2xy

mm INP IPE IPB " mm Nm

SH 3 80 KE-S33 B= 90...500 B+67*1 1.5 70 137 210

SH 4 100 KE-S44 B+67*1 1.5 80 147 210

SH 5 140 KE-S65 B= 119...500 B+67*1 1.5 95 162 210

SHR 6, SH 6 200 KE-S76 B= 124...500 B+92*1 1.5 95 187 210

Table 2

ØD

[mm]

B

[mm]

Drive shaft

L [mm] Position

80

100

90 - 145 390 X3 -

146 - 195 - X4

196 - 250 495 X3 -

251 - 306 - X4

301 - 350 595 X3 -

351 - 399 - X4

400 - 450 695 X3 -

451 - 500 - X4

140

119 - 145 505 X3 -

146 - 200 - X4

201 - 250 505 X3 -

251 - 305 - X4

330 - 400 710 X3 -

401 - 500 - X4

200

124 - 220 510

see page 12221 - 400 740

401 - 500 780

Table 3

ØD

[mm]

L3 ±2

[mm]

L4 ±2

[mm]

80

100 96.4 46.4

140 124.6 46.4

*1 with INP beam: -2 mm

09.07

BASH_02_1.FM

3 Installation

12

Drive shaft for trolley drive (trolley KE-S76)

• The drive shaft is suitable for girder flange widths "B" from 124 to ≤220, >221 to ≤400

and >401 to 500 mm; see table 2, page 11 for length "L".

• Insert drive shaft (5) into the two drive pinions (6) from the counterweight side,

then assemble spacer tube (7) and adjusting ring (8).

• Adjust drive shaft (5) so that on the hoist side the shaft end projects by between

"min. 0 mm" and "max. 120 mm" beyond the drive pinion (6) and on the

counterweight side the shaft end projects by between "min. 48 mm" and "max. 160

mm" beyond the trolley side cheek (10).

• Lock adjusting ring (8) with adjusting screw so that on spacer tube (7) lying against

drive pinion (6) there is a play of approx. "3 mm" to adjusting ring (8).

• After fitting travel drive, check drive shaft (5) for ease of movement.

For dimensions B, c, f/2, x and y see tables 1 and 2, page 11

09.07

BASH_02_1.FM

3 Installation

13

3.3.2Monorail trolley (UE-S4) with SH 4, SH 5 1/1 wire rope hoists (single fall)

• Check flange width "B" and clearance "c±2" against the table and set trolley to

beam width if necessary. Ensure that the connection piece (square tube) (6) is in

the centre (of dimension "c") between the trolley side cheeks ("z1" = "z2").

• After unscrewing nuts (3) together with nuts (2), adjust clearance "c±2" and tighten

nuts (3).

• Tighten nuts (3) with torque spanner. Tightening torques see table.

• Clearance "c" results in a flange play of "f/2+1" on each side. If necessary, correct

flange play by means of clearance "c".

Installation if end of runway is freely accessible

• Slide trolley onto end of runway and check play f/2.

Installation if end of runway is not accessible

• Loosen nuts (3) on threaded bolts (1) in the square tube of the trolley side cheeks

(4) and unscrew by dimension "x".

• Push trolley side cheeks (4) apart in parallel up to the unscrewed nuts (3) until

dimension "B+y or c+x" is reached, and lift trolley onto runway from below.

• Slide trolley onto the bottom flange of the runway beam on the axle keep plate side

(8) and secure against shifting.

• Push trolley side cheeks (4) back to nuts (2), retighten nuts (3).

• Check track gauge "c±2" and play of guide rollers "f/2".

• Tighten nuts (3) with torque spanner. Tightening torques see table.

Centering connection piece

• Loosen nuts (5) and shift connection piece (6) on connecting bolt (7) so that dimen-

sions "z1" and "z2" between trolley side cheeks (4) and connection piece (6) are

equal on both sides.

• Tighten nuts (5) with torque spanner. For tightening torques see table.

Connecting bolt and drive shaft

• Use connecting bolt and drive shaft suitable for beam range "B".

(For dimensions, see sketch and table 2, page 11).

ØD Trolley cf/2x y

mm INP IPE IPB " mm Nm

100 UE-S4 B= 90...500 B+67*1 1.5 75 142 210

*1 for INP beam: -2 mm

07.04

BASH_02_1.FM

3 Installation

14

3.3.3Monorail trolley (UE-S776) with SH 6, 4/1 wire rope hoists (four-fall)

• Check flange width "B" and clearance "c±2" against the table and set trolley to

beam width if necessary. Ensure that the connection piece (square tube) (6) is in

the centre (of dimension "c") between the trolley side cheeks ("z1" = "z2").

• After unscrewing nuts (3) together with nuts (2), adjust clearance "c±2" and tighten

nuts (3).

•Donot distort plate (10)! Tighten nuts (5) lightly and then unscrew by a quarter turn.

Lock nuts 9 against nuts 5 with a torque spanner. See table for tightening torques.

• Tighten nuts (3) with torque spanner. See table for tightening torques.

• Clearance "c" results in a flange play of "f/2+1" on each side. If necessary, correct

flange play by means of clearance "c".

Installation if end of runway is freely accessible

• Slide trolley onto end of runway and check play f/2.

Installation if end of runway is not accessible

• Loosen nuts (3) on threaded bolts (1) in the square tube of the trolley side cheeks

(4) and unscrew by dimension "x".

• Push trolley side cheeks (4) apart in parallel up to the unscrewed nuts (3) until

dimension "B+y or c+x" is reached, and lift trolley onto runway from below.

• Slide trolley onto the bottom flange of the runway beam on the axle keep plate side

(8) and secure against shifting.

• Push trolley side cheeks (4) back to nuts (2), retighten nuts (3).

• Check track gauge "c±2" and play of guide rollers "f/2".

• Tighten nuts (3) with torque spanner. For tightening torques, see table.

Centering connection piece

• Loosen nuts (5) and shift connection piece (6) on connecting bolt (7) so that dimen-

sions "z1" and "z2" between trolley side cheeks (4) and connection piece (6) are

equal on both sides.

• Tighten nuts (5) with torque spanner. For tightening torques see table.

Connecting bolt and drive shaft

• Use connecting bolt and drive shaft suitable for beam range "B".

(For dimensions, see sketch on page 15).

ØD Trolley cf/2x y

mm INP IPE IPB " mm Nm

200 UE-S776 B= 185....500 B+92 1.5 95 187 210

10.08

BASH_02_1.FM

3 Installation

15

Drive shaft for trolley drive (trolley UE-S776)

• The drive shaft is suitable for girder flange widths "B" from 185 to 500 mm, see table

for length "L".

• Insert drive shaft (1) into the two drive pinions (6) from the counterweight side,

then assemble spacer tube (3) and adjusting ring (4).

• Adjust drive shaft (1) to dimension L1, dimension L2 must lie between the values

given in the table.

• Lock adjusting ring (4) with adjusting screw.

• After fitting travel drive, check drive shaft (1) for ease of movement. The axial play

should be approx. 3 mm.

For dimensions f/2 see table on page 14

B

[mm]

L

[mm]

L1

[mm]

L2

[mm]

185 - 220 510 84 191 - 95

221 - 360 620 84 172 - 33

361 - 450 740 134 98 - 9

451 - 500 740 84 58 - 9

10.08

BASH_02_1.FM

3 Installation

16

3.4 Articulated trolley

(DKE-S4 / DKE-S6)

with SH 3, SH 4, SH 5 wire rope hoists

• Check flange width "B" and clearance "c" against the table and set trolley to beam

width if necessary. Ensure that the connection piece (square tube) (6) is in the

centre (of dimension "c") between the trolley side cheeks ("z1" = "z2").

• After unscrewing nuts (3) together with nuts (2), adjust clearance "c" and tighten

nuts (3).

• Tighten nuts (3) with torque spanner.

• See table for tightening torques.

• Clearance "c" results in a flange play of "f/2" on each side. If necessary, correct

flange play by means of clearance "c".

Installation if end of runway is freely accessible

• Slide trolley onto end of runway.

Installation if end of runway is not accessible

• Loosen nuts (3) on threaded bolts (1) in the square tube of the trolley side cheeks

(4) and unscrew by dimension "x".

• Push trolley side cheeks (4) apart in parallel up to the unscrewed nuts (3) until

dimension "B+y or c+x" is reached, and lift trolley onto runway from below.

• Lift trolley onto runway from below.

• Slide trolley onto the bottom flange of the runway beam on the hoist side and

secure against shifting.

• Push trolley side cheeks (4) back to nuts (2), retighten nuts (3).

• Check track gauge "c" and play of guide rollers "f/2".

• Tighten nuts (3) with torque spanner.

• See table for tightening torques.

Centering bogie

• Loosen nuts (5) and shift bogie (6) on connecting bolt (7).

• Dimension "z" between trolley side cheeks (4) and bogie (6) is equal on both sides.

• Tighten nuts (5) with torque spanner.

• For tightening torques see table.

Hoist ØD Trolley B f/2 c x y Nut (3) Nut (5)

[mm] [mm] [Nm]

SH 3

SH 4

100 DKE-S 4 90 - 220 1.5 B+80 67 147 215 85

SH 5 140 DKE-S 6 119 - 300 1.5 B+84 75 159 215 85

07.04

BASH_02_1.FM

3 Installation

17

Drive shaft for travel drive (DKE-S4 / DKE-S6)

Trolleys with one travel drive

• Mount a drive shaft of a length (L) suitable for the beam width (B)

• Fit lockwashers (S) acc. to dimension L4

• The mounting position of the drive shaft does not change over the corresponding

beam range (B).

Trolleys with two travel drives

• Drive shaft is completely independent of the beam width

• Mount lockwashers (S) acc. to sketch

ØD

[mm]

B

[mm]

Drive shaft

L

[mm]

L4 ±2

[mm]

100 90 - 128 390

46.4

129 - 220 495

140 119 - 280 495

281 - 300 710

W0904

ØD100 ØD 140

01.06

BASH_02_1.FM

3 Installation

18

End stops

• Mount end stops with rubber buffers at end of runway.

Suggestion for solution by customer

*1 Incl. counterweight

*2 Travel speed V max.: 20 m/min.

*3 E = 0.1415 • mka • v2• x (Nm) mka (t), v (m/min)

x = with travel limit switch: 0.72

x = without travel limit switch: 1.0

Type B

max

L

max

E max

*3 *1

ØD Order no.

mm mm kg Nm kg mm

PA 50/200 200 350

3200 200 700

63

80

100

01 740 24 27 0

PA 50/300 300 450 01 740 25 27 0

PA 50/500 500 650 01 740 26 27 0

PA 63/200 200 350

10000 440 3200 100

140

01 740 27 27 0

PA 63/300 300 450 01 740 28 27 0

PA 63/500 500 650 01 740 29 27 0

ØD bcdefg M..

*2 Order no.

mm

80 L80x80x10 30 34 9 32 34 40 M10,M12 577 985 0

100 L80x80x10 30 57,5 9 32 34 40 M10,M12 577 985 0

125 L80x80x10 30 68,5 11 32 42 50 M10,M12 577 971 0

160 L80x80x10 30 68,5 11 32 42 50 M10,M12 577 971 0

200 L80x80x10

L100x100x10

40

50

95

105

11

14

32

36

53

66

63

80 M10,M12 577 992 0

577 993 0

*4

07.04

BASH_02_1.FM

3 Installation

19

3.5 Double rail crab (OE-S ) • Check track gauge Spw on crab and rail.

• L1 max - L1 min = 5 mm, see sketch.

• Check lateral play between rail and flange, see sketch.

• Bolt rubber buffers to crab or runway end stop.

• Fit suitable stops. For dimensions see sketch and table.

• Remove transport anchor screw TS (only on crabs with wheel Ø 125).

• The runway must meet the requirements of DIN 4132.

• The rail joints must be even on both running and guide surfaces; grind down if

necessary.

S as per table if crab is positioned symmetrically on runway. If asymmetrically,

Sleft + Sright = 2 x S

End stops

Ø100

ø DS

100 2,5-5

125 2,5-5

160 3,5-6

200 4,5-7

Crane

Ø125 - Ø200

Crane

ø Dh

100 45

125 97

160 100

200 100

07.04

BASH_02_1.FM

3 Installation

20

3.6 Travel limit switch 3.6.1 Monorail trolley

The travel limit switches (optional) are mounted on the trolley.

3.6.2 Double rail crab

The travel limit switch assembly is supplied ready-wired but not mounted and must

be secured to the towing arm for the power supply.

The switching contacts are designed for control current.

Switching functions:

1. Limit switching in both directions of travel (1 two-way switch, 2 ramps).

2. Pre-switching and limit switching in both directions of travel (1 two-way switch, 4

ramps).

The speed is switched over from "fast" to "slow" before the end of the runway is

reached, and is cut off at the end of the runway.

X = stop, left

Y = stop, right

Z = fast / slow

Monorail trolley Double rail crab

Type HC

[mm]

OE-S 04 77 795

OE-S 05 85 915

OE-S 06 87 915

OE-S 07 107 915

09.07

*1 Switch activator by customer

This manual suits for next models

4

Table of contents

Popular Lifting System manuals by other brands

Vulcan-Hart

Vulcan-Hart VPT Operator's manual

Sumner

Sumner GH3/4T quick start guide

Hyster

Hyster N30XMXDR3 Safety Precautions Maintenance And Repair

Terex

Terex C5000 Series Tech tips

Street Crane

Street Crane ZX6 Installation, operation and maintenance instructions

TBI

TBI TRU-BILT TRU-LEVEL Installation & owner's manual

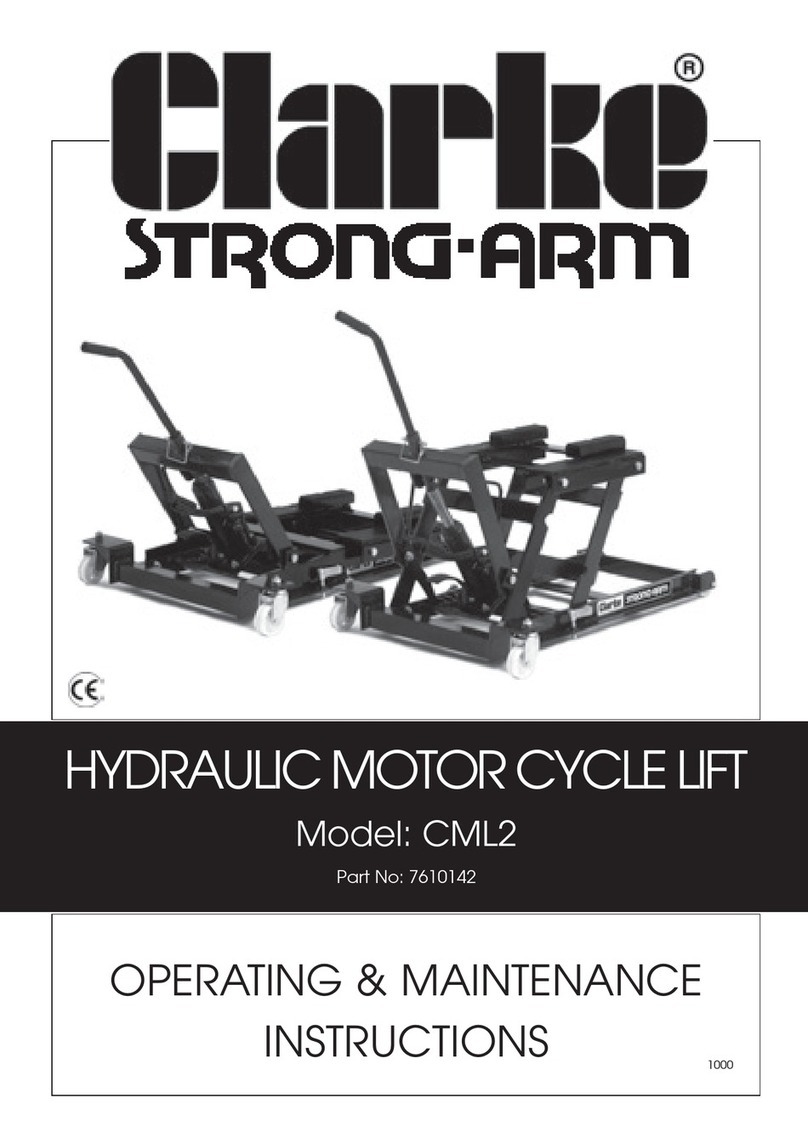

Tommy Gate

Tommy Gate Railgate 1600 Series Owner's/operator's manual

Youngman

Youngman BOSS X Series manual

PVI Industries

PVI Industries ATH1232 quick start guide

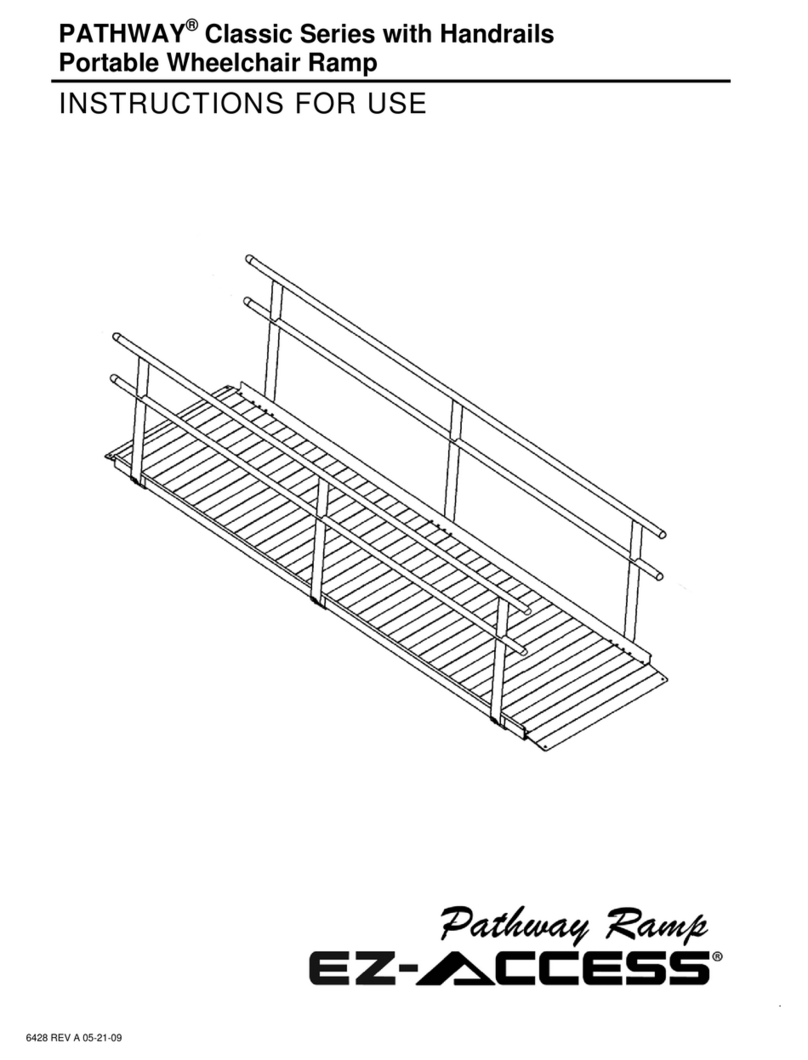

Clarke

Clarke Strong Arm CML2 Operating & maintenance instructions

edmolift

edmolift PL 2002 owner's manual

EZ-ACCESS

EZ-ACCESS PATHWAY Classic Series Instructions for use