Vulcan-Hart VPT User manual

OPERATOR’S MANUAL

VPT & VGT –Vulcan Push & Gear

Trolley

WARNING

DO NOT INSTALL, USE OR REPAIR THIS EQUIPMENT BEFORE

READING THIS MANUAL IN ITS ENTIERETY. FAILURE TO READ

AND FOLLOW THE INSTRUCTIONS DESCRIBED IN THIS MANUAL

COULD RESULT IN SERIOUS INJURY, DEATH AND/OR MATERIAL

DAMAGES

Vulcan Push & Gear Trolley 22020-02-05, rev1a

WARNING

All persons involved in using, inspecting, maintaining or

repairing this equipment must be thoroughly familiar with the

contents of this manual and follow the recommended

instructions and procedures to avoid injury or property damage.

WARNING

The equipment described in this manual is not designed to

lift or move people nor to lift or move loads over people and must

therefore not be used for such applications.

WARNING

Do not use this trolley in areas containing flammable

vapors, liquids, gasses or combustible dust or fibers. Do not use

this trolley in highly corrosive, abrasive, wet environments or in

temperatures below -10°C or above 50°C.

NOTICE

Please visit Vulcan’s website www.vulcanhoist.com for the

latest manual version or any other questions regarding the

equipment.

Vulcan Push & Gear Trolley 32020-02-05, rev1a

Safety and Warnings

Dangerous Practices to be Avoided

DO NOT use the trolley before reading the manual

DO NOT let an unqualified person use or repair the trolley

DO NOT exceed the rated capacity of the trolley

DO NOT use the trolley to grab, secure or lift the load

DO NOT use as a “below-the-hook” lifting device

DO NOT install trolley on beams of unknown capacity

DO NOT use the trolley in temperatures below -10°C or above

50°C

DO NOT use a damaged or malfunctioning trolley

DO NOT lift people nor carry loads over people

DO NOT stay in the “fall zone” when lifting a load

DO NOT lift if the trolley is not firmly tightened and adjusted on

the beam width with the necessary clearance

DO NOT lift unbalanced loads or loads that are not centered

DO NOT leave the load supported by the trolley unattended

DO NOT shock load or side load

DO NOT allow the load to swing

DO NOT allow a welding electrode to touch the beam trolley

DO NOT use the trolley as ground for welding

DO NOT remove or obscure labels

DO NOT use if nameplate or safety and warning labels are

missing or illegible

WARNING

Use the trolley ONLY to attach or suspend a load

underneath a fixed, stationary and rated for that purpose beam.

DO NOT use the trolley to grab, secure or lift the load. The

trolley is not designed as a “below-the-hook” lifting device and

must not be used as one.

Vulcan Push & Gear Trolley 42020-02-05, rev1a

WARNING

DO NOT attempt to modify this equipment or use it in a

manner different than described in this manual. Use only Vulcan

authorized replacement parts in the service and maintenance of

this equipment. Failure to comply with the above limitations will

void the warranty and may result in property damage, injury or

death.

Installation

Installation Procedures

1

Measure the width of the runway beam

2

Loosen the hex nuts on the stay bolts and remove the side

plate

3

Adjust the width of the trolley to match the beam width by

using the appropriate number of washers to spread apart

the side plates

4

Leave a slight clearance of about 1/8 inch between the

edge of the beam flange and the wheel flange

5

Make sure the suspension plate is centered and you have

equal number of washers on each side of it

6

Put the remaining washers on the outside of the side

plates. On gear trolleys, the equalizer pin must be offset as

to not interfere with the chain wheel. Do so by putting more

washers on the side opposite to the chain wheel

7

Reassemble the trolley on the beam and tighten slightly by

hand

8

Make sure all wheels are in contact with the beam flange

9

Tighten the hex nuts to the torque specified in the table

below

10

Install stoppers on the runway beam or other means of

preventing the trolley from rolling off unintentionally

Vulcan Push & Gear Trolley 52020-02-05, rev1a

Push model

Gear model

Stay bolt tightening torque

Nm (ft-lb)

VPT1/2T

VGT1/2T

138 (102)

VPT1T

VGT1T

138 (102)

VPT1.5T

VGT1.5T

138 (102)

VPT2T

VGT2T

239 (176)

VPT3T

VGT3T

239 (176)

VPT5T

VGT5T

475 (350)

WARNING

DO NOT use the trolley unless the load plate is centered.

Vulcan Push & Gear Trolley 62020-02-05, rev1a

ATTENTION

When installing the trolley on curved beams, orient trolley

with the gear wheels and the chain wheel on the outside of the

curve.

Refer to the table below for the minimum radii of

curvature compatible with each model as measured on the inside

of the curved beam.

Push model

Gear model

Minimum radius of curvature (in)

VPT1/2T

VGT1/2T

32

VPT1T

VGT1T

40

VPT1.5T

VGT1.5T

44

VPT2T

VGT2T

48

VPT3T

VGT3T

60

VPT5T

VGT5T

60

Vulcan Push & Gear Trolley 72020-02-05, rev1a

Operation

Operation Procedures

1

Prior to lifting, make sure the lift can be performed safely

and the lift path is clear

2

Ensure the beam is of suitable capacity for the load and

will not be damaged by the trolley rolling on the flange

3

Make sure the beam is fitted with stops at both ends to

prevent the trolley from rolling off

4

Make sure the load is properly centered below the trolley

5

Verify that all lifting devices used (including the trolley) are

properly fastened and of suitable working load limit

6

While performing the lift, do not let people to stay in or

cross the “fall zone” under the trolley

7

While performing the lift, do not allow the load to swing or

to move briskly

8

If using a push trolley, push the load from behind to move it

9

If using a gear trolley, steadily pull down on the hand chain

to move the load

10

At the end of the travel path slow down the load gently and

do not allow the trolley to hit the stoppers

WARNING

NEVER stay or pass through the “fall zone” under the

trolley.

ALWAYS keep your hands and feet away from the “fall

zone” under the trolley.

Vulcan Push & Gear Trolley 82020-02-05, rev1a

Inspection and Maintenance

ATTENTION

The trolley must be inspected by the operator daily. If any

deficiencies are noted, stop using the trolley until it is repaired or

replaced.

Suggested Daily Inspection List

1

Check for cracks or distortions in the structural frame,

welds or mechanical components

2

Check for loose or missing fasteners or other components

3

Check if trolley rolls smoothly

4

Check for signs of heat damage or weld splatter

5

Check for excessive wear on load bearing parts like, but not

limited to the wheels, the suspension pin, the thread, etc.

6

Make sure the nameplate and the warning labels are

present and legible

ATTENTION

A qualified person must inspect regularly and in depth the

trolley and its components to ensure the equipment is safe for

use. These inspections may vary in frequency and detail

according to the intensity of the equipment use but must include

at least the daily inspection procedure.

The user is responsible for keeping dated records of all

periodic inspections and maintenance procedures as means of

continuously monitoring the condition of the equipment.

Vulcan Push & Gear Trolley 92020-02-05, rev1a

Suggested Inspection Frequency

Initial

Initial installation, re-installation, altered,

repaired or modified equipment

Functional

Beginning of each shift

Frequent

Normal service –monthly

Heavy service –weekly to monthly

Severe service –daily to weekly

Periodic

Normal service –yearly

Heavy service –semi-annually

Severe service - quarterly

ATTENTION

Keep the moving components clean and well lubricated to

protect against premature wear.

Vulcan Push & Gear Trolley 10 2020-02-05, rev1a

Vulcan Push & Gear Trolley 11 2020-02-05, rev1a

Push

model

Gear

model

WLL

(lbf)

Weight1

(lbs)

A

(in)

B

(in)

C

(in)

D

(in)

E

(in)

F

(in)

G

(in)

H

(in)

L2

(ft)

R3

(in)

VPT1/2T

VGT1/2T

1100

16 (25)

8.6

1.26

3.7

2.8

1.0

2.50 –6.00

.82

10.0

10

32

VPT1T

VGT1T

2200

23 (34)

9.4

1.38

3.8

3.8

1.0

3.00 –5.50

.91

10.0

40

VPT1.5T

VGT1.5T

3300

29 (40)

10.2

1.57

4.2

3.8

1.1

3.00 –5.50

1.17

11.0

44

VPT2T

VGT2T

4400

45 (58)

12.2

1.77

5.0

4.2

1.3

3.38 –6.50

1.16

11.5

48

VPT3T

VGT3T

6600

64 (78)

14.3

2.20

5.1

4.2

1.4

3.94 –6.50

1.20

12.0

60

VPT5T

VGT5T

11000

111 (124)

15.0

2.56

5.9

5.5

3.0

4.50 –7.25

1.38

13.8

60

1

Push trolley weight (Gear trolley weight with standard chain length)

2

Standard length for gear trolleys. Custom lengths available on demand

3

Minimum beam radius of curvature

Vulcan Push & Gear Trolley 12 2020-02-05, rev1a

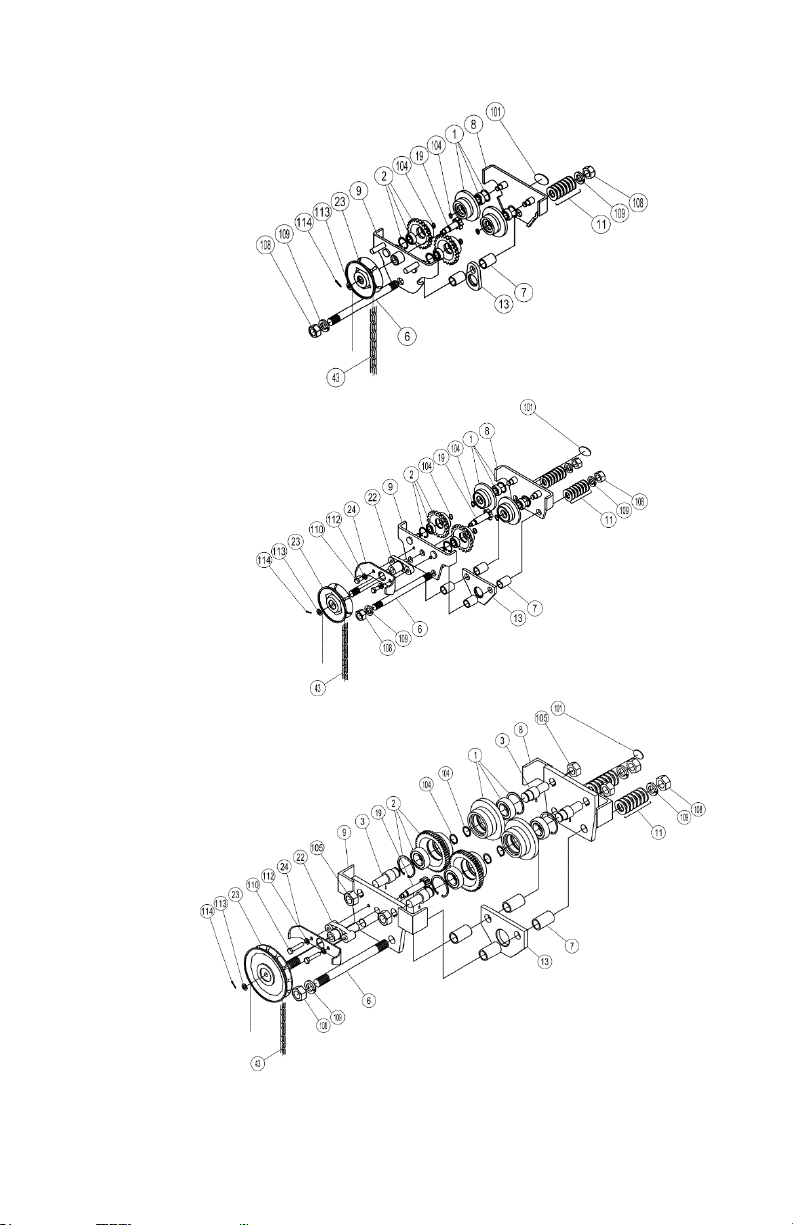

VPT1/2T

VPT1T

VPT1.5T

VPT2T

VPT3T

VPT5T

Vulcan Push & Gear Trolley 13 2020-02-05, rev1a

Item

Description

VPT1/2T

VPT1T

VPT1.5T

VPT2T

VPT3T

VPT5T

1

Plain wheel asm

4

4

4

4

4

4

3

Wheel pin

-

-

-

-

-

4

6

Stay bolt

1

2

2

2

2

2

7

Stay pipe

2

4

4

4

4

4

8

Plain-side plate

2

2

2

2

2

2

11

Adjustable collar

34

68

78

48

38

34

13

Hanging plate

1

1

1

1

1

1

101

Name plate

1

1

1

1

1

1

104

Retaining ring

4

4

4

4

4

4

105

Wheel pin nut

-

-

-

-

-

4

108

Stay bolt nut

2

4

4

4

4

4

109

Spring washer

2

4

4

4

4

4

Vulcan Push & Gear Trolley 14 2020-02-05, rev1a

VGT1/2T

VGT1T

VGT1.5T

VGT2T

VGT3T

VGT5T

Vulcan Push & Gear Trolley 15 2020-02-05, rev1a

Item

Description

VGT1/2T

VGT1T

VGT1.5T

VGT2T

VGT3T

VGT5T

1

Plain wheel asm

2

2

2

2

2

2

2

Gear wheel asm

2

2

2

2

2

2

3

Wheel pin

-

-

-

-

-

4

6

Stay bolt

1

2

2

2

2

2

7

Stay pipe

2

4

4

4

4

4

8

Plain-side plate

1

1

1

1

1

1

9

Gear-side plate

1

1

1

1

1

1

11

Adjustable collar

34

68

78

48

38

34

13

Hanging plate

1

1

1

1

1

1

19

Pinion shaft

1

1

1

1

1

1

22

Pinion shaft metal

-

1

1

1

1

1

23

Hand wheel

1

1

1

1

1

1

24

Hand chain guide

-

1

1

1

1

1

43

Hand chain

1

1

1

1

1

1

101

Name plate

1

1

1

1

1

1

104

Retaining ring

4

4

4

4

4

4

105

Wheel pin nut

-

-

-

-

-

4

108

Stay bolt nut

2

4

4

4

4

4

109

Spring washer

2

4

4

4

4

4

110

Pinion shaft bolt

-

2

2

2

2

2

112

Spring washer

-

2

2

2

2

2

113

Plain washer

1

1

1

1

1

1

114

Split pin

1

1

1

1

1

1

This manual suits for next models

1

Table of contents

Other Vulcan-Hart Lifting System manuals

Popular Lifting System manuals by other brands

Nibotechnics

Nibotechnics Autolift electric installation instructions

John Bean

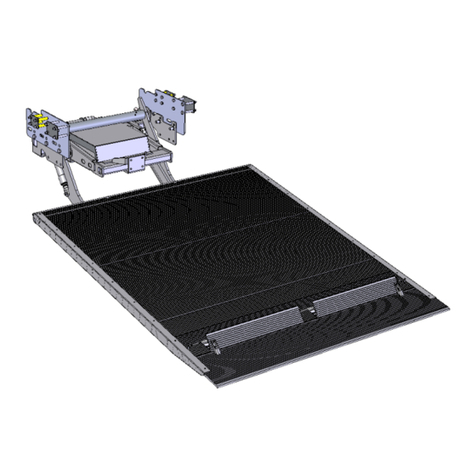

John Bean JLT4500S manual

Dhollandia

Dhollandia DH-LSP.07 installation manual

morse

morse 400AM-60 Assembly & operators manual

Motorline professional

Motorline professional CHAINLIFT User& installer's manual

Bishamon

Bishamon X Series Operation and service manual