CC-08 11/17

9995223

To Order: 800.4.STAHLS • Fax: 800.346.2216

International: 586.772.5551 • Canada: 800.521.5255

StahlsID.com • StahlsCanada.com

for current application instructions visit us online

All technical information and recommendations are based on tests we believe to be reliable. However, we cannot guarantee performance for conditions not under manufacturer's control.

Before using, please determine the suitability of product for its intended use. The user assumes all risk and liability whatsoever in connection with the use of this product.

Seller's and manufacturer's only obligation shall be to replace such quantity of the product proved to be defective by manufacturer.

INSTRUCTIONS FOR USING

Thermo-GRIP®

A Lettering Material for Problem Fabrics and more

RECOMMENDED FABRICS

• Nylon meshes-micro, tricot,

mini, reversible

• 100% nylon knits

• Dazzle nylon

• 100% Cotton

• Poly/cotton blends

• 100% Polyester

REQUIRED ACCESSORIES:

Kraft Paper or Teon Sheet

CARE INSTRUCTIONS

Machine wash warm water, medium

dryer heat on household machines.

Remove promptly from dryer. Liquid

bleach can be used during laundering.

Do not iron directly on lettering.

Thermo-GRIP®can be dry cleaned.

STORAGE

Stahls’ Thermo-GRIP®should be stored

around 65 to 70 degrees Fahrenheit with

50% relative humidity. We recommend

shelf life for materials be one year.

REMOVAL

(Stahls’ Solvent is available in the

Continental US only. In Canada, call

800.521.5255 for Solvent referrals)

If an application error is made, Stahls’

Thermo-GRIP®can be removed by

applying Stahls’ Solvent to the reverse

side of the fabric behind the lettering.

Saturate the area thoroughly and wait

20 seconds. By gently tugging the

garment, the letters will pop o.

Picking at the Thermo-GRIP®will

make removal more dicult.

2-COLOR APPLICATION

Align foreground and background on

garment. Heat seal together at 330° for

10 seconds with light pressure.

NOTES — APPLICATION

Thermo-GRIP®can be applied over

garment and cap seams.

StahlsID.com

800.4.STAHLS

StahlsCanada.com

800.521.5255

Hotronix is a registered trademark of Stahls’ ID Direct with one or more patents or patents pending. © Stahls’ ID Direct 2008

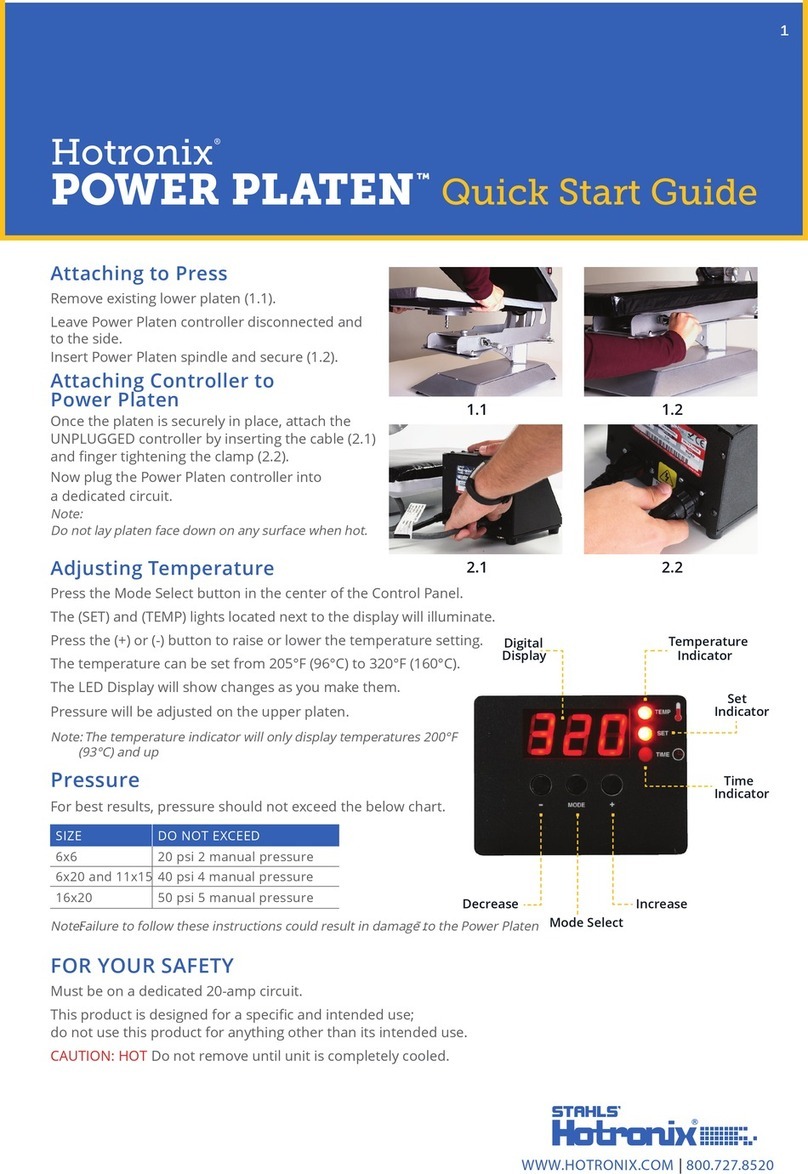

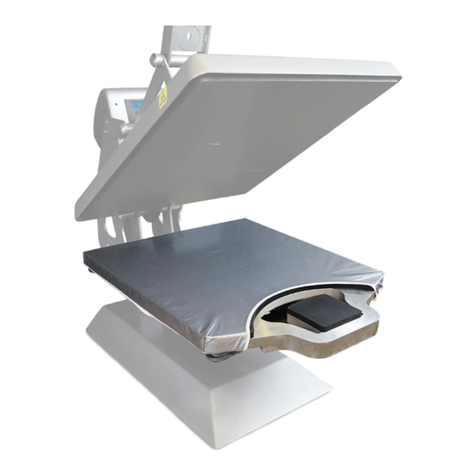

PREHEAT BOTTOM PAD

Before application, lower the

top platen for 60 seconds.

This helps the adhesive to melt

properly during application.

COVER LETTERING

Use a Teon cover sheet for a

screenprinted nish.

Kraft paper for a matte nish is

also available from Stahls’.

PREHEAT GARMENT!

Place garment on bottom pad

and press for 5-10 seconds to

remove moisture and chemical

treatment from lettering area

on garment.

HEAT APPLY

Time: 330°F; 165°C

Temp:

6

-

8 seconds

Pressure:

Medium

(#4 Based on Stahls’ Hotronix® & Hot

One® heat presses. Settings on other

heat presses may vary.)

LAYOUT LETTERING

Place adhesive side down on

garment.

(The textured side should be up.)

RUB & COOL GARMENT

Rub cover sheet with a heat

eraser. To prevent letters from

sticking together, allow garment

to cool at on the platen or

carefully remove.