ENOTOSCANA MINI VIRGILIO 6 User manual

Pagina 1

ENOTOSCANA SRL

VIA PROV.LE PISANA, 141

50050 CERRETO GUIDI (FI) – ITALY

Telefono / Fax 0571/400474

www.enotoscana.it

USER MANUAL

FILTER PLATES 20x20

MODEL:

SERIAL NUMBER

YEAR OF CONSTRUCTION 2018

VOLT/HZ 220/50

ATTENTION:

This manual must be kept in the vicinity of the machine and in a place known to the personnel in charge of

use, maintenance and repair.

Pagina 2

INDEX

1

GENERAL

PAGE 3

2

DESCRIPTION

PAGE 3

3

TECHNICAL FEATURES

PAGE 4

4

IDENTIFICATION OF THE COMPONENTS

PAGE 4

5

CONDITIONS OF EXPECTED

PAGE 4

6

CHOOSE CARTONS FILTER

PAGE 5

7

ASSEMBLY OF CARTONS

PAGE 6

8

ASSEMBLY OF CARTONS OIL FILTRATION

PAGE 6

9

ASSEMBLY OF DOUBLE FILTRATION PLATE

PAGE 6

10

PIPING CONNECTION DIAGRAM

PAGE 7

11

STARTING

PAGE 7

12

STOP

PAGE 7

13

ROUTINE MAINTENANCE OF THE MACHINE

PAGE 8

14

DIVESTEMENT AND DISPOSAL OF THE MACHINE

PAGE 8

15

TECHNICAL ASSISTANCE SERVICE

PAGE 8

16

TROUBLESHOOTING AND SOLUTIONS

PAGE 9

17

WARRANTY

PAGE 10

18

CE DECLARATION OF CONFORMITY

PAGE 11

Pagina 3

1. GENERAL

• Do not proceed with the installation, maintenance and commissioning of the machine before having read this manual

in its entirety.

• This manual must be kept near the machine and in a place known to the personnel in charge of use, maintenance and

repair.

• The manufacturer declines all responsibility for damage resulting from improper use of the machine or failure to

comply with the instructions in this manual.

• Start the machine only after having ascertained that all its structural parts are intact and that they do not show

mechanical defects or corrosion phenomena.

• Do not start the machine if one or more components are missing or incorrectly assembled.

• Do not move the machine during operation

• Do not use the machine for products other than those described in this manual.

•

Never use the machine to treat FLAMMABLE PRODUCTS

• Never use the machine in environments with EXPLOSIVE ATMOSPHERE

• Before proceeding with the electrical connection, make sure that the system

complies with current grounding regulations.

Check that the mains voltage is the same as the one shown on the rating plate on

the machine

•During every intervention use security gloves .

2. DESCRIPTION

The filters are made of stainless steel AISI 304 suitable for the treatment of food products.

• The plate filters have been studied to filter WINE, OIL, BEER and all the products that have similar characteristics of

filterability.

Filtration takes place by means of filtering layers inserted inside the plates made of food material.

• The filters can work with the specific pump supplied or with any other type of pump as long as it has a pressure of at

least 2 bar and a flow rate suitable for the filter model.

• Filters can be equipped with accessories such as the double filtration plate

Pagina 4

3. TECHNICAL FEATURES

Model Number

plates

Carton

dimension

Filtering

surface m2

Wine

production

l/h

Oil

production

l/h

Clearances

and weight

MINI VIRGILIO 6 6 20X20 cm 0.24 80 - 200 80

600 x 330 x h440

13 kg

MINI VIRGILIO 10 10 20X20 cm 0.40 130 - 280 130

600 x 330 x h440

13 kg

VIRGILIO 10 10 20X20 cm 0.40 130 - 280 130

600 x 500 x h750

32 kg

VIRGILIO 20 20 20X20 cm 0.80 600 - 900 600

600 x 500 x h750

36 kg

VIRGILIO 30 30 20X20 cm 1.20 900 - 1500 900

970 x 500 x h750

49 kg

VIRGILIO 40 40 20X20 cm 1.60 1400 - 1800 1400

970 x 500 x h750

54 kg

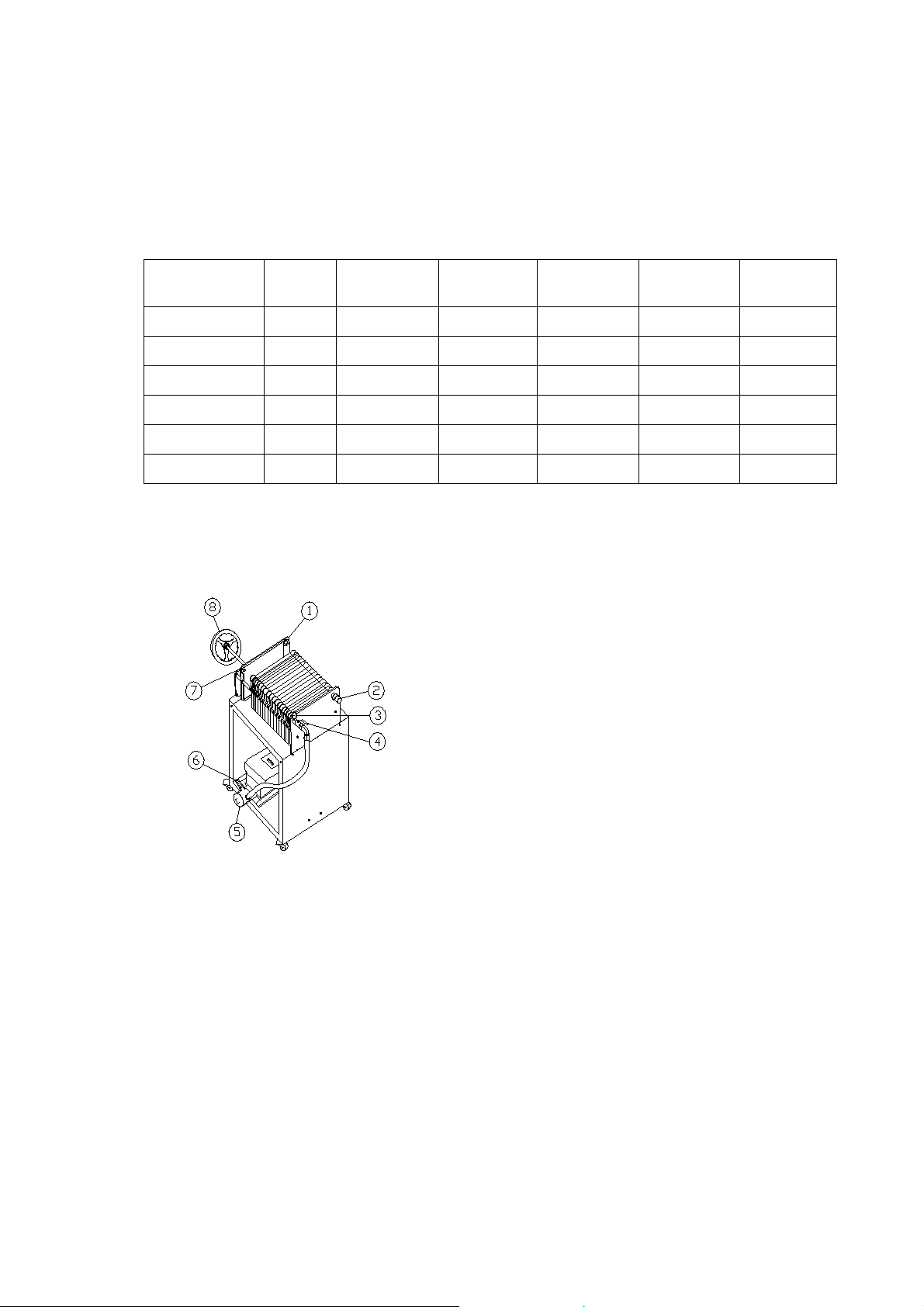

4. COMPONENTS IDENTIFICATION

5. PROVIDE USE CONDITIONS

• The filter has been constructed and designed for well-defined filtration applications. Improper use and / or use other

than that for which it was designed is strictly forbidden. An improper use and / or tampering with the devices, provides

for the cancellation of the warranty and the forfeiture of the declaration of conformity.

• The filters have been designed to work in environments where the environmental parameters taken as reference are:

TEMPERATURES INCLUDED BETWEEN + 5 ° C AND + 30 ° C - MOISTURE WITHOUT CONDENSATION

BETWEEN 40% - 60%

• It is not recommended to use filters in places with environmental characteristics different from the aforesaid.

1

Sample taste

2

Exit filtered liquid

3

Manometer

4

Pressure regulator

5

Pump

6

Entry for liquid to filter

7

Thrust plate

8

Barra centrale

Pagina 5

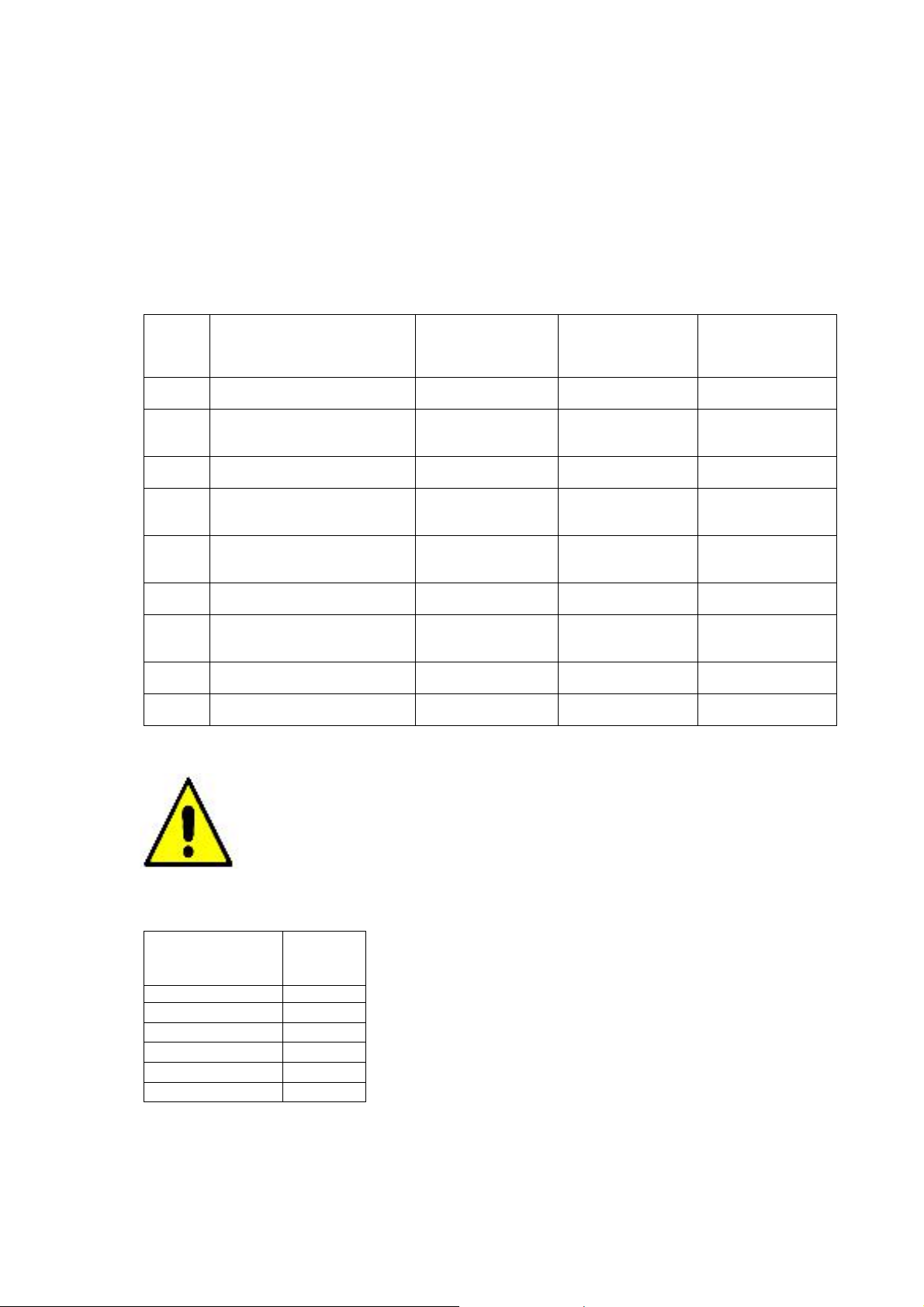

6. CHOICE OF CARTONS FILTER

• Refer to the following table for choosing the type of cardboard.

TYPE USE

PRESSURE

(bar)

QUANTITY

l/h

FOR 10

CARTONS

EMPLOYMENT

V.0 WASHABLE 4.0 720

FOR CLOUDY YOUNG

WINES

V.4 DEGREASING 3.0 680

PER VINI

FOR CLOUDY YOUNG

WINES

V.8 THIN DEGREASING 2.5 650

FOR CLOUDY YOUNG

WINES

V.12 MEDIUM BRIGHT 2.5 500

PER VINI

COMPLETAMENTE

FERMENTATI

V.16 BRIGHT 2.0 350

PER VINI

BRILLANTATURA DI

VINI ROSSI

V.18 PRE STERILISING 2.0 300

BRIGHTENING FOR

WHITE WINES

V.20 STERILISING 1.5 220

STERILISING WINES

WITH SUGAR

RESIDUES

V.24 SUPER STERILIZZANTE 1.0 120

FOR WINES TO

STABILIZE

E2 SGROSSANTE 2.5 50

FOR FILTERING OLIVE

OIL

ATTENTION: before to insert the cartons in to the filter, wet them with water or

with a product yet glazed.

For the filtering of the olive oil , the cartons have to be wet with oil.

Model

Number of

cartons

filter

MINI VIRGILIO 6

6

MINI VIRGILIO 10

10

VIRGILIO 10

10

VIRGILIO 20 20

VIRGILIO 30

30

VIRGILIO 40

40

Pagina 6

7. ASSEMBLY CARTONS

•Each carton must be inserted between each pair of adjacent plates. As shown in the figure,

each rough face must face a rough face and each smooth face on a smooth one.

1

Terminal plate, manometer side

2

Rough side carton

3

Smooth side carton

4

Terminal plate brochure side

5

Thin gaskets

8. CARTONS ASSEMBLY FOR CARTONS OIL FILTERING

•For oil filtration, 2 boxes must be inserted between each pair of adjacent plates as shown in the figure.

Then place the other cartons (always 2 between each pair) always following the principle that each

rough face must face a rough face and each face smooth on a smooth

2

Rough side carton

9. PLATE ASSEMBLY DOUBLE FILTERING

•Using the double filtration plate, it is possible to insert two different types of filtering cartons, one for

each of the two sectors.

• Warning: the plug 2 and the filtered liquid outlet 8 must be mounted as shown in the figure below

(inverted with respect to the individual filtration)

1

Liquid entry to filter and pressure

regulator with manometer

2

Cork

3

Thin gaskets

4

Terminal plate brochure side

5

Blind buckle

6

Punctured buckle

7

Inversion plate

8

Exit filtered liquid

9

Sample taste

LATO A

PIASTRE CENTRALI

DISPARI

LATO B

PIASTRE CENTRALI

PARI

Pagina 7

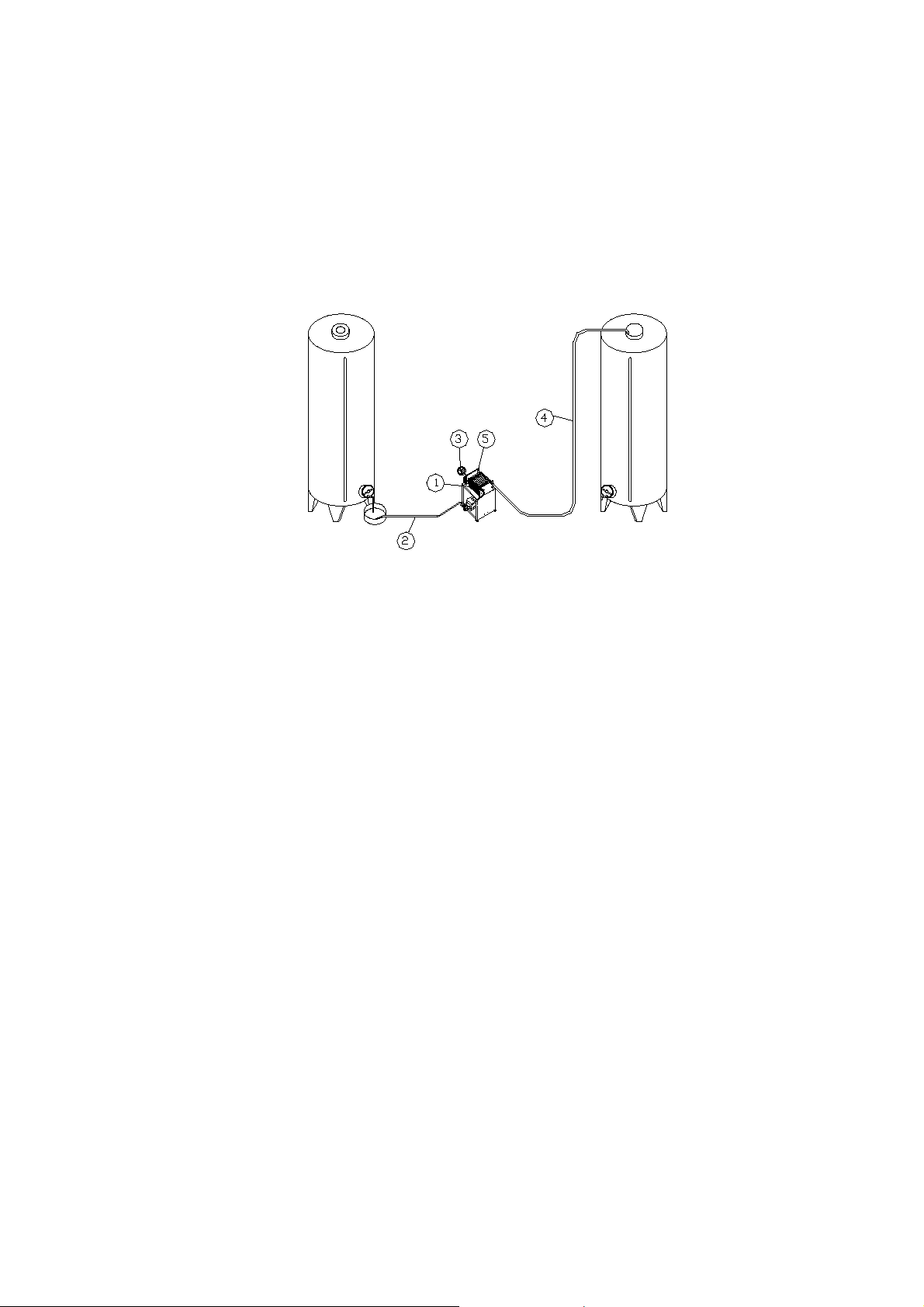

10.PIPE CONNECTION DIAGRAM

11.STARTING

•After correctly inserting the cartons, the supplied gaskets and after having tightened them by means of

the handwheel of the central bar (3), proceed as follows:

1. Fill the pump housing with the product to be filtered.

2. Close the pressure regulator (1) for around halfway.

3. Start the pump making sure it turns in the right direction.

4. Slightly open the sampling handwheel (5) and wait for the air to escape.

5. Close the sampling handwheel (5) again only when the product comes out without air.

6. Using the Pressure regulator (1) bring the pressure to 0.3 bar and keep it for a few seconds.

7. Adjust the pressure to the value given in the table of characteristics of the used filter boxes.

8. Continue the filtering

9. During the filtration check through the pressure gauge that there will be no pressure

variations compared to the established value, eventually proceed to slow adjustments.

12.STOP

• To stop the machine, switch off the pump and wait at least 3 minutes before loosening the

handwheel (3) to allow complete circuit depressurization.

• Using the special tap, proceed to unload the product that is collected in the tray below the

filter plates.

• Loosen the handwheel

1

Pressure regulator

2

Apsiration pipe

3

Central bar

4

Delivery pipe

5

Samples taste

BOTTE DI VINO DA FILTRARE BOTTE DI VINO FILTRATO

Pagina 8

13.ROUTINE MAINTENANCE OF THE MACHINE

•At the end of the filtration, it is absolutely necessary to remove all the residues of the filtered product and the

filtering cartons.

During every intervention on the machine, wear security gloves.

Before carrying out any operation, make sure that the machine is in stop condition and

that any hot parts have had time to cool down and that the power supply is

disconnected

• Loosen the handwheel.

• Move the thrust plate towards the handwheel and remove the filtering cartons.

• It is necessary to wash all its parts with water or neutral products for food use.

• Cold sanitization of the plates in MOPLEN is possible.

• For sterilization with steam at 120 ° C, it is necessary to request the plates in NORYL when

ordering.

13.DISPOSAL AND DISPOSAL OF THE MACHINE

•The machine must be taken out of service by disposing of it as waste characterized by INOX

components, in accordance with the relevant regulations in force in the user country. The

differentiation of materials is recommended for the purpose of facilitating the start-up of storage or

recovery processes. Regarding the disposal of FILTERED LAYERS and plates in NORYL AND

MOPLEN including rubber components (GASKETS) it is necessary to proceed separately from the

previous ones, always in accordance with the provisions in force in the country of the user.

14.TECHNICAL ASSIATANCE

•• The filter assistance service is carried out by our authorized dealers or directly by ENOTOSCANA SRL

through telephone calls or faxes to the following numbers:

Tel./Fax 0571/400474 E-mail: info@enotoscana.it

Pagina 9

15. SEARCHING OF FAILURES AND SOLUTIONS

• THE PUMP DOES NOT SUCK - Check that the rotation direction is correct. For pumps installed on the

filter, check that the pump has been filled. If you still do not aspire to check that there are no foreign bodies

inside the pump. Then, proceed with filling the pump body again.

• THE PUMP IS NOT PRESSURE - Check that there is no air in the circuit. Check that the free end of the

suction pipe is submerged. Proceed again to fill the pump body.

• EXCESSIVE DRIPPING OF THE FILTERED LAYERS - Check the correct tightening of the cartons. The

filtering cartons are not suitable and / or the gaskets are worn.

• THE FILTER DOES NOT REACH THE PRODUCTION PROVIDED - When the filter does not reach the

production expected from the table of layers, probably the type of cardboard suitable for the wine to be

filtered has not been chosen. Always consult the table.

• THE PRESSURE IS NOT SALE - Also in this case an unsuitable type of cardboard was chosen.

• DURING THE CARTOON FILTRATION THE PRODUCT STARTS TO EXIT DIRTY - This problem may be

caused by the pressure exerted on the cardboard used, which in some cases causes the fibers to open in

the filtering state, consequently the product is not filtered. The problem could also be the presence of air in

the filter circuit.

Pagina 10

16.WARRANTY

• The warranty covers the machine for the first twelve months after commissioning. In case of non-immediate

use, the warranty covers up to eighteen months from the date of delivery, and subsequently lapses.

• The warranty does not cover all the glass parts, the knobs, the fuses, the aesthetic parts and the removable

parts made of plastic materials, microswitches, solenoid valves, etc ...

• The warranty also does not cover damaged parts caused by transport, faults caused by bad or incorrect

installation or maintenance, incorrect electrical power supply, negligence, negligence, incorrect use and in

any case not in accordance with the instructions in the instruction booklet.

• The warranty also does not cover failures caused by tampering or interventions carried out by personnel

not belonging to ENOTOSCANA SRL or unauthorized by it.

• The guarantee of ENOTOSCANA SRL entitles the customer to the replacement, in the shortest possible

time, of the components or parts which, due to the bad quality of the workmanship, are found to be defective.

• The guarantee does not extend to the obligation to compensate damages to things or people deriving from

the use of our product even in case of breakage or defect.

• Conduct the immediate termination of warranty obligations, the non-fulfillment of the agreed payment

terms.

• All possible complaints must be communicated by the buyer within 8 days of purchase, in writing to

ENOTOSCANA s.r.l.

Are excluded from the guarantee:

- compensation for damages or production arrests

- transport costs

-customs duties

- import / export costs

- any other tax or expense related to the delivery to our factory of the parts under warranty and return to

destination, are charged to the customer.

- After the 12 month period from the time of shipment, the warranty will lapse and any repairs, replacements

or assistance will be made by debiting the charges according to our current rates.

- Reserve of ownership: as prev art. 1523-1524 and following of the civil code, the transfer of ownership of

the goods subject to sale will take place only after the complete payment of the agreed upon. The place of

jurisdiction for any dispute is that of Florence. Even if foreign citizens or goods supplied abroad, any dispute

is regulated by Italian law.

Cerreto Guidi (Fi)

Data ____/____/____

Il responsabile di produzione

PEPE DOMENICO

Pagina 11

17.CE DECLARATION CONFORMITY

The company ENOTOSCANA SRL with registered office in Via Provinciale Pisana, 141 - 50050 Cerreto

Guidi (Fi) - Italy as manufacturer and seller of the machine, declares under his own responsibility that the

machine has been built respecting all the prescriptions provided by:

-Direttiva macchine 2006/42/CE, recepita in Italia con D. Lgs del 27/01/2010.

-Rules CEI EN 60204-1 (1998) Security of the machinery, electric equipment of the machines.

-Rules UNI EN 292 part 1/2 (1192) Security of the machinery, important concepts, specifications and technical

principles.

-Rules UNI EN 292 part 2A1 (1995) Security of the machinery,important conceps specifications and technical

principles.

-Directive 2004/108/CE, received in Italy con D.Lgs del 09/11/2007, relative to Electromagnetic compatibility.

-Rule CEI EN 50081/1 (1997) Electromagnetic compatibility. Generic rule about the emission.

-Rule CEI EN 50082/1 (1997) Electromagnetic compatibility. Generic rule about the immunity.

-Directive 2006/95/CE, relative to " Electric material, intended to be used in some tension limits” ( Low directive

tension ).

-Dec.Leg. n°626 del 96 Rule CEI EN 60335-1 (1998) Security of electric machines domestic use or similar : Part 1 :

General rules.

SUPPLY

together with the machine referred to in this document, the Instruction and Use Manual to carry out the

operations of use, maintenance and repair without any risk.

DECLARE

to have checked and tested the machine in question for the purposes of safety and functionality, with a positive result. In

addition, all mechanical, electrical and electronic parts of the machine, if spoiled as a result of defects in materials or

constructional errors are under warranty from the date of shipment / installation / testing for the duration of 1 (one) year,

unless otherwise agreed Act of the Purchase Contract.

DECLINE

any liability for accidents to persons or property deriving from tampering with the machine by third parties and for failure

to comply with the instructions in use, maintenance and repair.

Cerreto Guidi (Fi)

Data ____/____/____

Il responsabile di produzione

PEPE DOMENICO

Pagina 12

This manual suits for next models

5

Table of contents