Envirotech Instruments APM 460 PUF User manual

OPERATION MANUAL

PUF SAMPLER

Envirotech Model APM 460 PUF

Application

•Monitoring of Polycyclic Aromatic Hydrocarbons (PAHs)

•Monitoring of Pesticides and Polychlorinated Biphenyls

(PCBs)

Envirotech Instruments Pvt. Ltd.

A-271, Okhla Industrial Area, Phase-1, New Delhi – 110020

Tel No. 011-26813887, 26814139 Fax No.011-26811833/26810591

email envirotech@vsnl.com website www.envirotechindia.com

CHAPTER I

BACKGROUND

Polycyclic Aromatic Hydrocarbons (PAHs) have been extensively studied in recent years

due to their carcinogenic properties. Benzo (a) pyrene in particular has been studied

extensively and is a proven carcinogen in this class of compounds.

PAHs are ubiquitous in environment and are known to form due to anthropogenic and

natural sources.

Common pesticides and Polychlorinated Biphenyles (PCBs) are also found in ambient air

mostly due to their extensive use in agriculture.

Measurement of PAH and PCBs in ambient air can be done by passing large volume of air

through glass micro fibre filter of a High Volume Sampler where high molecular weight long

chain PAH and PCBs associated with particulates are expected to remain on the filter.

Later filter is extracted in Soxhlet apparatus by following standard procedure and

concentration of these compounds is determined using GC-FID/HPLC/GC-MS. Often

concentration of these compounds measured in ambient air is in nanogram per meter

cube.

Results of large number of research studies where PAH and PCBs are measured in filter

dust of HVS (TSPM) and in filter dust of RDS (PM10) have shown presence of PAH &

PCBs in particulates. As a result world over measurement of PAH/PCBs are done in

particulates collected on the filter paper. Monitoring results have also shown relatively

higher concentration of these compounds in PM10 dust compared to TSPM.

In recent years it has been realized that due to volatilizing of PAH and PCBs all fractions of

these compounds are not trapped with particulates on the glass microfibre filter. It is now

known that a major portion of PAH and PCBs, especially compounds with 3-4 rings are

passed through the filter. Thus ordinary High-Volume-Respirable Dust Sampler is not

suitable for sampling of these compounds. To find out ambient concentration of total

PAH/PCBs gaseous fraction of PAH/PCBs must also be sampled in a porous extractable

media. Poly Urethane Foam is one media which is widely used for sampling of these

compounds.

TECHNICAL SPECIFICATIONS OF APM 460 PUF

Flow Rate = 200 - 300 liters/min

Particle Fractionater = A cyclone device designed for flow range of 200-

250 liter/min for fractionating dust into two

fractions. PM10 dust is accumulated on the filter

paper (8’’ x 10’’ size) while coarse dust is

collected in a cup placed under the cyclone.

Puf Cartridge = Polyurethane foam for trapping the low molecular

weight PAH and PCBs

Size: 60mm diameter length about 75mm.

Puf Housing = Housing of APM 460PUF is compatible with

Standard borosilicate glass cartridges available

from SKC or other international vendors. It is

lined with Teflon and fitted at the bottom of filter

adapter casting.

Recommended Filter = Any standard 8”x10” filter such as Whatman

GF/A or EPM 2000 for sampling of PM10 dust

where high molecular weight PAH are collected

with particulates.

Sampling Time = upto 48 hours.

Sampling Time Record = Electromechanical Time Totalizer (0 to 9999.99

hours) accurate upto 0.6 minute gives actual on

time of the sampler.

Automatic sampling time

Control = A programmable Digital Timer is used to shut off

the sampler after a preset sampling interval.

Voltage stabilizer = Input Voltage in the range 190-245V is stabilized

to an acceptable range of 230 + 10V. The

Stabilizer will automatically shut down output

power if input voltage is below 180V or above

250V so that the Blower is protected.

Power Requirements = Nominal, 220V,Single Phase, 50-Hz AC mains

supply. Power consumption is 400 watts

Overall Size = Approximately 430 x 320 x 930mm.

Weight = 45 kg.

PUF SAMPLER APM 460PUF

Envirotech India’s leading manufacturer of air quality monitoring instruments has

pioneered the development of an indigenous PUF sampler where gaseous fraction of PAH

and PCBs present in the air are trapped in a PUF cartridge fitted just below 8’’ x 10’’ glass

microfibre filter. Thus APM 460PUF Sampler is a complete system using which PAH

present in particulate as well as gaseous phase are sampled for further analysis of various

components.

While designing the APM 460PUF sampler USEPA method number TO 13A and TO 4A

have been referred and the sampler has been developed to meet most of the sampling

system requirements outlined in these two methods. Besides decades of experience of

Envirotech in manufacturing of Respirable Dust Sampler which is most suitable to Indian

conditions has been incorporated in selecting user friendly features. Some of these

features of APM 460PUF are.

1. To ensure portability of the sampler a cyclone based PM10 sampler has been

designed and the PUF cartridge has been located just below the glass microfibre

filter paper.

2. The Cyclone has been designed for required flow rate of 200-300 liters/min for

fractionating dust into two fractions. PM10 dust passes through the cyclone and

gets deposited on the filter paper while coarse dust (above 10 micron) is removed

from the air and accumulates in the cup fitted under the cyclone hopper.

3. A brushless blower with heavy duty induction motor has been developed for

required flow rates. The Blower is robust in design and can be operated for 48 hrs

continuously so that sizeable PM10 dust sample is collected on filter paper and

gaseous fraction of PAH are trapped in PUF.

4. Instrument has been fitted with voltage stabilizer, time totalizer and digital timer for

un-attended operation.

5. The APM 460PUF Sampler is fitted with orifice & manometer flow metering system

for accurate measurement of air flow.

6. The APM 460PUF Sampler is compatible with PUF cartridges from any standard

vendor such as SKC etc..

7. To simplify installation and removal of the PUF cartridge the PUF holder has been

made modular and suitable gaskets & Teflon lining provided to ensure a leak tight

unit.

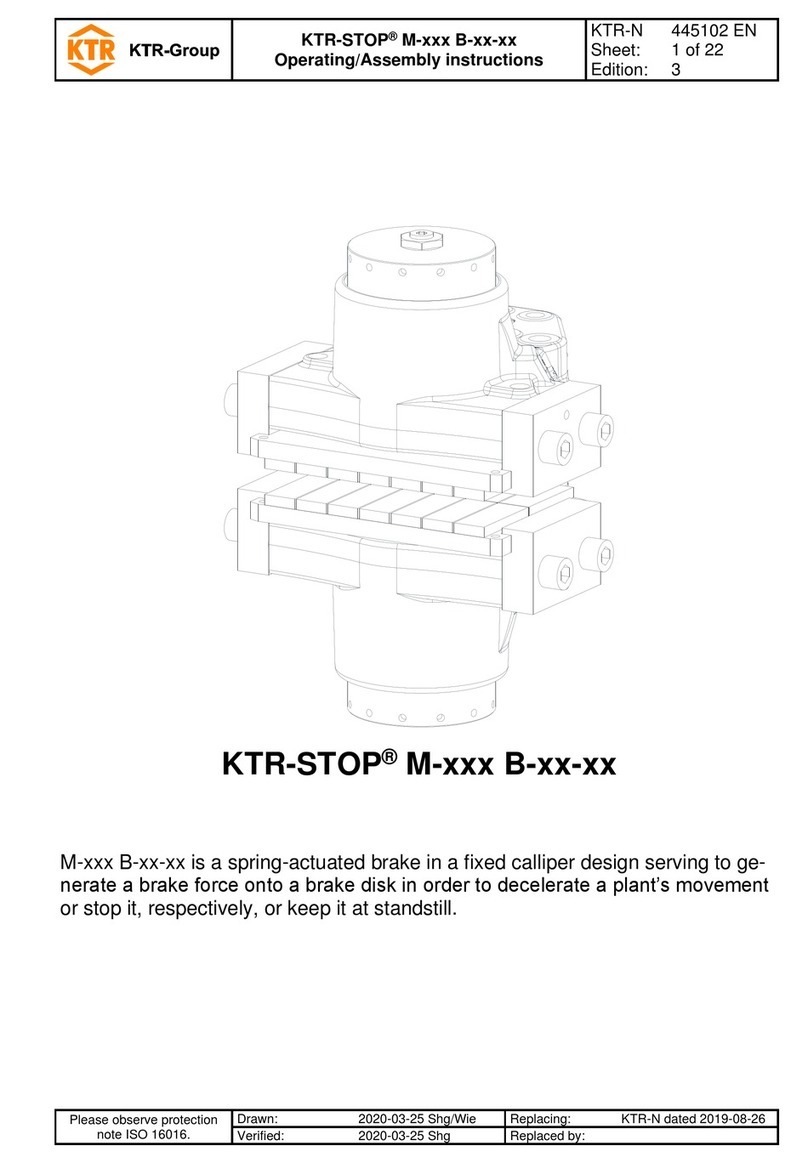

Figure 1

The figure above shows a schematic diagram of

the APM 460PUF Sampler while the photograph

shows the actual instrument.

CHAPTER II

PRINCIPLE OF OPERATION

Figure 1 shows a schematic diagram of the PUF Sampler Model APM 460PUF. Ambient

air laden with suspended particulates enters the system through the Inlet Pipe. As the air

passes through the cyclone, coarse, (non respirable dust) is separated from the air

stream by centrifugal forces acting on the solid particles. These separated particulates

fall through the cyclone‘s conical hopper and collect in the sampling bottle placed at its

bottom. The fine dust forming the Respirable Fraction (PM10) of the Total Suspended

Particulate (TSP) passes through the cyclone and is carried by the air stream to the Filter

Paper, clamped between the Top Cover and Filter Adaptor Assembly. The Respirable

Dust (PM10) is retained by the filter and particulates free gases pass through the PUF

cartridge immediately below the Filter holder assembly.

PARTICLE SIZE CUT OFF OF THE PUF SAMPLER APM 460PUF

The PUF sampler APM 460PUF has been extensively operated in parallel with reference

PM10 sampler in various climatic conditions and found giving comparable results.

Envirotech has decades of experience in manufacturing of cyclones which are fitted in

various models of the Respirable Dust Samplers since 1992. The cyclone of the PUF

sampler gives comparable PM10 values at flow rate in the range of 200-300 liters/min.

The Cyclone is made up of non-corrosive material of construction with smooth surface.

Cyclone assembly is so designed that it is easy to open for periodical cleaning purposes.

FLOW MEASUREMENT IN THE APM 460 PUF SAMPLER

The APM 460 PUF Sampler uses Envirotech‘s field proven Orifice Plate based Flow

Metering System. The design has proven its reliability through trouble-free operation of

few thousand field installations of Envirotech‘s popular APM 410/415 High Volume

Samplers and Respirable Dust Sampler model APM 451/460/460BL/460NL. The Orifice

Plate is built into the body of the Filter Adaptor Assembly just before the PUF cartridge

and there are no joints or leakage paths between the Orifice Plate and the filter. The

pressure drop across the orifice is measured by a Manometer, in which the scale is

calibrated in units of flow (m3/min). In the APM 460 PUF Sampler, the Manometer

Assembly is placed in the upper portion of the front panel assembly so that it is

convenient to read, and a reflecting tube support has been added to minimize parallax

error.

The glass tube containing the PUF cartridge is placed in a Teflon lined holder

immediately below the Filter Adaptor assembly. Suitable seal rings have been

incorporated at each joint to ensure a leak tight assembly.

MAIN PARTS AND CONTROLS

√

Refer to figure 1 and 2 to locate the controls and parts described in this

section.

Mains Input and its Fuse: The APM 460 PUF sampler requires 220 Volts AC

single phase, 50 Hz AC mains supply for operation. Mains power is

connected to the system through a three pin IEC socket provided at

the back of the instrument. An appropriate chord is provided with the

instrument. Use only a three pin AC mains socket so that earth /

ground connection of the instrument cabinet is maintained. A neon

indicator has also been provided to indicate the mains supply. An

over current cutoff has been provided to protect the system. If the

current protection trips off, you have to press the RED reset button

on the instrument panel. CAUTION: Do check the reason for over-

current tripping before re-starting the operation.

Power on/off switch :This DPST toggle switch is used to control the AC mains

power coming to the instrument.

Time Totalizer : The Time Totalizer is wired to operate only if the Blower, drawing

air through the sampler, is in operation. Therefore it records the

actual duration of each sample and can also be utilized to keep track

of preventive maintenance schedules of the instrument.

Digital Timer : The Timer is provided to shut off the instrument after pre set time.

The Digital Timer provided in APM 460PUF allows a user to

automatically control ON/OFF cycles. The equipment will

automatically start up or shutdown as per the program fed into the

timer. Details of operation of the timer are given in Chapter IV

Voltage Stabilizer: A voltage stabilizer is fitted in the instrument to control

supplies of input power within acceptable range 230 +10V. The

Stabilizer has 4 step input voltage control to give indicated out put

voltage. It has an inbuilt cut-off that will shut down the instrument at

too high or too low mains voltage. CAUTION: Operating the

instrument at too low (below 180V) and too high (above 250V) mains

voltage by bypassing the voltage stabilizer is likely to damage the

Blower Motor.

Top Cover : This is a single piece casting, filter Cover with provision of clamps for

fitting of the filter for collecting the Pm10 fraction.

Cyclone : This unit separates the coarse particulates from the air stream. This

coarse fraction gets accumulated in the sampling bottle placed under

the hopper assembly of cyclone while fine dust (PM10) passes

through the cyclone and is collected on the filter paper. The sampling

bottle MUST be emptied and cleaned after every run.

CHAPTER III

INSTALLATION AND PREPARATION FOR USE

The APM 460PUF Sampler is dispatched from the factory pretested and fully assembled. For

safe transit the Air Inlet Pipe is dismantled and has to be reassembled before the sampler can be

put to use.

ATTACHING THE AIR INLET PIPE

The Air Inlet Pipe is attached to the cyclone inlet by four socket head cap screws. An appropriate

Allen Key has been provided in the tool-kit of the instrument. Unscrew the retaining bolts, apply

some silicone grease on the faceplate gasket and fix the inlet pipe taking care to tighten the

retaining bolts uniformly. Mount the yellow color Inlet Cover Cap on the top of the inlet pipe.

Attention: Do not over tighten the retaining screws. It may damage the rubber

gasket of the inlet pipe bend.

PREPARING THE MANOMETER

The Manometer Assembly is provided to accurately measure the pressure drop across

the Orifice Plate fitted in the filter adaptor casting and its scale is graduated to read

directly the flow rate of air in meter cube per min. The manometer scale is not linear and

it is important to carefully zero the level of the liquid column prior to use.

The Manometer uses distilled water as a manometer fluid and a Filling Plug is provided

to allow topping up of the manometer fluid. A syringe with a needle has been provided in

the tool kit to facilitate filling of the fluid.

Use the following steps in sequence to top-up the manometer:

Open the Filling Plug Screw

Use the syringe to squirt approximately 16cc of water into the filling plug.

Cover the filling plug aperture with a finger and switch ON the Blower for a few

seconds (shutting it off immediately). The liquid column will oscillate up and down

in the manometer tube. Check that no air bubbles are trapped in the liquid column.

Allow the water column to settle down and check that the lower level of the

meniscus is at the zero mark of the scale. If necessary, add a few more drops of

water and repeat for above step to remove air bubbles.

When the water level has reached the zero mark, replace the filling plug screw

and tighten it in place.

Finer adjustment of zero adjustment can also be done by shifting the

manometer scale up or down.

CAUTION:

Fill a small quantity of water into the manometer at each step for making upto zero

mark as it is much more inconvenient to remove the extra fluid if the water level goes

beyond the zero level. Therefore fill it slowly and carefully.

In case, water level has gone above zero level, excess water has to

be taken out. It is recommended to flush out all water from the tank

after removing PVC pipe connections of the manometer to pressure

taps of orifice plate.

Hold the PVC tube, connected to glass tube, and blow air in PVC

tube connected to manometer tank, to drain all water from the tank. Ensure

that filling port is closed while this operation otherwise all water will

come out from filling port.

Now connect PVC tubes, again to pressure taps in correct polarity

PVC pipe of glass tube must be connected to lower pressure tap and the

PVC tube connected to manometer tank nozzle is connected to upper

pressure tap. Open the filling plug and fill up manometer fluid with the help of

syringe as described in above steps.

PREPARING THE FILTER

The respirable dust concentration is determined by a gravimetric analysis, requiring an

accurate estimation of the change in weight of the filter on account of the dust deposited

on it. As such, handling of the filter paper must be minimized and care should be taken

that the paper does not get sheared or damaged during handling.

Almost all the filter papers in use for High Volume Samplers are made of binder free

glass fibers and are expected to be non-hygroscopic. However, dust deposited on the

filter could be Hygroscopic. As such it is important to condition the filters prior to their

weighment. For conditioning the filters may be placed in a Desiccator where active

desiccant silica gel is kept. Normally filters should be conditioned at 25 deg C and 35%

Humidity for at least 16 hours both for initial weighment and after sample collection.

Check the following points during filter preparation:

Check for Pinholes: Inspect the filters against a bright lamp or light for

pinholes and micro-cracks.

Numbering: In case the filters are not pre-numbered, put identification

numbers on a corner of the underside of each filter.

Conditioning: Place the filter papers in a desiccator or conditioning room for

at least 16 hours to remove traces of moisture. Weigh the filters immediately

after they are taken out of the desiccator.

Attention: Ensure that your desiccator is having active desiccant

Silicagel.

Storage: Store the filters without folding the paper in a clean flat box.

Handling: Since the filter paper is binder-free, it is quite fragile. During

weighment and handling prior to sampling, do not fold the paper to form a

crease.

PREPARATION AND INSTALLATION OF PUF CARTRIDGE

PUF cartridge is to be

thoroughly cleaned prior to

use to remove any traces of

PAH or PCBs from previous

runs. For cleaning the PUF

cartridge follow the procedure

specified in standard test

methods such as EPA TO13

and after cleaning it should be

placed inside the glass tube.

Ensure that SS wire mesh is

placed at the bottom of glass

tube and rests on notch of the

tube. This loaded glass tube

with cartridge should be

placed inside the Teflon PUF holder and properly tightened with the help of

retainer Teflon ring. Tighten the PUF Holder assembly between the blower

and the filter adopter using the knurled rings. The PUF cartridge is re-

useable after extraction in Soxhlet apparatus for 12-16 hrs or as specified in

the test method. Detailed procedure of PUF cleaning and preparation is

given in standard USEPA method TO 13.

Precautions:

•Do not touch the PUF cartridge with bare hands. Handle only the

glass PUF holder from outside.

•During transit, cover the PUF holder with Aluminum foil and place it in

the glass jar provided with the instrument.

•Avoid installation of the PUF cartridge into the Glass holder in the field

as it is likely to get contaminated. A spare PUF holder has been

provided with the APM 460PUF sampler so that the PUF cartridge can

be loaded in the glass holder in a clean lab environment.

INSTALLING THE FILTER ON THE APM 460 PUF

The filter paper is mounted on the backing screen at the top of the Filter Adaptor

Assembly. The filter is clamped down by the top cover held in place by the four

wing nuts.

To mount the filter follow the steps below:

Loosen the four wing nuts and open the top cover.

Check that the filter clamping gasket and backing screen are clean.

Place the filter sheet on the backing screen taking care to ensure that it is

centralized.

The top cover is polarized, and fitted on the top of sampler with the help of two

non sliding wing nuts. Align the mounting slots to the eyebolts and gently lower it

on the filter adaptor pressing down the filter paper. Avoid repositioning the cover

since it is likely to shift the filter from its original position on the backing screen.

Uniformly tighten the cross wing nuts maintaining almost equal pressure on all

sides of the cover.

CHAPTER IV

OPERATION

Check that the following preparatory steps have been completed before starting up the

instrument:

•A pre-weighed filter has been installed in

the Filter holder.

•A fresh / clean PUF cartridge has been

loaded in the PUF Holder and the PUF

holder has been placed at its location

between the Filter Adaptor and Blower

Assembly.

•Check that the PUF Holder is positioned

centrally in the knurled rings and the rings

are tight – hand tightening is adequate.

•Check that distilled water is filled upto the

zero mark of the Manometer scale.

•Mains power is available to the instrument.

Open the door of the instrument and note the INITIAL Reading of the TIME TOTALIZER.

Note the digits display the operation time in HOURS (upto 2 places of decimal). So if the

reading is 1254.23 DO NOT interpret it as 1254 hours and 23 minutes.

Put the Main Power Switch on the Panel of the instrument ON. The Blower motor will come

ON with an audible sound. The manometer will indicate the flow rate of air through the

instrument. Allow the flow rate to stabilize for a few minutes and note down the flow rate in

Cubic Meters per minute. Close the door and leave the Sampler operating for the desired

sampling duration.

At the end of this time check and note down the Manometer reading to confirm the flow

rate prevailing at the end of sample collection. Switch OFF mains power and record the

FINAL TIME TOTALIZER reading. The difference between the final and initial reading will

give you the correct amount of time in HOURS that the instrument has operated.

Open the Filter Holder Cover and carefully remove the Filter paper. Note the filter should

be folded inwards to ensure that the sample is protected when you place the filter in a

carrying envelope. Open the PUF Holder and remove the PUF Cartridge including the

glass PUF Carrier tube. Immediately cover the Glass tube with clean Aluminum foil and

store in a safe container for transit to the lab for analysis.

The procedure above describes the steps to be taken for a manually supervised operation

of the instrument. A small degree of automation to facilitate startup and shut down of the

instrument is available via the Timer provided on the front panel.

CHAPTER VI

MAINTAINANCE

The APM 460 PUF Sampler haa few moving parts that would require maintenance. The

flow metering is performed by a completely static orifice plate assembly requiring no

regular attention. However, for trouble free operation, the manometer assembly used to

indicate the flow rate and the blower causing the suction must be periodically cleaned only

distilled water should be used as manometer fluid.

PREVENTIVE MAINTENANCE OF THE BLOWER ASSEMBLY

The Blower used to sample air through the instrument in driven by a belt coupled ½hp

motor. The unit has been designed for trouble free operation over extended periods of

time. However, as the prime-mover of the system it will have the most wear and tear and

for optimum performance must be inspected at regular intervals as per schedule given

below.

After every 1000 hrs of operation the condition of belt slack should be checked.

If belt is loose than shift the motor with the help of mounting bolts and adjust the

tension so that the belt slack remains in normal / safe range. If noise level

increases with time it is often because of a loose belt.

Due to the high Blower RPM some amount of belt wear is normal and can be

expected. During belt inspection if you observe excessive shredding of the belt

and powder form of rubber deposits on the inside portions of the unit it would be

best to replace the belt. Normal life of the belt is one year or 3500 hrs operation.

A new belt will show slight elongation after the first 24 hrs of operation so you

should check the belt tension after 24 hrs. of changing the belt only once.

CAUTION

Do not delay replacement of the belt until it is completely worn and finally breaks. This will

disrupt the sample being collected. When the belt breaks and can also cause damage to

your instrument. The time totalizer reading can be conveniently utilized to determine when

the belt is due for check-up or replacement.

MAINTENANCE OF THE MANOMETER ASSEMBLY :

The manometer assembly uses distilled water as a manometer fluid. With time the water

acquires residues and floating precipitate forms are seen which tends to clog the nozzles

connecting the manometer tank to the manometer tube. To remove the precipitate and

other deposits the manometer must be flushed out periodically (at least once in a month).

If the instrument is not expected to remain in use for two weeks or more it is recommended

that the water be drained out from the manometer tank to avoid formation of the

precipitate. To flush and clean the manometer assembly follow the steps given below:

Observe the polarity of the PVC pipes connecting the manometer to the pressure

taps of the Orifice Plate. The glass tube of the manometer is connected to the lower

nozzle while the manometer tank is connected to the upper nozzle of the filter

adaptor casting. Remove both the PVC pipes from the orifice plate pressure taps.

Hold the pipe from the glass tube pointing downwards and away from the

instrument and blow into one pipe connected to the tank. The old water residues will

be drained from the system.

Refill the manometer with fresh distilled water (through the filling plug) and drain it

as above. Repeat the process 2-3 times to thoroughly flush out any residues.

Re-connect the PVC pipes to their respective places on the filter adaptor casting

and fill fresh distilled water prior to use of the instrument.

REPLACING A BROKEN MANOMETER TUBE

Occasionally the Glass Manometer tube will get damaged in transit and must be replaced.

To change the tube follow the steps given below.

Open the four retaining screws to remove the front panel of the instrument.

Observe the polarity of the PVC pipes connecting the manometer to the

pressure taps of the Orifice Plate. The glass tube of the manometer is connected

to the lower nozzle while the manometer tank is connected to the upper nozzle

of the filter adaptor casting. Remove both the PVC pipes form the orifice plate

pressure taps.

Open the two screws retaining the upper end coupling of the manometer tube.

The two screws near the bottom of the tube retain the tank assembly. On

removing the tank assembly and upper coupling the tube support will open out

and the manometer tube will come out.

Check that the seal rings rubber (O-rings) in the upper coupling and tank

opening are in place.

Apply a little silicone grease on the ends of the Manometer tube and insert one

end firmly in the tank assembly and the other into the upper coupling.

Place the tube support reflector behind the manometer tube and mount the

assembly at its place on the front panel.

Re-connect the PVC tubes connecting the manometer assembly to the pressure

taps of the Orifice plate.

Mount the front plate on the main instrument and re-fill manometer fluid into the

system as per instructions in chapter III of this manual.

Note:-

1. No warranty is given on parts made up of Glass.

2. Warranty is also not applicable for moving parts that are expected to wear

and tear with normal operation such as Blower, Bearing and Belt etc.

Table of contents