Standa 8SMC1-USBhF User manual

8SMC1-USBhF

1.5A Microstep Driver with USB Interface

User Manual

Note: Information in this manual is believed to be accurate and reliable. However no responsibility is assumed

for the consequences of its use or for any infringement of patents or other right of third parties which may

result from it use. Specifications are subject to change without notice.

Note: Windows are registered trademark of Microsoft Corporation, LabVieW and NI VISA is registered

trademark of National Instruments Inc. All other products and corporate names appearing in this manual may

or may not be registered or copyrights of their respective companies, and are used only for identification or

explanation and to the owner’s benefit, without intent to infringe.

1/14/2008 www.standa.lt Page 1 of 83

Index

1General information........................................................................................................................5

1.1 Features ...................................................................................................................................5

1.2 Description...............................................................................................................................5

1.3 Applications..............................................................................................................................6

1.4 Compatibility............................................................................................................................6

1.4.1 Connectivity .....................................................................................................................6

1.4.2 Stepper motors ...............................................................................................................6

1.5 Warranty ..................................................................................................................................6

2Functional description ....................................................................................................................7

2.1 Board overview .......................................................................................................................7

2.2 External connections ............................................................................................................10

2.2.1 Power..............................................................................................................................10

2.2.1.1 USB Powered logic mode.....................................................................................10

2.2.1.2 5V DC powered logic mode.................................................................................11

2.2.1.3 Single 7-12V DC power supply mode ................................................................11

2.2.1.4 Double power supply mode ................................................................................12

2.2.2 Stepper motor connection...........................................................................................12

2.2.3 Connection of external sensors ..................................................................................13

2.2.4 Limit switches................................................................................................................14

2.2.5 Emergency Stop switch................................................................................................15

2.2.6 Revolution sensor .........................................................................................................15

2.2.7 Encoder ..........................................................................................................................16

2.2.8 Synchronization Out .....................................................................................................18

2.2.9 Synchronization In........................................................................................................18

2.2.10 Manual control knobs...................................................................................................19

2.2.11 Local indication LEDs ...................................................................................................19

2.2.12 USB In/Out.....................................................................................................................20

3Specifications.................................................................................................................................21

3.1 Electrical.................................................................................................................................21

3.2 Motion.....................................................................................................................................21

3.3 Remote control......................................................................................................................21

3.4 Mechanical .............................................................................................................................22

3.5 Wiring diagram......................................................................................................................23

3.5.1 Wiring diagram for multi-purpose 40 pin connector ...............................................23

3.5.2 Wiring diagram for Stepper motor connector ..........................................................24

3.6 EMC.........................................................................................................................................24

4Installation .....................................................................................................................................25

4.1 Software installation.............................................................................................................25

4.1.1 SMCVieW installation....................................................................................................25

4.1.2 MicroSMC driver installation........................................................................................27

4.1.3 MicroSMC for WM installation .....................................................................................30

4.2 Hardware installation ...........................................................................................................34

4.2.1 Current sense resistors ................................................................................................34

4.3 First start on Windows XP ...................................................................................................35

4.4 First start on Windows Vista ...............................................................................................37

4.5 Switching between NI VISA and MicroSMC drivers on Windows XP ............................38

4.6 Switching between NI VISA and MicroSMC drivers on Windows Vista ........................40

1/14/2008 www.standa.lt Page 2 of 83

4.7 Known USB driver installation problems ...........................................................................44

5Application SMCVieW ...................................................................................................................46

5.1 General information..............................................................................................................46

5.2 Main screen............................................................................................................................46

5.2.1 General view..................................................................................................................46

5.2.2 Positioners and axes names........................................................................................47

5.2.3 Current and Destination positions..............................................................................47

5.2.4 Speed and precision .....................................................................................................48

5.2.5 Status and power..........................................................................................................48

5.2.6 Position slider ................................................................................................................48

5.2.7 Reset and standoff .......................................................................................................49

5.3 Main menu .............................................................................................................................49

5.4 Setup ......................................................................................................................................50

5.4.1 Buttons ...........................................................................................................................50

5.4.2 Positioner .......................................................................................................................50

5.4.3 Positioner -> Picture ....................................................................................................51

5.4.4 Positioner -> Wiring .....................................................................................................51

5.4.5 Controller identifier.......................................................................................................52

5.4.6 Power management .....................................................................................................52

5.4.7 Manual control...............................................................................................................53

5.4.8 Manual control -> Acceleration Curve.......................................................................54

5.4.9 Reset and Standoff.......................................................................................................54

5.4.10 Limit switches................................................................................................................55

5.4.11 Revolution sensor .........................................................................................................55

5.4.12 Encoder ..........................................................................................................................56

5.4.13 Synchronization.............................................................................................................57

5.4.14 Calibration......................................................................................................................58

5.4.15 Backlash compensation................................................................................................59

5.4.16 Acceleration ...................................................................................................................60

5.4.17 Safety..............................................................................................................................60

6VI’s library......................................................................................................................................62

6.1 General information..............................................................................................................62

6.1.1 Find Devices (uSMC) ....................................................................................................63

6.1.2 Initialize All Structures .................................................................................................63

6.1.3 Set Current Position (uSMC) .......................................................................................63

6.1.4 Set Mode (uSMC)..........................................................................................................63

6.1.5 Set Parameters (uSMC) ...............................................................................................63

6.1.6 Save Parameters to Flash (uSMC)..............................................................................63

6.1.7 Get Serial (uSMC) .........................................................................................................63

6.1.8 Get State (uSMC)..........................................................................................................63

6.1.9 Get Version (uSMC)......................................................................................................64

6.1.10 Start (uSMC)..................................................................................................................64

6.1.11 Stop (uSMC) ..................................................................................................................64

6.1.12 Load Profile (uSMC)......................................................................................................64

6.1.13 Update Speed Ctl (uSMC)............................................................................................64

6.2 Structures...............................................................................................................................64

6.2.1 Mode ...............................................................................................................................64

6.2.2 Parameters.....................................................................................................................65

6.2.3 State................................................................................................................................67

6.2.4 StartPlus .........................................................................................................................67

1/14/2008 www.standa.lt Page 3 of 83

6.2.5 Position...........................................................................................................................69

6.3 Examples................................................................................................................................69

7Dynamic link library USMCDLL.dll for Win2000/XP .................................................................70

7.1 New version information......................................................................................................70

7.2 General information..............................................................................................................70

7.3 File list ....................................................................................................................................70

7.4 MicroSMC.exe ........................................................................................................................71

7.5 Functions................................................................................................................................71

7.5.1 General information......................................................................................................71

7.5.2 Functions list..................................................................................................................71

7.5.3 USMC_Init ......................................................................................................................72

7.5.4 USMC_GetState.............................................................................................................72

7.5.5 USMC_SaveParametersToFlash ..................................................................................73

7.5.6 USMC_GetMode ............................................................................................................73

7.5.7 USMC_SetMode.............................................................................................................74

7.5.8 USMC_GetParameters ..................................................................................................74

7.5.9 USMC_SetParameters ..................................................................................................75

7.5.10 USMC_GetStartParameters..........................................................................................75

7.5.11 USMC_Start....................................................................................................................76

7.5.12 USMC_Stop ....................................................................................................................76

7.5.13 USMC_SetCurrentPosition ...........................................................................................77

7.5.14 USMC_GetEncoderState...............................................................................................78

7.5.15 USMC_GetLastErr..........................................................................................................78

7.5.16 USMC_Close...................................................................................................................79

7.6 Structures...............................................................................................................................79

7.6.1 USMC_Devices...............................................................................................................79

7.6.2 USMC_Parameters ........................................................................................................79

7.6.3 USMC_StartParameters................................................................................................80

7.6.4 USMC_Mode...................................................................................................................80

7.6.5 USMC_State ...................................................................................................................81

7.6.6 USMC_EncoderState.....................................................................................................81

7.7 Examples................................................................................................................................81

7.7.1 C++ example ................................................................................................................81

8Dynamic link library USMCDLL.dll for WM ................................................................................82

8.1 General information..............................................................................................................82

8.2 File list ....................................................................................................................................82

8.2.1 Host PC files...................................................................................................................82

8.2.2 Mobile device files.........................................................................................................82

8.3 Functions................................................................................................................................83

8.4 Test Applications...................................................................................................................83

8.5 Examples................................................................................................................................83

8.5.1 C++ example ................................................................................................................83

1/14/2008 www.standa.lt Page 4 of 83

1General information

1.1 Features

Electrical

Average current per phase of stepping motor up to 1.5A

Short circuit, overcurrent, overvoltage and temperature protections

Screw mounted and easy to change current sense resistors

Multi-purpose 40 pin connector for embedded applications

A number of additional connectors (15 pin D-Sub, USB type A, 2x USB type B, DC input) for

stand alone applications

Different ways of power supply, including single power, dual power and USB power (last for

8SMC1-USBhF logic only)

Motion

Resolution: full step, 1/2, 1/4,

1/8

Speed up to 5000 steps/s

Programmable speed and trip

points

Programmable accel and decel

ramps

Soft start/stop mode

Synchronization I/O

Control

Two knobs and three LEDs for

manual control and local

indication

Two programmable limit

switches and emergency stop

switch

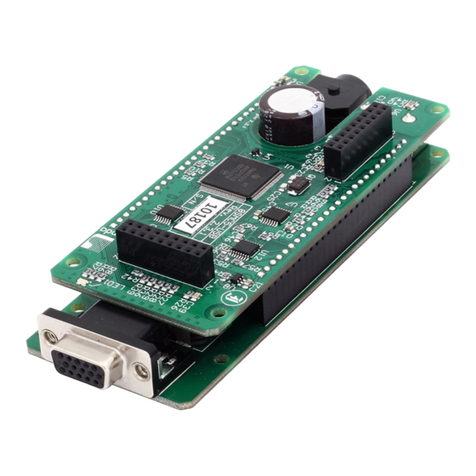

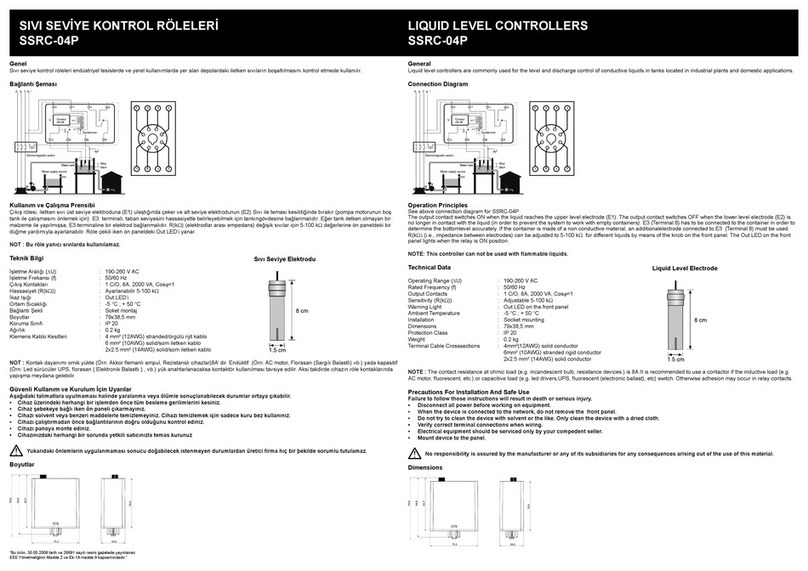

Figure 1. 8SMC1-USBhF

Quadrature encoder or

revolution sensor support

Remote control via USB 1.1

interface (up to 12 Mbps)

Embedded 3-port USB Hub, two USB ports are free for other USB device connections

Graphical user interface for Windows 2000/XP/Vista

Drivers and dynamic link library for Windows 2000/XP/Vista/Mobile host programming

Set of virtual instruments for National Instruments LabVieW

1.2 Description

The 8SMC1-USBhF controller is designed to drive one bipolar stepping motor by local

and/or remote means. Local control and indication are implemented by two knobs and three

LEDs. Remote control and monitoring are implemented via USB interface from PC. Inputs for

two limit switches, emergency switch and revolution sensor are provided.

The 8SMC1-USBhF incorporates PWM chopper type sinusoidal micro step bipolar

stepping motor driver, fully integrated mixed-signal System-on-a-Chip MCU, USB controller

1/14/2008 www.standa.lt Page 5 of 83

and 3-port USB hub on one board. Rated current for each stepping motor is set by selection

of two current sense resistors. The latter are screw mounted and easy to change. Sufficient

set of resistors is supplied with 8SMC1-USBhF. Controller features include built in over

temperature, over voltage, short circuit and reverse supply protections. There is a potential

of 40% current reduction in hold mode. In order to improve the high speed performance and

to reduce heating separate supply for logic and stepping motor can be used. Logic of 8SMC1-

USBhF can be powered by three different ways: directly from USB, from external +5V DC

power supply, from external 7-12V power supply. Emergency stop switch for unconditional

stepping motor power down is available. It may be utilized when safety is necessary. There

are two ways of communication to 8SMC1-USBhF board: by multi-purpose 40 pin connector

(convenient for embedded applications) or by a number of special additional connectors (15

pin D-Sub for stepping motor, USB type A as USB input, 2x USB type B as USB outputs, DC

input for stepper motor power supply). Embedded 3-port USB hub allows cascading of the

8SMC1-USBhF boards: it possible to connect 8SMC1-USBhF board to each of two free

downstream USB ports on another 8SMC1-USBhF board. Thus, it is possible to connect up to

30 devices per USB host controller in tree-like structure without any additional USB hubs.

The built-in powerful MCU on the 8SMC1-USBhF allows the user, via USB interface, to

control parameters such as position, acceleration/deceleration ramps, velocity, direction,

resolution, drive current, etc., to form simple or complex motions. Most of all commands are

executed on-the-fly. All parameters can be saved on PC or in MCU flash memory. The

8SMC1-USBhF has a variety of built-in functions, including local control, programmable limit

switch inputs, homing algorithm, quadrature encoder or revolution sensor support, additional

input/output for synchronization.

Thus 8SMC1-USBhF is compact, all-in-one, low cost microstep stepping motor driver

with high functionality and modern USB interface.

1.3 Applications

Controller can be used to drive any motorizes devices if their stepper motor parameters

match specifications for 8SMC1-USBhF.

1.4 Compatibility

1.4.1 Connectivity

Controller is designed to work with IBM AT compatible computer systems (with

Pentium or better processors) with Microsoft Windows 2000/XP/Vista operation systems or

mobile devices with Microsoft Windows Mobile 5.0 and higher. Only presence a USB host port

on your host device is necessary.

1.4.2 Stepper motors

Controller can operate with stepper motors according to the technical specification and

wiring requirements. Maximum allowable average phase current is 1.5A, rated voltage is 40V.

1.5 Warranty

Producer warrants the controller card 8SMC1-USBhF for the period of 1 year from the

date of sale.

1/14/2008 www.standa.lt Page 6 of 83

2Functional description

2.1 Board overview

Appearance of the 8SMC1-USBhF printed circuit board is shown on Figure 2.

Figure 2. Appearance of 8SMC1-USBhF printed circuit board

Power driver

- Sinusoidal micro step bipolar stepping motor driver. It

controls the stepper motor.

Warning: The Power driver IC fin (rear) is electrically connected to the rear of the

chip. When current flows to the fin, the Power driver IC malfunctions. If there is any

possibility of a voltage being generated between the ground of the 8SMC1-USBhF and the

fin, either ground the fin or insulate it.

Warning: There are appreciable power dissipation on Power driver (up to 6 W

depending on input voltage and rated current of stepper motor). Appropriate heatsink must

be used to maintain temperature range. Heating the Power driver over 85 oC is forbidden!

USB hub

- This chip provides one upstream port and three

downstream ports in compliance with the USB version 1.1 specification. Ports support both

full-speed and low-speed devices by automatically setting the flow rate according to the

speed of the device attached to the ports. Upstream port is wired to

USB In

and

P1

connectors and used for connections with computer or higher USB hub. One of downstream

ports is wired to

MCU

.

MCU

- Full Speed USB, 16K ISP FLASH Microcontroller. This chip

provide interface between computer and stepper motor. It keeps all current data about

stepper motor state and sends it to computer on demand.

1/14/2008 www.standa.lt Page 7 of 83

USB Out

- Two USB type A connectors are placed on the rear of

8SMC1-USBhF printed circuit board. It allows the connection of other USB devices or lower

USB hubs.

JP1

- Enable/Disable Emergency stop switch jumper, see Figure

3

and Figure 4.

Figure 3. Emergency stop switch Enabled Figure 4. Emergency stop switch Disabled

USB In

- USB type B connector is placed on the front of 8SMC1-

USBhF printed circuit board. It is used for connections with computer or higher USB hub.

Stepper motor connector

- This 15 pin D-Sub (female) connector is used for

connection of 8SMC1-USBhF device to stepper motor. All additional wiring (limit switches,

emergency limit switch, revolution sensor and corresponding power supply) is included in this

connector too. Dimensions of stepper motor connector see on Figure 5. For more information

see 2.2.2.

Figure 5. Stepper motor connector: dimensions and pinout

Current sense resistors

- Pair of current sense resistors is necessary to keep correct

rated current on windings of stepper motor. Resistors are screw mounted and easy to

change. Sufficient set of resistors is supplied with 8SMC1-USBhF.

Warning: Current sense resistors must be chosen for every stepper motor according to

its rated current and connection diagram. For more details see 4.2.1. of User Manual. Wrong

current sense resistors can cause the malfunction of 8SMC1-USBhF or damage stepper

motor.

Voltage regulator

- It is used for supply board logic when external 7-12V

power supply for logic is used (for more details see 2.2.1).

Warning: There is some power dissipation on Voltage regulator (up to 0.5 W

depending on input voltage). Appropriate heatsink may be required. Heating the Voltage

regulator over 85 oC is forbidden!

JP2

- Board logic power supply jumper. A way of logic power

supply is determined by this jumper. There are three different ways: directly from USB (as

1/14/2008 www.standa.lt Page 8 of 83

shown on Figure 6), from external +5V stabilized DC power supply (as shown on Figure 7),

from external 7-12V unstabilized DC power supply (as shown on Figure 8).

Figure 6. USB

powered board logic

Figure 7. Board logic powered

by 5V DC power supply

Figure 8. Board logic powered

by 7-12V power supply

Note: If you want to change the power logic jumper position make the following steps:

Turn the power of 8SMC1-USBhF board OFF, unplug the USB In connector, change the JP2

position, turn the power of 8SMC1-USBhF board ON and plug USB In connector back.

Don’t change the JP2 position when USB cable is plugged because it can entail

some mistakes in USB root hub operation.

Connector P1

- Multi-purpose 40 pin connector. All other connectors (USB

In, USB Out, Stepper motor connector and Power In) are duplicated here. This connector is

designed for embedded applications. Only one standard ribbon cable required for all

connections by P1. Connector P1 Pin assignment is shown on Figure 9. Dimensions are

shown on Figure 10.

Figure 9. Connector P1. Pinout

Figure 10. Connector P1. Dimensions.

Note: Some specific contacts (LEDs and knobs for manual control, for example) are only

on connector P1.

Power In

- Low-voltage power socket. 7-40V power input for stepper

motor only or 7-12V power input for stepper motor and board logic. Operating mode is

determined by JP2 and Connector P1.

1/14/2008 www.standa.lt Page 9 of 83

Figure 11. Power In connector. Dimensions. Figure 12. Power In connector. Pinout.

Dimensions are shown on Figure 11. Contacts appointment is shown on Figure 12.

Outside contact has 6,3 mm diameter. It is Ground. Central contact has a 2,0 mm diameter.

It is a positive contact for 7-40V stabilized DC power supply connection.

2.2 External connections

2.2.1 Power

8SMC1-USBhF board allows several different ways of power supply connections. They are

shown on Table 1.

Stepper motor supply

Powered by 7-12V DC Powered by 7-40V DC

USB Powered logic modeUSB powered , for details see 2.2.1.1

5V DC powered logic modePowered by 5V DC , for details see 2.2.1.2

Logic

supply Single 7-12V DC power

supply mode, for details

see

Double power supply

mode, for details seePowered by 7-12V DC

2.2.1.3 2.2.1.4

Table 1. 8SMC1-USBhF power supply modes

Warning: 8SMC1-USBhF power supply must never exceed 40V. Power driver can be

damaged if such exceeding happened.

Note: Exact current consumption from external 7-40V DC power supply for stepper motor

supplying purposes depends on stepper motor rated current and voltage. It is recommended

that rated current and voltage loading of this DC power supply exceed the stepper motor

rated current and voltage. It is true for all ways of power supply connection.

Let’s examine this table more accurately.

2.2.1.1 USB Powered logic mode

In this case logic of 8SMC1-USBhF board is powered by USB; stepper motor is powered

by external 7-40V stabilized DC power supply. Connection diagram for Power In is shown on

Figure 12, for multi-purpose 40 pin connector P1 on Figure 13. Correct position of board logic

power supply jumper (JP2) is shown on Figure 6.

1/14/2008 www.standa.lt Page 10 of 83

Figure 13. Connection of 7-40V stabilized DC power supply to P2 connector

Note: In this mode 8SMC1-USBhF requires 80 mA from USB. Make sure that feeding USB

hub can provide this current.

Note: Almost all active USB hubs (include USB root hubs) provide 500 mA power supply

that is sufficient for five 8SMC1-USBhF devices.

2.2.1.2 5V DC powered logic mode

In this case logic of 8SMC1-USBhF board is powered by external stabilized +5V DC

power supply; stepper motor is powered by external 7-40V stabilized DC power supply.

Correct position of board logic power supply jumper (JP2) is shown on Figure 7. Connection

diagram for multi-purpose 40 pin connector P1 is shown on Figure 14.

Figure 14. Power supply connection to P2 connector in +5V DC powered logic mode

Note: In this mode 8SMC1-USBhF requires 80 mA from external stabilized +5V DC power

supply. Make sure that external stabilized +5V DC power supply can provide this current.

2.2.1.3 Single 7-12V DC power supply mode

In this case logic of 8SMC1-USBhF board and stepper motor is powered by single 7-12V

DC power supply. Correct position of board logic power supply jumper (JP2) is shown on

Figure 8. Connection diagram for powering through multi-purpose 40 pin connector P1 is

shown on Figure 15. Connection diagram for powering through Power In connector is shown

on Figure 12. In the last case pins 1 and 3 of multi-purpose 40 pin connector P1 must be

connected together by jumper or other way as shown on Figure 16.

1/14/2008 www.standa.lt Page 11 of 83

Figure 15. Power supply connection to P2 connector in single 7-12V DC power supply mode

Figure 16. Pin 1 and 3 connection in single 7-12V DC power supply mode

Warning: If a single power supply mode is used, make sure that input voltage is not

exceeding 12V. Otherwise the overheating of the Voltage regulator may happen. Heating the

Voltage regulator over 85 oC is forbidden!

2.2.1.4 Double power supply mode

In this case logic of 8SMC1-USBhF board is powered by external 7-12V DC power

supply; stepper motor is powered by external 7-40V stabilized DC power supply. Correct

position of board logic power supply jumper (JP2) is shown on Figure 8. Connection diagram

for multi-purpose 40 pin connector P1 is shown on Figure 17.

Figure 17. Power supply connection to P2 connector in double power supply mode

2.2.2 Stepper motor connection

There are two ways of stepper motor connections: by Stepper Motor Connector (see

Figure 19) or by multi-purpose 40 pin connector P1 (see Figure 18).

Figure 18. Stepper Motor Connection to multi-purpose 40 pin connector P1

1/14/2008 www.standa.lt Page 12 of 83

Figure 19. Stepper Motor Connection to Stepper Motor Connector

Warning: Make sure that there are no contact between stepping motor phase windings

and 8SMC1-USBhF ground. Power driver will be damaged obligatory if such grounding

present.

Warning: You must never connect to, or disconnect from the 8SMC1-USBhF any

stepping motors while the controller keeps currents in the motor windings. Power driver can

be damaged if such reconnection happened.

2.2.3 Connection of external sensors

All external sensors (limit switches, emergency limit switch, revolution sensor and knobs)

are connected to 8SMC1-USBhF by the same way. There are several different possibilities of

connection for every sensor. Farther we examine these possibilities more accurately.

Electrically external sensors may be a dry contact type or phototransistor based. All

inputs have an internal weak pull up to 3.3V. Open circuit correspond to high level on input,

closed to ground circuit correspond to low level on input. Controller inputs are marked on

Figure 20, Figure 21, Figure 22, Figure 23 and Figure 24 as XX.

Note: Be careful with optocouples. Makes sure that voltage drop on phototransistor

exceed 2.5V in off state and do not exceed 0.5V in on state. It is important for correct work

of 8SMC1-USBhF input 3.3V logic.

The pattern of phototransistor based external sensor connection to multi-purpose 40

pin connector P1 is shown on Figure 20, to Stepper motor connector - on Figure 21. One

optocouple can be connected to Stepper motor connector by simple way that illustrated on

Figure 22. No external current-limiting resistors are required. Revolution sensor (see 2.2.6)

is connected by this way usually. The pattern of dry contact type external sensor

connection to multi-purpose 40 pin connector P1 is shown on Figure 23, to Stepper motor

connector is shown on Figure 24.

1/14/2008 www.standa.lt Page 13 of 83

Figure 20. Pattern of optocouple connection to multi-purpose 40 pin connector P1

Figure 21. Pattern of optocouple connection to Stepper motor connector (Method 1)

Figure 22. Pattern of optocouple connection to Stepper motor connector (Method 2)

Figure 23. Pattern of dry contact connection to multi-purpose 40 pin connector P1

Figure 24. Pattern of dry contact connection to Stepper motor connector

2.2.4 Limit switches

Two limit switches can be used: Limit switch 1 and Limit switch 2. These contacts are

used for determination of limits in translational stages, for determination a null position in

rotational stages, etc. It can be programmed as normally opened or closed contact. It can be

enabled or disabled by software (see 5.4.10). Also it is possible to swap limit switches by the

software. Limit switches are connected to 8SMC1-USBhF according to 2.2.3. Controller inputs

for each limit switch are shown on Table 2.

1/14/2008 www.standa.lt Page 14 of 83

Pin number on

External sensor Stepper motor connector Multi-purpose 40 pin connector P1

Limit switch 1 9 20

Limit switch 2 8 17

Table 2. Connection of Limit switches

2.2.5 Emergency Stop switch

Emergency stop switch is used for unconditional stepping motor power down. It can stop

stepper motor forcedly if it is impossible to do by software in consequence of program error.

This sensor is connected directly to power down circuit of Power driver. Emergency stop

switch must be a dry break contact. There is no possibility to control this switch by software,

only monitoring is possible. If Emergency stop switch is not used, set emergency stop jumper

in Off position (see Figure 4), otherwise in On position (see Figure 3).

Note: If Emergency stop switch is not used but emergency stop jumper set in On position

then stepper motor will be de-energized and Ext. off indicator will lighting up (see. 5.2.5).

For correct working set the jumper in Off position (see Figure 4).

Connection diagram to multi-purpose 40 pin connector P1 is shown on Figure 25, to

Stepper motor connector is shown on Figure 26.

Figure 25. Connection Emergency Stop switch to multi-purpose 40 pin connector P1

Figure 26. Connection Emergency Stop switch to Stepper motor connector

2.2.6 Revolution sensor

Revolution sensor is intended for stepper motor stall detection. 8SMC1-USBhF can

receive data about the real position of stepper motor shaft from Revolution sensor. Latter is

an external sensor (see 2.2.3) that joins directly to stepper motor shaft and change electrical

state several times per stepper motor shaft revolution.

Usually Revolution sensor is a small disk with narrow axial slit. Disk mounts directly on

stepper motor shaft. Optocouple is used as an external sensor. Optocouple’s emitter and

detector are set near the slit of the disk, by different sides. When slit is positioned on emitter

and detector optocouple is opened (optocouple output signal is low). If slit closes emitter

from detector optocouple is closed (optocouple output signal is high).

Examine how the Revolution sensor works more accurately by the example of SMCVieW

application (see chapter 5). When Revolution sensor is enabled and stepper motor is moving,

controller counts tics (one full step is equal to 64 tics) which it gives to stepper motor and

compare this number of pulses with the value Tics per revolution (see 5.4.11). If the

difference is greater than ErrorVal, Revolution sensor error flag is setting up, indicator RT

1/14/2008 www.standa.lt Page 15 of 83

error is lighting up (see 5.2.5) and stepper motor stops if Stop driver if error is detected

checkbox is marked or continue moving in other way. If Revolution sensor error flag is

setting up, it remains up until it will be reset by Reset error status button.

When revolution sensor is enabled error value is accumulated for all movements that

happened (for right direction and left direction separately) and Revolution sensor error flag

will be set if accumulated error value exceeds ErrorVal. It provides accuracy about

ErrorVal/64 steps for all movements when revolution sensor is enabled. Configuration of

Revolution sensor is possible by software (for example, see 5.4.11).

Controller inputs for Revolution sensor is shown on Table 3.

Pin number on

External sensor Stepper motor connector Multi-purpose 40 pin connector P1

Revolution sensor 12 18

Table 3. Connection of Revolution sensor

2.2.7 Encoder

Encoder is a sensor of mechanical motion. Quadrature encoder is intended for direct

measurement of stepper motor shaft position. It translates shaft angle into two shifted

electrical signal on CH A and CH B outputs (see Figure 27). Mechanical action of optical

quadrature encoder is illustrated on Figure 28. Two optocouples are used. Emitter and

detector are set near the disk, by different sides. When slit is positioned on emitter and

detector then optocouple is opened (optocouple output signal is low). If slit closes emitter

from detector then optocouple is closed (optocouple output signal is high). Optocouple

signals usually are shifted by half of encoder cycle (see Figure 27).

The main characteristic of quadrature encoder is a number of cycles per revolution

(CPR). Most common encoders have 100-1000 CPR. Each cycle can be decoded into 1, 2 or 4

codes, referred to as X1, X2 or X4 resolution multiplication. This controller used X2 resolution

multiplication.

Connection diagram of encoder to multi-purpose 40 pin connector P1 is shown on Figure

30, to Stepper motor connector is shown on Figure 29.

Figure 27. Electrical signal on CH A and CH B outputs of quadrature encoder

1/14/2008 www.standa.lt Page 16 of 83

Figure 28. Optical quadrature encoder mechanical alignment

Figure 29. Encoder connection to Stepper motor connector

Figure 30. Encoder connection to multi-purpose 40 pin connector P1

Note: Encoder share one input on board with revolution sensor and one input with

synchronization in. Therefore makes sure that revolution sensor and synchronization input

are disconnected from corresponding devices before using the quadrature encoder.

Note: Usually encoder module outputs are open collector with internal pull-up resistors.

When driving a cable, they will provide good high-to-low transition times. But low-to-high

times will stretch out in proportion to the cable length and capacitance. If a cable driver is

not used, you can add a pull-up resistor R=1-5K Ohm (see Figure 29, Figure 30) to +5 Volts

on each output to improve these rise times.

Note: For correct work of encoder at high speed it is necessary to use special version of

8SMC1-USBhF controller board. Ask this option your local dealer.

1/14/2008 www.standa.lt Page 17 of 83

2.2.8 Synchronization Out

8SMC1-USBhF can serve as an external synchronization for other devices. It can produce

TTL output pulse every Nsteps, where Nis controlled by software. It is usually used for

starting some repeated action like a routine measurement.

Synchronization output sends a TTL signal. Maximum output high level current is 5 mA.

Active state is high. Duration is programmable (see 5.4.13).

Connection diagram to multi-purpose 40 pin connector P1 is shown on Figure 31, to

Stepper motor connector is shown on Figure 32.

Figure 31. Synchronization output on multi-purpose 40 pin connector P1

Figure 32. Synchronization output on Stepper motor connector

Note: It is possible to use synchronization output as general purpose digital output. Use

USMC_SetMode() function (see Chapter 0) or Set Mode (uSMC) VI (see Chapter 6), or

SMCVieW application (see Chapter 5) for control it.

2.2.9 Synchronization In

8SMC1-USBhF can work in pulse triggering mode. In this case controller waits

synchronization pulse then executes predefined movement. 8SMC1-USBhF can shift stepper

motor by predefined number of steps only after first synchronization pulse or on every

synchronization pulse. It is usually used for starting predefined movement after each

measurement by synchronization pulse from measuring instrument. Wide range of devices

may use as a synchronization pulse generator. For example, synchronization outputs of other

8SMC1-USBhF may be used as a synchronization pulse generator.

Synchronization input receives TTL signal. Required input current is 1 mA. Active state is

high.

Connection diagram to multi-purpose 40 pin connector P1 is shown on Figure 33, to

Stepper motor connector is shown on Figure 34.

Note: When synchronization input mode enabled, press Start button in SMCVieW (see

5.2.3) or execute Set Mode (uSMC).vi in VI’s library (see 6.1.4), or run USMC_Start in

USMCDLL.dll (see 7.5.11). Then controller starts waiting input synchronization pulse.

Figure 33. Synchronization input on multi-purpose 40 pin connector P1

1/14/2008 www.standa.lt Page 18 of 83

Figure 34. Synchronization input of Stepper motor connector

2.2.10 Manual control knobs

Manual control is possible on 8SMC1-USBhF. There are inputs for two knobs: "Up” and

“Down”. Knob "Up” is intended for moving positioner "Up” (step counter in 8SMC1-USBhF is

incremented), Knob "Down” is intended for moving positioner "Down” (step counter in

8SMC1-USBhF is decremented).

Knobs are usually used for manual precise positioning of stage, for example in

calibrating. Another common application of knobs – control of stepper motors without

computer.

When knob is pushed positioner makes one step (or microstep, depends on current

resolution). If knob stays pushed during Tbto1 (see 5.4.8 for more information) stepper motor

starts rotation with Vbp1 speed. If knob stays pushed during Tbto1+Tbto2 stepper motor

increases speed up to Vbp2. If knob stays pushed during Tbto1+Tbto2+Tbto3 stepper motor

increases speed up to Vbp3. If knob stays pushed during Tbto1+Tbto2+Tbto3+Tbto4 stepper

motor increases speed up to Vbp4. If knob is released stepper motor stops rotation

immediately.

If two knobs are pushed and held during Reset timeout (see 5.4.8) then 8SMC1-

USBhF resets and shifts to null position (in ticks).

All speeds and timeouts are programmable.

Knobs are connected to 8SMC1-USBhF according to 2.2.3. Controller inputs for each

knob are shown on Table 4.

Pin number on

External sensor Stepper motor connector Multi-purpose 40 pin connector P1

Knob Up - 15

Knob Down - 16

Table 4. Connection of knobs

2.2.11 Local indication LEDs

Local indication is possible on 8SMC1-USBhF. There are outputs for three LEDs: "Up”,

“Down” and “Status”. LED "Up” blinks when stepper motor is moving "Up” (step counter in

8SMC1-USBhF is incremented) and light if Limit switch 1 is reached (or Limit switch 2, if

Swap Limit switches option is enabled). LED "Down” blinks when stepper motor is moving

"Down” (step counter in 8SMC1-USBhF is decremented) and light if Limit switch 2 is reached

(or Limit switch 1, if Swap Limit switches option is enabled). For more information about

Limit switches see 2.2.4. LED "Status” blinks when 8SMC1-USBhF is powered and works

properly but USB connection to 8SMC1-USBhF software driver on computer is unavailable.

LED "Status” light when 8SMC1-USBhF works properly and USB connection to 8SMC1-USBhF

software driver is established.

1/14/2008 www.standa.lt Page 19 of 83

Output current for LED is limited by 10 mA. Any LEDs with rated current 5-10 mA may

be used for local indication. LEDs wiring on Multi-purpose 40 pin connector P1 is shown on

Figure 35.

Figure 35. LED wiring on Multi-purpose 40 pin connector P1

2.2.12 USB In/Out

There are two ways of communication to 8SMC1-USBhF board: by multi-purpose 40 pin

connector (convenient for embedded applications) or by special USB In and USB Out

connectors (see 2.1).

USB In (USB type B connector) is used for connection with computer or higher USB

hub. Embedded 3-port USB hub allows cascading of the 8SMC1-USBhF boards. USB Out (two

USB type A connectors) allow the connection of other USB devices or lower USB hubs to this

8SMC1-USBhF board.

Caution: Use only operable USB cables! Defective USB cable may be a cause of 8SMC1-

USBhF malfunction.

USB pins on multi-purpose 40 pin connector may be useful for embedded multi-axis

applications. No bulky USB connectors are necessary. Only one ribbon cable is used.

Pinout of USB ports on multi-purpose 40 pin connector P1is shown on Table 5.

Pin number on Multi-purpose 40 pin connector P1

Pin description USB In USB Out 1 USB Out 2

D+ 37 33 29

D- 38 34 30

GND 39 35 31

+5V 40 36 32

Table 5. USB ports pinout on Multi-purpose 40 pin connector P1

1/14/2008 www.standa.lt Page 20 of 83

Other manuals for 8SMC1-USBhF

1

Table of contents

Other Standa Controllers manuals

Popular Controllers manuals by other brands

LEGRAND

LEGRAND Wattstopper LMJA-8125-SM installation instructions

IAI

IAI ROBO Cylinder RCS4-TA4C instruction manual

Kramer

Kramer FC-28 user manual

Leviton

Leviton miniZ mZb00-102 user guide

Precision Digital Corporation

Precision Digital Corporation ProtEX-MAX PD8-6210 instruction manual

Grozone Control

Grozone Control Dual Zone CO2 Controller manual