CONTROLS

Your new garage

door openeroffers momentary control. To

operate

the door simply press

either the hand held transmitter

button or thewall mounted

pushbutton

for oneto two seconds

andthedoor will automaticallyopenor close. The openercan

be stopped

during anyportion of the openingor closing cycle

by pressing

either of the buttons.The next time the button is

pressed,

the openerwill re-startthe door in motion in the

oppositedirection.

OBSTRUGTIONSENSING

When properly adjusted,the door will automaticallyreverseif

it sensesanobstructionduring

theclosingcycle. This system

will alsostopthedoorif it hits anobstaclewhen opening.

SAFE.T.CYCLETM

This electronic systemwill reverse

the door in 30 secondsor

lessif thedooris unableto travelto thefull closed

position.

This feature

providesautomatic

reversing

shouldother sys-

temsfail to operateandthedoor doesnot fully close.

SAFE.T.SIGNALTM

Lights will flash wheneverSafetyReverseor Safe-T-Cycle

has

beenactivated.

FORCEADJUSTMENTS

IndependentOPEN and CLOSE dials allow you to selectthe

minimum requiredopeningandclosingforce.

EMERGENCY

RELEASE

Your door openeris equippedwith an emergencyrelease

device. In the event of a power failure, pull the knob on the

pull cord down and slightly to the back (away from door)

allowing the disconnect

to latch. This will allow you to man-

ually openor closethe door. When power hasbeenrestored,

gently pull the disconnectcord, releasingthe traveler detent,

then presseither the transmitter or pushbutton. The opener

will automaticallyreconnect.

SAFE.T.MONITORTM

A dynamic obstruction detection device that continuously

monitors the amountof force requiredto move the garage

door, andautomaticallyadjuststheobstructiondetectionlevel

in addition to the homeowneradjustableforce levels. This

SAFETY SYSTEM addsthe additionallevel of protection

indicating our commitmentto safe

garage

door operation.

CONTROL

CONNECTIONS

All openermodels are provided with screw terminals for the

attachment

of a wall mountedpushbutton

or four-function

wall console.

The console

includes

a pushbutton,

worklight

switch, vacationswitch, andpedestrian

light. Somemodels

are

provided

with a pushbutton

only,but ALL MODELS can

be connected

to the four-function wall consolewhich is sold

separately.

VoltageRequired: 120

Voltsa.c.

60cycle

SinglePhase

A grounded,

three(3) hole electricaloutlet is required.

MotorSpecs: Permanent

Split Capacitor-Internal

AutomaticOverloadReset

Current Required: 7 AMPS

Overload Protection: The motor is equippedwith anauto-

matic thermal over load device. Should the motor become

over heated,

the over load devicewill renderthe openerinop-

erative. Simply wait approximately 5 to 10 minutes for the

motortocool.

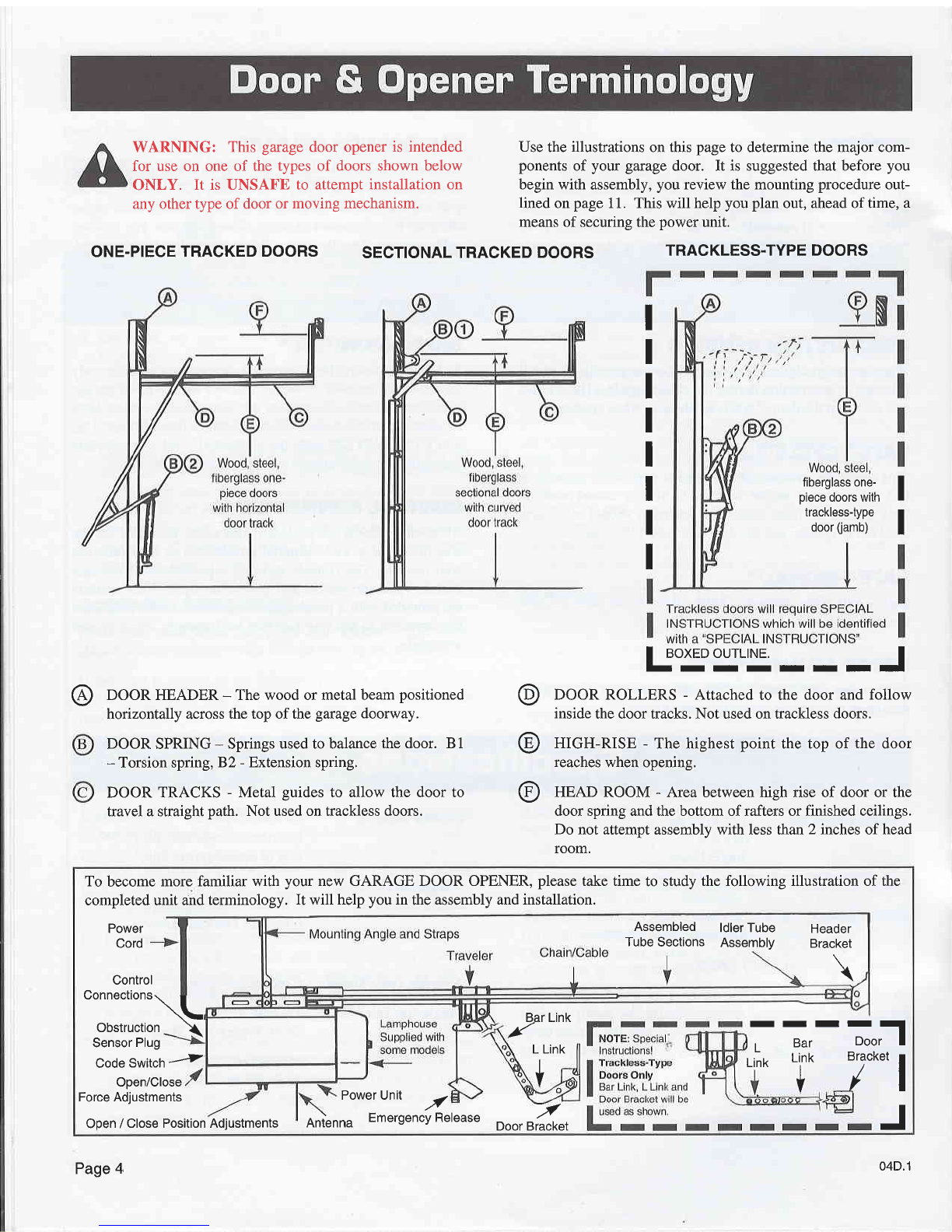

OpenerLength:

Minimum Head

Room Required:

AverageDoor Speed:

Maximum Door Size:

10Feet-8Inches

Fromendof tubeassemblyto

rearof opener

powerunit.

2 Inches(TrackedDoors)

6 Inches

(Trackless

Doors)

6 Inches

persecond

L/4H}.:

16Ft.Wide / 7 Ft.High

1/3H.P.or I/2HP.:

18Ft.Widel7 ll2Ft.High

03c.1 Page

3