INSIDE

Take note of the air supply system and air tube connection

Keep the tube from bursting by checking the air pressure before operating the tool.

Avoid intertwining or running over the tube.

Ensure that the air supply is clean and dry before use.

Regularly clean the air compressor and tube to optimize the life span of the tool.

More Than 1/100 Slope

Auto Drain Valve

Air Tool

Filter Regulator

Lubricator

Stop Valve

Branch Line =2 Times

Tool Inlet/hose Size

Main Line =3 Times

Tool Inlet/hose Size

Auto Drain

Valve

Stop Valve

Air Compressor

Maintenance Notifications:

Use the specified lubricant to lubricate the tool.

Make use of the filler while conducting lubrication and limit the flow to two (2) drops per minute.

If the filler is unavailable, lubrication should be conducted whilst rotating the tool every one (1) to two (2)

minutes until it is complete.

The life span and performance of the tool will be greatly improved if the aforementioned steps are taken.

Thoroughly read and understand the user manual before attempting to operate

the tool.

Any attempt to alter the structural design and mechanics of the tool may result in

grievous bodily harm.

Do not directly point the tool at any living object.

Consistently wear protective gear, such as safety goggles, ear plugs, and mask, while

operating the tool. The use of protective gear is also advisable while repairing or

changing the tool’s spare parts.

Long hair must be tied back and it is advisable to remove all adornments including,

but not limited to scarves, neckties, and clothing with loose sleeves, to avoid any

interference with the tool.

Do not make direct contact with any part of the transmission while the tool is

in operation.

Only purchase and use original Stanley spare parts in order to maintain the precision

and accuracy of the tool.

Operating the air tool will deliver strong back throw; please stabilize yourself with

equal strength

During repair and maintenance or when not in use, turn off the air compressor and

remove the tool from the air source.

Ensure that the air tube is not placed in an area with high foot traffic.

Should bodily irritation, numbness, or fatigue occur at any time during the operation

of the tool, seek immediate medical attention.

STANLEY®PNEUMATIC TOOL USER GUIDE

The tool must be used accurately to comply with the design parameters and usage range.

Care for the tool by conducting regular inspections.

Safety precautions must be taken into account during usage, removal and storage of the tool.

Take note of potential hazards in the surrounding environment, such as people and objects, while

operating the tool.

Use the appropriate tool based on the working application and capacity.

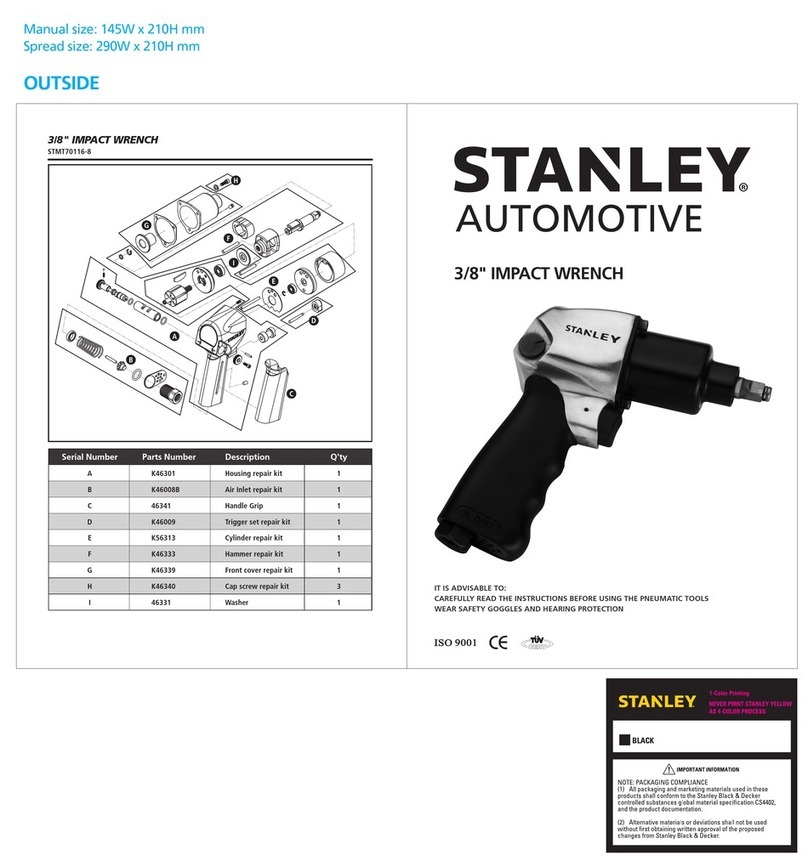

Forward 1

700 2,500

STMT97134-8

Technical Notifications:

Torque ft-lb RPM

Forward 2

950 2,850

Torque ft-lb RPM

Forward 3

1,100 3,600

Torque ft-lb RPM

This tool has been designed to drive fasteners with specific impact sockets;

using standard sockets could cause injuries to the operator.

NEVER USE STANDARD SOCKETS ON IMPACT TOOLS