Star ECONO EC-CCY User manual

ECONO CONVEYER

EC-CCY

OPERATION MANUAL

INTRODUCTION

INTRODUCTION

Thank you for purchasing the Star conveyer “ECONO CONVEYER”.

This operation manual describes the conveyer’s functions, hot to operate it, and the precautions

necessary when using it. Please read this manual thoroughly in order to understand the features

of this conveyer better and use it more efficiently.

Features

● Compact structure because of aluminum frame and resin belt used.

● Can be interlocked with external signals such as your unloader, making it possible to have

intermittent operations and change the tact time for moldings with ease.

● Can be used as a service platform for finishing work because of flat belt surface used.

CONTENTS

CONTENTS

1. SAFETY-RELATED INFORMATION

1-1. Safety-Precaution Indications ··········································· 1

1-2. Safety Precautions ····················································· 2

1-3. Caution plates ························································· 7

1-4. Mechanical Specifications ················································ 8

2. FEATURES AND THEIR LOCATIONS

2-1. General Structure ···················································· 9

2-2. Control Box (Operation Panel) ··········································· 11

3. MECHANICALADJUSTMENTS

・Height adjustment ······················································ 12

・Belt tension adjustment ·················································· 12

・What to do after adjustment ·············································· 13

・Maintenance and inspection ·············································· 13

4. PARTS LIST ························································ 15

5. WARRANTYAND AFTER-SALE SERVICE ······················· 16

6. ELECTRIC CIRCUIT DIAGRAM ···································· 17

7. OVERALL DIAGRAM ················································ 18

-1-

1. SAFET

Y

-RELATED INFORMATION

1. SAFETY-RELATED INFORMATION

1-1. Safety-Precaution Indications

■Danger Level Symbols

The safety precautions in this manual are classified into the following three levels.

DANGER Failure to follow this safety precaution may result in great

physical danger to the operator, or even death.

WARNING Failure to follow this safety precaution may result in great

physical danger to the operator, or severe damage to the

equipment.

CAUTION Failure to follow this safety precaution may result in injury

to the operator, or damage to the equipment.

■About Important Points

Important points on handling are indicated with in the manual.

-2-

1. SAFET

Y

-RELATED INFORMATION

1-2. Safety Precautions

DANGER

PROHIBITING WORKER TO RIDE ON CONVEYER

Never attempt to ride on the conveyer. If the worker rides on the conveyer, it may cause

the risk of making the conveyer unstable and so fall down, getting the worker injured.

DO NOT PERFORM MAINTENANCE WHILE CONVEYER

IS RUNNING!

Never attempt to service or perform maintenance on the conveyer while it is running.

Before carrying out maintenance, be sure to shut down the machinery as follows: (1) Shut

down the air supply. (2) Switch off the POWER switch in the control box. (3) Cut the

power breaker.

WARNING

Wear appropriate work clothes.

Do not wear bulky clothing and accessories when working at the conveyer, as these may

be caught in the machinery, getting the worker seriously injured.

Do not attempt to modify the conveyer.

Do not redesign, rebuild, or otherwise modify the conveyer. The manufacturer cannot be

responsible for accidents or damage caused by modified equipment.

Be sure to ground the conveyer.

Use a No.3 ground setup to help reduce the risk of electric shock at installation. Also,

after moving the conveyer to another place or performing periodic inspection, make sure

that the specified ground setup has been done.

-3-

1. SAFET

Y

-RELATED INFORMATION

Use a non-fuse circuit breaker.

To avoid the risk of fire due to overcurrent, include a non-fuse circuit breaker in the

wiring leading to the power source.

Do not open the cover on the power box.

High voltages are present within the power box. Opening the cover may lead to serious

electric shock.

Do not remove the chain cover for operation.

Operating the conveyer with the chain cover removed may cause the risk of getting the

worker caught or pinched in the machinery.

Do not touch the conveyer belt while it is running.

Never put your hands inside the conveyer belt while it is moving. Doing so may cause the

risk of getting your hands caught or pinched in the conveyer driving rollers.

Shut down operation during periods of frequent power outage.

The machinery should be shut down during times when power supply is frequently going

off due to thunderstorm or other such external event. Operating with an irregular power

supply may lead to equipment damage. If you cannot locate the cause of failure, please

contact the engineering service personnel of our sales office.

CAUTION

Confirm mutual safety in the case of cooperated work.

When two or more persons jointly work together, be sure to clarify who is responsible and

confirm safety by pointing the finger to all safety confirmation places and saying “O.K” if

safe before getting operation started, in order to avoid accidents due to miss-operation or

safety confirmation failure at manual adjustment.

-4-

1. SAFET

Y

-RELATED INFORMATION

Secure adequate maintenance space.

For safe operation, please leave at least 1 meter of maintenance space (with empty floor)

around the circumference of the conveyer.

Work under bright illumination.

To ensure that work is done safety in setting the conveyer and performing service or

maintenance, be sure to work under bright illumination.

Carry out daily maintenance inspections.

Check machinery daily to make sure it is in safe operating condition. Contact STAR

SEIKI in the event of problem.

Stop working in the event of breakdown or other problems.

If you think that the conveyer is abnormal or malfunctioned, do not keep working based

on your own thought. Simply stop operating it. Be sure to get operation started on the

basis of appropriated instructions from our engineering service personnel.

Never touch the switches with wet or dirty hands.

Doing so may cause the risk of not only getting the conveyer malfunctioned but also

accidents due to electric shock.

Stop all devices linked to the conveyer during operation.

Before carrying out inspection, repair, adjustment, cleaning or lubrication work in the

conveyer’s moving range, be sure to shut down not only the conveyer itself but also all

devices linked to is, such as your molding machine, etc. A failure to do this may cause the

risk of getting the worker seriously injured due to unexpected drive.

-5-

1. SAFET

Y

-RELATED INFORMATION

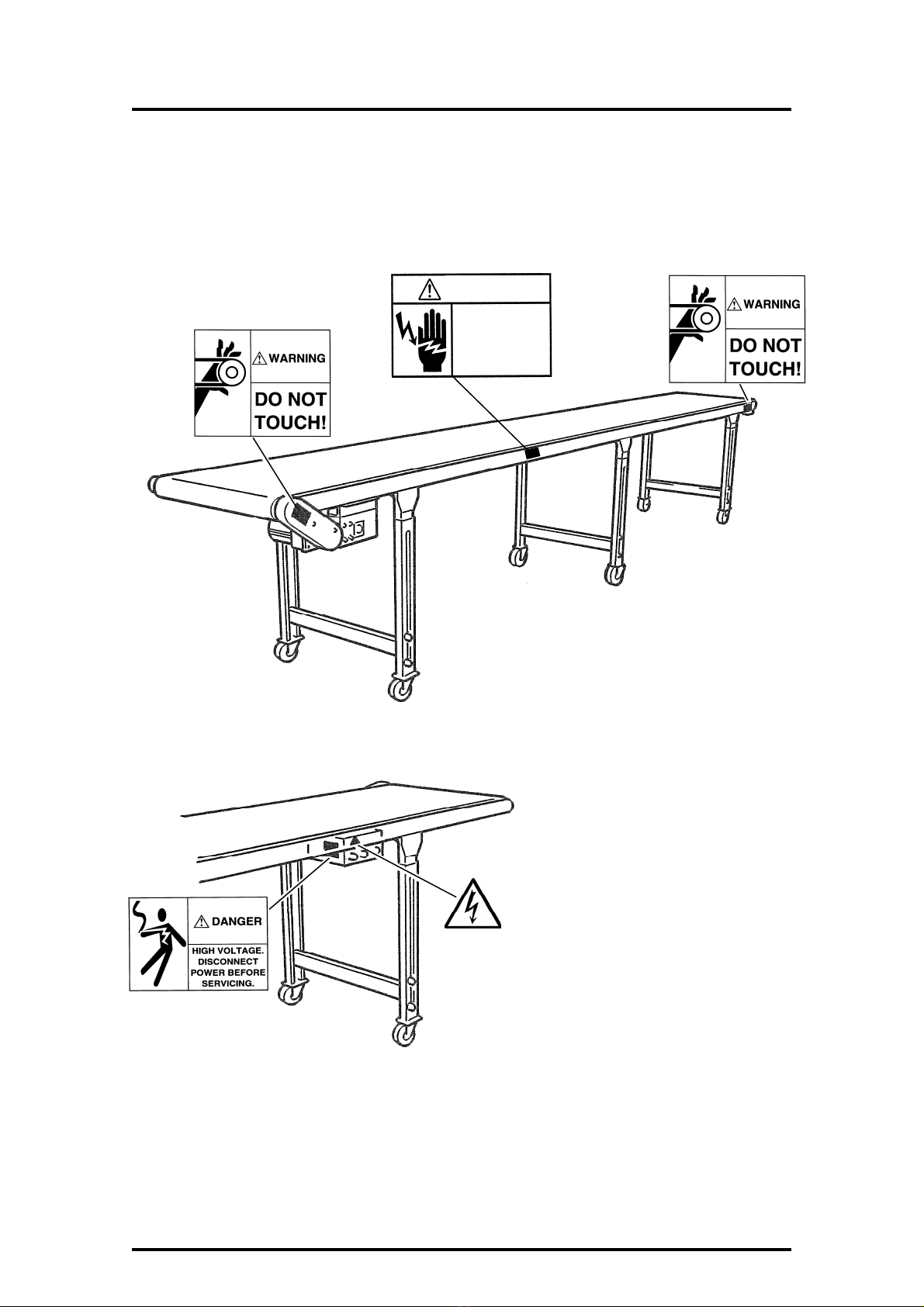

■Kinds of Caution Plates

* Note that some of the caution plates given below are not used on the conveyer.

Caution for high voltage electrical shock

Make sure to cut off the breaker of

controller while maintenance work is

being done. Especially during such work

for inside the box, disconnect connecting

cable with molding machine and cut off

primary power supply of the factory.

This label can be found at the locations

(terminal block, etc.) where special

attention is required in the range of high

voltage warning.

Caution for danger of enfolding

To work in moving zone for maintenance

or other purposes, do not touch carelessly

with such parts as motor, rotary axis, gear,

pulley, belt which have danger of

enfolding you. Cut off power supply and

air pressure to work.

-6-

1. SAFET

Y

-RELATED INFORMATION

● Caution for static electricity

The conveyor belt or the product on the

conveyor may be charged by static

electricity. You may be shocked by electric

when approaching.

.

The conveyor belt

may be charged by

static electricity.

CAUTION

-7-

1. SAFET

Y

-RELATED INFORMATION

1-3. Caution plates

The following diagram shows the location and content of caution plates affixed to the conveyer.

■Example of caution plates disposition

CAUTION

The conveyor belt

may be charged by

static electricity.

-8-

1. SAFET

Y

-RELATED INFORMATION

1-4. Specifications

Model

EC****-* CCY

Control box CC-4BⅢtype

Belt width 3…300 mm

4…400 mm

5…500 mm

Overall length 4000…4000 mm

5000…5000 mm

Height m/m 900~1300 Free adjustment

Working electric power AC200V 40W

Speed 1~3 m/min (60HZ)

Maximum transport weight

(horizontal position)[kg] 25(15 When option is mounted)

Total weight [kg] See accompanying table.

Optional specifications 1002-02 feet + variable speed specifications

(1~7.5 m/min 60HZ)

●Overall weight (Kg)

Belt width

Overall length 3CCY 4CCY 5CCY 6CCY

EC2000- 41 44 47 50

EC3000- 47 51 55 58

EC4000- 64 69 74 78

EC5000- 69 75 80 86

-9-

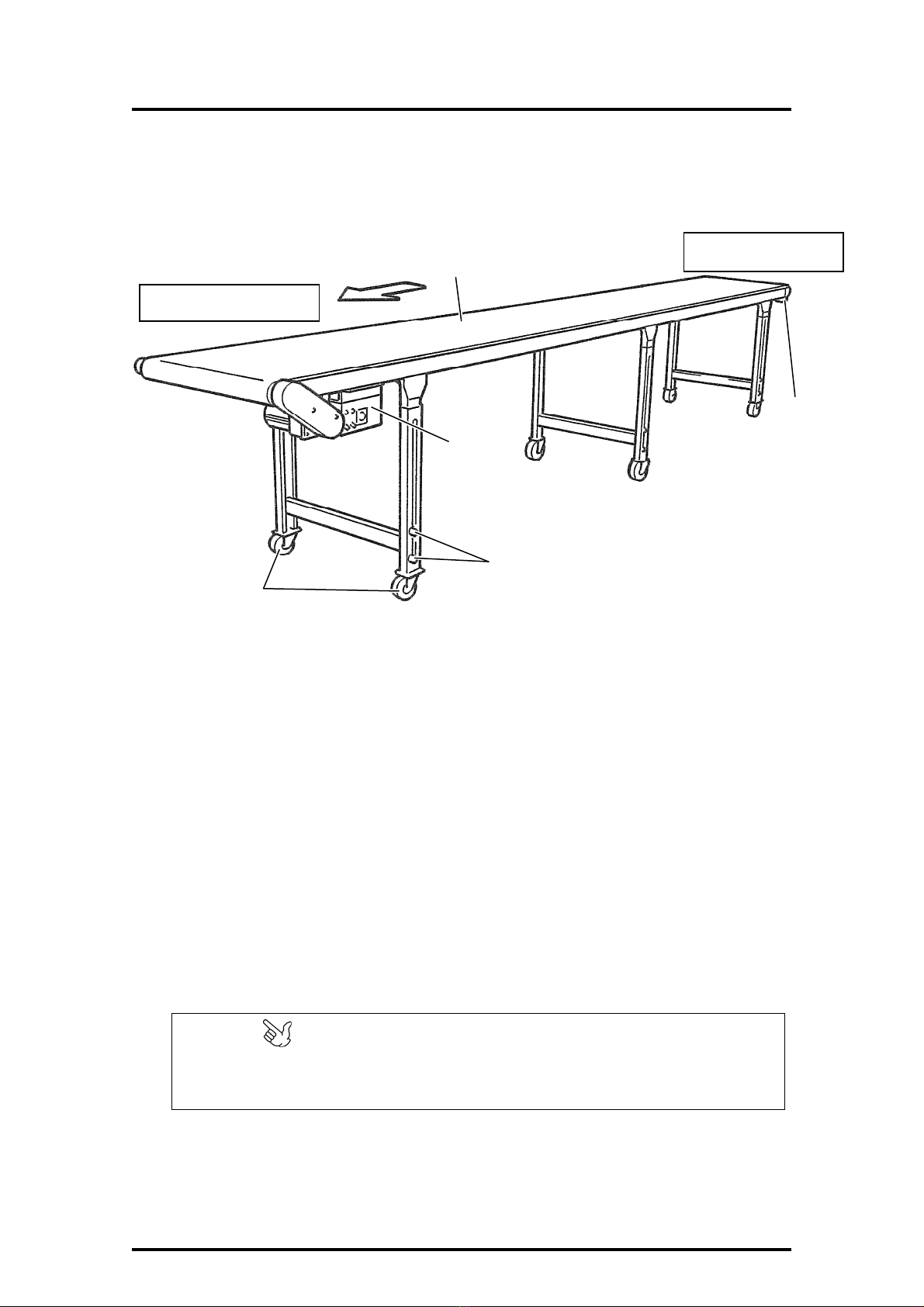

2. FEATURESAND THEIR LOCATIONS

2. FEATURES AND THEIR LOCATIONS

2-1. General Structure

①Conveyer belt

This is a special belt made from synthetic resin.

②Control box

This box is used to set and operate the conveyer drive.

③Caster

These casters are used to move the conveyer. Lock them with the stopper after installing

the conveyer in place.

④Tension adjusting bolt

This bolt is used to adjust the conveyer belt if it is loosened. After adjustment, tighten the

bolt.

⑤Height adjusting/securing bolt

To adjust the height of legs, loosen these securing bolts and adjust the height.

After adjustment, tighten the bolts.

Conveying-out Side

Conveying-in Side

④

②

③

⑤

①

POINT

Do not tense the belt too taut.

Adjust the bolts on both sides uniformly.

-10-

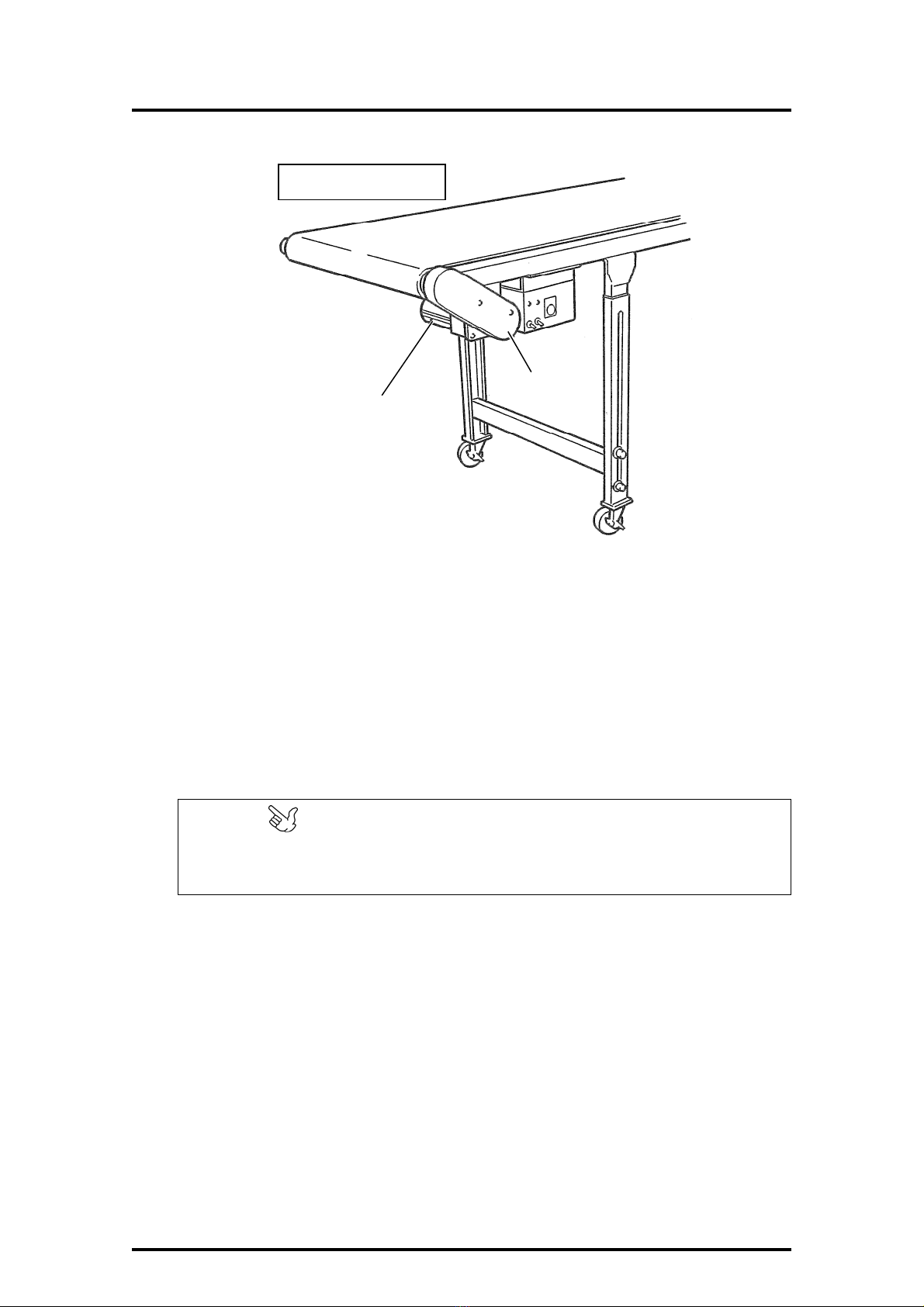

2. FEATURESAND THEIR LOCATIONS

⑥Motor reducer

This is the source of powering up the conveyer. The speed is 1 to 3m per minute (60HZ)

(standard type).

⑦Chain cover

To adjust, maintain or inspect the chain sprocket, remove this cover.

Conve

y

in

g

-out Side

⑦

⑥

POINT

If the conveyer needs to be reversed in rotation, please contact the engineering

service personnel of our sales office.

-11-

2. FEATURESAND THEIR LOCATIONS

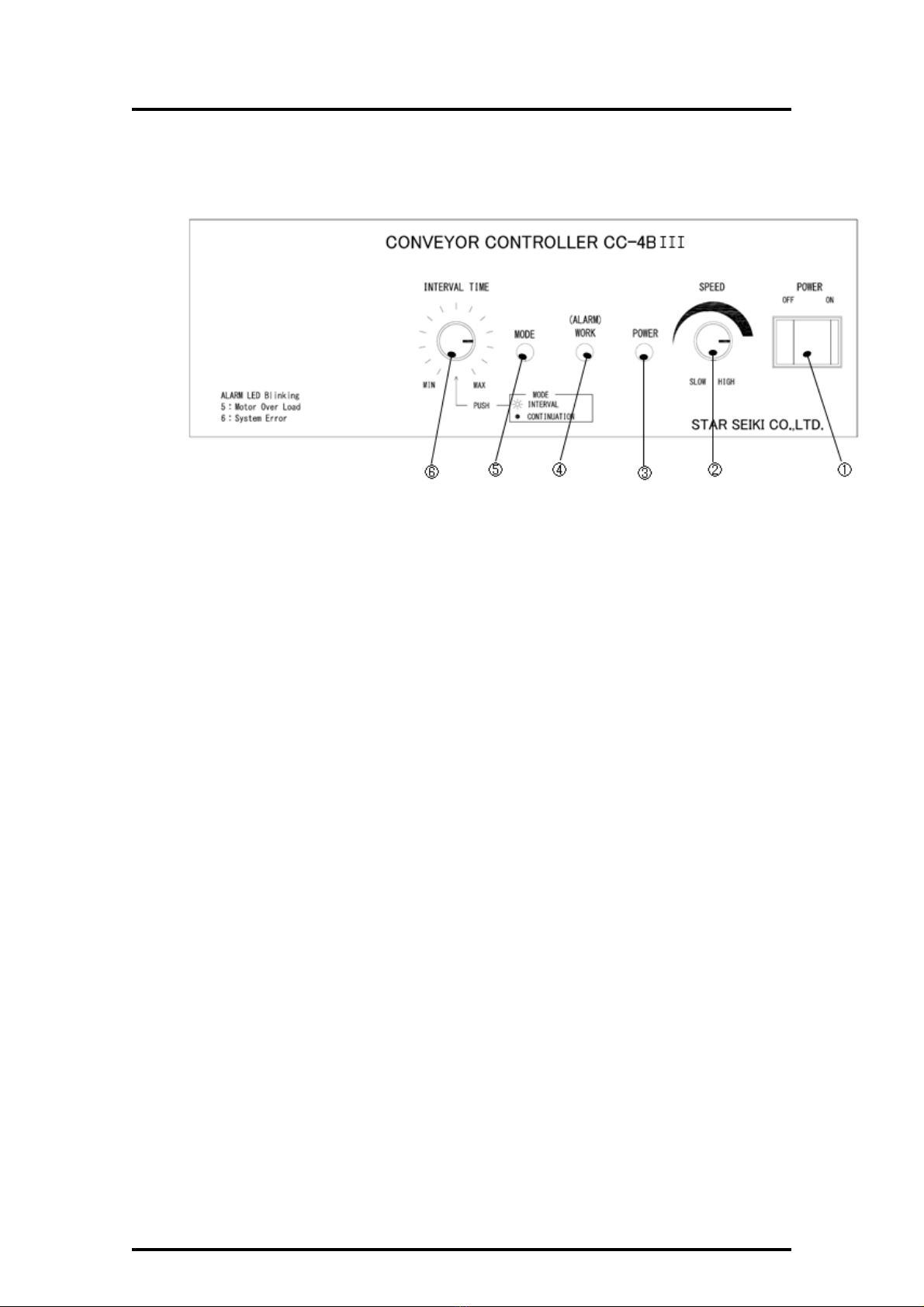

2-2. Control Box (Operation Panel)

●Standard type (CC-4BⅢ)

①Power Switch

Turn on/off the power of conveyor

②Speed Setting Switch

This switch is used to set the speed of product delivery.

Setting range: 1~3m/min

Note: this speed is measured at a frequency of 60Hz.

③Power LED

This LED is on when turning on the power.

④Working LED

The green LED is on when conveyor works normally. The green LED flashes when alarming.

⑤Mode LED

This LED is on when conveyor works in interval mode.

⑥Mode Selecting Switch

This switch is used to shift modes (Press)

・INTERVAL……………Conveyor start signal is input from an Unloader. Conveyor works in

the setting time of timer.

・CONTINUATION………The conveyor works continuously.

Product Delivery Timer (Rotate)

After pressing switch No.6 and select interval mode, please rotate the switch No.6 to set

the time interval for the conveyor to deliver products.

Use this knob to set the product feed speed.

Conveyor speed specified range: 0.25 to 3 m/min (1 to 3 Recommended)

Note : The speed is for 60 Hz.

-12-

3. MECHANICALADJUSTMENTS

3. MECHANICAL ADJUSTMENTS

To determine conveyer arrangement, stop the casters and make the following adjustments.

●Height adjustment

Loosen the height adjusting bolts (2 bolts × 4 to 6

places) located on each leg as shown in the illustration

using a hexagon wrench and adjust the conveyer height.

* Note that after adjustment, tighten the bolts.

●Belt tension adjustment

CAUTION

Adjustment should be made only if the conveyer zigzags sideward or only if the conveyer

driving rollers run idle during operation. Otherwise, there is no need to make adjustment.

Adjust the belt tension using the tension adjusting

bolts at both ends of conveying “IN” side if

necessary.

POINT

Do not tense the belt too taut.

Tighten the bolts on both side uniformly for

adjustment.

After adjustment, tighten the securing nut.

Tightening

Loosening

Tension

adjusting bolt

Securing nut

Securing

Releasing

-13-

3. MECHANICALADJUSTMENTS

●What to do after adjustment …

① Wire the power supply and conveyer start signals.

DANGER

・ Before wiring, shut down the supply-or primary-side power supply.

・ For how to wire conveyer start signals (SG1 and SG2), see the instruction manual for

the control box of your unloader. Also, to input conveyer start signals from other than

the unloaders by STAR SEIKI, please contact the engineering service personnel of

our sales office before using, because incorrect connection procedure may cause the

risk of damaging the electric of the conveyer.

Before plugging in or out the metal connectors, shut down the supply. A failure to do this

may cause the risk of accidents due to electric shock.

●Standard type

WARNING

-14-

3. MECHANICALADJUSTMENTS

●Maintenance and inspection

Remove the chain cover once every 6 months and

apply grease to the chain using brush.

After maintenance or inspection,

return the chain cover in place. A

failure to do this may cause the risk of

getting you caught or pinched in the

chain.

CAUTION

-15-

4. PARTS LIST

4. PARTS LIST

Part Name Type Manufacture Qty Code No.

Motor M91X40GV4Y Panasonic 1 122616

Gear head MX9G90B Panasonic 1 122615

Gear head

(0P 1~7.5m/min)MX9G36B Panasonic 1 122614

Conveyer belt SL-F1502 ****-*** Bando 1

-16-

5. WARRANTYANDAFTER-SALE SERVICE

5. WARRANTY AND AFTER-SALE SERVICE

For information about repairs and other service, refer to the nearest STAR SEIKI business

office.

■Warranty

1. The term of the warranty specified by the contact shall begin upon purchaser’s approval of

the delivered machine. In principle, the term of warranty shall be six (6) months.

2. Breakdowns that occur within the term of warranty period shall be repaired free of charge,

with the exceptions noted immediately below.

3. The following are not covered by the warranty.

・Breakdown caused by inadequate maintenance or inspection.

・Damage caused by improper handling of the machine.

・Damage caused by fire or natural disaster (act of God).

・Damage related to expendable components (chucking parts, etc.)

・Damage caused by modification or attempted repair carried out by user. (Refer to Section

1-5 for machine specifications.)

-17-

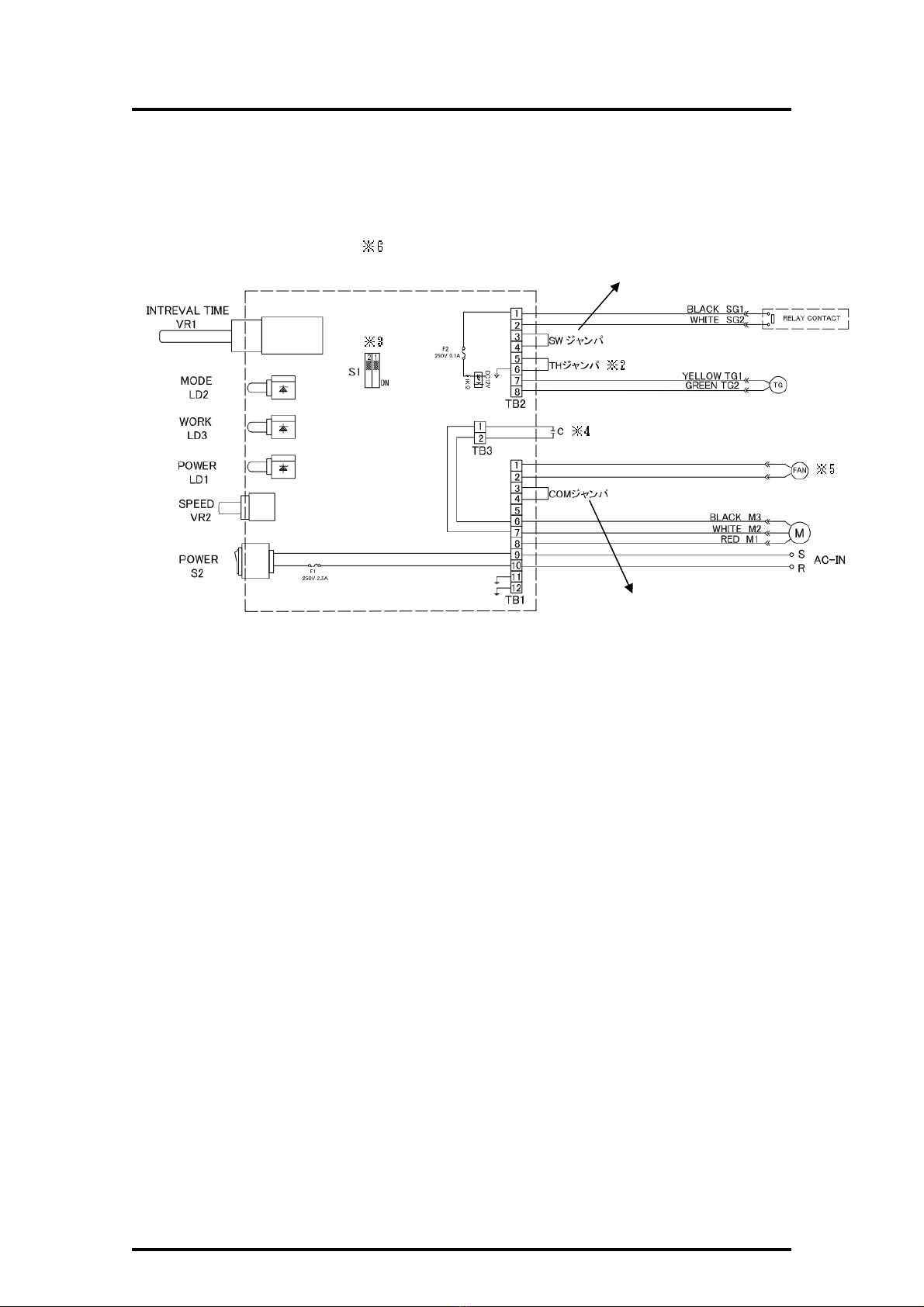

6. ELECTRIC CIRCUIT DIAGRAM

6. ELECTRIC CIRCUIT DIAGRAM

●Econo Conveyer Electric Circuit Diagram (Standard Specifications)

AC200V specifications

※1. Usage method of SW terminal

Under Intermittent action mode, if want to control the conveyor manually, please use SW terminal.

Please use B connection switch.

※

2 Temperature fuse input terminal

SEC conveyor can not use.

※

3 Time selection

S1-2:OFF According to the setting time of Interval Time(VR1)to perform the action.(Standard

Mode)

S1-2:ON Interval Time(VR1)is invalid, SG1 2 is ON, execute the action.

Unloader need to control the time of the action, please use S1-2 ON

※

4 The capacity of TB3 capacitor(The accessory of the Motor)

100V : 12uF/250V

115V : 10uF/250V

200V : 3uF/450V

220/230V : 2.5uF/450V

※

5 If use 90W (Or above 90W) type of motor, need to connect the fan.

The supply voltage of the fan is the same as the output voltage of the conveyer。

※

6 The input voltage of the Board is AC100V or AC200V. Do not need power supply shift switch。

Due to the different voltage, the connection of the motor, TB3 capacitor etc. are also different.

Please pay attention to it.

※1 External switch OPEN: Permanent action

External switch Close: Intermittent action

Rotation direction shift terminal

(COM,CW,CCW)

SEC conveyor can not use

Please do not alter the COM Jumper

Table of contents

Other Star Accessories manuals

Popular Accessories manuals by other brands

Wavion

Wavion WBSn-2400 quick start guide

Endress+Hauser

Endress+Hauser Deltabar S PMD70 Exchange instruction

Bühler technologies

Bühler technologies easyMont IO-Link Pressotronik PT77 Brief instructions

Betta

Betta 6000 installation guide

LEGRAND

LEGRAND Wattstopper FSP-211B installation instructions

Paramount Fitness

Paramount Fitness Ultra UV2 Replacement manual

Interlogix

Interlogix HDX-135 installation instructions

Continental Refrigerator

Continental Refrigerator CBC37 Specifications

Pentair

Pentair PENTEK VFD-WS owner's manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 080A130 Installation and operating manual

JoeCo

JoeCo Cello user manual

Leviton

Leviton OSSMD-FT install guide