Contents

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Further information................................................................................... 5

1.3 Symbols and document conventions...................................................... 5

2 Safety information............................................................................ 7

2.1 Basic safety notes..................................................................................... 7

2.2 Qualification of personnel........................................................................ 7

2.3 Intended use............................................................................................. 8

2.4 Improper use............................................................................................. 8

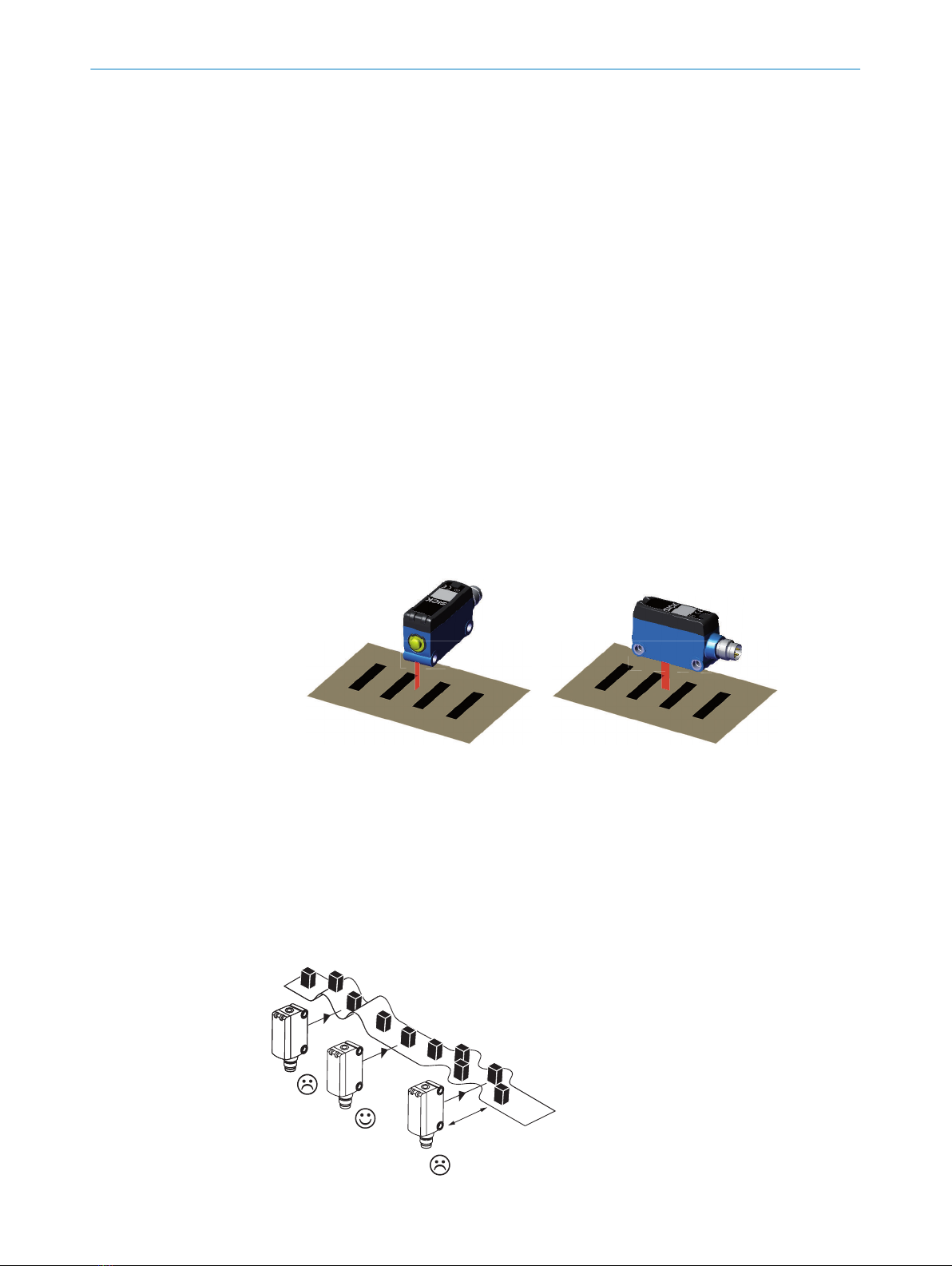

3 Mounting............................................................................................. 9

3.1 Scope of delivery....................................................................................... 9

3.2 Mounting requirements............................................................................ 9

3.3 Mounting the device................................................................................. 9

4 Operating and status indicators...................................................... 11

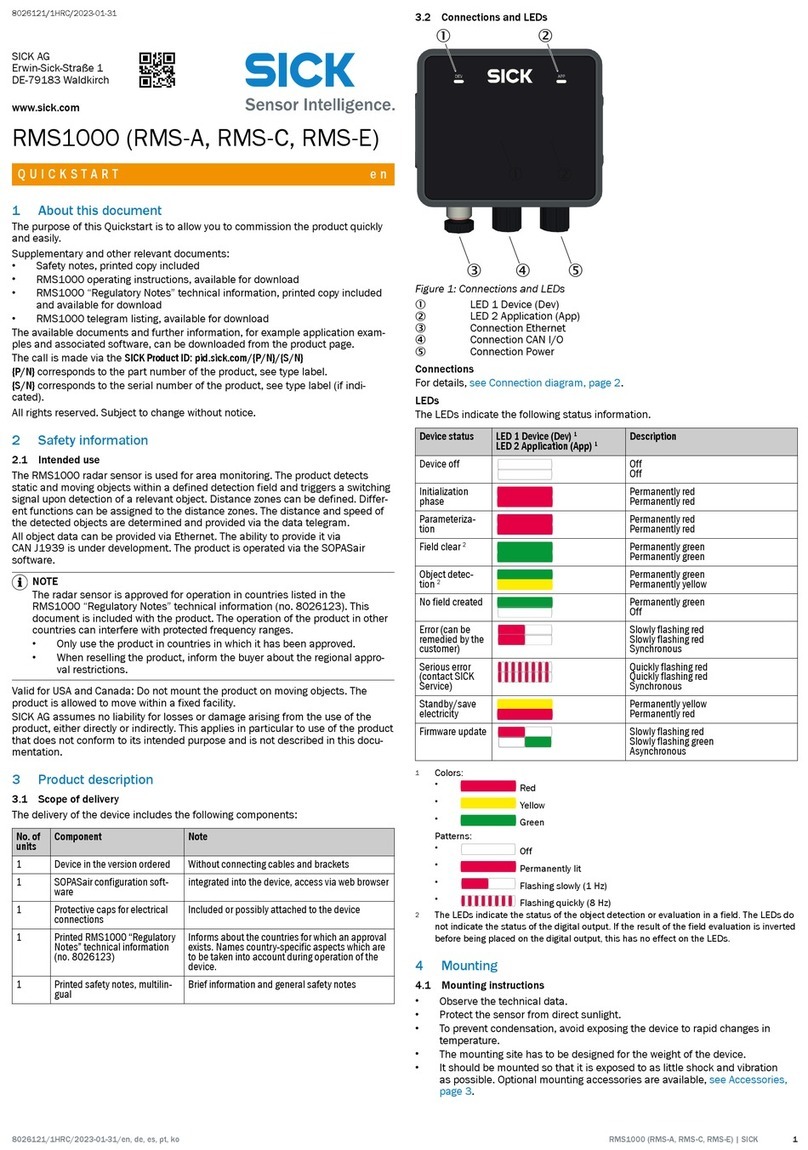

5 Electrical installation........................................................................ 12

5.1 Notes on the electrical installation.......................................................... 12

5.2 Pin assignment of the connections......................................................... 13

5.3 Connecting the supply voltage................................................................. 13

5.4 Notes on UL approval............................................................................... 13

6 Commissioning.................................................................................. 14

6.1 Sensitivity.................................................................................................. 14

6.2 2-point-teach-in (static) via teach-in button............................................ 15

6.3 Dynamic teach-in...................................................................................... 16

7 Troubleshooting................................................................................. 18

7.1 Possible errors.......................................................................................... 18

8 Maintenance...................................................................................... 19

8.1 Maintenance............................................................................................. 19

8.2 Cleaning the device.................................................................................. 19

9 Disassembly and disposal............................................................... 21

10 Technical data.................................................................................... 22

10.1 General data............................................................................................. 22

10.2 Dimensional drawing................................................................................ 23

11 Recommended accessories............................................................ 24

12 Annex.................................................................................................. 25

12.1 Conformities and certificates................................................................... 25

CONTENTS

8025181.1EEN/06.02.2023 | SICK O P E R A T I N G I N S T R U C T I O N | KTML 3

Subject to change without notice