Star D7 Mini User manual

D7 Star Ride on Mini

Operator manual

Please read this operator manual carefully before use

2

contents

1.0summary ...........................................................3

2.0summaryofsecuritymatters.............................................3

3.0technicalparameter ..................................................4

4.0machineloadingandunloading...........................................5

5.0disassemblyofmachine.......................... .....................5

6.0instructions...........................................................5

6-1view...............................................................5

6-2view...............................................................6

6-3view..............................................................6

6-4view..............................................................6

6-5view...............................................................7

6-6view...............................................................7

6-7view..............................................................8

6-8view..............................................................8

7.0 maintenance.........................................................9

8.0 common faults and processing methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

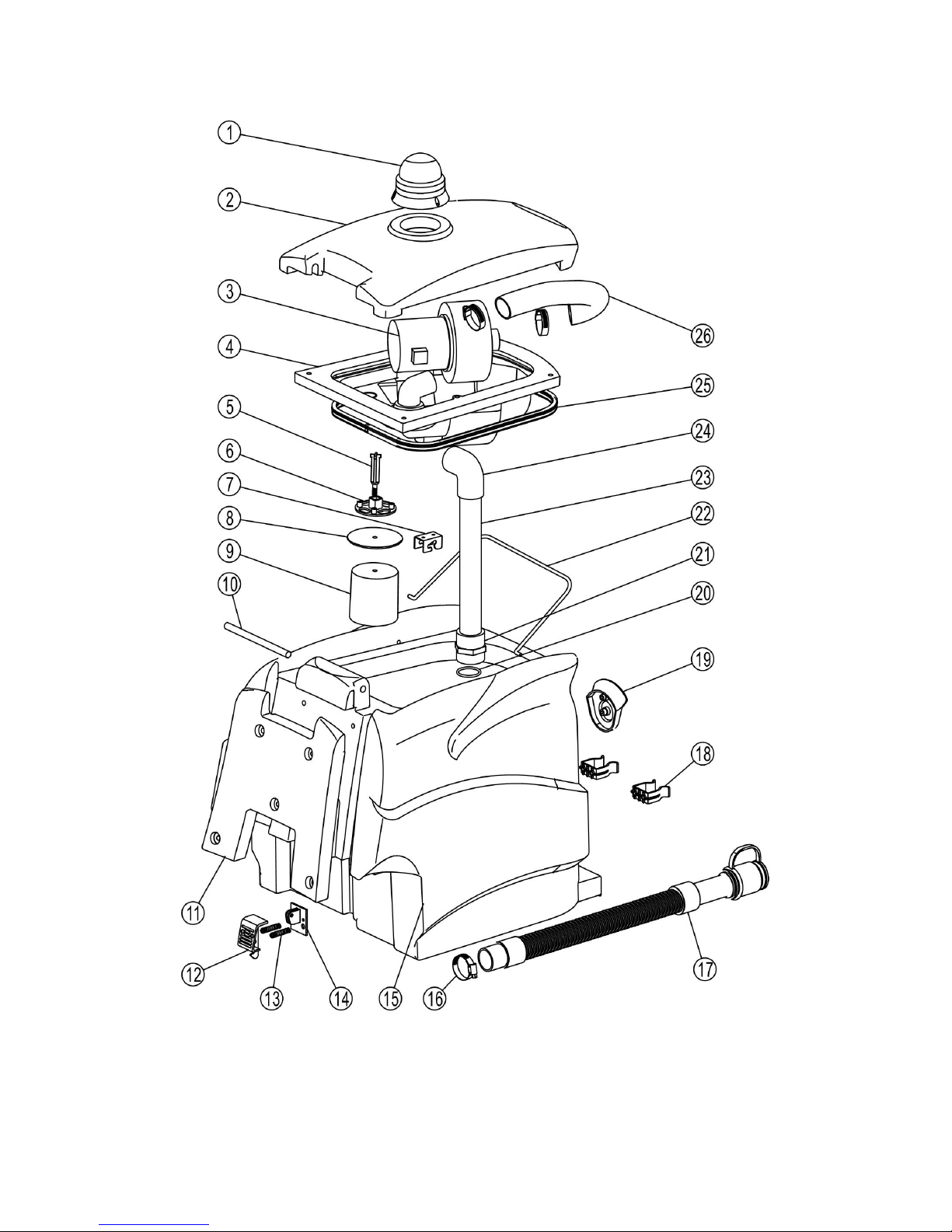

D7explosiondrawing ....................................................12

D7explosiondrawing.....................................................13

D7explosiondrawing......................................................14

D7explosiondrawing.....................................................15

D7explosiondrawing.....................................................16

D7explosiondrawing.....................................................17

3

summary

attention :Please read this manual carefully before operating D7 floor

scrubber.

introduction

D7 is a compact mini automatic ride on floor scrubber, suitable for using in medium

environment, for cleaning stains on various hard floor, it can remove the stains and not

absorbed by the floor cleaning solution recovery, it is a simple and high-efficient cleaning tool.

usage

Widely used in a large area of the airport, commercial complex, sports stadiums, municipal,

inter-city train, factory production workshop, purifying workshop, food processing, electrical

and top five-star hotel of semi open square, underground parking, building channel site, regular

circulation of the rapid mechanical floor cleaning, cleaning operations more efficient.

The device is not suitable for use in the rain or placed under the gun. It is strictly prohibited to

use the equipment in the flammable and explosive environment to collect dangerous dust or

flammable liquid. In addition, the equipment is not suitable for the use of transport.

Summary of security matters

attention: operator must read this manual carefully

before starting any work, be sure to be familiar with all the design, control methods and

functions of this machine.

first use of the machine, the operator should be placed in the open area to understand its

various function.

4

before starting any operation, check the machine and its parts in general and in the state of

operation.

if the machine doesn't work properly, you can't use.

the operator must be applied to the appropriate application areas when they operate the

machine.

operation attention to obstacles in the workplace, such as stairs, shelves, and pay attention to

the people around, especially in children.

using a suitable cleaning agent, washing machine cleaning agent is used only in accordance

with the use of detergent manufacturers, the use of cleaning agents according to the appropriate

dose and limit requirements.

only by those who have received appropriate training using appropriate tools for maintenance

and repair of the washing machine.

The cleaning or maintenance of the washing machine to turn off power or remove the battery.

To prohibit the use of high-pressure water or steam cleaning equipment for the washing

machine.

The prohibition of electrical components of water.

Note: the use of this cleaning machine to clean up flammable liquids, solvents, fuel, active

metal water vapor or flammable dust.

Item

parameter

Rated voltage

DC24V

Wording width

510mm

5

Suction width

830mm

Work efficiency

3000 ㎡/h

brush

510mm

Brush speed

175rpm

Brush motor

550W

Brush pressure

20kg

Suction motor

500W

vacuum degree

160mbar

Walking motor

500W

Speed

0-6km/h

Maximum gradability

10°(without water)

Turning radius

900mm

Solution tank

70L

Recovery tank

75L

Noise grade

68dB

Battery group

2×DC12V 100AH 3H

Battery weight

70kg

weight(without battery)

112kg

6

4.0 Machine loading and unloading

Special packing fit for forklift loading and

unloading. Can not stack. The net weight is

190kg(without packing).

Packing dimension:

Length: 1400mm

Width: 750mm

Height: 1360mm

5.0 machine disassembly

Take the bag-packed machine in a wide area to

remove the outer packing.

remove the wedge of the fixed wheel. Check if

the brush base and squeegee mounting

brackets are raised.

release the motor brake handle after lifting.

slope down the machine from the wooden

pallet.

direction for use

①power indicator light

②power key switch

③quantity of electricity : three lights

are all on when full power, if only

left light flashed, please

immediately turn off the machine

and charge the battery

④the front and rear walking

converter

7

⑤release lever handle (upward pull water

volume increase)

⑥loudspeaker button

⑦squeegee lifting handle(when the power lock

open, put down this handle, the suction motor

will work automatically, at this moment the

machine can not backward, the handle must

be raised if backward )

⑧brush lifting handle(power lock open, put

down this handle and step⑨accelerator

pedal,brush will work)

⑨accelerator pedal(from shallow to deep, the

machine will from slow to fast)

○

10 steering wheel

○

11 water tank button(water tank could be

tip-back when press the bottom)

○

12 solution tank thread cap(after unscrew,

clean water can put in)

○

13 total power emergency switch

○

14 drive axle electronic brake conversion

handle.

Dial up to stop the use of electronic brake

machine can not use the electric power to

walk, you can use human resources.

Dial down to enable electronic brake, foot

pedal can walk, release the pedal will

8

automatically stop the brake, using human

power to push.

9

○

15 drain out pipe

○

16 water tank cover support frame

○

17 float bowl

○

18 charger power plug

○

19 charger

To start charging, the machine will

automatically cut off the operation,

until the end of charge

10

Brush installation diagram:

1.put ⑧handle up。

2.the brush on the ground, from the side to push

it into the brush under the lid, Visual Basic is the

brush cover round center.

3.put ⑧handle down, the brush cover down

automatically on the brush plate

4.stepping on⑨the pedal to intermittent light

two or three, the brush will be automatically

installed.

Squeegee installation diagram

1.put squeegee in the correct location of

tank back, then pull out the suction pipe

joint out of the cylinder into the middle

of the water column(A)

2.put the bottom of stud insert (B)

3.The plum nut (C) according to the

direction indicated by appropriate

tightening will be installed by hand.

11

1.daily maintenance

1)take down pad holder/brush, and clean specific cleaning agent.

2)drain out the water both in solution tank and recovery tank, and clean by clean water.Check

if there are debris left, if yes, please remove immediately.

3)raise the squeegee assembly off the floor and wipe the rubber with a wet towel

4) remove the vacuum suction filter device rinse with water

5) wipe the machine clean with a specific cleaner

6)charge the battery

7)check the squeegee rubber if damage, if yes,change the other side.

2.monthly maintenance

(1)check the top of battery is clean to prevent corrosion.

(2)check the battery cable is loose or corrosion.

(3)check the water tank cover seal, if damaged please replace.

(4)lubricate all lubrication parts and shafts with special lubricants.

(5)check if machine fasteners are loose.

(6)check if the water tank is leaking.

3. motor maintenance

(1)please contact floor scrubber manufacturer directly.

(2)every 250 hours of use, should check the motor brushes. If the wear is serious, please

contact the manufacturer to replace.

4.battery maintenance

(1)please follow the manufacturers operating manual.

(2)the top electrode and the battery corrosion, soda is ok, can not put the solution into the

battery.

(3)brush for the battery and the battery line part with soda water

(4)regularly check whether the battery cable wear and contact loose, if necessary, please

replace.

5. machine storage

(1)stored in the room, stored in a dry place.

(2)upright storage.

(3)lift brush set off the floor.

(4)lift squeegee assembly off floor.

(5)if the storage place is extremely cold, need to keep the machine completely dry before the

storage machine, in order to avoid low temperature damage.

(6)drain solution and recovery tank.

12

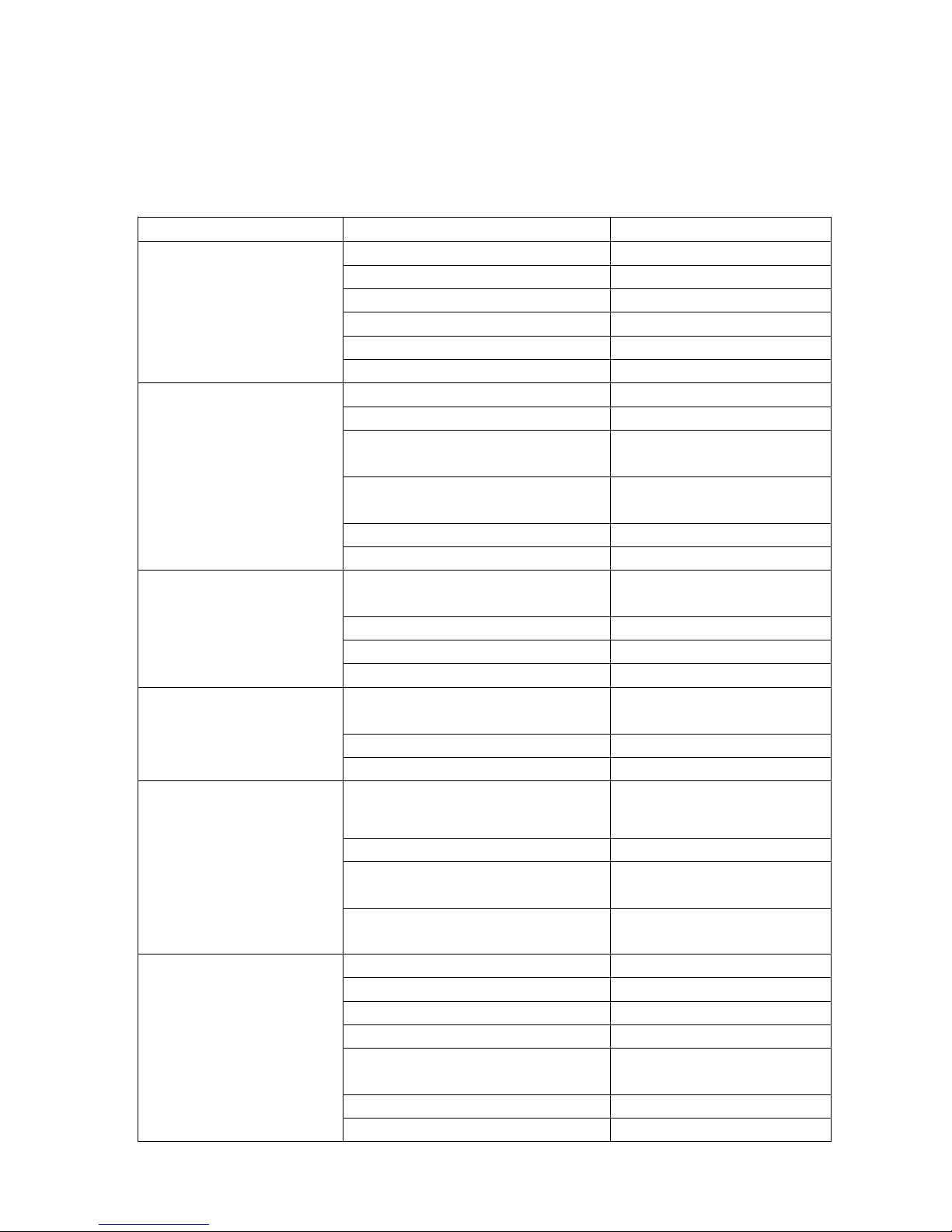

8.0 common faults and solutions

fault

reason

solution

Machine not working

Not open power switch

Open power switch

Battery low power

Charging

Battery damage

Replace battery

Battery connection line loosen

tighten connection line

Fuse damage

Replace fuse

Power key switch damage

Contact supplier

Brush motor not working

Brush not contact with floor

Put down brush

Low battery

Charging

Brush lifting protection switch

damaged

Contact supplier

Brush motor damaged or its line

damaged

Contact supplier

Brush motor carbon brush wear

Contact supplier

Electromagnetic switch damage

Contact supplier

Machine not running

Controller overload protection start

Turn off the power switch

and wait for 2 minutes

Controller damaged

Contact supplier

Drive motor or its line damaged

Contact supplier

Brush motor carbon brush wear

Contact supplier

Suction pump can not run

Suction pump overload fuse burn

off

Replace fuse

Water pump or line damage

Contact supplier

The suction pump wear serious

Contact supplier

Solution flow is little or

no

The ball valve is too small or

closed.

Adjust flow switch

Flow switch is too small or closed

Adjust flow switch

Solution hose or filter blockage

Rinse pipe or filter strainer

with clean water

Drain solenoid valve blocking

Open water solenoid valve

cleaning

Poor water absorption

performance

recovery tank full

Drain recovery tank

The pipe plug is loose.

Tighten the pipe plug.

Floating ball filter blocking

Rinse floating ball filter

Squeegee assembly blocking

Rinse squeegee assembly

Rubber abrasion

Change the other side of

replace

Rubber position is not correct

Adjust the rubber

The suction pipe is not connected

Reliable connection suction

13

reliably with the squeegee

assembly

pipe

Suction pipe blockage

Clear blockage

Water absorption pipe damage

Replace

the lid of the recovery tank is not

covered.

Cover up

recovery tank cover sealing strip

Replace sealing

Suction pump damage

Contact supplier

Short running time

Battery low

Charging

Battery damaged

Replace battery

Battery need maintenance

Check battery maintenance

Charger damaged

Repair or replace charger

Attention: special tips

When a higher step or obstacle is encountered on the ground to block the wheel and when the

upper slope is over, 还要踩死脚踏板硬闯的时候,because the motor torque is not enough to

pass, in order to protect motor, the controller will start overload protection, failure of pedal

walking function. relieve overload protection method is: turn off the power switch and wait 2

minutes, then restart. If the machine cannot pass the obstacle, please use the handle in the

figure 14 indicating dial up. Think of a way to use human resources.

14

15

16

17

18

19

www.starmakina.com.tr

Star Temizlik Makinaları ve Ekipmanları San. Tic. Ltd. Şti.

Ferhatpaşa Mah. 34 Sok. No. 30A

34888 Ataşehir İstanbul TÜRKİYE

Tel. +90 216 471 23 47 Dah./Ext.121

Faks. +90 216 471 22 02

star@starmakina.com.tr

www.staff.com.tr