4

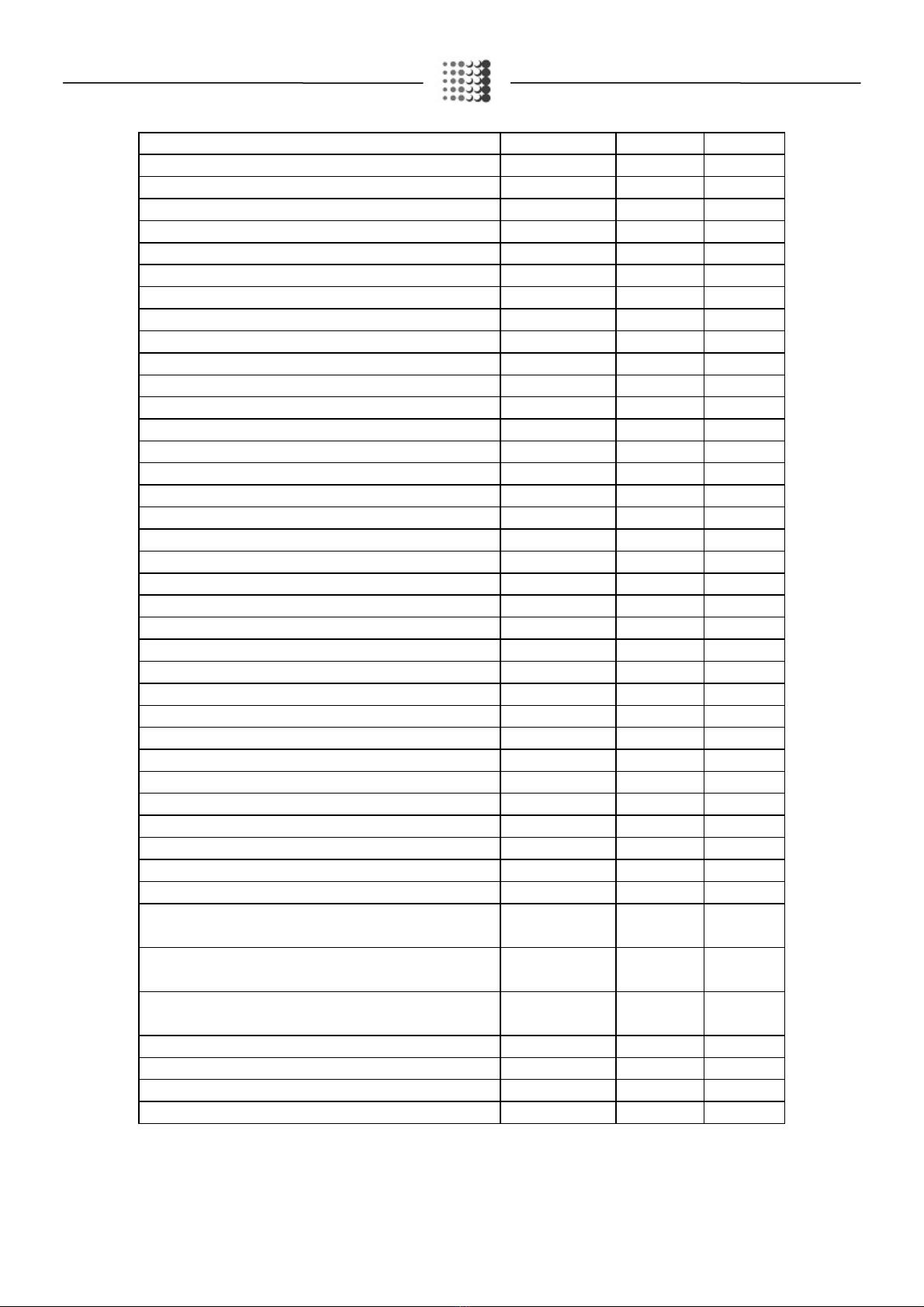

CONTENTS

ON CONSIGNMENT OF THE MACHINE............................................................................................................................................................6

INTRODUCTORY COMMENT............................................................................................................................................................................6

IDENTIFICATION DATA.....................................................................................................................................................................................6

TECHNICAL DESCRIPTION...............................................................................................................................................................................6

INTENDED USE..................................................................................................................................................................................................6

SERIAL NUMBER PLATE..................................................................................................................................................................................6

TECHNICAL DESCRIPTION...............................................................................................................................................................................7

SYMBOLS USED ON THE MACHINE................................................................................................................................................................8

GENERAL SAFETY REGULATIONS...............................................................................................................................................................10

MACHINE PREPARATION...............................................................................................................................................................................11

1. HANDLING OF THE PACKED MACHINE......................................................................................................................................................................... 11

2. HOW TO UNPACK THE MACHINE................................................................................................................................................................................... 11

3. HOW TO MOVE THE MACHINE....................................................................................................................................................................................... 11

4. HANDLEBAR CONTROL COMPONENTS........................................................................................................................................................................ 12

5. STEERING COLUMN COMPONENTS (B VERSIONS).................................................................................................................................................... 12

6. STEERING COLUMN COMPONENTS (HYBRID VERSIONS)......................................................................................................................................... 12

7. FOOTBOARD COMPONENTS.......................................................................................................................................................................................... 12

8. FRONT COMPONENTS.................................................................................................................................................................................................... 13

9. SIDE COMPONENTS........................................................................................................................................................................................................ 13

10. REAR COMPONENTS OF THE MACHINE..................................................................................................................................................................... 13

11. BATTERY TYPE (B VERSIONS)..................................................................................................................................................................................... 13

12. BATTERY TYPE (HYBRID VERSIONS).......................................................................................................................................................................... 14

13. BATTERY MAINTENANCE AND DISPOSAL.................................................................................................................................................................. 14

14. FITTING THE BATTERIES INTO THE MACHINE (B VERSIONS)................................................................................................................................. 14

15. FITTING THE BATTERIES INTO THE MACHINE (HYBRID VERSIONS)...................................................................................................................... 15

16. CONNECTING THE BATTERIES AND BATTERY CONNECTOR (B VERSIONS)........................................................................................................ 16

17. CONNECTING THE BATTERIES AND BATTERY CONNECTOR (HYBRID VERSIONS)............................................................................................. 17

18. BATTERY CHARGER CONNECTION (B VERSION, WITHOUT BC)............................................................................................................................. 17

19. BATTERY CHARGER CONNECTION (B VERSION, WITH BC).................................................................................................................................... 18

20. CONNECTING THE BATTERY CHARGER (HYBRID VERSIONS)................................................................................................................................ 20

21. BATTERY CHARGE LEVEL INDICATOR (B VERSIONS).............................................................................................................................................. 21

22. HOUR METER ................................................................................................................................................................................................................. 21

23. WORKING FORWARD SPEED....................................................................................................................................................................................... 21

24. BLINKING LIGHT (OPTIONAL)........................................................................................................................................................................................ 22

25. FILLING THE FUEL TANK (HYBRID VERSIONS).......................................................................................................................................................... 22

26. HEADLIGHTS................................................................................................................................................................................................................... 22

PREPARING TO WORK...................................................................................................................................................................................23

27. PREPARING TO WORK (B VERSIONS)......................................................................................................................................................................... 23

28. PREPARING TO WORK (HYBRID VERSIONS) ............................................................................................................................................................. 24

WORK ...............................................................................................................................................................................................................25

29. STARTING WORK (B VERSIONS).................................................................................................................................................................................. 25

30. STARTING WORK (HYBRID VERSIONS) ...................................................................................................................................................................... 27

31. EMERGENCY BUTTON................................................................................................................................................................................................... 31

32. ALTERNATOR FAULT WARNING LIGHT (HYBRID VERSIONS).................................................................................................................................. 31

33. EMPTYING THE DEBRIS HOPPER................................................................................................................................................................................ 32

AT THE END OF WORK...................................................................................................................................................................................34

DAILY MAINTENANCE ....................................................................................................................................................................................36

34. CLEANING THE CENTRAL BRUSH ............................................................................................................................................................................... 36

35. CLEANING THE SIDE BRUSH........................................................................................................................................................................................ 37

WEEKLY MAINTENANCE................................................................................................................................................................................38

36. CLEANING THE PANEL FILTER..................................................................................................................................................................................... 38

37. CLEANING THE FABRIC FILTER (OPTIONAL).............................................................................................................................................................. 39

38. CLEANING THE DEBRIS HOPPER................................................................................................................................................................................ 40

EMERGENCY MAINTENANCE........................................................................................................................................................................41