1P128

Introduction..............................................................................................................................3

Location Reference............................................................................................................3

Parts Ordering....................................................................................................................3

SECTION I - MACHINES WITH FRONT BOX ONLY

Safety Suggestions ...................................................................................................................4

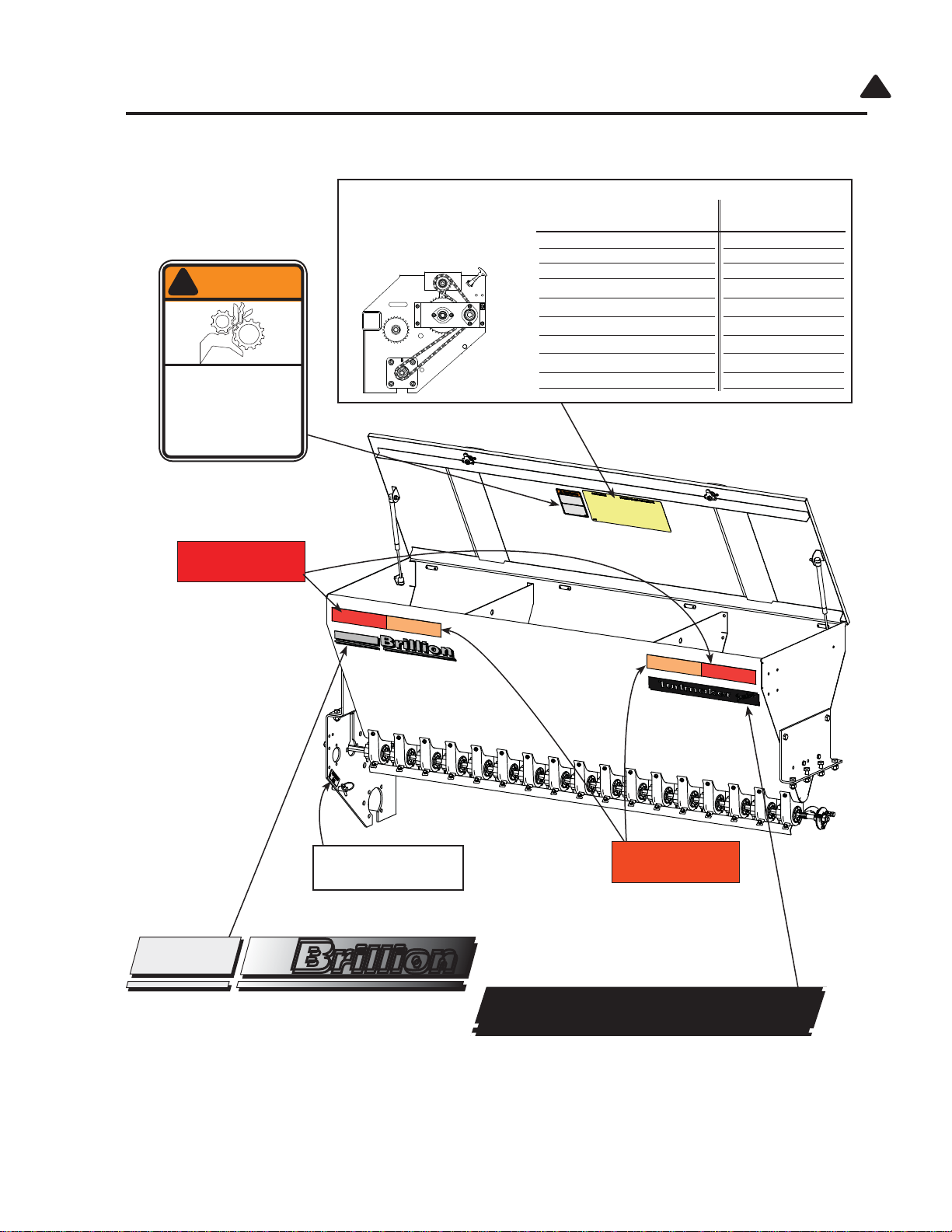

Safety Warning Decals.......................................................................................................5

Safety Decal Location- Front Seedbox ..........................................................................6, 7

Assembly/Set-up .......................................................................................................................8

Unhitching & Parking Pin ...................................................................................................8

Assembly of Options .................................................................................................................9

Lift Sling Kit........................................................................................................................9

Acre Meter Kit .............................................................................................................10-11

Operating Instructions .............................................................................................................12

Acre Meter ..................................................................................................................12-13

Seeding Rate Adjustment ...........................................................................................14-15

Seed Rate Calibration & Seed Charts .............................................................................16

Adjustment of Wheel Track Remover ..............................................................................17

Maintenance............................................................................................................................18

Lubrication .......................................................................................................................18

Roller Wheels...................................................................................................................18

Chain Tension ..................................................................................................................19

Acre Meter .......................................................................................................................19

Feed Cup Adjustment ......................................................................................................20

Adjustment Wrenches......................................................................................................21

SECTION II - ADDITION OF OPTIONAL REAR SEEDBOX

Decal Locations - Rear Seedbox ....................................................................................25

Assembly Instructions .............................................................................................................26

Rear Box End Plates........................................................................................................26

Deflector...........................................................................................................................27

Seed Box .........................................................................................................................28

Right End Seed Shaft & Bearing......................................................................................29

Transmission..............................................................................................................30, 31

Operating Instructions .............................................................................................................32

Seed Rate, Feed Cup Adjustment .............................................................................32, 33

Seed Rate Calibration & Seed Charts .............................................................................34

Chain Tension ..................................................................................................................35

Specifications ..........................................................................................................................36

Model Designations .........................................................................................................36

Dimensions ......................................................................................................................36

Optional Equipment List w/ Weights........................................................................................36

Contents

806 Page 1