Stardex 0304 User manual

HELSINKI, FINLAND, 2015

COMMON RAIL INJECTORS TESTER

STARDEX® 0304

Safety rules for working with STARDEX 0304 device.

Before using the device STARDEX 0304 (further “the device”) read this manual carefully.

The device should be plugged only in a circuit of alternative current, mentioned in the

passport of the device. In order to power up the device, use only supply cable from the

delivery kit.

Getting the electrical charges on device body is strongly prohibited!

Ingress of moisture inside the device is strictly unacceptable!

Device body is constructed to protect its components from mechanical impact while

operating. Avoid body damage, do not drop the device and do not put any heavy objects on

its cover.

At any sign of device defect, as smoke, sparking or specific smell, unplug the device

immediately and contact the nearest STARDEX service center.

All cables, connected to the device, must be supplied with standard plugs without

mechanical damage.

There are no self-repairable parts inside the device. It is strongly prohibited to open the

device.

Store and use away from children and pets.

The device is designed to work with common rail system. A user must understand the

structure and principle of operation of injection systems.

Incorrect use of the device can lead to breakage of the equipment or user’s injury.

Specifications and operation directions

Dimensions

450х400х200 mm

AC power supply

220V 50Hz or 110V 60Hz

Power consumption in stand-by mode

40W

Power consumption in load mode

400W

Operating temperature

From -100С to + 500С

Relative air humidity

not more than 90% at 250С

Purpose and range of application.

STARDEX 0304 is a highly professional universal device for testing pumps and

injectors of Common Rail system.

The device is designed to work with Common Rail systems by Bosch, Delphi, Denso,

Siemens, Caterpillar, Cummins and is also able to test all mechanical injectors as well

as nozzles of the unit-injectors.

The device is specified to test from one (combined with a hand pump) to six (while

using a test bench) injectors simultaneously.

It works both with electromagnetic and piezoelectric Common Rail injectors.

It enables to test current characteristics of an injector, displaying a high-precision

current graph on the screen.

The device is equipped with a full-fledged industrial PC system powered by Ubuntu

Linux, allowing you to connect a keyboard, mouse, printer and monitor directly to

STARDEX 0304.

STARDEX 0304, combined with a hand pump, enables to make an express test of

Common Rail injectors on the following parameters: efficiency, leakage, quality of

injection, pressure at the beginning of the injection, state of electromagnetic coil

(solenoid) or piezoelement of injector.

The memory of the device contains approximately 1500 test-plans for checking

pumps and Common Rail injectors: Bosch, Delphi, Denso, Siemens, Caterpillar,

Cummins and over 10000 test-plans for checking mechanical injectors of different

manufactures.

The device STARDEX 0304 combined with the bench is a full-fledged, highly

professional solution, which enables doing completed test and setting of Common

Rail system pumps and injectors according to all necessary parameters in semi-

automatic mode, following step-by-step instructions contained in the device in the

form of test-plans.

The device is suitable for fitting out any high pressure pump test bench, including

test benches without measuring unit.

Connectors and control buttons.

①Power cable connector.

②Power switch.

③RPM sensor connector.

④Pressure sensor connector.

⑤Injector cable connector.

⑥Regulator connector 1.

⑦Regulator connector 2.

⑧Regulator connector 3.

⑨USB ports.

⑩Output for external display.

1

2

3

4

9

5

8

7

6

10

①Front panel light diode

Has 3 states:

No light –the device is de-energized.

Red light –standby mode.

Green light –the device is on.

②On/off button.

1

2

Switching on / off the device.

Fix the AC power switch 230V –115V in the needed position.

Plug in the device, using the power cable from the supply kit which must be attached to the

power cable connector.

Connect mouse, keyboard, printer and LCD monitor to appropriate connectors on the back

panel of the device.

Connect the pressure sensor to the pressure sensor connector using the appropriate cable.

Connect the fuel rail pressure regulator to regulator connectors 2, 3 using the appropriate

cables.

Connect injectors to the injector cable connector using the appropriate cable.

Switch on the power button.

Run the operating system using the on/off button on the front panel.

Once the operating system is loaded, the device is ready to be used.

To switch off the device, press the on/off button on the front panel of the device. When

the light diode is red, switch off the power button.

Main menu.

After switching on and loading the device, the main menu is shown on the display, where

the user can choose the mode of the device.

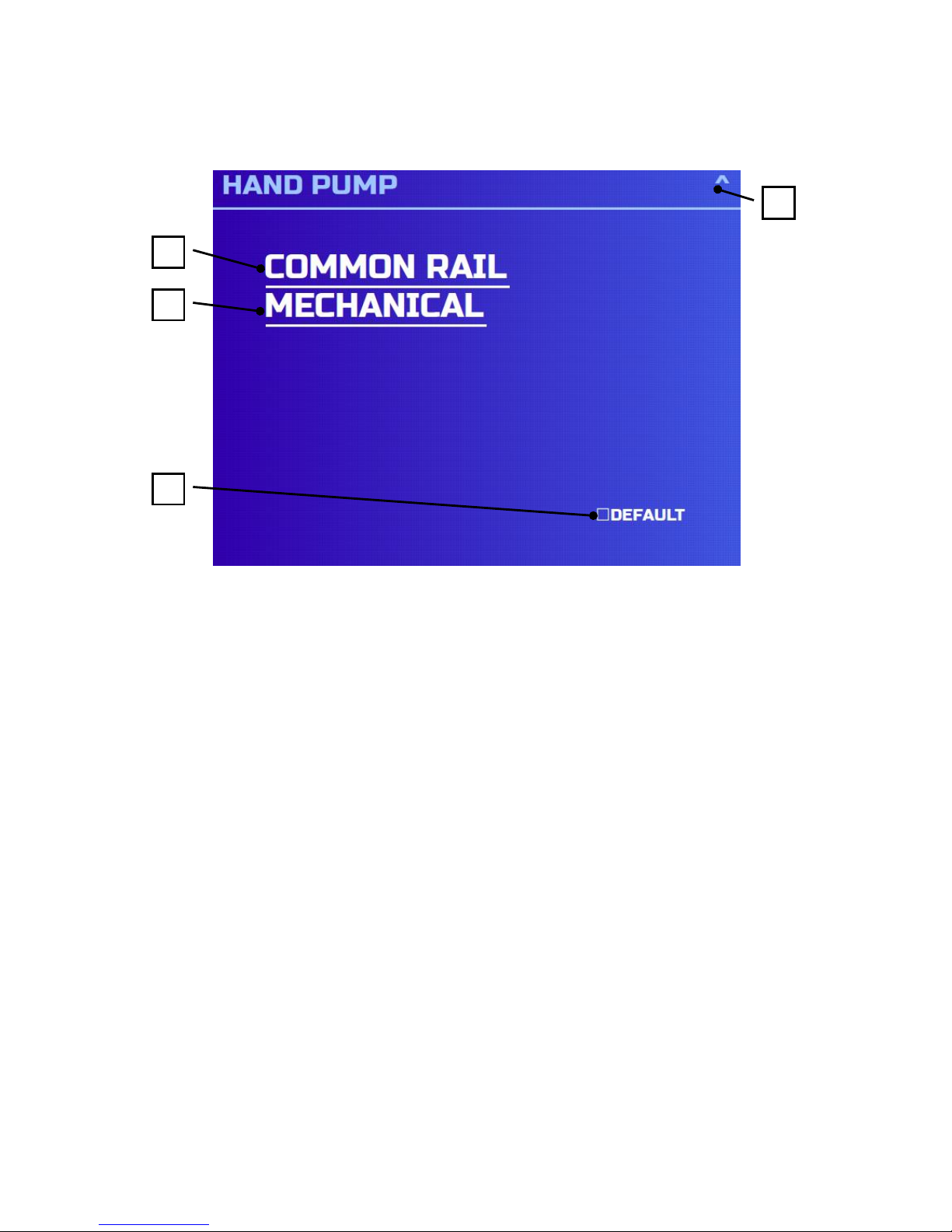

①HAND PUMP is a mode for testing mechanical and common rail injectors with the hand

pump.

②TEST BENCH is a mode for testing injectors and common rail pumps on the high

pressure pump bench.

③DEFAULT if the field is ticked the next chosen mode will be loaded by default during the

following launch.

1

2

3

HAND PUMP (MAIN > HAND PUMP)

After going to HAND PUMP, the hand pump mode menu will be displayed.

①COMMON RAIL –testing of Common Rail injectors on the hand pump (express test).

②MECHANICAL –testing of usual mechanical injectors on the hand pump.

③DEFAULT –if the field is ticked, the next chosen mode will be loaded by default, during

the following launch.

④Quit to main menu (MAIN).

1

2

3

4

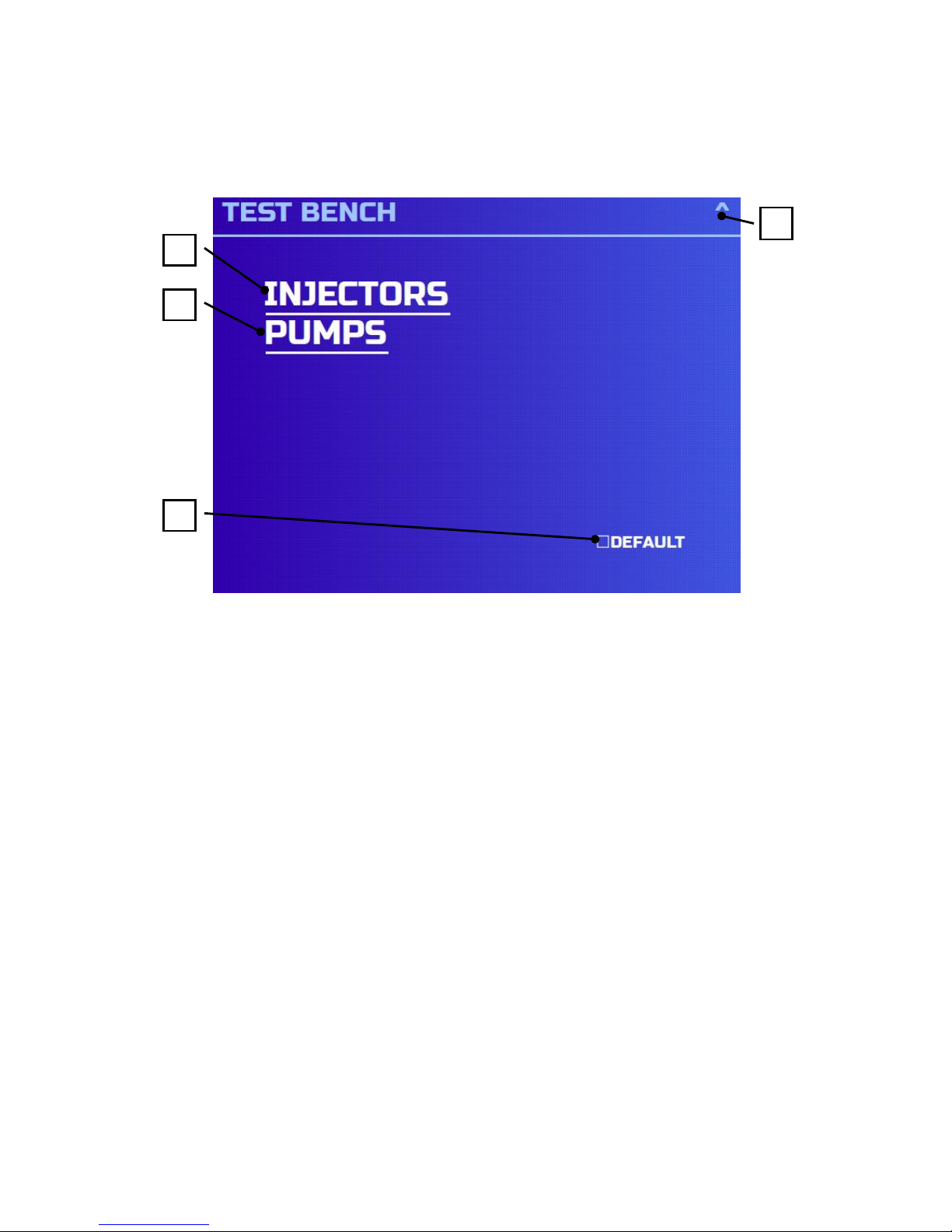

High pressure pump bench (MAIN > TEST BENCH)

After going to TEST BENCH, the high pressure pump bench menu will be shown on the

display.

①INJECTORS –testing of common rail injectors on the high pressure pump bench in hand

or semi-automatic mode.

②PUMPS –testing of common rail pumps on the high pressure pump bench in hand or

semi-automatic mode.

③DEFAULT - if the field is ticked, the next chosen mode will be loaded by default, during

the following launch.

④Quit to main menu (MAIN).

1

2

3

4

1

2

3

4

5

6

7

Testing of common rail injectors on the hand pump (MAIN > HAND

PUMP > COMMON RAIL)

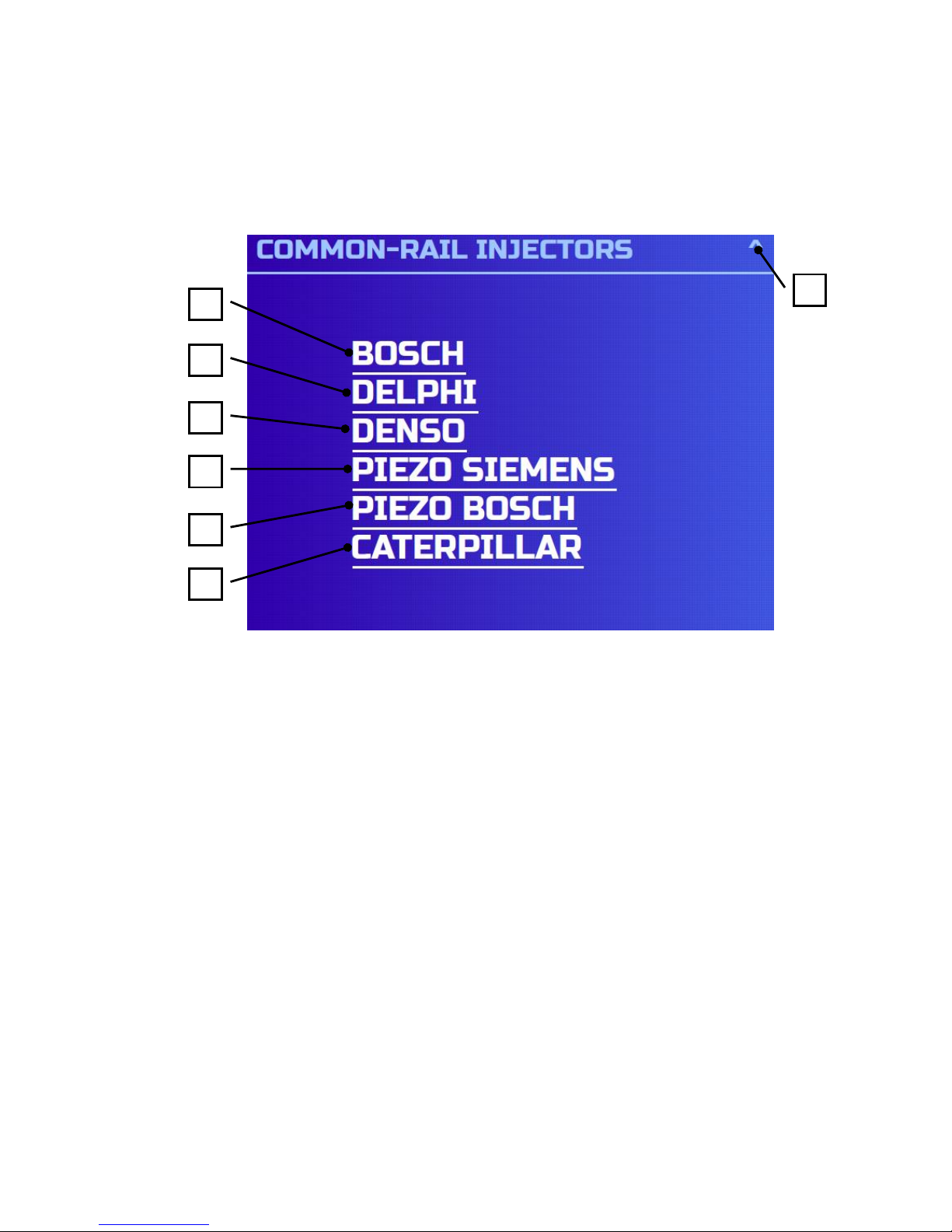

After going to the common rail injector test mode on the hand mode, the selection of

injector types will be displayed on the screen.

①BOSCH –electromagnetic injectors Bosch.

②DELPHI –electromagnetic injectors Delphi.

③DENSO –electromagnetic injectors Denso.

④SIEMENS –piezoelectric injectors Siemens.

⑤PIEZO BOSCH –piezoelectric injectors Bosch.

⑥CATERPILLAR –electromagnetic injectors Caterpillar.

⑦Quit to main menu (MAIN).

All Common Rail injectors have different current-voltage characteristics, so, it is

extremely important to select the type of the tested injector correctly. Incorrect choice

may cause injector’s or device’s damage!

After selecting the type of the injector, the express test window will open.

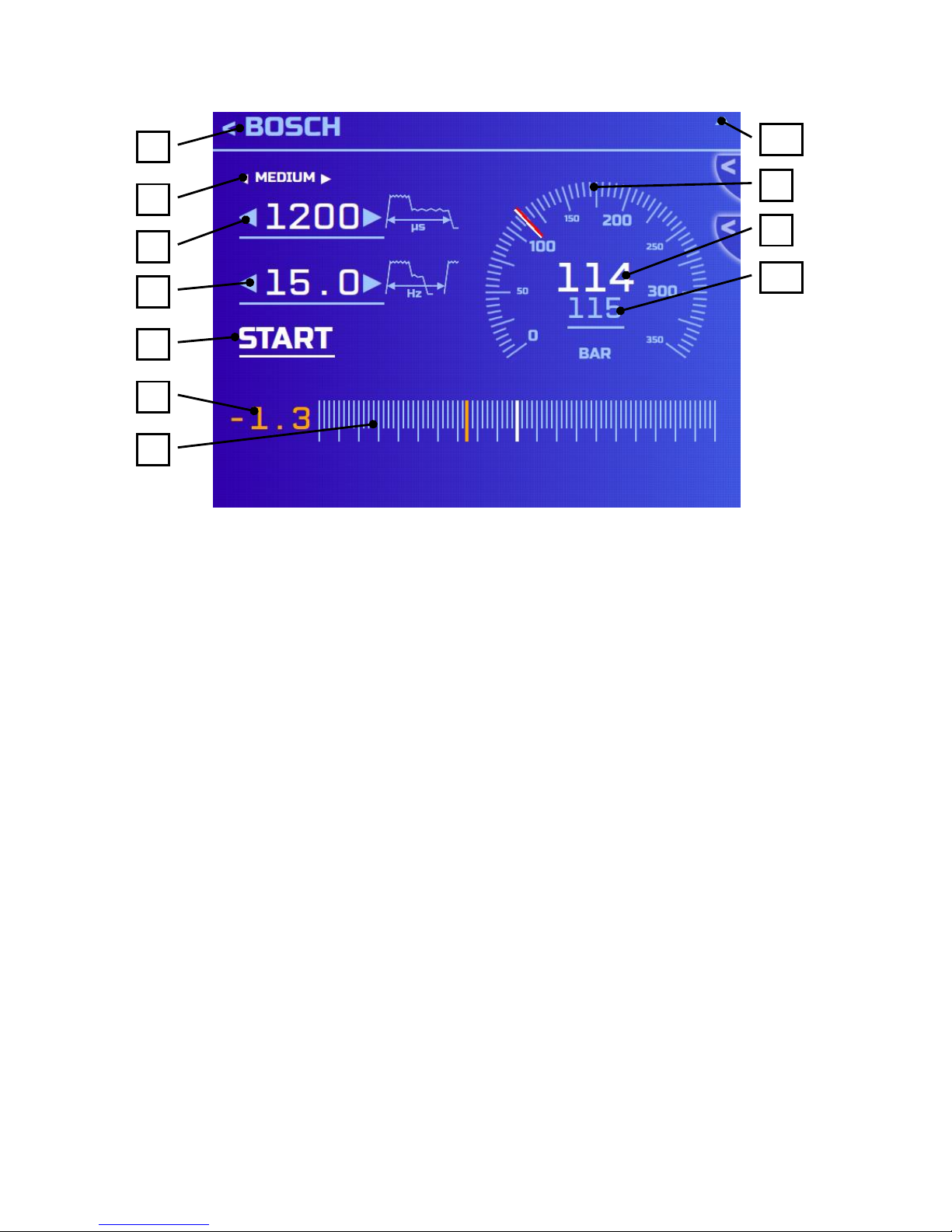

①Type of tested injector.

②Pre-installed pulse mode –beforehand installed pulse characteristics for an injector

(width, frequency).

Minimal –500 microseconds 20Hz.

Low –800 microseconds 20 Hz.

Medium –1200 microseconds 15 Hz.

High –1500 microseconds 10 Hz.

③Pulse width is the exact period of time when the injector is operating, which is called

pulse width of injection or duration of injection, and is measured in microseconds.

④Pulse frequency –the number of complete injections per 1 sec measured in Hz.

⑤START/STOP button switches on and off pulse to the injector with the determined

width and frequency.

⑥Leakage is a digital speed indication of pressure, falling in the injector, which is

expressed by the time needed for pressure to fall from 350 bar to 200 bar in the tested

injector on the hand pump.

⑦Leakage scale is a graphical display of leakage on the screen. The fixed white stripe

stands for 0. Movable stripe, that changes its color, identifies the current value of leakage.

1

2

3

4

5

6

7

11

8

9

10

⑧Pressure scale is a graphical display of pressure on the screen. The movable white stripe

shows the value of pressure in the rail at the moment. The movable red stripe shows

maximal fixed pressure in the fuel rail.

⑨ Current pressure is real pressure in the fuel rail, fixed by the pressure sensor.

⑩Maximal pressure is maximal pressure fixed in the fuel rail. The value of maximal

pressure is instantly updated, when user presses on it.

⑪Quit to main menu (MAIN).

Install Common Rail injector on the hand pump and make sure all connections are sealed.

Connect injector to injector cable connector using universal cable with an appropriate cap.

Connect the fuel rail pressure sensor for testing one injector installed on the hand pump to

the pressure sensor connector. Switch on STARDEX 0304 and follow MAIN > HAND PUMP >

COMMON RAIL. Select the type of the injector tested. Select pulse width and frequency.

Press START/STOP button to start injector’s work. Create pressure in the fuel line using the

hand pump handle. Measure pressure at the beginning of an injection. Press START/STOP

button to stop injector’s work and create pressure in the fuel rail, higher than 370 bar,

using the hand pump handle. With the falling of pressure in the fuel rail, starting with 350

bar, counting of injector leakage will automatically start and will stop when it is 200 bar.

Pressure at the beginning of injection and leakage of the injector are the most important

parameters in the express diagnostics of Common Rail injectors.

Reference data on leakage of Common Rail injectors.

Bosch and Denso Common Rail injectors have the following gradation of leakage:

From -5 to -2 critically bad

From -2 to -1 relatively bad

From -1 to 0 relatively operational

From 0 to 1 good

From 1 and higher very good

Delphi, Piezo Bosch, Siemens Common Rail injectors have the following gradation of

leakage:

From -5 to -1 critically bad

From -1 to 0 relatively bad

From 0 to 1 relatively operational

From 1 to 3 good

From 3 and higher very good

Reference data at the beginning of injection on MEDIUM pulse.

Bosch cars 190 bar ± 25 bar

Bosch trucks 200 bar ± 30 bar

Denso cars, trucks 190 bar ± 40 bar

Delphi cars 175bar ± 30 bar

Delphi trucks 200 bar ± 30 bar

Siemens and Piezo Bosch 170bar ± 25 bar

These reference materials are generalized and accurate for most of Common Rail

injectors!

When conduct express diagnostics, it is important to note, that all tested Common Rail

system injectors taken from one engine have the same pressure at the beginning of the

injection, otherwise adjustment on the high pressure pump bench is required.

Testing of mechanical injectors on the hand pump (MAIN > HAND

PUMP > MECHANICAL)

After going to MECHANICAL, the window for selecting a serial number will open.

① Filter is a line for inputting a part of a serial number to simplify search in the data base.

Data base records which do not contain the inserted part of the number will be

automatically removed from the screen.

② Quit to menu HAND PUMP.

1

2

After selecting the type of tested injectors, the test window will open.

①Opening injector pressure –fixed pressure of the injector opening.

②Reset button cleans a value of opening injector pressure before next testing.

③Reference data is a list of the reference data about opened injector or nozzle (data span

of opening pressure in bar).

④Pressure scale is a graphical display of pressure on the screen. The movable white stripe

shows the value of pressure in the rail at the moment. The movable red stripe shows

maximal fixed pressure in the fuel rail.

⑤Current pressure is real pressure in the fuel rail fixed by the pressure sensor.

⑥Maximal pressure is maximal pressure fixed in the fuel line. The value of maximal

pressure is instantly updated when press on it.

⑦Quit to menu HAND PUMP.

Install a mechanical injector on the hand pump and make sure all connections are sealed.

Connect the fuel rail pressure sensor for testing one injector installed on the hand pump to

the pressure sensor connector by the cable from the kit. Switch on STARDEX 0304 and

follow to MAIN > HAND PUMP > MECHANICAL. Choose the serial number of the injector or

the nozzle. Create pressure in the fuel rail which is enough for the injector to be activated

by the hand pump. Pressure of the tested injector is shown by big numerals in the left top

corner of the screen and by the red stripe on the pressure scale.

1

2

3

5

4

6

7

1

2

3

To get accurate value of opening injector pressure the handle of the hand pump must be

moved several times!

Testing of Common Rail injectors on the high pressure pump bench

(MAIN > TEST BENCH > INJECTORS)

After following to INJECTORS, the window for selecting the test mode will open.

①Manual is a manual mode for testing on the high pressure pump bench.

②Testplan is a semi-automatic mode for testing injectors according to testplan.

③ Quit to menu TEST BENCH

1

2

3

4

5

6

7

After going to TESTPLAN, the window for selecting the type of common rail injectors will

open.

①BOSCH –electromagnetic injectors Bosch.

②DELPHI –electromagnetic injectors Delphi.

③DENSO –electromagnetic injectors Denso.

④SIEMENS –piezoelectric injectors Siemens.

⑤PIEZO BOSCH –piezoelectric injectors Bosch.

⑥CATERPILLAR –electromagnetic injectors Caterpillar.

⑦Quit to menu TEST BENCH.

All Common Rail injectors have different current-voltage characteristics so it is extremely

important to select the type of the tested injector correctly. Incorrect choice may cause

injector’s or device’s damage!

1

2

After choosing the manufacturer, the window for selecting injector serial number will open.

① Filter is a line for inputting a part of a serial number to simplify search in the data base.

Data base records, which do not contain the inserted part of the number, will be

automatically removed from the screen.

② Quit to menu TEST BENCH.

1

2

3

4

5

6

7

8

10

9

12

11

13

14

17

15

16

After selecting injector serial number, the window for testing Common Rail injectors on the

high pressure pump bench will open.

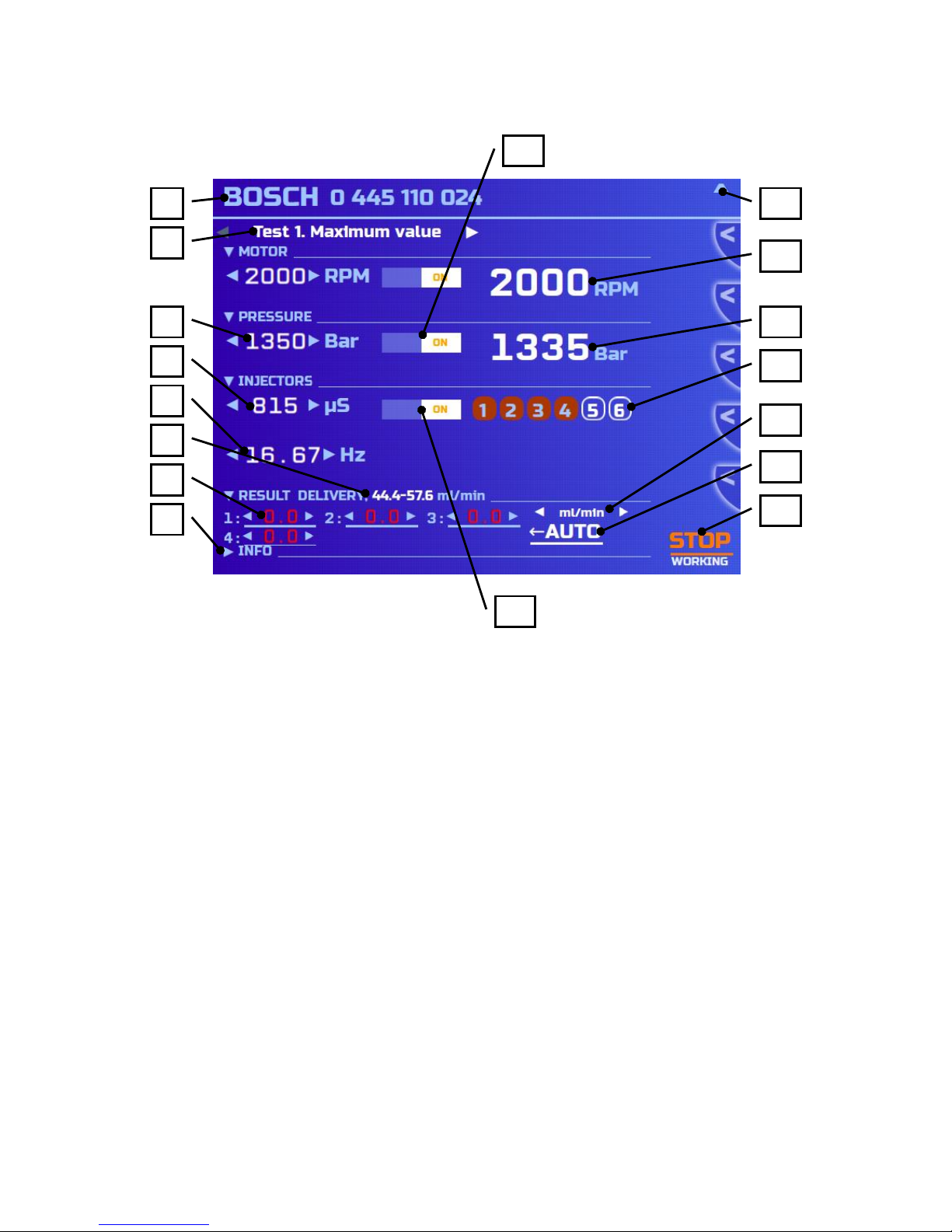

①Information line is a line where manufacturer and serial number of tested injectors are

shown.

②Test step shows the name of the current testing mode, the horizontal arrows change

modes.

③Target pressure is pressure which will be set in the fuel rail if you activate control of the

reducing valve by ON/OFF switch in the section PRESSURE or by the button START/STOP.

If the Common Rail bench pump has lower productivity than required for testing this type

of injectors or back flow of injector is too high, real pressure in the rail can be fixed

considerably lower than target. In such case Common Rail bench pump should be

replaced by more productive one or number of injectors tested simultaneously should be

lessened.

④Pulse width –the exact period of time when the injector is operating, which is called

pulse width of injection or duration of injection, it is measured in microseconds.

⑤Pulse frequency –the number of complete injections per 1 sec measured in Hz.

Table of contents

Other Stardex Test Equipment manuals

Popular Test Equipment manuals by other brands

TES

TES TES-1392 instruction manual

PCE Health and Fitness

PCE Health and Fitness PCE-EMF 823 Operation manual

PCB Piezotronics

PCB Piezotronics 301A03 Installation and operating manual

Fluke

Fluke 712B/EN user manual

Temper

Temper Koban KCER-01MF manual

Spirent

Spirent A1-400-QD-16-T1P installation instructions