Stardex 0803 User manual

Test Bench

STARDEX® 0803/ STARDEX® 0803M

"Compact"

Safety rules for working with STARDEX 0803/ STARDEX 0803M.

Before using the device STARDEX 0803/ STARDEX 0803M (further “the test bench”), read

this manual carefully.

The test bench should be plugged only in a three-phase circuit of alternative current 380 -

400 V with grounding.In order to power up the test bench, use only a supply cable from the

delivery kit.

Getting the electrical charges on device body is strongly prohibited!

Ingress of moisture inside the device is strictly unacceptable!

Test bench body is constructed to protect its components from mechanical impact, while

operating. Avoid the body damage, do not drop the test bench and do not put any heavy

objects on its cover.

At any sign of the device defect as smoke, sparking or specific smell, unplug the test bench

immediately and contact the nearest STARDEX service center.

All cables, connected to the test bench must be supplied with standard plugs without

mechanical damage.

Opening operating test bench is strictly prohibited.

Store and use away from children and pets.

The test bench is designed to work with high pressure systems.A user must understand the

structure and principle of operation of the high pressure injection systems.

Incorrect use of the test bench may lead to breakage of the equipment or user’s injury.

While working on the bench with high pressure, it is necessary to use protective cover.

Initial bench connection to AC3 power should be done only by a qualified electrician.

Specifications and operation directions.

European version

Dimensions

1250х800х1620 mm

AC power supply

AC3 380 - 400 V

Motor power

7.5 kW

Tank capacity

42 L

Maximum supply pressure

6 Bar

Power consumption in maximum load

Up to 7.5 kW

mode

Operating temperature

from +100С to + 300С

Relative air humidity

No more than 90% at 250С

Purpose and range of application.

STARDEX 0803/STARDEX 0803M is a universal bench for testing elements of

Common Rail,Unit Injector and Unit Pump systems by such manufacturers, as

Bosch, Delphi, Denso, Continental (Siemens), Detroit, Caterpillar, Cummins and

others.

STARDEX 0803is designed to work with simulators STARDEX 030x or STARDEX

100x.Bench control is performed directly from the interface of STARDEX simulators.

STARDEX 0802M is designed to work with third-party simulators and controlled by

itsown built-in computer.

There are two types of STARDEX 0803 configuration:

-to test Common Rail system (pumps, injectors, high pressure rails, regulators

and pressure sensors).

-to test Unit Injector and Unit Pump systems.

The complex to test Common Rail system consists of STARDEX 0803, pulse simulator

STARDEX 0304 and measuring unit STARDEX 0104.

The complex to test Unit Injector and Pump Unit systems consists of STARDEX 0803,

STARDEX 1002 and CAMBOX.

Conversion of the bench from one configuration to another takes about 10 -

15 minutes

Using the STARDEX 0803 has several advantages against the "usual" classical

benches. Firstly, it is fully compatible with STARDEXsimulators. Secondly, it

has test automation. Thirdly, it has small size and weight.

Installing and connecting

Unpack the test bench and install it on antivibration mountings.

Distance between the wall and the back panel must not be less, than 0,3 m for free

work of the cooling fans.

The front and back panels must be opened, in order to make sure there are no

damages of the equipment, wiring and fuel lines, which may be caused by incorrect

transporting.

Pour a calibration fluid into the mouth of the tank and open its ventilation by turning

a special valve on the cover of the tank.

Install the front and rear panels of the bench, back to the bench.

Plug into a three-phase circuit of alternative current 380 - 400 V with grounding with

the power cable (Pin description of a power connector is in the next chapter).

Install on the bench additional necessary equipment.

The test bench is ready to be used.

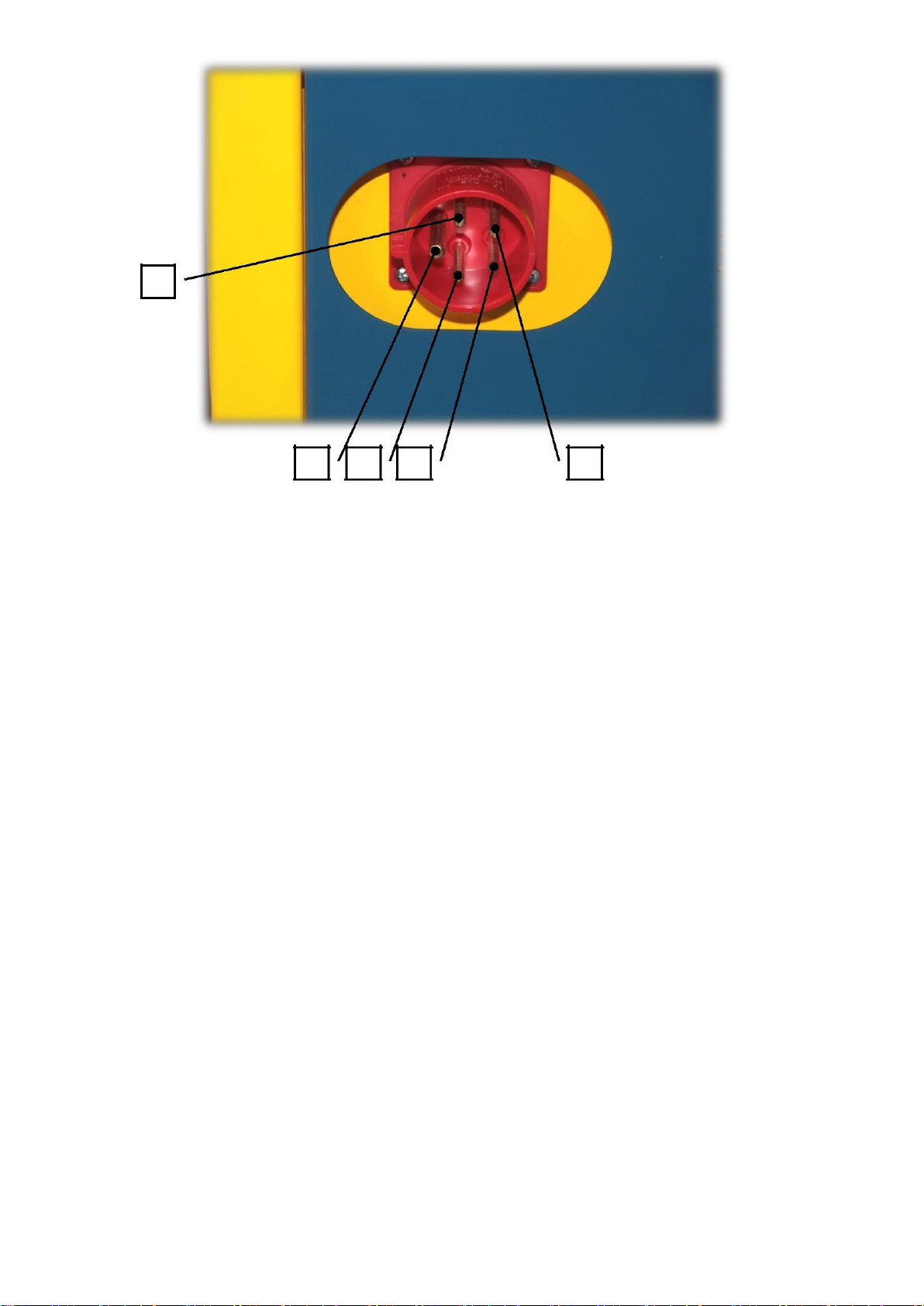

Buttons and connectors.

1

2

3

① Emergency stop.

② The bench on/off.

③ Internal bench lightning.

4

④ USB connector for STARDEX 030x or STARDEX 100x

1

① N

② Ground

③ L1

④ L2

⑤ L3

2

3

4

5

Low pressure lines.

1

2

3

4

4

3

2

5

① Pressure regulator for the line ②

② Fuel supply from the feed pump

③ Return flow into the tank

④ Return flow into the tank through the regulator ⑤

⑤ Return flow pressure regulator

Unused lines must be closed by special plugs!

The test bench service procedures.

It is important to monitor the condition of the test fluid in the tank of the bench

and if necessary replace the filter elements in a timely manner.

Sludge storage tank should be drained as required. For this purpose, it is necessary

to remove, drain and set it in its place.

In case of leakage of compounds, due to normal wear, it is necessary to timely replace

the worn parts.

12

① Filter

② Filter

3

③ Tank filler cap with ventilation valve

4

④ Sludge storage tank

Bench control.

Additional menus for speed control and direction of rotation of the motor will automatically

appear in the program interface of STARDEX 030x or STARDEX 100х. Turning on and off the

feed pump is also performed with these devices. Pressure control of the feed pump and

pressure in the return flow is performed by mechanical valves and electronic pressure sensors,

mounted on the bench. Detailed descriptions of the testing procedures of CommonRail system

contained in the STARDEX 0304 user’s manual. Detailed descriptions of thetesting procedures

of UIS and UPS systems contained in the STARDEX 1002user’s manual.

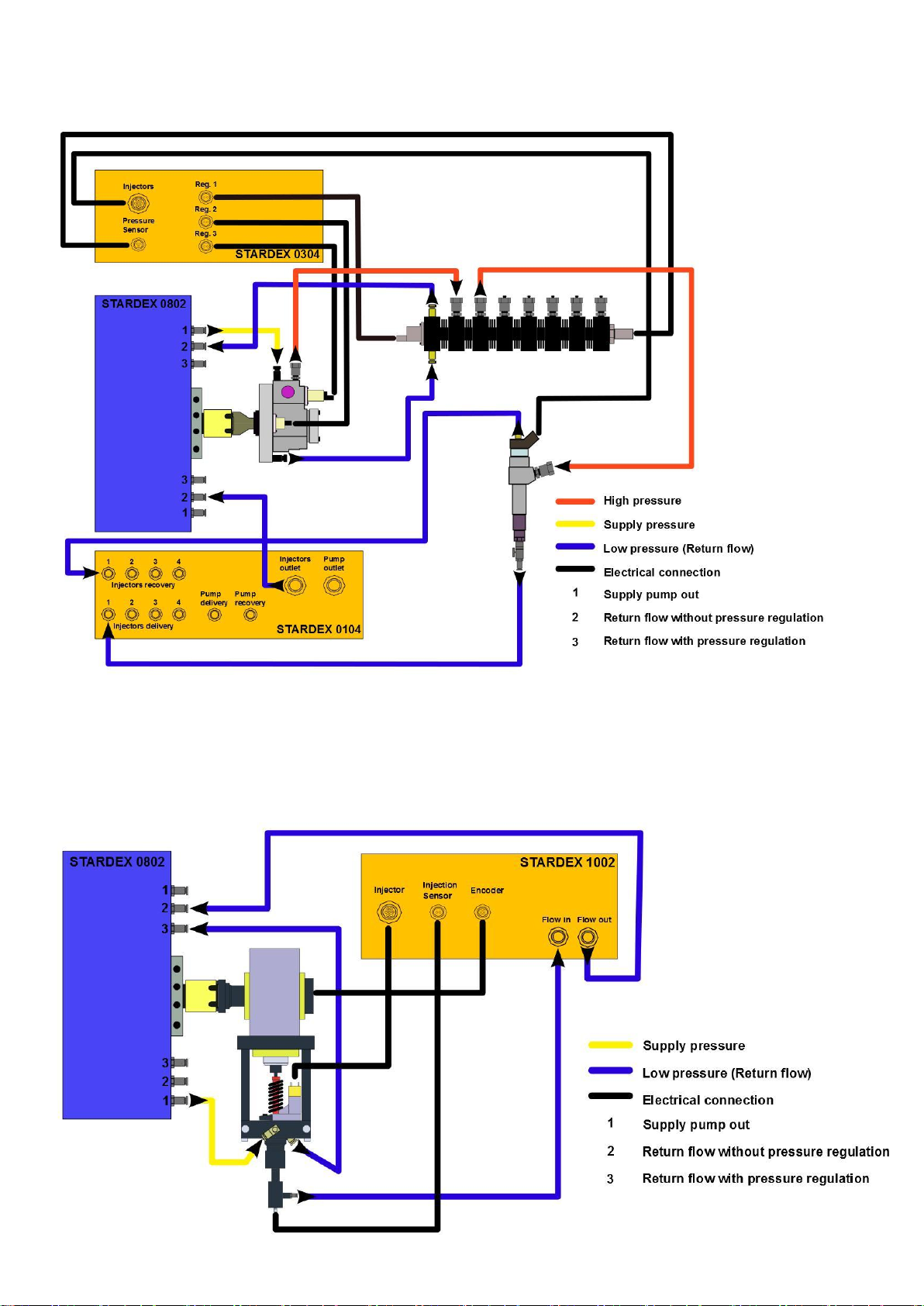

Connection pattern for Common Rail pump test.

Connection pattern for Common Rail injectors test.

Connection pattern for UIS test

Supply kit.

Basic

STARDEX 0803assembled

1 шт.

Power cable

1 шт.

USB cable

1 шт.

Users manual

1 шт.

Warranty card

1 шт.

The additional test equipment for testing Common Rail system, UIS and UPS (simulators,

flow meter, mounting kits, protective cover, trolley, etc.) is not included in the supply kit

and should be purchased separately.

Warranty and technical support.

The equipment has 1 year warranty. The manufacturer is not responsible for the damage,

due to violation of the operation terms, misuse including unskillful or mistaken personnel

actions and if there are traces of mechanical impact. Post-warranty service of device is

performed at cost components and the work. The manufacturer reserves the right to

design modifications, equipment and the warranty period without advance notice. Details

of warranty described in the warranty card.

MANUFACTURED BY:

OY STARDEX LTD

PULTTITIE 2

00880 HELSINKI

FINLAND

+358 (0)44 5523130

www.stardex.fi

This manual suits for next models

2

Table of contents

Other Stardex Test Equipment manuals

Popular Test Equipment manuals by other brands

MULTILANE

MULTILANE ML 4015D user manual

Kikusui

Kikusui TOS5101 Operation manual

Kusam-meco

Kusam-meco KM 4234 ER Operation manual

BZB Gear

BZB Gear BG-AVTPG-8K user manual

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. 8031 instruction manual

Metrix

Metrix MX 407 user manual

EMTEST

EMTEST CNI 503 Series Manual For Operating

digi-tech

digi-tech CG Wizard user manual

phase II+

phase II+ SRG-2000 instruction manual

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. 3005A instruction manual

EMTEST

EMTEST CWS 500A / 75 manual

DuraSat

DuraSat DUR-line SF 4000 BT quick start guide