EAZY-CAL™ LVC-4500

LVDT Diff/Sum Mode Signal Conditioner

TE CONNECTIVITY SENSORS /// LVC-4500 USER MANUAL 07/2019

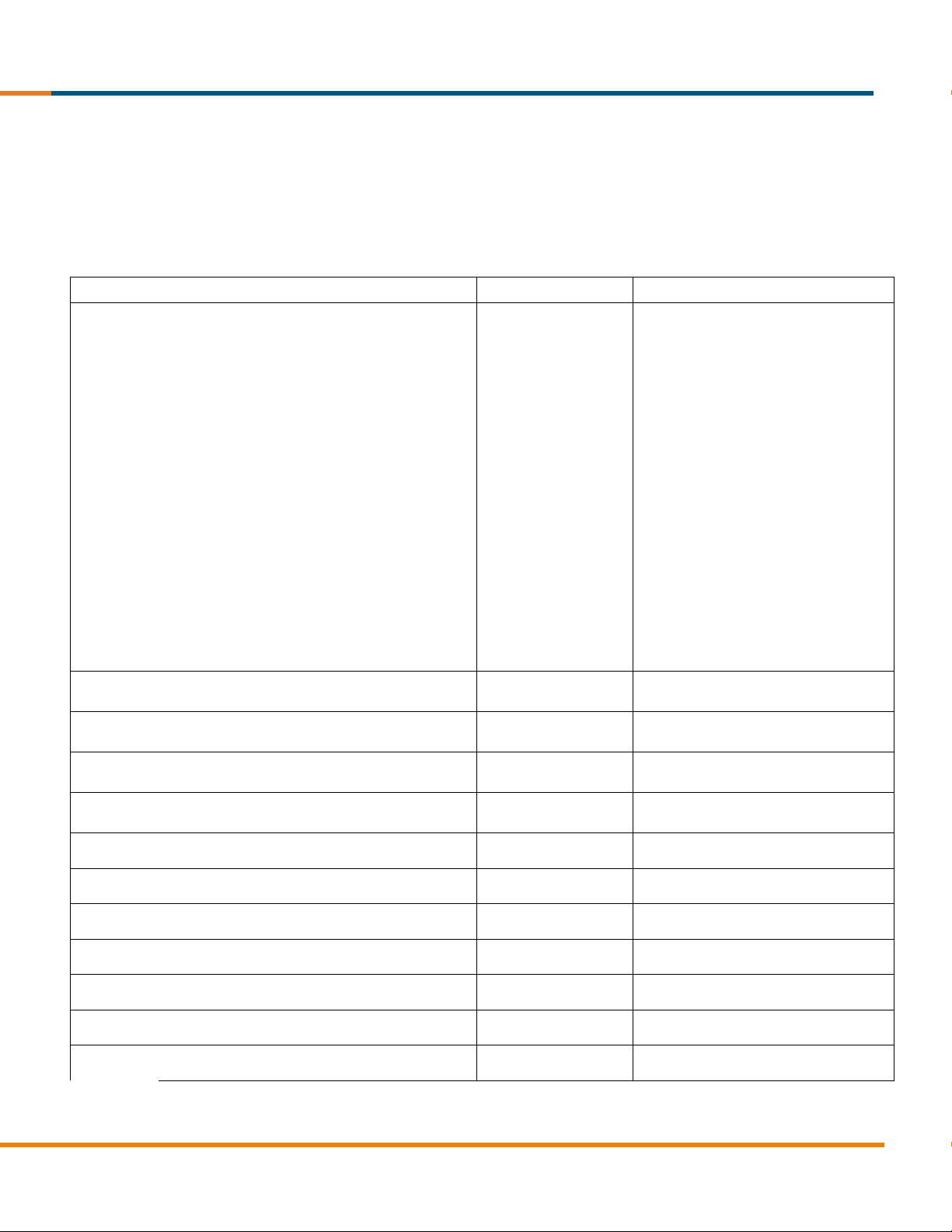

Pess FULL SCALE utto to set oe aiu edpoit positio

Pess oth uttos fo seods to aot Caliatio Mode

5 Calibration Procedure

Calibrating the LVC-4500 consists of entering Calibration Mode, finding the NULL (center) position of the LVDT core, attaching the core to the

object to be measured, and then moving the core to set the ZERO and FULL SCALE positions that will correspond to the minimum and

maximum output voltage or current. The LVC-4500 returns to Operating Mode immediately after both positions have been set.

The basic calibration instructions are printed on the side of the LVC-4500 for reference.

Directions are as follows:

1. Set the LVC-4500 DIP Switches for the desired application. The factory default settings are typical for most standard LVDTs. Refer

to Section 3 for details.

2. Connect the LVDT to the LVC-4500 as shown in the connection diagram. The Secondary Center Tap connection is required in

Diff/Sum Mode, but optional in Differential Mode.

3. Apply power. The OPER/CAL LED will light, along with the Green NULL LED (if the unit is in Master Sync mode), or the Yellow +

LED (if the unit is in Slave mode). Three minutes of warm-up time is recommended.

4. Enter Calibration Mode by pressing and holding the FULL SCALE and ZERO Buttons on the LVC-4500 front panel, simultaneously

for 3 seconds minimum. The OPER/CAL LED will begin blinking.

5. Move the LVDT core to NULL (green LED) position by observing the 3 Position LEDs. The + and – LEDs indicate that the core is

inserted or extended beyond the NULL, respectively.

6. Attach the core to the workpiece to be measured so that the workpiece center of motion is aligned with the LVDT NULL.

7. Move workpiece to its minimum position and press the ZERO button. Wait for the Position LEDs to stop blinking.

8. Move workpiece to its maximum position and press the FULL SCALE button. The unit will exit Calibration Mode and operate with its

new calibration. The OPER/CAL LED will be steady On.

5.1 Notes Regarding Calibration

It is important that the NULL position be set as close as possible to the center of the displacement range. Otherwise, non-linearity errors

may result at or near the endpoint positions.

The LVDT core MUST NOT protrude from the LVDT during the calibration, or erroneous calibration will result.

Calibration may be performed by setting the FULL SCALE position first rather than ZERO position. Either end position may be on either

side of NULL.

Any portion of the LVDT specified displacement can be calibrated to produce a full output span with an LVDT having sufficient sensitivity.

If the desired displacement is asymmetrical, set the endpoint that is farthest from NULL first.

Swapping SEC-1 with SEC-2 or PRI-1 with PRI-2 LVDT connections will reverse the direction indicated by the Position LEDs.

Calibration mode can be canceled at any time by pressing the 2 buttons simultaneously for 3 seconds.

LVDTs without a constant secondary voltage sum may not yield as linear an output when operated in the Diff/Sum Mode.

6 RS-485 Digital Interface

Included on the LVC-4500 is a 2 wire multi-drop RS-485 communications port. This allows a user to perform a remote calibration through a

host computer. It also offers the user the capability of receiving operational status information and the retrieval of measurement data. Data

can be exchanged between one or more units and a PC with a USB-to-RS485 adapter attached. A terminal program (Hyperlink) or 3rd party

software is required. Port parameters are set to 9600 bps, no parity, 8 data bits and 1 stop bit (9600, NP, 8,1). Data is ASCII.