Stark Tools USA 61110 User manual

800W ELECTRIC JACK HAMMER DEMOLITION CHISEL BIT

SAVE THIS MANUAL: KEEP THIS MANUAL FOR SAFETY WARNINGS, PRECAUTIONS, ASSEMBLY,

OPERATING, INSPECTION, MAINTENANCE AND CLEANING PROCEDURES. WRITE THE PRODUCT’S

SERIAL NUMBER ON THE BACK OF THE MANUAL NEAR THE ASSEMBLY DIAGRAM (OR MONTH

AND YEAR OF PURCHASE IF PRODUCT HAS NO NUMBER)

OWNER’S MANUAL AND SAFETY INSTRUCTIONS

ITEM: 61110

FOR QUESTIONS PLEASE CALL OUR CUSTOMER SUPPORT: (909) 628 4900 MON-FRI 9AM TO 3PM PST

IMPORTANT SAFETY INFORMATION

GENERAL SAFETY WARNINGS

Read all safety warnings and instructions. Failure to follow the warnings and instructions

may result in electric shock, re and/or serious injury. Save all warnings and instructions

for future reference.

SAFETY

The warnings, precautions, and instructions discussed in this instruction manual cannot cover

all possible conditions and situations that may occur. It must be understood by the operator that

common sense and caution are factors which cannot be built into this product, but must be supplied

by the operator. Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS

before operating. Failure to follow the safety rules and other basic safety precautions may result in

serious personal injury.

Read and understand all instructions. Failure to follow all instructions may result in serious injury

or property damage.

DO NOT allow persons to operate or assemble the product until they have read this manual and

have developed a thorough understanding of how it works.

DO NOT modify this product in any way. Unauthorized modication may impair the function and/or

safety and could affect the life of the product. There are specic applications for which the product

was designed.

Use the right tool for the job. DO NOT attempt to force small equipment to do the work of larger

industrial equipment. There are certain applications for which this equipment was designed. This

product will be safer and do a better job at the capacity for which it was intended. DO NOT use this

equipment for a purpose for which it was not intended.

Keep children and bystanders away from the work area while operating the tool. DO NOT allow

children to handle the product.

Hazardous voltage can shock, burn, or cause death. To reduce the risk of electric shock, DO NOT

use an extension cord to connect unit to electric supply. Provide a properly located outlet. It is required

that licensed electricians do all electrical wiring. All electrical wiring MUST be in conformance with

applicable local and national codes and regulations. Before working on pump or motor, disconnect

motor wiring.

People with pacemakers should consult their physician(s) before use. Electromagnetic elds in close

proximity to heart pacemaker could cause pacemaker interference or pacemaker failure.

Before plugging in the tool, be certain the outlet voltage supplied is within the voltage marked on the

nameplate. Do not use “AC only” rated tools with a DC power supply.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is grounded. If operating the power tool in damp

locations is unavoidable, a Ground Fault Circuit Interrupter must be used to supply the power to your

tool. Electrician’s rubber gloves and footwear will further enhance your personal safety.

When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W.” These

cords are rated for outdoor use and reduce the risk of electric shock.

Always use both handles for maximum control over this hammer. Never attempt to operate this tool with

one hand. This tool develops intense percussive forces during operation and you may lose control if

attempting one hand operation.

1

POWER TOOL USE AND CARE

DO NOT force the power tool. Use the correct power tool for your application. The correct power tool

will do the job better and safer at the rate for which it was designed.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power

tool to operate the power tool.

DO NOT use the power tool if the Switch does not turn on and off. Any power tool that cannot be

controlled with the Switch is dangerous and must be repaired by a qualied technician.

Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s operation. If damaged, have the power tool repaired

before use.

Disconnect the plug from the power source before making any adjustments, changing accessories or

storing power tools.

Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into

account the working conditions and the work to be performed.

Wear ear protectors. Exposure to loud noise can cause hearing loss. Wear steel-toed boots during use.

Use auxiliary handles supplied with the tool. Loss of control can cause personal injury.

Hold power tools by gripping surfaces when performing an operation where the cutting tool may contact

hidden wiring or its own cord. Keep clear of moving parts.

Unplug before inspecting, removing or installing chisel or performing any service.

Pull on chisel after installation and before use; chisel may move but MUST NOT slide out.

DO NOT operate this tool if you have back, neck, wrist injuries or other conditions that will be

aggravated by the forces that this tool exerts upon the operator.

Avoid unintentional starting. Prepare to begin work before turning on the tool.

DO NOT lay the tool down until it has come to a complete stop. Moving parts can grab the surface and

pull the tool out of your control.

When using a hand-held power tool, maintain a rm grip on the tool with both hands to resist starting

DO NOT leave the tool unattended when it is plugged into an electrical outlet. Turn off the tool and unplug

it from its electrical outlet before leaving.

IMPORTANT SAFETY INFORMATION

Use clamps or other practical way to secure and support the work-piece to a stable platform. Holding the

work by hand or against your body is unstable and may lead to loss of control.

Tool service must be performed only by qualied repair personnel. Service or maintenance performed by

unqualied personnel could result in a risk of injury. For example: internal wires may be misplaced or

pinched, safety guard return springs may be improperly mounted.

When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section

of this manual. Use of unauthorized parts or failure to follow Maintenance Instructions may create a risk of

electric shock or injury. Certain cleaning agents such as gasoline, carbon tetrachloride, ammonia, etc. may

damage plastic parts.

DO NOT use dull or damaged bits and accessories. Dull or damaged bits have a greater tendency to bind

in the work-piece.

2

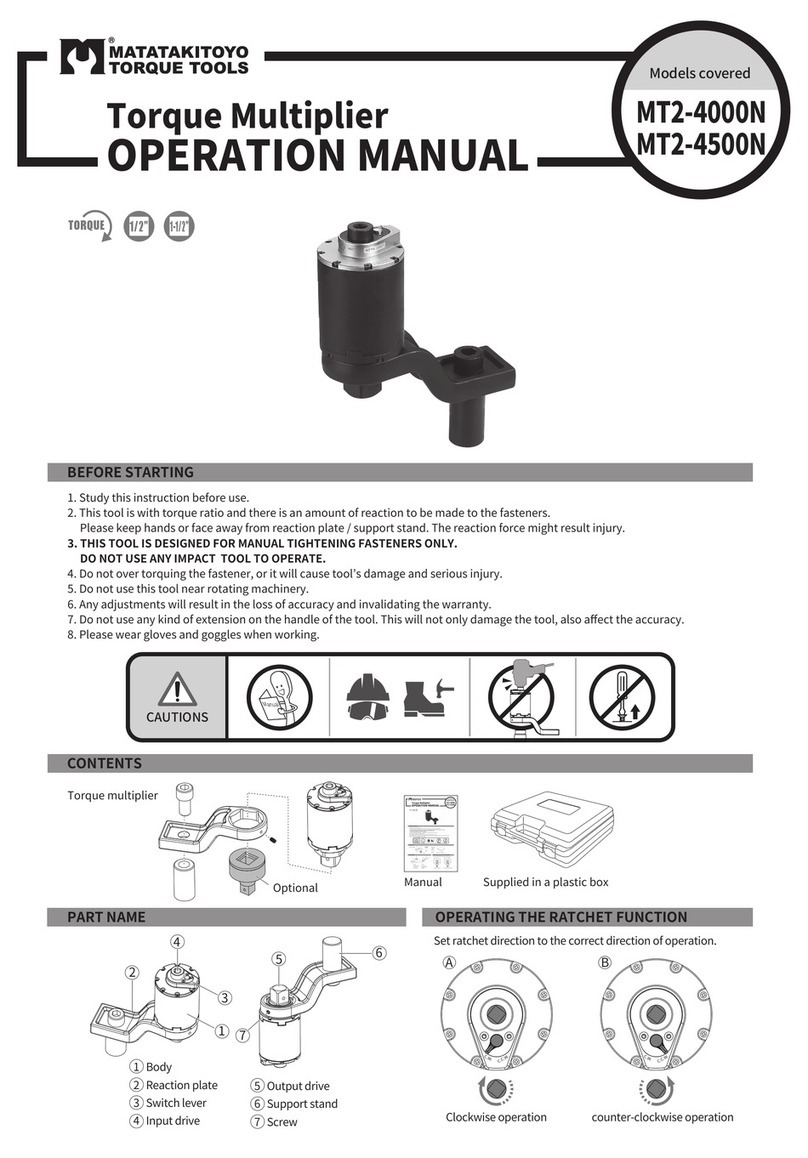

FEATURES & SPECIFICATIONS

POWER SWITCH

SCALING BIT

BULL POINT BIT

SPADE BIT

SQUARE CLAY CHISEL

BIT

LOCKING

SLEEVE

AUXILIARY

HANDLE

POWER

CORD

SELECTOR RING

VENTILATION

OPENINGS

HAND

GRIP

FEATURES AND SPECIFICATIONS

2800W input power

Assembled Product Dimensions (L x W x H) 35.00 x 14.00 x 8.00 Inches

Industrial Quality, Very Durable

Heavy Duty Construction

Voltage: 120v/60hz

No Load Speed: 1900RPM

Impact rate 1400 r/min

360 Swivel Handle

Slip Prevent Handle Grip

Suitable For Home And Business Heavy Duty Case With 2 Wheels & Handle

This 2800W jack hammer is ideal for demolition, trenching, chipping, breaking holes in concrete-block-

brick, removing foundation concrete slab, oil chimney and so on. It features heavy duty construction

with industrial grade for high durability. It features two chisels for multiply functions. It comes along with

360 degree swivel handle with slip prevent grip for stable grips. It is suitable for home and commercial

applications.

3

OPERATION

FEATURES AND SPECIFICATIONS

Heavy Duty Case With 2 Wheels & Handle

4

COMMON APPLICATIONS:

Piping & wiring installation

Sanitary facility installation

Machinery installation

Water supply & drainage work

Interior work

Civil engineering work

PRIOR TO OPERATION:

1. POWER SOURCE: Ensure that the power source to be utilized conforms to the power specications

on the nameplate.

2. GROUNDING: This tool should be grounded while in use to protect the operator from electric shock.

This tool is equipped with a three conductor cord and grounding type plug to t the proper grounding

receptacle. The green (or green and yellow) conductor in the cord is the grounding wire. Never connect

the green (or green and yellow) wire to a live terminal.

3. POWER SWITCH: Make sure the power switch is in the OFF position. If the plug is connected to a

power receptacle while the power switch is in the ON position. Make sure you are ready to start work

before starting the tool. Failure to do so may cause serious injury.

4. EXTENSION CORD: ALWAYS use an extension cord of sufcient thickness and rated capacity. The

extension cord should be kept as short as is practical.

5. FEEDING OIL: Prior to using the power tool. Remove the oil gauge and ll the oil tank with the provided

oil. Although the oil tank is built in, it contains only a small amount of oil when shipped from the factory.

MOUNTING A TOOL:

(A) Rotate the Stop Lever 180-degrees in a clockwise

direction while pulling it towards you. Next, insert the

tool shank into the hexagonal hole on the front cover.

(B) Clamp the tool by turning the stop lever half a turn in the

opposite direction. NOTE: When removing the tool, follow the

above procedure in reverse order.

COMMON APPLICATIONS:

USING THE HAMMER: After placing the tip of the tool in the

base, hold the switch ON. By utilizing the weight of the machine

and rmly holding the hammer with both hands, one can

effectively control the recoil motion. Proceed at a moderate work

rate. The use off too much force will impair efciency.

CAUTION: Sometimes the tool will not begin the striking stroke even when the motor rotates because the

oil has become too thick. If the tool is used at low temperatures, or if it is used after an extended idle time,

the tool should be used after running it for ve minutes to warm it up.

MAINTENANCE AND INSPECTION

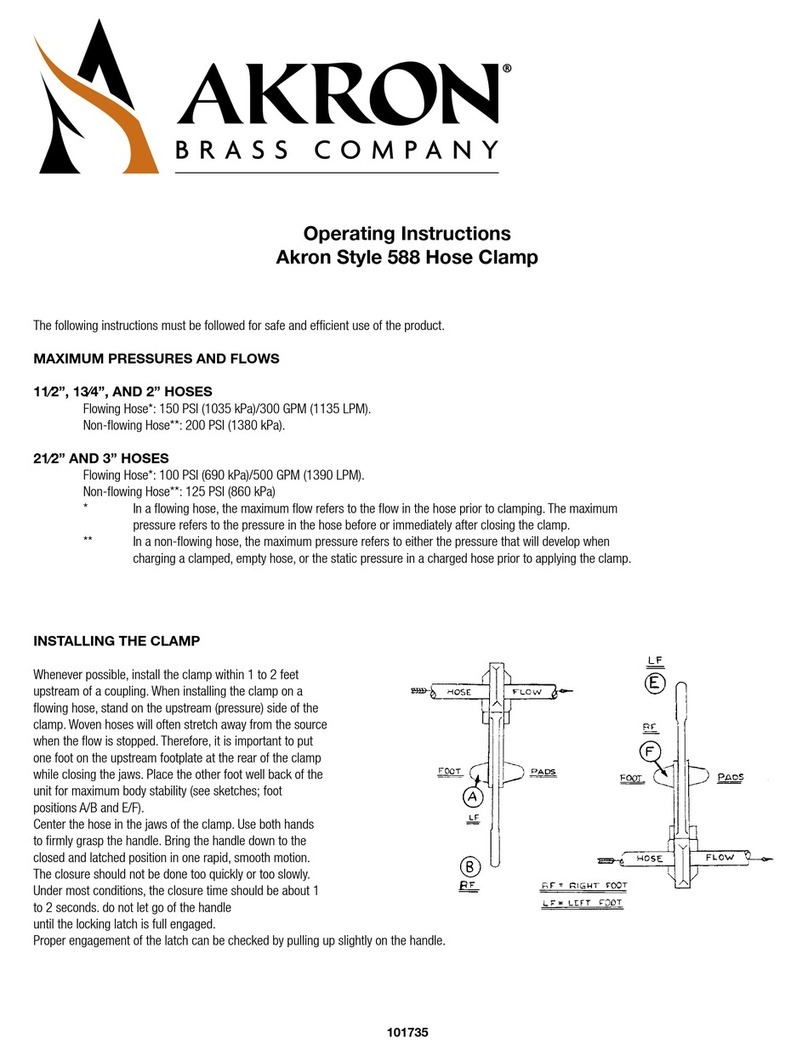

OIL FEEDING: Prior to oil feeding, ALWAYS disconnect the

plug from the power receptacle. Since the oil chamber is built

into the tool, it can be used approximately 20 days at 3-4 hours

a day, without supplying lubricating oil.

Just before there is no oil visible in the oil gauge window when

holding the hammer upright use the provided wrench to remove

the oil gauge. Be careful not to lose the rubber backing attached

below the oil gauge. Fill the chamber with oil.

Check the oil level daily, conrming the oil level is full. After

feeding oil be sure to securely clamp the oil gauge.

INSPECTING THE TOOL: Using a dull or worn tool can cause

motor malfunctions and degraded efciency. Replace with a new tool

when wear is noted.

Inspecting the Mounting Screws: Regularly inspect all mounting

screws and ensure they are sufciently tightened. Should any of the

screws be loose. Re-tighten immediately before use.

Maintenance of the Motor: The motor unit Winding is essential to

the power tool. Ensure the Winding does not become damaged or wet

with oil or water.

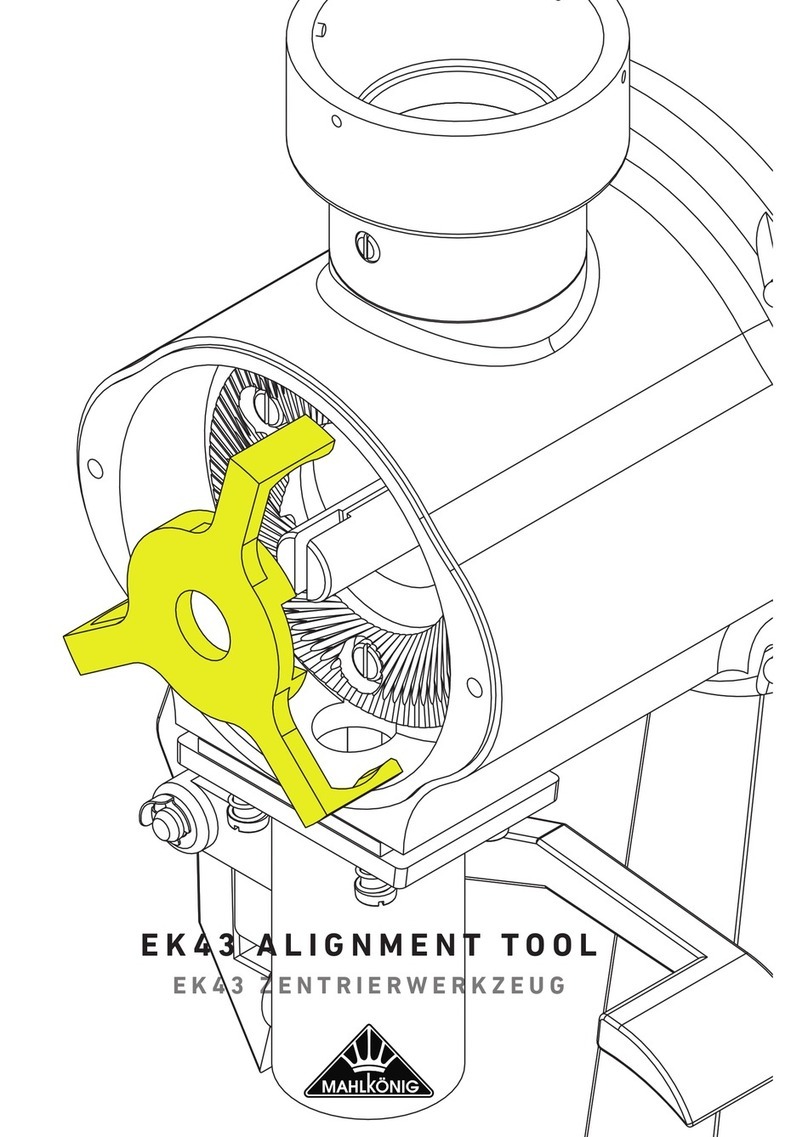

Inspecting the Carbon Brushes: The motor employs carbon brushes which

are consumable parts. When they become worn, or near to wear limit, it can

result in motor malfunction when the “Auto-Stop” carbon brush is equipped,

the motor will stop automatically. At that time, replace both carbon brushes

with new ones. Always keep brushes clean and ensure they slide freely within

the brush holders. The carbon brush can be removed by removing the cap

cover. Cap rubber and brush cap in the order at the interior.

NOTE: Due to continuing program research and development, the specications herein are subject to

change without prior notice.

Lubrication: Your tool comes has been properly lubricated and ready for use. It is recommended that tools

with gears be re-greased with a gear lubricant at every brush change.

Bearings: Every second brush change, the bearings should be replaced by a qualied technician.

Bearings that become noisy, due to heavy load or very abrasive material cutting, should be replaced

immediately to avoid overheating or motor failure.

Cleaning: Disconnect the tool from power source prior to maintenance or cleaning of the power tool. The

tool may be cleaned most effectively with compressed dry air. Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do not attempt to clean by inserting pointed objects through

openings.

Certain cleaning agents and solvents damage plastic parts. Some of these are gasoline, carbon tetrachloride,

chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.

5

6

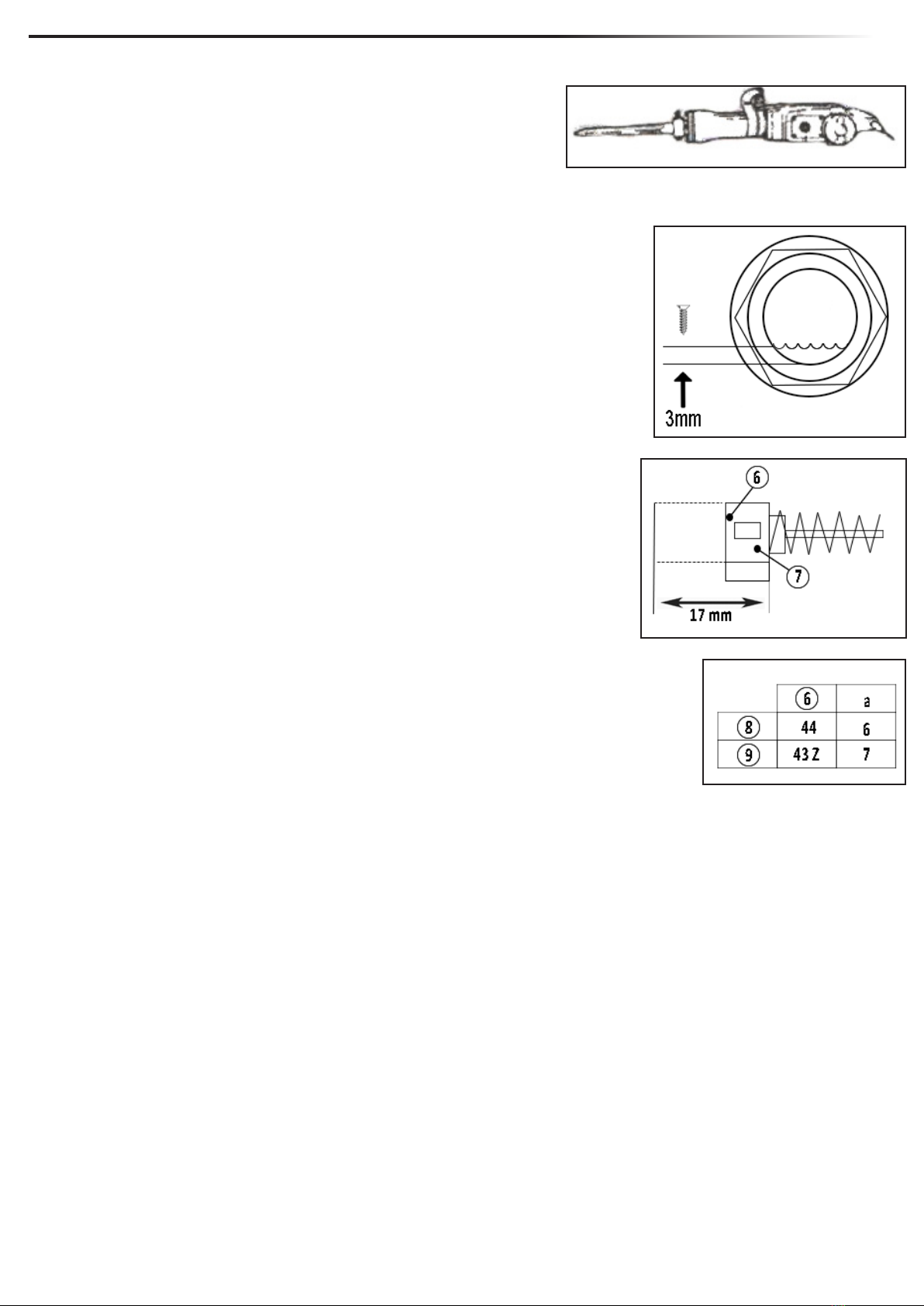

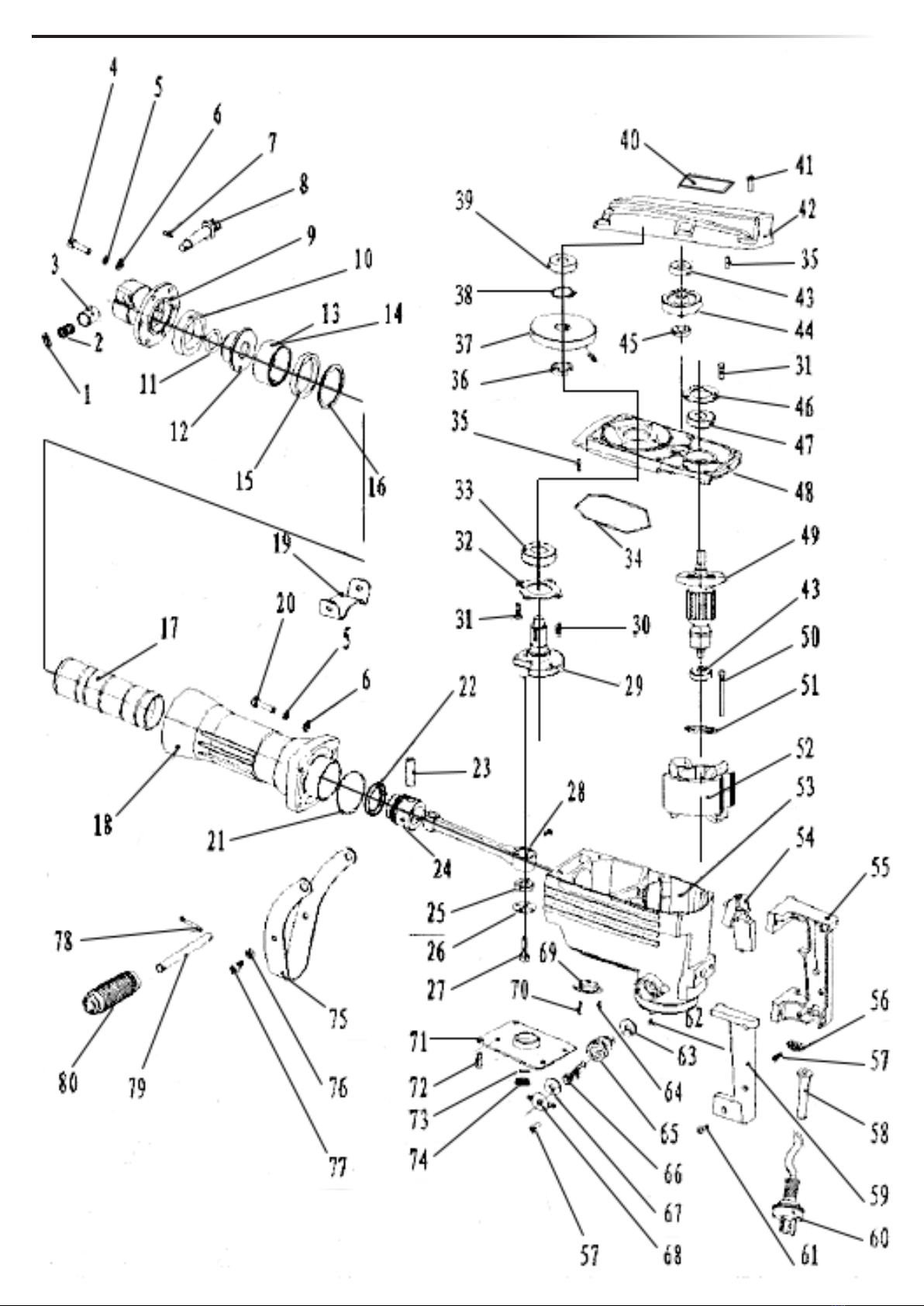

PARTS LIST

PARTS LIST

7

8

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE

UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS,AND NOT BY THE BUYER. THE BUYER

ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION

OF REPLACEMENT PARTS THERETO.

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only and are not available individually

as replacement parts.

PLEASE READ THE FOLLOWING CAREFULLY

Table of contents