Start LD 5000 User manual

10/07

4270 Airborn Drive

Addison, TX 75001, USA

Toll Free 800.259.1986

Tel 972.248.1999

Fax 972.248.1991

www.startinternational.com

LD

5000/5100/7000

instructions

7

2

CONTENTS

Read this user’s manual before use to ensure proper operation. Keep the manual on hand for

reference in case there is a problem.

Warranty Information ..............................2

Features .......................................................3

Notes ............................................................3

Repair Policy ..............................................3

Specifications .............................................3

Set-up ..........................................................4

Operation/Adjustments ............................5

Maintenance ...............................................6

Legend .........................................................6

Exploded View ..........................................7

START International warrants all parts on LD series label dispensers against defects in

design, materials and workmanship for a period of 360 days. Labor to replace defective

parts will be performed at no charge for the first 120 days after date of purchase.

Warranty does not cover transportation costs.

Our sole obligation under this warranty is limited to repair, replacement or credit of the

purchase price, at our option, for the machines listed above, which do not perform

properly the function for which they were designed.

Warranty repair is contingent upon our examination and determination that alleged

defects have not been caused by misuse, abuse, improper installation or application,

repair, alteration, accident or neglect in use, storage, transportation or handling.

The above warranty and remedy constitutes START International’s sole liability hereunder

and are in lieu and exclusive of all other warranties and remedies expressed, implied, or

statutory, including, but not limited to, those of merchantability and fitness for a particular

purpose.

WARRANTY POLICY FOR LD SERIES LABEL DISPENSERS

EXPLODED VIEW

5

4

PostScript Picture

SENSORA1 [Converted] EPS

PostScript Picture

SENSORAL [Converted] EPS

PostScript Picture

SENSORA2 [Converted] EPS

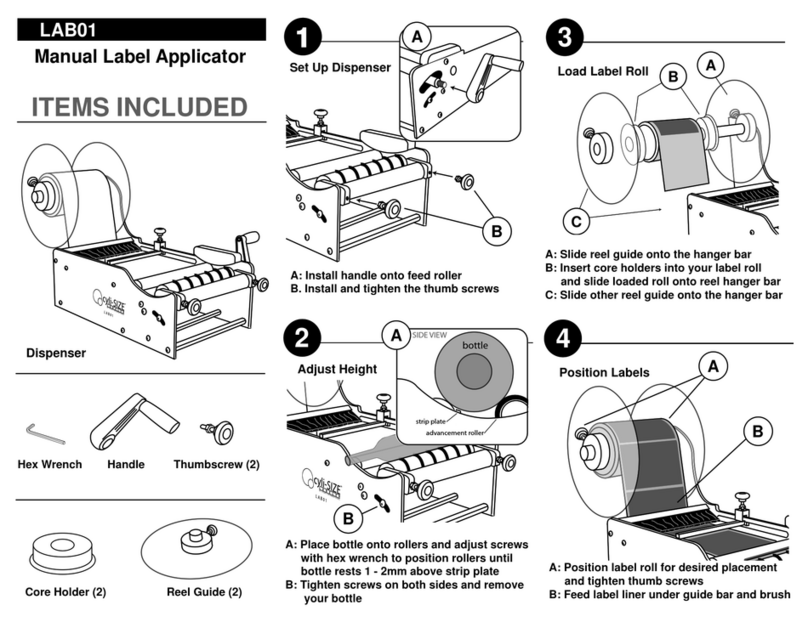

Using 5/32" (4mm) hex wrench, adjust reel holder arm to vertical.

Place the label roll on the 1" (25mm) reel hanger bar.

*If roll has 3" (76.2mm) core, use plastic spool*

Slide Material Guide onto reel hanger bar to hold roll against reel holder arm to ensure it is

held straight.

(Hex wrench, Material Guide and spool included.)

Thread the liner under the guide rod, between the hold down pad and the strip plate, then

back under the strip plate. Lay the liner across the slot in the take-up hub. Slide the lock rod

into the slot to secure the liner. Align shaft guide on guide rod with edge of liner to keep

material feeding straight.

Hold Down Pad:

Using the upper thumbscrew on the side of the machine, adjust the hold down pad for

tensioning.

For best results, labels should be pressed firmly against the strip plate. If labels are held too

tightly, they will cause excessive drag on the motor.

Photosensor:

The photosensor can be adjusted in any direction to accommodate virtually any label.

Loosening the lower thumbscrew allows the photosensor to swivel and sets the overhang

distance of the label over the strip plate. When the label is being fed the correct distance,

tighten the lower thumbscrew.

Loosen the two screws on the front of the sensor holder to align the photosensor with the

center of the label. If there are two or more labels across, align the photosensor with the last

label to be removed. When these two screws are tightened, the machine is set.

Hold Down Pad

Photosensor

Strip Plate

Guide Rod

Lock Rod

Take-up Hub

Reel Hanger Bar

Reel Holder Arm

Incorrect

Correct

Sensor sees beyond label

- Will not stop

Sensor sees strip plate

- Will not feed

Sensor sees front edge of label

ADJUSTMENTS

SET-UP INSTRUCTIONS

Positioning of Photosensor

63

MAINTENANCE

Turn machine off when not in use. Remove liner material from take-up hub at approximately

3" in diameter or if motor appears to be straining. Do not operate machine without covers in

place. Do not operate if inspection reveals a damaged

power or sensor cord.

• Will dispense butt-cut and die-cut material.

• Adjustable photosensor for pinpoint accuracy.

• Handled lock rod makes scrap removal easy.

• No tools required for adjustment.

• Keep strip plate free of adhesive build-up.

• Clean photosensor with compressed air or dry cloth.

• Do not drop the dispenser or subject it to heavy shock.

• Turn off machine when not in use.

Contact START INTERNATIONAL to determine nature of problem.

Furnish START with the following information:

1. Who the unit was purchased from.

2. Model number and serial number.

3. Date purchased (copy of invoice or packing slip required).

START will issue an RGA (Return Goods Authorization) for repair.

Return machine to START by UPS, insured and prepaid.

START will notify the customer if there is a repair charge.

FEATURES

NOTES

REPAIR POLICY

Model#

Liner Capacity

Width

Label

Length

Roll Capacity

Feed Speed

Dimensions

Inches

Centimeters

Weight

Electrical

Requirements

LD5100

.25" to 4.5"

(6.35mm to 115mm)

.25" to 7"

(6.4mm to 178mm)

12" (30.5cm)

2.6" / sec*

(6.6cm / sec.)

10.8 (L) x 10.8 (W) x 14.5 (H)

27.4 (L) x 27.4 (W) x 36.8 (H)

10.5 lb. (4.76 kg.)

117V 50/60Hz, <1 amp

(220V 50/60Hz available)

LD5000

.25" to 4.5"

(6.35mm to 115mm)

.125" to 7"

(3.2mm to 178mm)

12" (30.5cm)

1.3" / sec*

(3.3cm / sec.)

10.8 (L) x 10.8 (W) x 14.5 (H)

27.4 (L) x 27.4 (W) x 36.8 (H)

10.5 lb. (4.76 kg.)

117V 50/60Hz, <1 amp

(220V 50/60Hz available)

LD7000

.25" to 7"

(6.35mm to 178mm)

.25" to 7"

(6.4mm to 178mm)

12" (30.5cm)

2.6" / sec*

(6.6cm / sec.)

10.8 (L) x 13.2 (W) x 14.5 (H)

27.4 (L) x 33.5 (W) x 36.8 (H)

11.3 lb. (4.76 kg.)

117V 50/60Hz, <1 amp

(220V 50/60Hz available)

SPECIFICATIONS:

*at start-up

Item #

1

1A

1B

2

2A

2B

3

3A

4

4A

5

6

6A

6B

7

8

8A

9

10

10A

11

11A

11B

12

13

13A

14

15

16

16A

16B

17

18

19

19A

20

20A

20B

21

21A

22

Model LD5100

Part #

LD50008D

LD50008-1

LD50008-2

LD50010

LD50010-1

LD50010-2

LD50017

LD50017-1

LD50023A

LD50023-2

LD-SPOOL

LD50001B2

LD50001-2

LD50018-2

LD50013D

LD50012D

LD50012-1

LD50014-4

LD50014A

LD50015-1

LD50026B

LD50011-2A

LD50026-1

LD50026A

LD50015A

LD50015-1

LD50011A

LD50002A

LD50011

LD50011-2A

LD50011-1

LD50007H

LD50003B

LD50009H

LD50007-1

LD50021S

LD50005-1

LD50021-1

LD50019

LD50019F

LD50018C

Model LD5000

Part #

LD50008D

LD50008-1

LD50008-2

LD50010

LD50010-1

LD50010-2

LD50017

LD50017-1

LD50023A

LD50023-2

LD-SPOOL

LD50001A

LD50001-2

LD50018-2

LD50013D

LD50012D

LD50012-1

LD50014-4

LD50014A

LD50015-1

LD50026B

LD50011-2A

LD50026-1

LD50026A

LD50015A

LD50015-1

LD50011A

LD50002A

LD50011

LD50011-2A

LD50011-1

LD50007H

LD50003B

LD50009H

LD50007-1

LD50021S

LD50005-1

LD50021-1

LD50019

LD50019F

LD50018C

Model LD7000

Part #

LD50008D

LD50008-1

LD50008-2

LD50010

LD50010-1

LD50010-2

LD70017

LD50017-1

LD50023A

LD50023-2

LD-SPOOL

LD50001B2

LD50001-2

LD50018-2

LD70013B

LD70012C

LD50012-1

LD50014-4

LD70014A

LD50015-1 --

LD70026B

LD50011-2A

LD50026-1

LD70026A

LD70015

LD50015-1

LD50011A

LD50002A

LD70011

LD50011-2A

LD50011-1

LD50007H

LD50003B

LD70009

LD50007-1

LD50021S

LD50005-1

LD50021-1

LD50019

LD50019F

LD50018C

LEGEND

This manual suits for next models

2

Other Start Label Maker manuals