STARWELD QUATRO 450 User manual

QUATRO 450

OPERATOR’S MANUAL

IMPORTANT

DO NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL

AND THE SAFETY SECTION

CONTAINED INSIDE THIS MANUAL

STARWELD WELDING SOLUTIONS

WEBSITE: www.starweld.co.za TEL: +27 11 914 4696

FAX: +27 11 914 3224

Starweld Quatro 450 Operator’s Manual

2

1 Table of Contents

1Table of Contents .............................................................................................2

2Safety.................................................................................................................3

3Installation.........................................................................................................6

3.1 SPECIFICATIONS........................................................................................................6

3.2 DUTY CYCLE .............................................................................................................6

3.3 SELECTING LOCATION ..............................................................................................6

3.4 WELD CABLE SIZES..................................................................................................8

3.5 STICK WELD CONNECTION.......................................................................................8

3.6 MIGWELD CONNECTION .........................................................................................8

3.7 TIGWELD CONNECTION ..........................................................................................8

3.8 CONNECTING INPUT POWER.....................................................................................9

4Operation.........................................................................................................10

4.1 CONNECTIONS.........................................................................................................11

4.1.1 Power.................................................................................................................11

4.1.2 Output Terminals..............................................................................................12

4.1.3 14-way Socket..................................................................................................12

4.2 LIFT TIG..................................................................................................................12

5Advanced Features.........................................................................................13

5.1 VOLT-LOC ...............................................................................................................13

6Maintenance and Troubleshooting ...............................................................14

6.1 ROUTINE MAINTENANCE.........................................................................................14

6.2 TROUBLESHOOTING ................................................................................................14

7Electrical Diagrams ........................................................................................15

8Parts.................................................................................................................16

9Warranty..........................................................................................................18

Starweld Quatro 450 Operator’s Manual

3

2 Safety

Only qualified persons should install, operate, maintain, and repair this unit.

During operation, keep everybody, especially children, away.

Electrical Hazards

Electric shock from welding can kill or cause severe burns. The electrode and work

circuit is electrically energized whenever the output is on. The input power circuit

and unit internal circuits are also electrically energized when the mains power is on.

When MIG welding, the wire, drive rolls, and all other metal parts touching the wire

are electrically energized. Incorrectly installed or improperly grounded equipment

presents a shock hazard.

Read the instruction manual before installing, operating, or servicing the unit.

Have all installation, operation, maintenance, and repair work performed only

by qualified people.

Do not touch live electrical parts.

Wear dry, insulating in good condition and protective clothing.

Insulate yourself from the workpiece and ground by wearing rubber-soled

shoes or standing on a dry insulated mat or platform.

Use fully insulated electrode holders. Never dip the holder in water to cool it

or lay it on conductive surfaces or the work surface. Do not touch holders

connected to two welding machines at the same time or touch other people

with the holder or electrode.

Do not use worn, damaged, undersized, or poorly spliced cables, welding gun

cables, and torch cables. Make sure all connections are tight, clean, and dry.

Do not wrap cables carrying welding current around your body.

In confined spaces or in electrically hazardous locations due to water or

perspiration, do not use a welder with AC output unless it is equipped with a

voltage reducer and remote output control. Use equipment with DC output.

Turn off all equipment when not in use. Disconnect the power to equipment if

it will be left unattended or out of service.

Wear a safety harness to prevent falling in a potentially hazardous area.

Keep all covers secured in place.

Many welding processes produce fumes and gases, which may be harmful to your

health.

Keep your head out of the fumes. Do not breathe the fumes.

If inside, use ventilation or an exhaust at the arc to remove welding fumes

and gases.

Welding Fumes and Gases

Starweld Quatro 450 Operator’s Manual

4

If ventilation is poor, use an approved respirator.

Do not weld near degreasing, cleaning or spraying booths. The heat and rays

from the arc can react with the gases from those processes to form toxic

fumes.

Do not weld on coated metals, such as galvanized, lead or cadmium plated

steel, unless the coating is removed. The coatings can give off toxic fumes if

welded.

Arc rays from the welding process produce intense rays that can burn skin and

eyes.

Wear a welding helmet fitted with correct shade of filter lens when welding in

order to protect eyes and face.

Use protective screens or barriers to protect passer-bys, warn others not to

watch the arc.

Wear protective clothing made from durable and flame-resistant material as

well as foot protection.

Protect exposed skin on hands with leather gloves.

Welding processes produce molten metal, sparks and hot work surfaces. These can

cause fire or explosion if precautionary measures are not followed. Welding on

closed containers can them to explode. Check and make sure the work area is safe

before doing any welding.

Remove any combustible material from the work area.

Remove or make safe all combustible materials for a radius of 10m around

the work area. If this is not possible then cover materials with approved

flame-resistant covers.

Do not weld where sparks can strike combustible material.

Do not weld on a container that has held an unknown substance or a

combustible material whose contents, when heated, can produce flammable

or explosive fumes.

Do not weld on a workpiece covered by an unknown substance or whose

coating can produce flammable, toxic, or reactive fumes when heated.

Do not use welder to thaw frozen pipes.

Do not weld on closed containers such as drums unless they are correctly

prepared.

Always keep a fire extinguisher close by.

Arc Rays

Fire and Explosion

Hot Surfaces / Flying Metal / Noise

Starweld Quatro 450 Operator’s Manual

5

Do not touch hot parts without gloves.

Allow cooling period before working on a gun or torch.

Welding, grinding and chipping can cause sparks and flying metal.

Wear approved safety glasses with side shields even under the welding

helmet.

Wear approved ear protection if noise level is too high.

Electric arc welding processes produce intense electric and magnetic fields.

Persons with a pacemaker should not go near welding operations until they have

consulted their doctor and obtained information from the manufacturer of the device.

Pacemakers

Starweld Quatro 450 Operator’s Manual

6

3 Installation

3.1 Specifications

Input

Input Voltages

Maximum Input Current

380V

43A

Rated Output

Duty Cycle

Output Amperes

Volts at Rated

Output Amperes

Input Amperes

380V

Stick 100%

450A

38V

43A

TIG 100%

450A

28V

32A

MIG 100%

450A

37.5V

43A

Output

Output Current Range

Open Circuit Voltage

Type of Output

15-450A

55V

DC

Physical Dimensions

Height

Width

Depth

Weight

370mm

350mm

500mm

33kg

Environmental

Operating

Temperature

Range

Storage

Temperature

Range

Relative Humidity

Altitude Above

Sea Level

-10C to +40C

-50C to +80C

Up to 50% at 40C

Up to 90% at 20C

Up to 1800m

3.2 Duty Cycle

Duty cycle is the percentage of ten minutes that the unit can weld at selected current

without overheating.

If the unit was used at 450A (Maximum Current) then the unit could weld

continuously, that is no time is needed in order to let the unit cool.

3.3 Selecting Location

The air is blown from the rear of the unit through the heatsink and out the front of the

unit, therefore adequate thought needs to be considered about the location of the

unit.

The unit should be spaced at least 15cm away from a wall at the rear of the

machine, this will allow adequate airflow into the unit.

Starweld Quatro 450 Operator’s Manual

7

15cm

Unit

Wall

Front of

Unit

Figure 1: Location of Unit

Starweld Quatro 450 Operator’s Manual

8

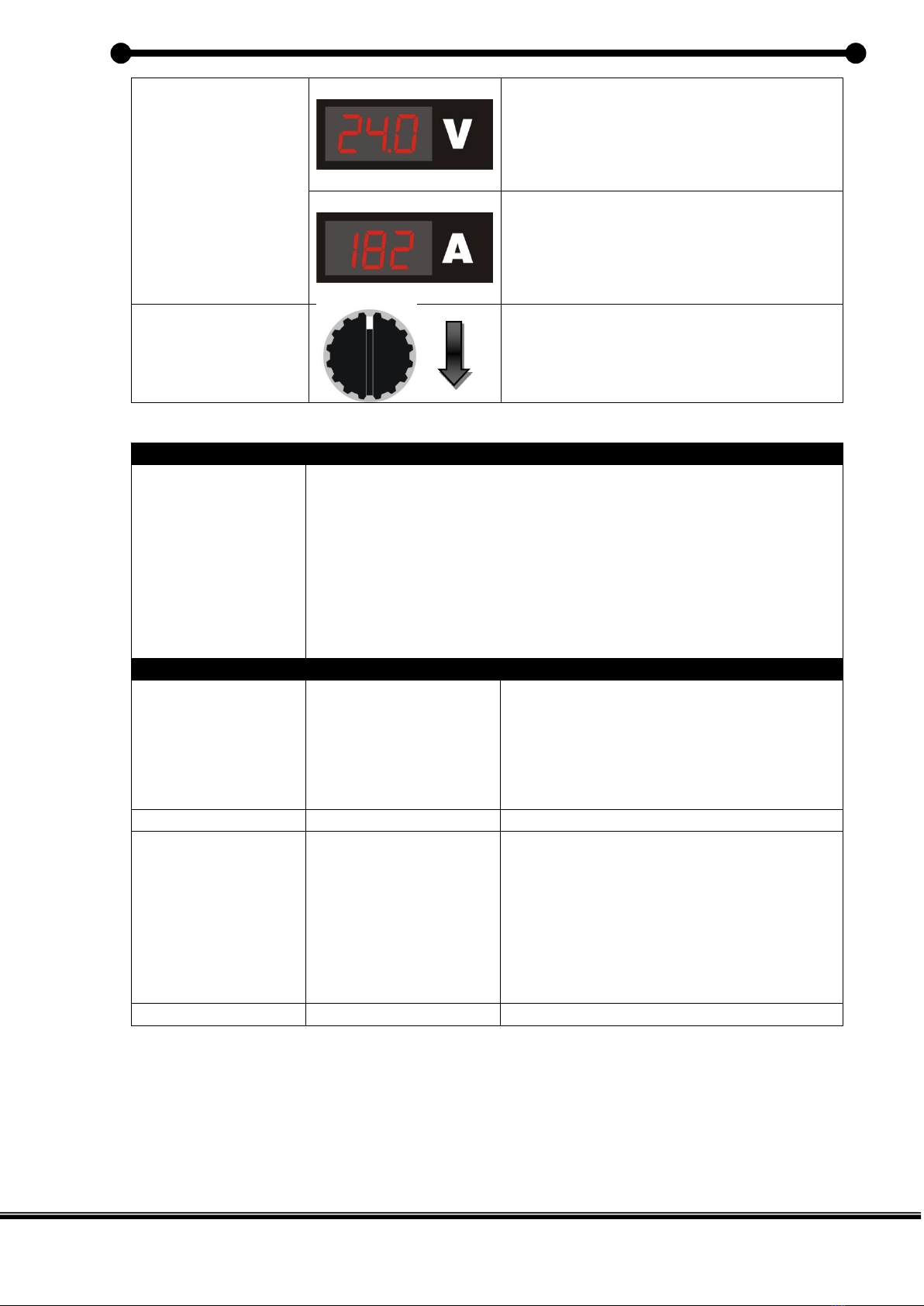

3.4 Weld Cable Sizes

Turn off power before connecting to unit output terminals

Do not use worn, damaged, and undersized cables

Minimum welder cable size (mm2)

Welding

Amperes (A)

20

40

60

80

100

Total

Cable

Length

(m)

50

16

16

16

25

25

100

16

25

35

50

50

150

16

35

50

70

70

200

25

35

70

95

95

250

35

50

70

95

120

300

35

70

95

95

120

350

50

70

95

120

120

400

50

70

95

120

120

Figure 2: Cable Area vs. Cable Length

This chart serves only as a general guide, if the unit tends to trip early on overtemp

or the cables become warm then the next size cable should be used.

If one wants to weld at 150A 60% duty cycle with the total cable length, that is earth

cable and electrode cable, of 100m then the cable size should be 70mm2.

3.5 Stick Weld Connection

Stick welding requires positive polarity, that is the electrode holder is connected to

the unit’s positive output socket (red connector) and the earth clamp is connected to

the unit’s negative output socket (black connector).

3.6 MIG Weld Connection

MIG welding requires positive polarity, that is the earth clamp is connected to the

unit’s negative output socket, the separate wire feeder unit is connected to the

positive terminal through an interconnecting cable, the wire feeder control cable also

needs to be connected to the female 14 way socket.

3.7 TIG Weld Connection

TIG welding requires negative polarity, that is the electrode holder is connected to

the unit’s negative output socket and the earth clamp is connected to the unit’s

positive output socket.

Starweld Quatro 450 Operator’s Manual

9

The Starweld Quatro 450 does not include a gas solenoid inside the unit, therefore a

TIG torch needs to be used with a gas valve built into it. The gas line from the torch

is then connected straight to the flowmeter on the gas cylinder.

3.8 Connecting Input Power

Turn off power before connecting unit to mains

Do not use worn, damaged, and undersized cables or plugs

The unit is supplied with usually a five meter trailing cable (other lengths are

available on request). If no plug is supplied with the unit then the connections are

the following:

Green/Yellow - Represents the earth wire

Brown - Represents Phase A

Blue - Represents Phase B

Black - Represents Phase C

The Quatro 450 is designed to work on a three phase with earth system only.

Starweld Quatro 450 Operator’s Manual

10

4 Operation

CONTROL PANEL

MODE

BUTTON

This button is used when selecting the

Welding Process to be used. With each

press of the button, one scrolls down

through the modes. An accompanying

LED indicates the selected mode.

LOCAL/REMOTE

BUTTON

Used to select the input reference.

Either from the main encoder (local) or

from a suitable remote controlling

device. When in the TIG and Stick

modes the remote device will control

from 0 –local setting.

ENCODER

This control is used to select the

required Amperage or Voltage to be

used. The Encoder is also used to set

values in Menu Settings. (To be

discussed later)

Starweld Quatro 450 Operator’s Manual

11

DIGITAL

DISPLAYS

In the MIG mode the preset welding

voltage is displayed before welding

commences, once welding the actual

voltage is displayed. All other modes

displays the actual voltage.

Before welding the preset welding

current is displayed, once welding the

actual current is displayed.

MENU

BUTTON

This button allows for the setting of the

various welding parameters, subject to

the selected mode.

MENU OPERATION

METHOD

1. Push the Menu Button twice.

2. Use the Encoder to select the parameter to be set. (This

will appear on the Voltage Display)

3. Push the Menu Button a second time.

4. The parameter in the Voltage Display will begin to flash,

indicating that this has been selected for change.

5. Use the Encoder to now adjust this parameter.

6. After the desired value is selected, press the Menu

Button again, to exit.

PARAMETERS OPTIONS

MIG Process

SLOPE

Setting: 1 –10

This is an inductance control that sets

the speed at which the current picks

up, after each short of the arc. A high

setting is recommended for Aluminium

and a low setting for Steels.

FCAW-SS

Nothing

Stick Process

DIG

Setting: 1 –10

Controls the amount of added current

during the deposition of welding

material to prevent freezing of the

puddle.

The higher the setting, the greater the

added current.

Lift TIG Process

Nothing

4.1 Connections

4.1.1 Power

The circuit breaker at the rear of the unit switches the unit on and off.

Starweld Quatro 450 Operator’s Manual

12

4.1.2 Output Terminals

Turn off power before connecting cables to unit

One can get shocked by the output terminals if correct care is

not exercised

Unit’s Positive Terminal, normally a red feed through connector, however if the unit

has been built using Dinse connectors then the terminal is marked as such:

Unit’s Negative Terminal, normally a black feed through connector, however if the

unit has been built using Dinse connectors then the terminal is marked as such:

4.1.3 14-way Socket

The 14 way socket is used for the connection of torch triggers, interconnection

cables and ancillary equipment

Pin

Function

1

TIG Trigger

2

TIG Trigger

3

Pot GND

4

Pot Wiper

5

Pot +5V

6

CAN Bus H

7

CAN Bus L

8

9

10

+24VAC Neutral

11

+24VAC Live

12

Trigger Return (11 to 12)

13

14

4.2 Lift TIG

The tungsten must be placed, not scratched on the work and the inverter will supply

a preset low current of approximately 100 amps after 100ms. On lifting the tungsten

the current will rise to the preset value. In order to break the arc simply pull the torch

away from the workpiece

NB It is important to remember for TIG welding the electrode is connected to the

negative and the earth clamp to the positive.

+

-

Starweld Quatro 450 Operator’s Manual

13

5 Advanced Features

5.1 Volt-Loc

Volt-Loc is the registered name of the Starweld voltage reducer.

Volt-Loc is a free option and is generally fitted as standard. It is used for the stick

and TIG modes. The Volt-Loc feature reduces the output voltage to 13 volts until

contact resistance below approximately 200 Ohms is made. On contact the full open

circuit voltage is applied and welding may continue as long as there is welding

current and after an internally set time for tacking. Thereafter the voltage is once

more reduced.

The time that is allowed for tacking is set to 2s.

The use of Volt-Loc provides considerable protection against electrocution.

Accidents occur when the equipment is improperly used or maintained and the rules

of safe practice for electric arc welding must be observed. Failure to observe these

practices may cause serious injury of death.

Starweld will not be liable for any claims for injury or death or consequential

damage.

Starweld Quatro 450 Operator’s Manual

14

6 Maintenance and Troubleshooting

6.1 Routine Maintenance

Turn off power before undergoing maintenance on the unit

The unit should be blown out every 6 months to remove dirt and dust build up,

depending on site conditions. Worn or damaged machine sockets should be

replaced. Damaged mains cable should be replaced.

If the unit is used in a dusty environment then the unit should be blown out every 3

months.

In order to blow out the machine the cover should be removed and the dust blown

out with compressed air. An air pressure of 5 bar will be sufficient to remove any

dust buildup. It is important to get all the dust out the heatsink and fan as well.

6.2 Troubleshooting

Fault

Remedy

Power LED does not light

Switch the circuit breaker at the rear of the unit to the

on position.

Switch the unit on at the wall plug.

Make sure the wall plug is correctly wired.

Power LED on but no weld

output

Make sure the unit is switched to the stick position.

Check for Overtemp error (Err Ot)

Make sure unit is in the local mode and not remote.

Erratic or improper weld

output

Use proper size and type of weld cable.

Clean and tighten all weld connections including the

earth connection to the work.

Fan not working

Look for something blocking the fan.

Send the unit in for service to replace the fan.

Wandering arc

Use proper size tungsten.

Use properly prepared tungsten.

Reduce gas flow rate.

Unit not MIG welding

Check interconnecting cable for any bad connections

especially in 14 way socket

Check 10A circuit breaker on front panel

Starweld Quatro 450 Operator’s Manual

15

7 Electrical Diagrams

Starweld Quatro 450 Operator’s Manual

16

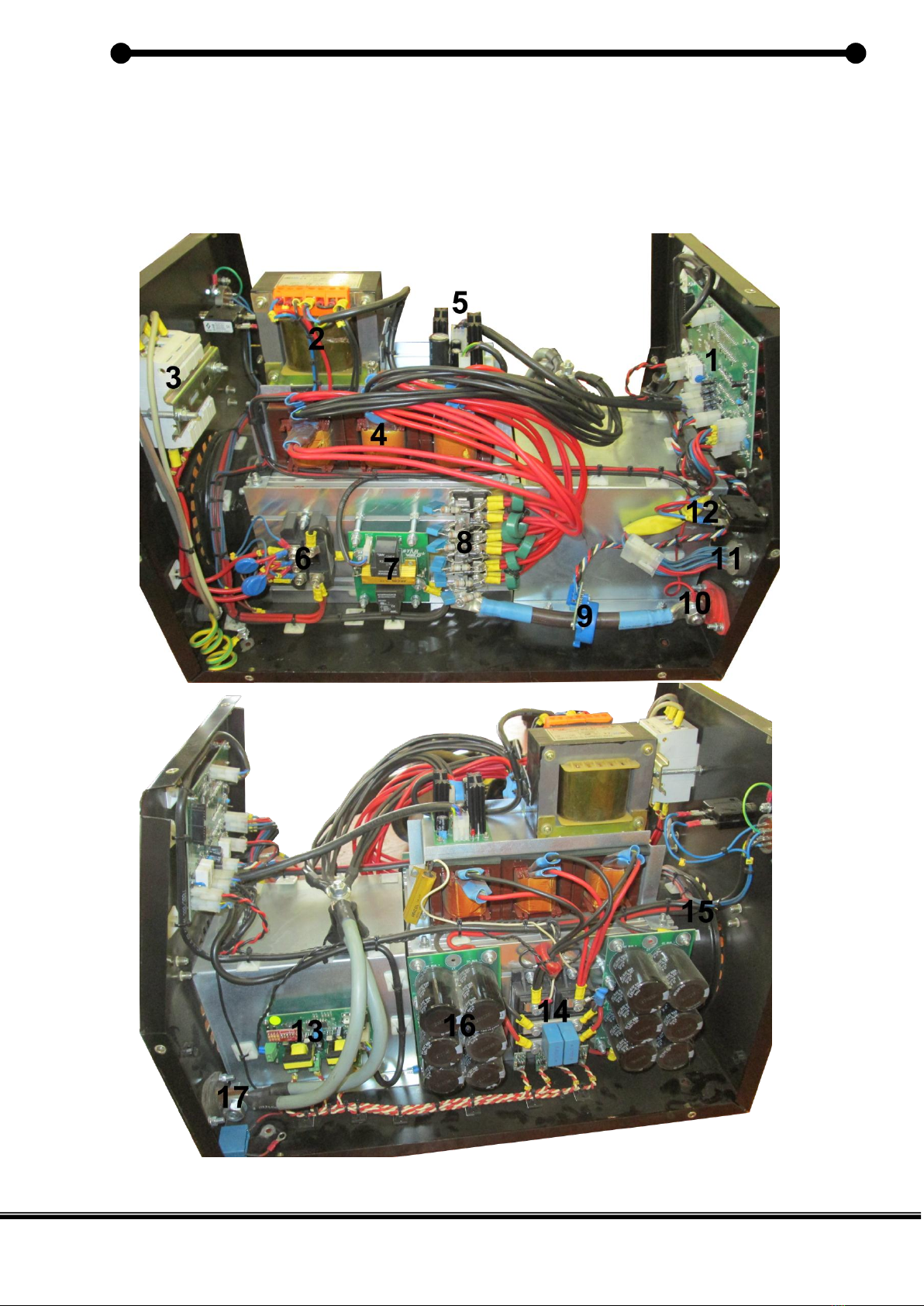

8 Parts

Starweld Quatro 450 Operator’s Manual

17

Parts List

1

WM000 Control Board

2

200VA Transformer

3

Circuit Breaker

4

HF Transformers

5

WM020 Power Board

6

Input Bridge

7

WM081 Soft Start

8

Output Diodes

9

LEM Module

10

Positive Socket

11

14 Way Socket

12

10A Circuit Breaker

13

WM010 Firing Board

14

IGBTs

15

Fan

16

WM080 Capacitor

Board

17

Negative Socket

Starweld Quatro 450 Operator’s Manual

18

9 Warranty

Arc Quip guarantees the product for a period of 24 months (2 years) from date of

sale against faulty design material and workmanship, fair wear and tear excepted

and excluding misuse and abuse.

The equipment must be returned to Arc Quip or its agents.

For service repairs and technical assistance contact your STARWELD dealer or the

manufacturer.

Distributor

Starweld Contact Details

Arc Quip cc

Unit 70D Van Dyk Secure Business Park

Cnr Van Dyk & Brakpan rd

Boksburg

South Africa

Po Box 1681

Fourways

2055

Tel: +27 11 914 4696

Technical: robert@starweld.co.za

Table of contents

Other STARWELD Welding System manuals

Popular Welding System manuals by other brands

Hobart Welders

Hobart Welders Handler 125 owner's manual

Lincoln Electric

Lincoln Electric statiflex 200-m Operator's manual

BOC

BOC Smootharc MMA 170 operating manual

Lincoln Electric

Lincoln Electric Fast Mate Guns Series Operator's manual

ESAB

ESAB Aristo Origo Feed 3004 instruction manual

STAMOS

STAMOS S-MAG 120 FL user manual

Miller

Miller GW-55C owner's manual

Lincoln Electric

Lincoln Electric Idealarc DC-600 Technical specifications

ESAB

ESAB Miggytrac 1001 instruction manual

BOSITE

BOSITE 5001A user manual

Shindaiwa

Shindaiwa EGW165M-I/UKV Owner's and operator's manual

MOSA Weld

MOSA Weld CT 230 YSX CC/CV Use and maintenance manual