Stick TIG MIG Flux-Cored

Subarc Gouging

Processes

DC-655

Order

Advantage Lincoln Digital Meter Kit, Air Filter Kit, Dual Process Switch,

Paralleling Kit, Remote Output Control, Remote Control

Adapter, Deluxe Adjustable Gas Regulator & Hose Kit,

Undercarriage

Reco ended General Options

LN-7, LN-7 GMA, LN-742, LN-8, LN-9, LN-9 GMA, LN-15,

LN-23P, LN-25, LN-10, DH-10, Cobramatic®, NA-3, NA-5,

LT-7

Reco ended Wire Feeders

K1609-2 DC-655 230/460/575/3/60

K1609-4 DC-655 460/3/60

K1610-1 DC-655 230/400/3/50/60

Accessory Kit

Reco ended Stick Options

Pro-Torch™ TIG Torches, TIG Module, Docking Kit, Hand

Amptrol™, Foot Amptrol, Remote Control Adapter, Amptrol

Adapter Kit, Water Valve, TIG Control Cable Extension

Reco ended TIG Options

• CC Arc Force Control Knob with built-in “Hot Start”.

• “Idle Shut Down ode” auto atically shuts achine

off when not in use to ini ize power consu ption.

• Fan-As-Needed™ – solid state ther ally controlled

cooling fan operates only when required. Mini izes

power consu ption, operating noise and dust intake.

• Full range calibrated output voltage and current

control for easy operation.

• Separate output studs let you choose low or high

inductance. Select high inductance for ost stick

and wire processes. Select low inductance for

Innershield®NR®-211-MP, NR-212, and NR-203 type

wires.

• Optional digital a eter/volt eter kit. Easy front

panel installation.

• Panel switches are behind front latched panel, for

re ote or achine panel output control, and output

“on” or re ote “on” selection, and CC, CV Subarc or

CV MIG ode selection.

• Low profile case allows stacking achines up to

three high to conserve floor space. (Stacking not

reco ended when using undercarriage).

• Electronic and ther al protection fro current

overload and excessive te peratures.

• Function lights built into the printed circuit boards

speed diagnosis.

MULTI-PROCESS WELDERS

Description

650 A p DC Multi-Process Welding Power Source

This 650-amp, 100% duty cycle CV/CC power source is ideal for construction

and shop fabrication because of its excellent arc performance and many energy

saving features.This machine also has a high overall efficiency of 84% for even

more energy and cost savings. Save money with the idle shut down timer that

powers down the DC-655 when not in use for extra energy conservation. Keep

internal components cool without wasting energy with Lincoln’s Fan-As-Needed

(F.A.N.) that shuts off automatically when the system is cooled. Don’t think you’re

sacrificing arc performance for efficiency; the DC-655 features a calibrated output

knob for precise procedure setting and adjustable arc force for a tailored arc and

ultimate low end performance – down to 50 amps – for excellent stick, MIG

and TIG performance.

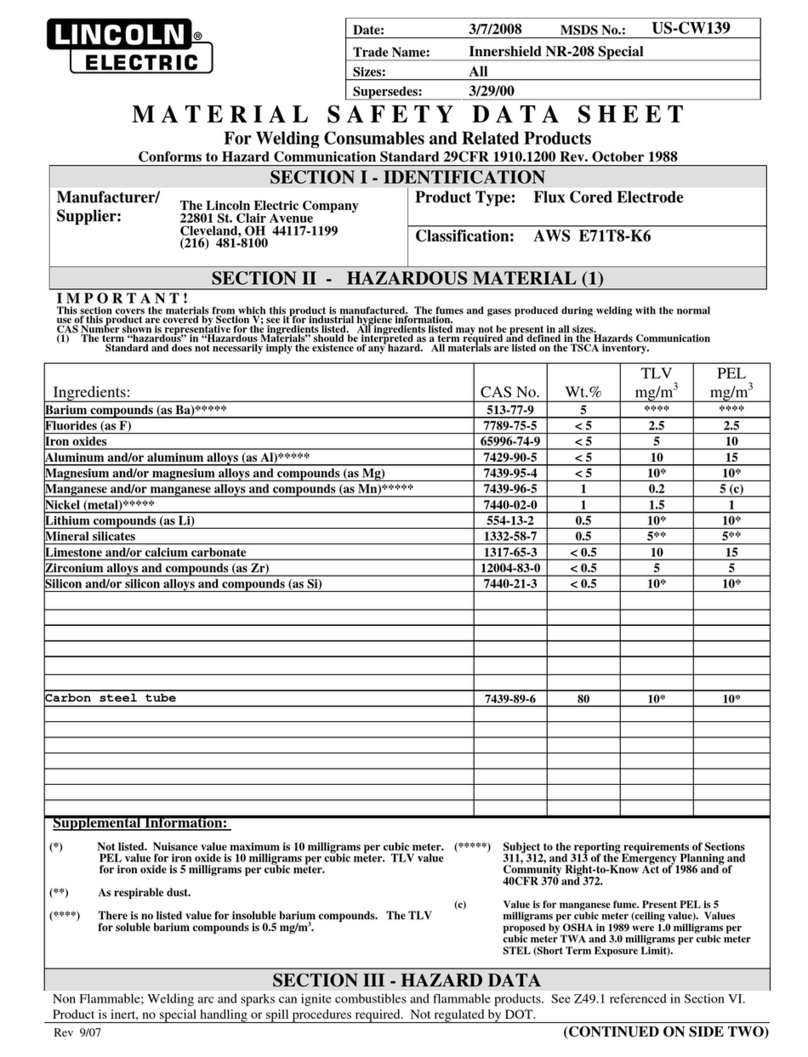

Technical Specifications

Dimensions

Product Product Rated Output Input Current @ H x W x D Net Weight

Name Number Input Power Current/Vo tage/Duty Cyc e Rated Output Output Range in. (mm) bs.(kg)

DC-655

K1609-2

K1609-4

K1610-1

230/460/575/3/60

460/3/60

230/400/3/50/60

650A / 44V / 100%

(815A / 44V / 60%)

122/61/49A

61A

122/70A

13-44V

50-815A

Max. OCV:

46V (CV)

68V (CC)

27.5 x 22.2 x 38.0

(699 x 564 x 965)

720

(327)

www.lincolnelectric.com

E5.46 11/02