STARWELD TIGFIL User manual

1

TIGFIL

2

3

CONTENTS

Introduction 2

Features 3

Installation 4

Spareparts 6

Optional 12

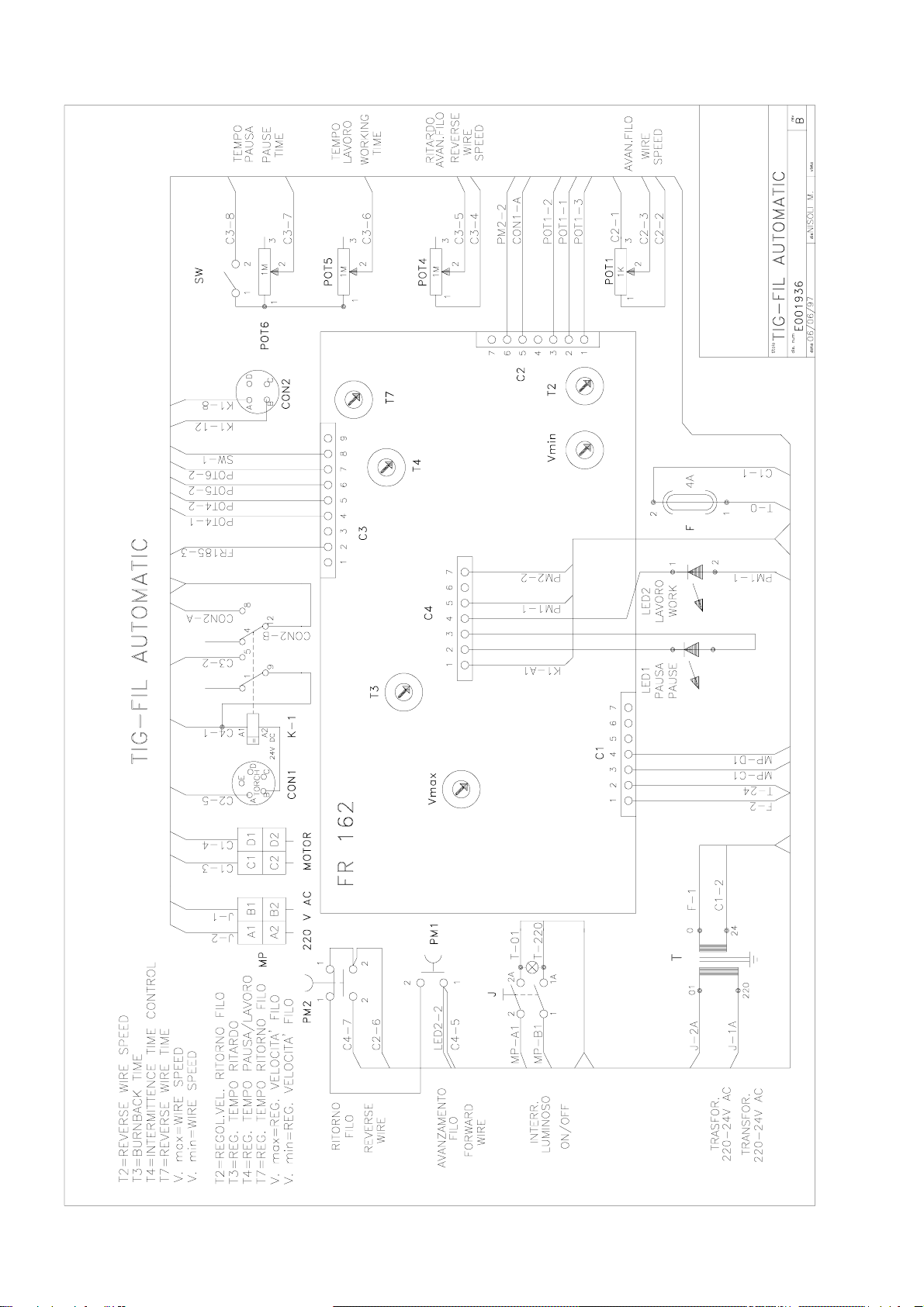

Electricdiagram 14

4

We kindly thank You for the confidence You showed in

purchasing one of our products.

We are sure we will not disappoint Your expectations; we

ask You to read the instructions shown in this manual

very carefully.

WARNING

GENERAL

This welding equipment has been designed, manufactured and tested to the

highestqualitystandardstoensurelongandtroublefreelife.However,regular

maintenanceisanessentialpartofkeepingthemachineoperatinginareliable

and safe manner and Your attention is drawn to any maintenance instructions

that are contained in this manual. In general, all welding equipment should be

thoroughly inspected, tested and serviced at least annually. More frequent

checking will be required when the equipment is heavly used. Wear and tear,

particularly in electro-mechanical and moving components, is a gradual

process. Caught in time, repair costs are small and benefits in performance,

reliabilityandsafetyaresignificant.Leftalone,theycanputtheequipment,and

You, at risk.

Thiswirefeederhasbeendesignedtofeedcoldwirewith TIGprocess.When

thetorchbuttonispressed,afteranadjustabledelay-time,thewirestartscoming

out with the preset feeding speed. The wire feeding can be continuous or

intermittent.Incaseofintermittentfeeding,thefeedingandpausetimemustbe

set.When weldingisoverandthetorchbuttonisreleased,thewireisretracted

so that it does not stick to the welding bath.

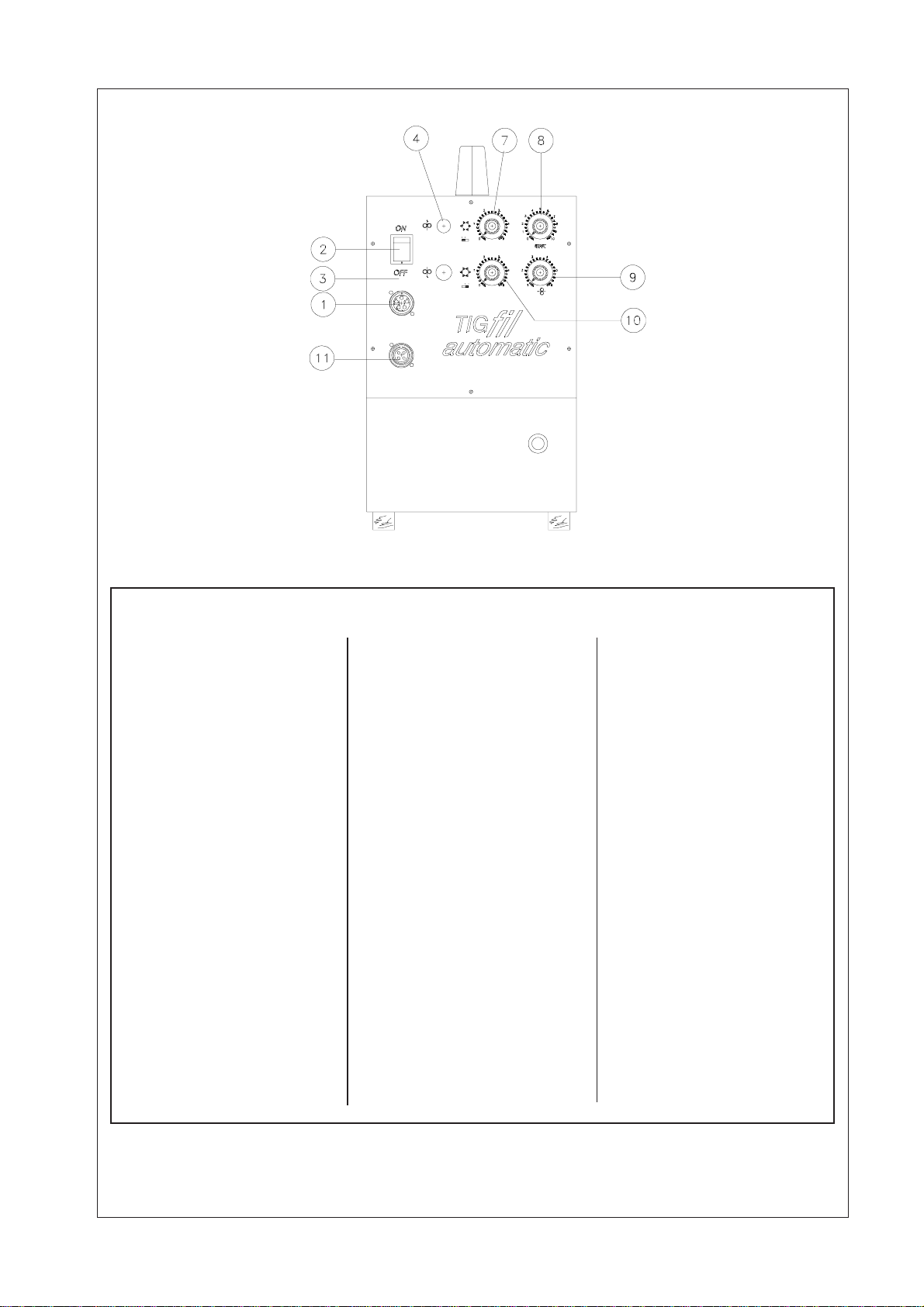

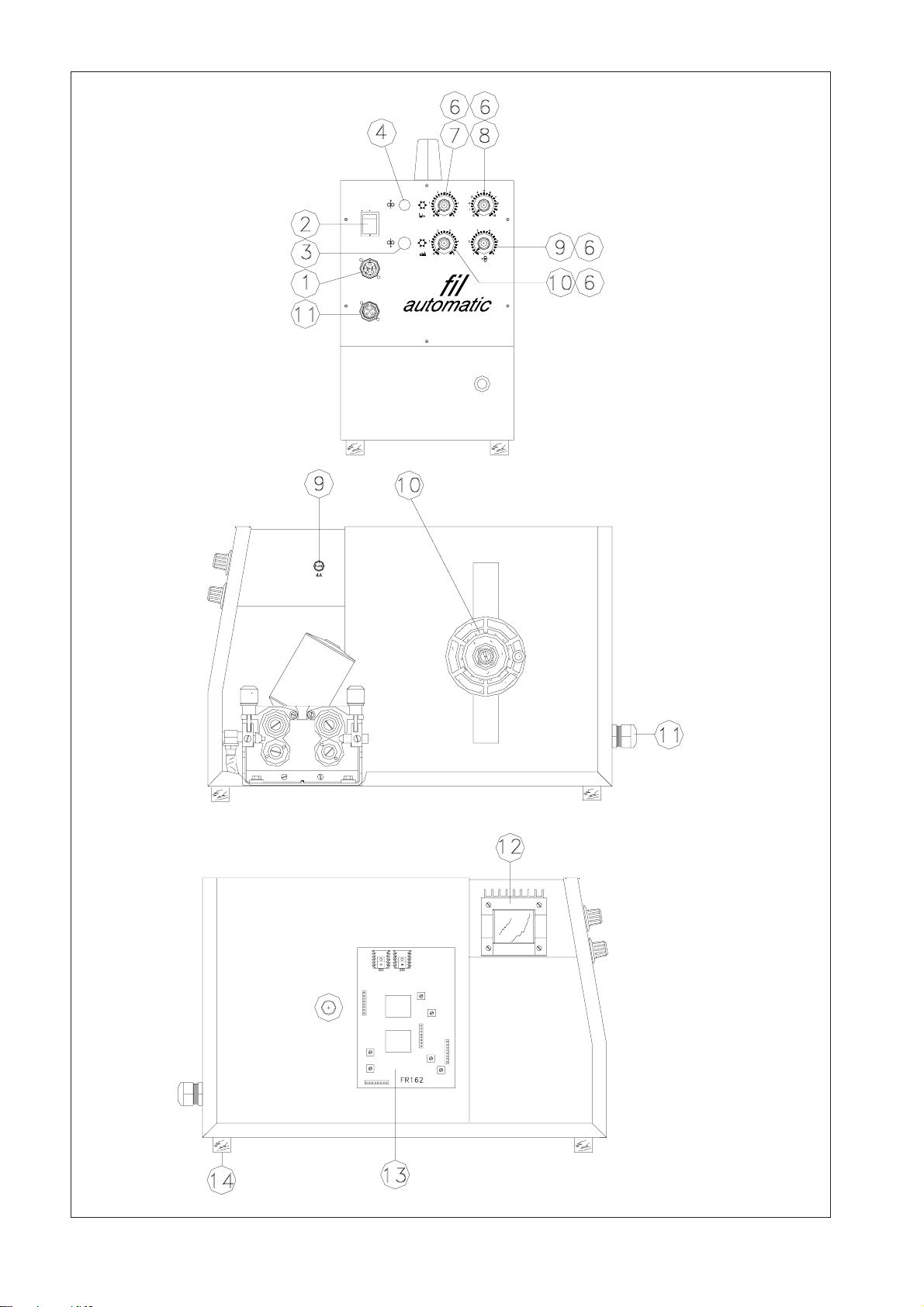

5

5

Working Time

Activation Indicator

6

Pause Time

Activation Indicator

7

Pause Time

Adjustsmotorpausetime

8

Delayed Start

Adjuststhewirestart

delayed

9

Wire Speed

Adjustment

Providescontinuous

adjustment of wire speed

from0 to 5 m/min

10

Working Time

11

Connector

Connectorto power source

CONTROLS

1

Main Connector

Connector for torch

2

On/Off Switch

3

Wire Return Button

4

Wire Inching Button

6

INSTALLATION

INITIALSETUP

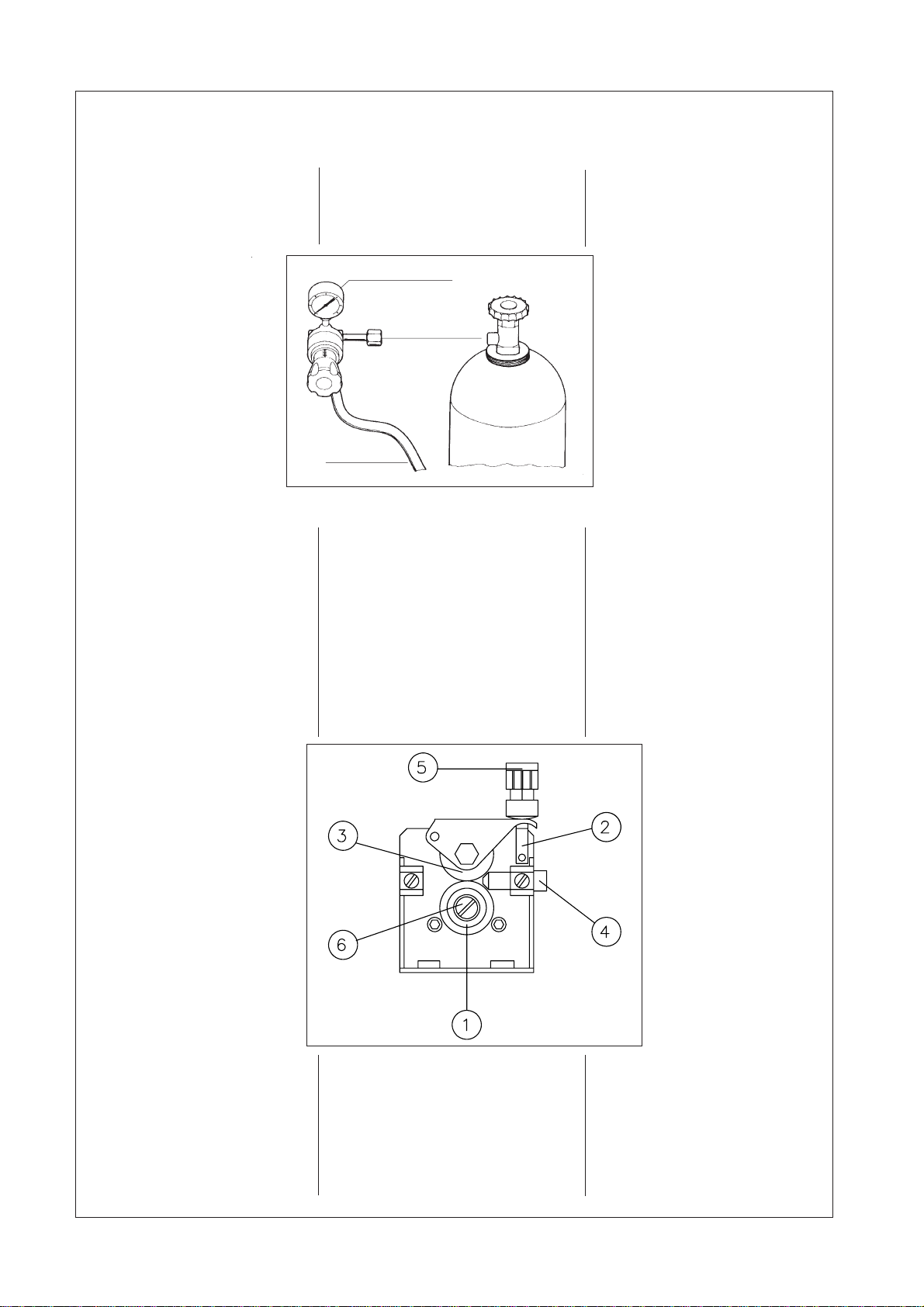

2. Connections

Mount a socket on the

1. Feed Rolls

Before connecting the

electrical and gas

supplies, ensure that

the equipment is set

forthetypeandsizeof

wiretobeused.Check

that the stamped on

thefeedrollisthesame

of the diameter of the

wireused. GASTUBE

PRESSUREREDUCER

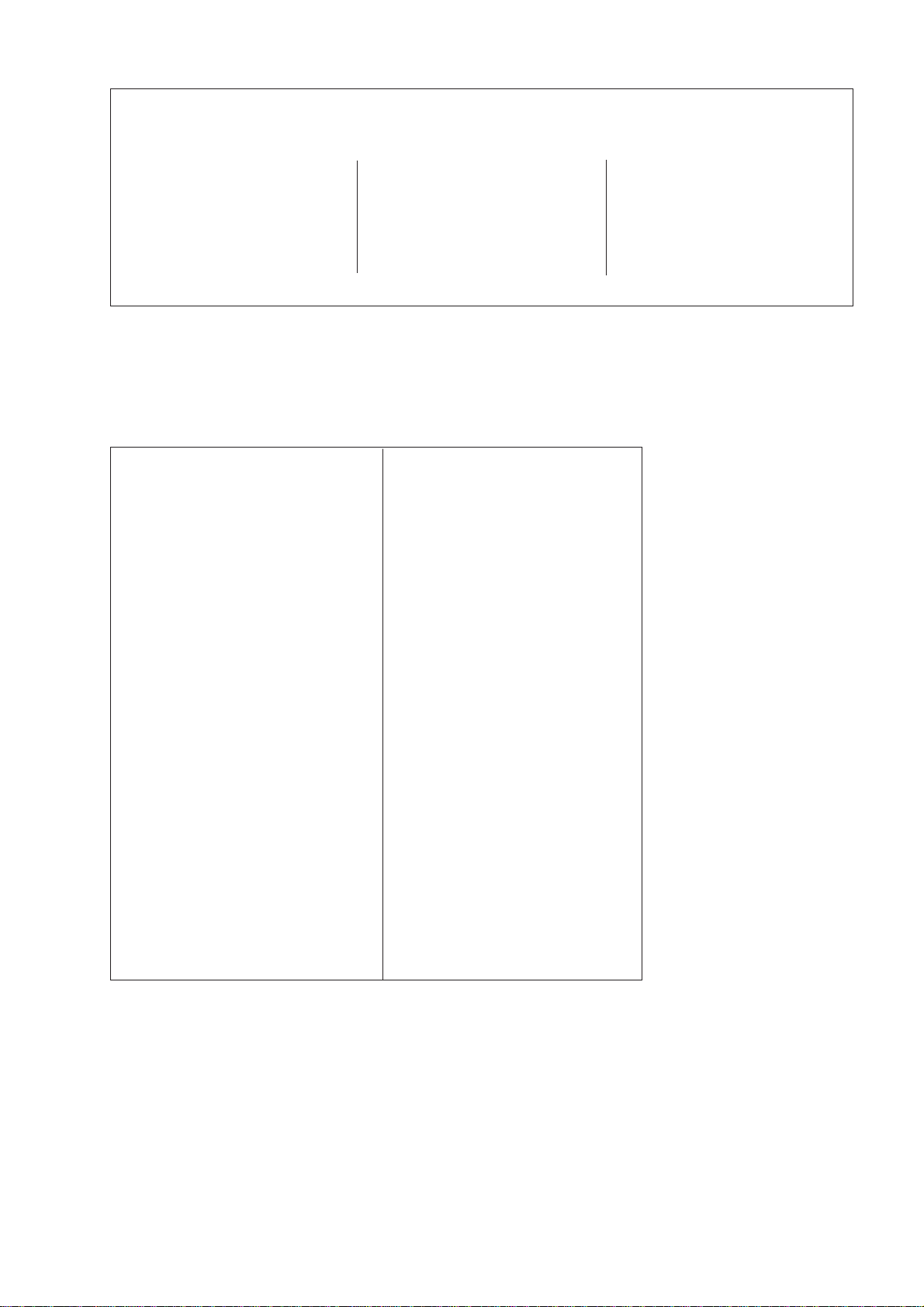

HUBASSEMBLYMOUNTING on ball bearings and lift it.

Threadthewirethroughthe

fitting inlet guide (4) and

feed it out of the central

adaptor.

6-Lower the pressure roll

(3), refit it into the

initialpositionbythe

lever (2), adjusting

thepressurewiththe

knob.

Minimumpressureis

sufficientsoasnotto

allow the feeding

rolls to slip.

Excessive pressure

will cause wire

deformations and

entanglements

insidetheliner (incasealu

wires ) and generally early

wear-and-tear of the wire

feeding motor bushings. A

scanty pressure will cause

weldingunevennesses.

4- Adjust the hub assembly

by using the screw inside the

hubassemblywireguide,so

as to prevent the wire reel

over-run (and subsequent

wire entanglements), once

the motor of the wire feeder

stops.

Do not tighten the hub

assemblytoomuch:toomuch

pressurewillcauseexcessive

drag.

5-Bythefittingleverrelease

thepressureroll(3)revolving

1- Remove the hand (hub)

nut from the hub assembly

wire guide.

2-Placethewirereelonthe

hub so that the wire will be

drawn off from the top.

Ensurethatthewirespool

locates correctly on the

small pin on the flange of

thehubassemblywiregui-

de. Refit the hub nut.

3-Releasetheendofthe

wire , but do not allow the

wire to loosen. Cut off the

kinked portion of the wire

removing any

deformations.Thismustbe

doneeverytimethewireis

refedthroughtheequipment.

connection cable equipped

by the factory and with the

machine switched off,

connect it to the mains

supply.

3. Gas

Beforestartinganyprocess,

slowly open the gas bottle

andcheckifthegasquantity

suppliedcorrespondstothe

workneeds.

7

FEEDROLLREPLACEMENT

The feeding roll bears on its

visible side the diameter of

the wire which can be fed.

Shouldthisdiameternotwant

to use, untighten the screw

(6)blocking thefeedroll and

turn it or replace it.

Every roll is provided with

two grooves fitted for the

feedingofwireswithdifferent

diameters.

Special feed rolls are

available for flux cored and

alu wires.

TECHNICAL DATA

Imput voltage 50/60Hz V230

Wire diameter mm 0,6/1,2

Delayed Start sec 0,5/10

Stitching time sec 0,5/5

Pausetime sec 0,5/5

Max wire speed m/min 5

Absorbed power VA 60

Protection class IP 21

Dimensions LxPxH210x580x450

Weight Kg 19,5

8

OFF

ON

TIG

START

9

ATTENTION!! STARWELD20010reservestheright toaltercharacteristicatany time

withoutnotice.

STARWELD2010assumes no liability for results of a wrongapplication

oftheproductswhichmaycausedamagetopersonsorequipement.

POS. Q.TY DESCRIPTION PARTNO.

1 1 5 poles female connector 000000625

2 1 Light on/off switch 000001856

3 1 Reversebutton 000002901

4 1 Button 000002897

5 1 1MPotentiometer+switch 000002883

6 1 Knob 000002227

7 1 1MPotentiometer 000060048

8 1 1KPotentiometer 000002870

9 1 Fuseholder 000002864

10 1 Hubassemblycomplete 000001237

11 1 Nut for cable 000000112

12 1 Auxiliarytransformer 000003688

13 1 PCBFR162 000003440

14 1 Rubberfeet 000000112

15 1 4 poles female connector 000000562

10

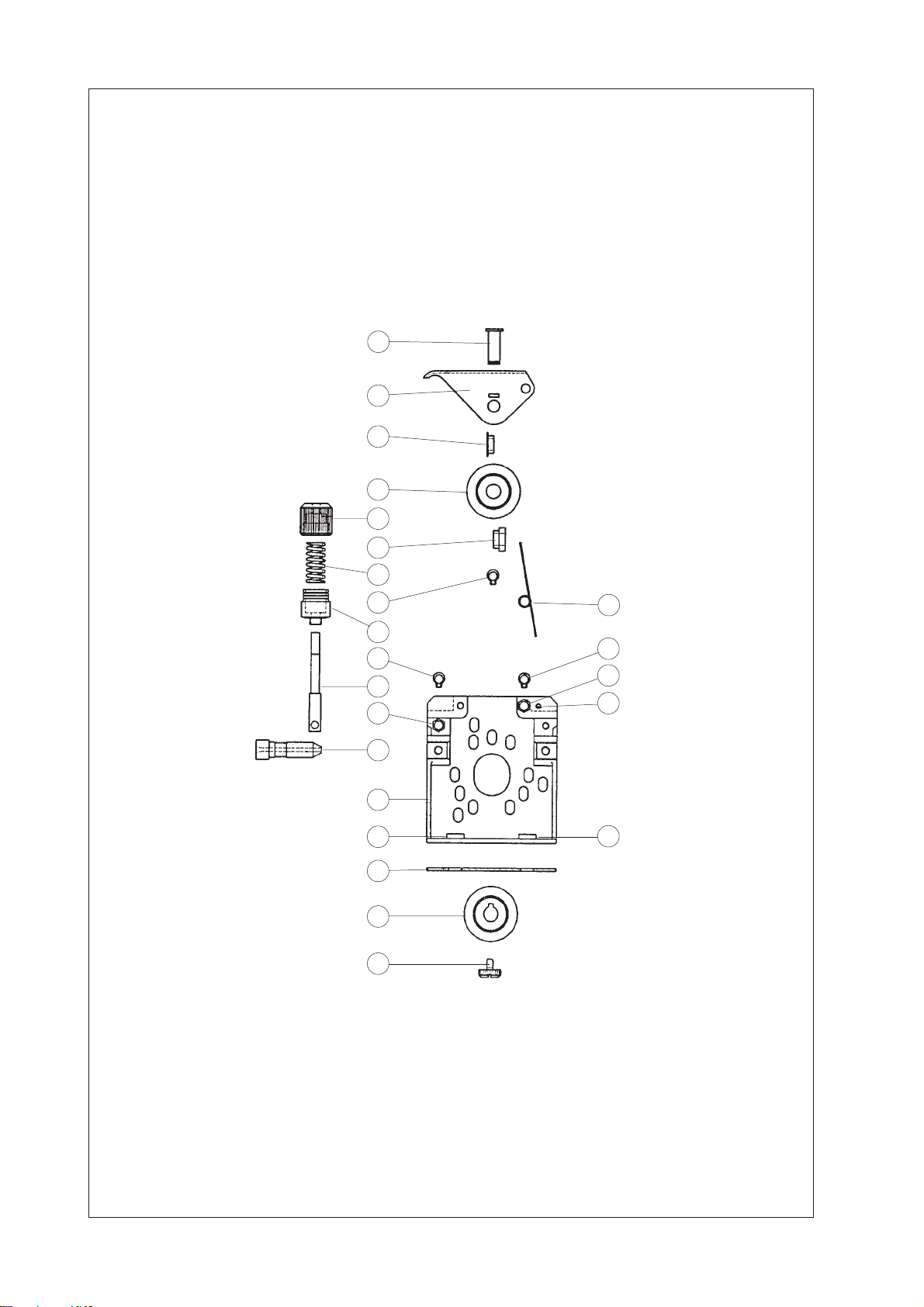

21

20

19

18 18

17

16

15

11

12

10

8

7

6

9

14

13

5

4

3

2

1

22

FEEDPLATETYPE4020-37

11

POS. Q.TY DESCRIPTION PARTNO.

1 1 Axle 000005107

2 1 Pressurearm 000005106

3 1 Spacernarrow 000000859

4 1 Pressureroll(37x12) 000002725

5 1 Fineadjustment 000005124

6 1 Spacerlarge 000020040

7 1 Spring 000005123

8 1 Clip 000005110

9 1 Spring left 000005126

10 1 Pressurebase 000005122

11 1 Axle 000005121

12 1 Clip 000005108

13 1 Axle 000005156

14 1 Pin 000005145

15 1 Axle 000005220

16 1 Inlet guide 000000254

17 1 Feedplate 000005150

18 2 Insulation 000002834

19 1 Insulationplate 000000205

20 1 Drive roll 0.6-0.8 000005239

20a 1 Drive roll 0.8-1.0 000005129

20b 1 Drive roll 1.0-1.2 000005136

20c 1 Drive roll 1.2-1.6 000005153

20d 1 Drive roll 1.2-1.6R 000005138

20e 1 Drive roll 1.0-1.2A 000005139

20f 1 Drive roll 1.2-1.6A 000005140

21 1 Screw 000004092

22 1 Clip 000005104

12

13

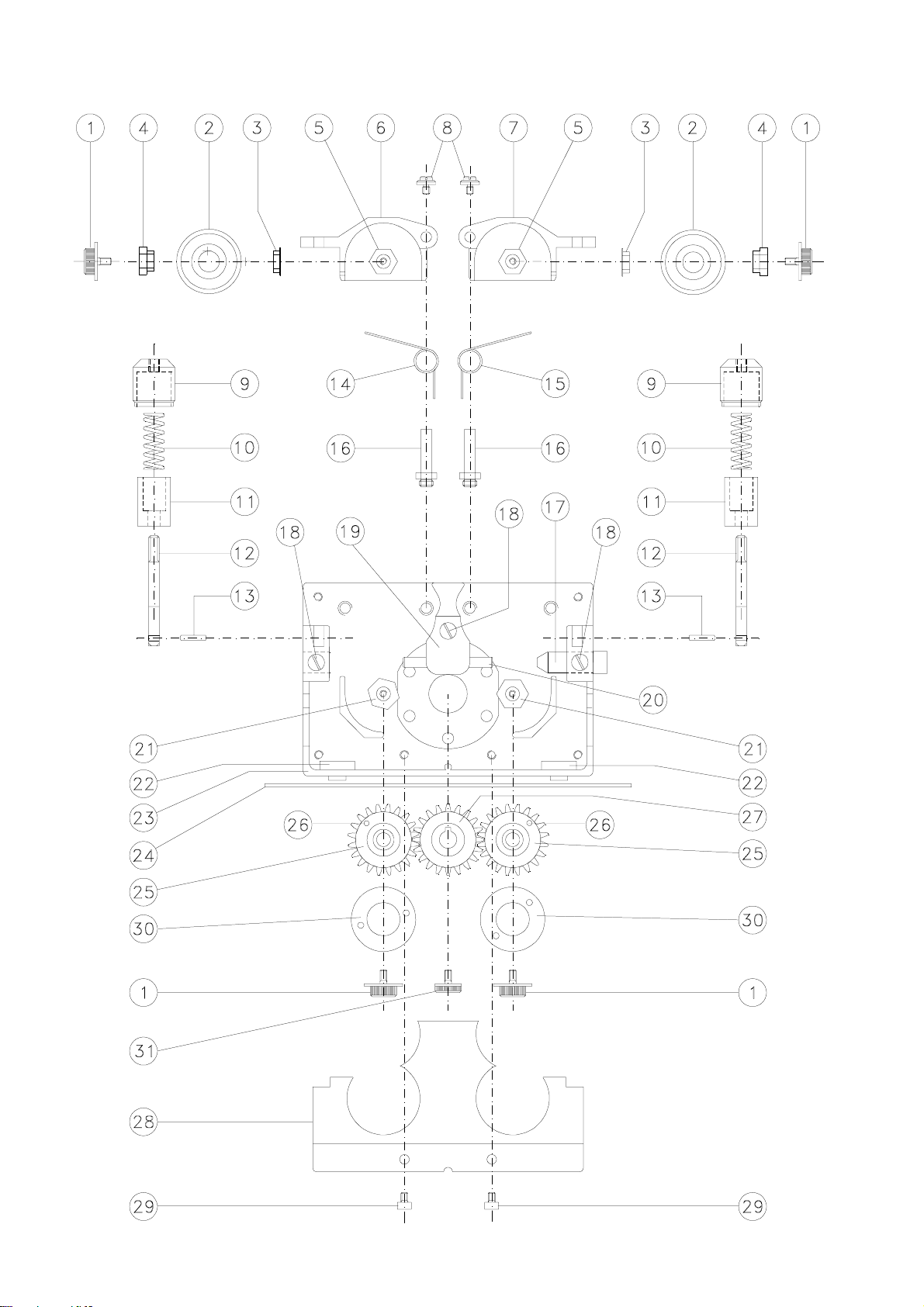

TYPE 1042

1 4 screw 000004092

2 2 Ball bearing 000002725

3 2 Spacernarrow 000000895

4 2 Spacerlarge 000020040

5 2 Axle 000100004

6 1 Pressurearmleft 000100005

7 1 Pressure arm right 000100007

8 1 Screw 000100006

9 1 Fineadjustment 000100008

10 2 Spring 000005123

11 2 Pressurebase 000100010

12 2 Axle 000100011

13 2 Axle 000100012

14 1 Spring 000100013

15 1 Spring 000100014

16 2 Axle 000100015

17 1 Inlet guide 000000254

18 3 Screw 000008545

19 1 Guide 000100022

20 1 Wire Guide 000100023

21 2 Axle 000100026

22 2 Insulation 000000027

23 1 Feed Plate 000100028

24 1 Insulation plate 000100030

25 2 Gear roll 000100002

26 2 Guide pin 000005119

27 2 Gear roll 000100029

28 2 Protection 001000031

29 2 Screw 001000032

30 2 DriveRoll 000005131

31 1 Screw 000004091

pos. piece Description part. NO.

14

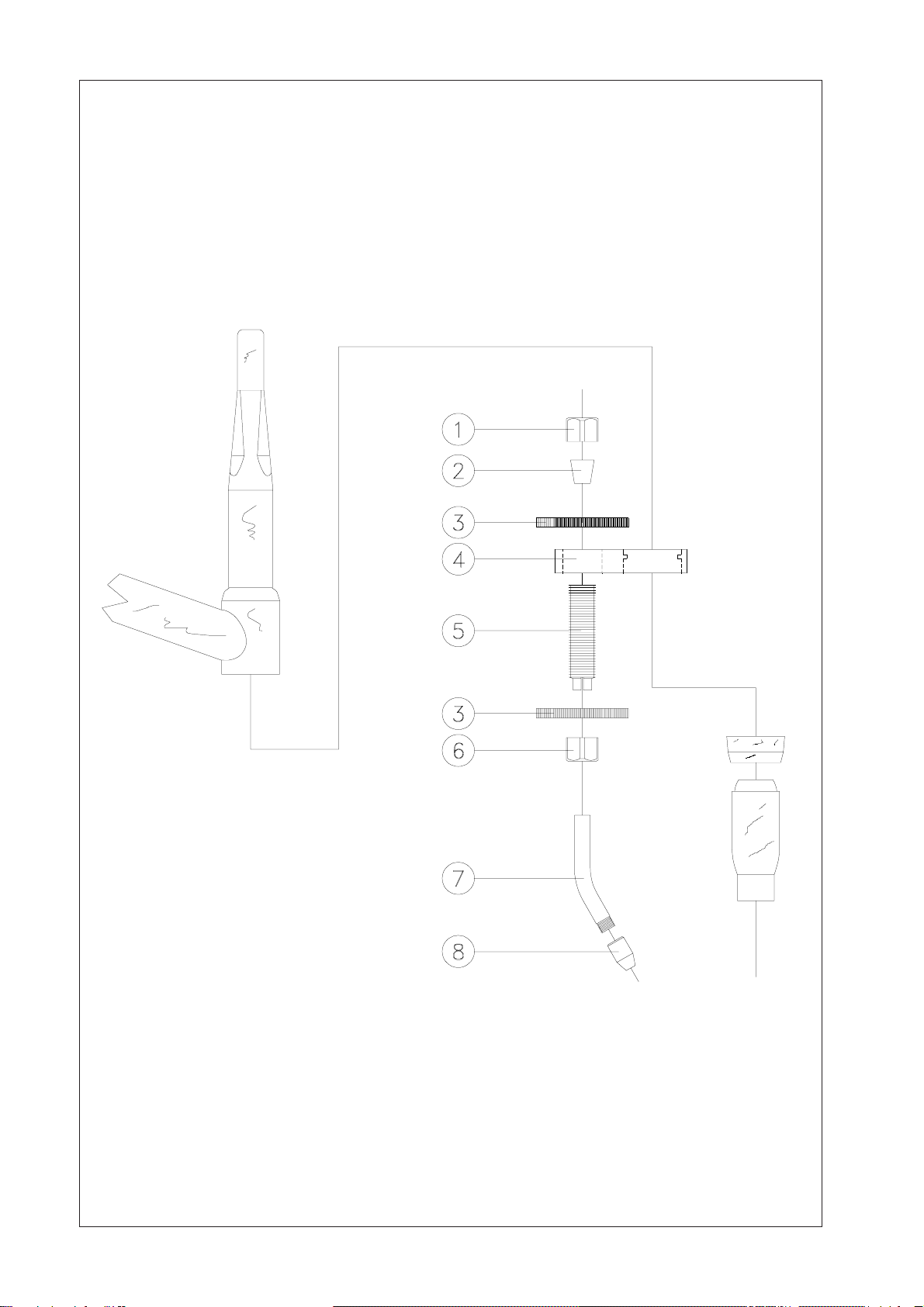

TIG-FIL TORCH KIT

(OPTIONAL )

15

POS. Q.TY DESCRIPTION CODE

1 1 linerstopscrew 000000336

2 1 Rubberconicalcap 000000175

3 1 Fixing ring 000000337

4 1 Support 000000338

5 1 Threadlever 000000339

6 1 Inletguidestopscrew 000000340

7 1 Inlet guide tube 000000341

8 1 Tip Ø 2 mm 000000342

TORCHKITPARTN°:000000355

ATTENTION!! STARWELD2010reservestherighttoalter characteristicat anytime

withoutnotice.

STARWELD2010assumes no liability for results of a wrongapplication

oftheproductswhichmaycausedamagetopersonsorequipement.

16

17

Model _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Serial N. _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Pageforcustomer'snotes

NOTES

Table of contents

Other STARWELD Welding System manuals

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric POWER WAVE 405 IM746 Operator's manual

REMS

REMS SSM 160 R operating instructions

ESAB

ESAB ET 300i instruction manual

Chicago Electric

Chicago Electric 58605 Owner's manual & safety instructions

Miller

Miller DYNASTY 350 owner's manual

Kemppi

Kemppi HiArc S 140 operating manual