Status Instruments SEM1720 User manual

D2572-01-06

SEM1720

USER INSTRUCTIONS

Important - Please read this document before installing.

Every effort has been taken to ensure the accuracy of this document; however, we do

not accept responsibility for damage, injury, loss or expense resulting from errors and

omissions, and we reserve the right of amendment without notice.

IMPORTANT – CE, UKCA & SAFETY REQUIREMENTS

Product must be DIN rail mounted, inside a suitable enclosure providing environmental

protection to IP65 or greater.

To maintain CE EMC requirements, input and supply wires must be less than 30

metres.

The product contains no serviceable parts, or internal adjustments. No attempt must be

made to repair this product. Faulty units must be returned to supplier for repair.

Before attempting any electrical connection work, please ensure all supplies are

switched off.

ABSOLUTE MAXIMUM CONDITIONS (To exceed may cause damage to the unit).

Working voltage terminals Inputs

±24 Vdc @ 10 mA

Working voltage terminals Outputs

±30 Vdc @ 50 mA

Supply voltage

(20 to 240) Vac 50/60 Hz or (20 to 240) Vdc,3 W

Ambient

Temperature (-20 to 70) °C

Approvals EN61010_1, EN61326

External supply

1 A anti-surge fuse recommended

Isolation supply to input/output

4200 V

Any input to output

3750 V

Output to output, input to input

3750 V

Important – Read this

document before installing.

---------------------------------------------------------------------------------------------------------------

1~DESCRIPTION.

SEM1720 is a dual channel signal conditioner designed to accept RTD, Thermocouple

or Potentiometer sensors and provide isolated, industrial process output signals in mA

or Volts. Each output channel may be linked to either an input sensor or to a maths

function of both sensor signals. This powerful feature allows the device to operate in

several different modes.

The output signal can also be adjusted over the full working ranges (0 to 20) mA or (0 to

10) V, to provide common or custom process signals, examples (4 to 20) mA, (0 to 1)

mA, (1 to 5) V.

SEM1720 is configured using the free software that allows the user to configure the

device without requiring calibration equipment. Maths functions on each channel can be

set up using the software as well as a 22-segment profile tool. Input/output simulation

tools for diagnostic purposes are also available

2~RECEIVING AND UNPACKING.

Please inspect the packaging and instrument thoroughly for any signs of transit

damage. If the instrument has been damaged, please notify your supplier immediately.

3~SPECIFICATION.

Refer to data sheet for full specification. Download at www.status.co.uk

Factory defaults

Basic mode, dual channel operation, (Ch1, Ch2) = Pt100,

Range (0 to 100) °C = (4 to 20) mA output. Burnout high

4~INSTALLATION AND WIRING.

Important safety requirements

This equipment is suitable for environment Installation category II pollution degree 1 and

is classed as "PERMANENTLY CONNECTED EQUIPMENT". The equipment is intended

for industrial and commercial application only and not suitable for domestic or medical

use.

The equipment must be mounted inside an enclosure that provides protection >= IP65.

In NORMAL USE, the equipment will only be accessed for maintenance by qualified

personnel. Please ensure the equipment is mounted vertically with terminals (101 to 204)

at the bottom. This will provide maximum ventilation. This equipment may generate heat:

ensure the enclosure size is adequate to dissipate heat. Be sure to consider any other

equipment inside the enclosure.

The equipment surfaces may be cleaned with a damp cloth. Use a mild detergent/water.

Ensure the supply is OFF before cleaning and on completion of cleaning the equipment

is completely dry before the supply is turned back ON.

This equipment must be installed by a qualified person. All electrical wiring must be

carried out in accordance with the appropriate regulations for the place of installation.

DC supply must be derived from a local supply and not a distribution system.

Supply (20 to 240) Vac 50/60 Hz (20 to 240) Vdc. If supply is a HAZARDOUS VOLTAGE,

a supply isolation switch must be installed close to the equipment with the “OFF”

position clearly marked. Also, the supply must be fused with a suitable 1 A (T) fuse

(circuit breaker) installed close to the equipment.

USB configuration can be performed without the supply being connected. For safety

reasons, use 24 Vdc for a functional test of the unit prior to fixed installation. The

following operations should only be carried out on a disconnected device and under

ESD safe conditions: General mounting, connection and disconnection of wires.

4.1~MECHANICAL.

The equipment must be mounted on a DIN rail style DIN EN50022 inside a plastic or

metal enclosure with a protection level >= IP65. All wiring must be secured. Maximum

cable sizes 2.5 mm. Connection two-part screw terminals.

4.2~ELECTRICAL

CONNECTIONS

For wiring connections, refer to the side label on the SEM1720 and this document.

SUPPLY

(20 to 240) V dc 50/60 Hz

(20 to 240) V dc

Max Power 3W

S1 -

S2 +

205

206

207

208

105

106

107

108

208108

OUTPUTS

Vdc

LOA D

207

107

External Powered mA

+

-

207107

205105

Internal Powered mA

LOA D

207

107

Vou t

206106

Voltage Output

+

-

205105

+

104

103

102

101

204

203

202

201

INPUTS

Thermocouple

203

103

204

104

+

-

RTD

202102

203103

203

103

201101

Slide Wire

201101

204104

202102

Input connections for cable length >3 metres: use screen or twisted pair cables. Max

cable run 30 metres.

Output connections for cable length >3 metres: use screen or twisted pair cables. For

current outputs max cable run 1000 metres, Voltage output 30 metres.

Supply maximum cable run 30 metres. As stated in the IMPORTANT SAFETY

REQUIREMENTS the supply must be fused with a 1A (T) fuse and provision provided

to isolate the circuit when hazardous voltages are being switched.

LED front panel indication.

Channel 1 and channel 2 LEDs show green for in-range input condition.

Channel 1 and channel 2 LEDs show red for out-of-range input condition.

D2572-01-06

5~USER CONFIGURATION.

Read the Important safety requirements

PC CONFIGURATION

During configuration the equipment takes its power from the USB port, therefore no

power connection is required. The equipment can be configured whilst powered but the

computer used must be isolated from the supply earth to avoid grounded earth loop

effects.

Device

USBSPEEDLINK software

www.status.co.uk

USB CABLE

COMPUTER

Configuration steps using USBSpeedLink

Download, install and run USBSpeedLink

Up to 8 configurations can be stored, the configuration chosen is set using a

DIP switch.

Set the switch on the SEM1720 to the required position (default position 1). The

switch is located behind the front panel. Repower the device after changing the

DIP switch position.

Do not remove front panel while the device is powered!

Connect device to PC using an A to mini B USB lead

Upload device set-up into the configuration software, “Basic” and “Advanced”

options are available for configuring the device.

Basic mode should be suitable for most applications.

An enhanced set of programming options are available in the Advanced

configuration mode.

Adjust settings as required

Send new configuration to the device

USBSpeedLink software configuration screen for SEM1720

Note: When the device is correctly connected, the “Send” and “Receive” menu buttons

will turn black and the “Read Data” button will become visible.

Basic configuration screen shown below.

Advanced configuration screen shown below

The following covers the Advanced mode, but descriptions apply to Basic mode as well.

CH In/Input (Ch1 and Ch2)

Select: RTD, TC or Slide-wire. RTD and TC will give a dropdown option for type.

CH In/Input (Ch1 and Ch2)

Select: High or Low condition for On Error Fail (burnout).

CH In/Input Pre-set (Ch1 and Ch2)

This will open a box to enter a value for the input (°C, %) that the device will take as its

input condition. The actual input will be ignored while this input pre-set is selected. The

device will respond accordingly to the pre-set input value on its output.

Profile In (A and B)

Select the input source for the Profile, normally CH1 or CH2 input, but can use the

dropdown tool to select from a range of maths comparisons such as Average.

Profile Seg/Segments (A and B)

The number of segments

Up to 22 user-segments can be used to create a user-curve or non-linear relationship

table, for example add corrections or calibration points to a probe with known errors.

This tool can also be used to enter the °C units to °F units if required.

Segments can be used if required to control out of limit conditions or create banded

temperature zones.

Profile Units Out (A and B)

Normally °C but can be any relevant unit such as °F (see above Seg/Segments)

CH Out/Output Source (Ch1 and Ch2)

Select the Profile source for the Output, normally Profile A or Profile B, but can use the

dropdown tool to select from a range of maths comparisons such as Average.

CH Out/Output Range (Ch1 and Ch2)

Set the engineering range, normally °C to be scaled to the output.

CH Out/Output Signal (Ch1 and Ch2)

Select mA or V and the output range to be scaled to the engineering range. This can be

any value within the physical capability of the device.

For a voltage output, the output load value, if known, can also be entered.

CH Out/Output Damping (Ch1 and Ch2)

A value to slow the rate of change on the output can be added for a rising and a falling

signal.

CH Out/Output Fixed Output (Ch1 and Ch2)

The output can be fixed to a known value. This can be useful for diagnostics on a

system

CH

Out/Output Tag (Ch1 and Ch2)

A free type field for information to be stored onto the SEM1720

Menu Options

The configuration can be saved to PC file for back-up and re-use as required.

The USBSpeedLink software will allow live readings to be taken from the device

showing input and output conditions.

For diagnostic use, the device can save live readings to a text file on the PC.

USBSpeedLink configuration software is available online at www.status.co.uk

This guide is also available online at www.status.co.uk

Status Instruments Ltd, Status Business Park, Gannaway Lane, Tewkesbury, Gloucestershire, UK, GL20 8FD,

Web Page: www.status.co.uk,

Technical Support: support@status.co.uk

Tel: +44 (0) 1684 296818, Fax: +44 (0) 1684 293746

Popular Tools manuals by other brands

blackburn

blackburn TBM8-750BSCR operating instructions

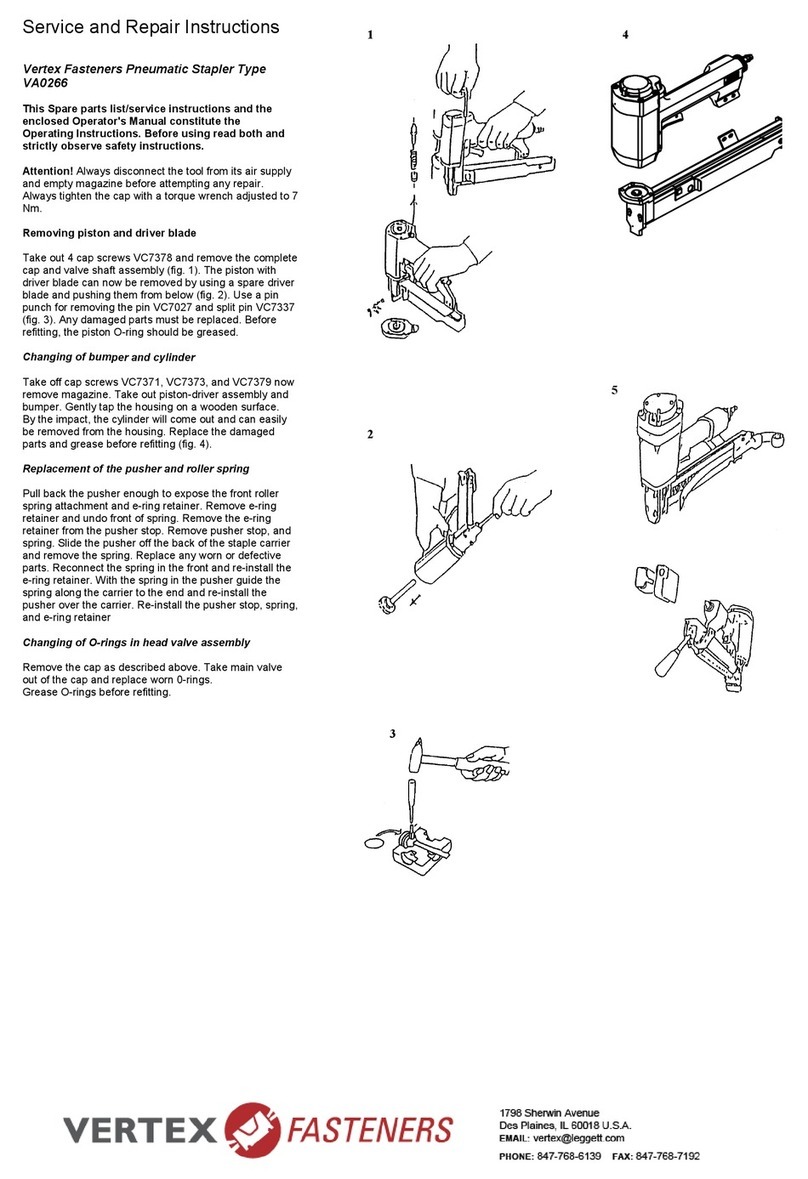

Vertex

Vertex VA0266 Service and repair instructions

Victaulic

Victaulic VE106 Groove-N-Go Operating and maintenance instruction manual

Josef Kihlberg

Josef Kihlberg JK35-590 operating instructions

Alcolock

Alcolock LR max installation manual

Hammerhead

Hammerhead HCID120 manual