STATUS SCIENTIFIC CONTROLS FGD14 User manual

STATUS SCIENTIFIC CONTROLS

Issue:

2.9

Date:

16/5/19

Firmware:

V8.0.x

FGD14 Single Channel

Environmental Monitor.

STATUS SCIENTIFIC CONTROLS LTD.

Hermitage Lane Industrial Estate,

Kings Mill Way,

Mansfield,

Nottinghamshire.

NG18 5ER

England

Tel

Fax

Internet

: 01623 651381

: 01623 421063

: www.status-scientific.com

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 1

1Introduction 3

1.1 SENSORS.....................................................................................................3

1.1.1 Infrared .......................................................................................3

1.1.2 Oxygen .......................................................................................3

1.1.3 Toxic...........................................................................................3

2Installation 4

2.1 SITING THE ‘FGD14’.....................................................................................4

2.2 POWER SUPPLY OPTIONS .............................................................................4

2.2.1 Mains Powered...........................................................................4

2.2.2 DC Powered................................................................................4

2.3 WIRE TERMINATION ......................................................................................5

2.3.1 Remote Indicator Connection......................................................6

3Menu System 7

3.1 DISPLAY UNIT............................................................................................... 7

3.2MENU MODE SELECTION...............................................................................7

Alarm Test..................................................................................................9

3.3CALIBRATION................................................................................................ 9

3.4.1 Calibration Gas Flow Rates......................................................... 9

3.4.2 Zero Sensor.............................................................................. 10

3.4.3 Span Sensor............................................................................. 11

3.4.4 Calibration Factors....................................................................11

3.4.5 Set Sensor FSD........................................................................ 12

3.4.6 Set Display Mode......................................................................12

3.4.7 Display Firmware Version..........................................................13

3.4.8 Restore..................................................................................... 13

3.4.9 View Engineer/Diagnostics Data ............................................... 14

3.4.10 Sensor Frequency..................................................................... 14

3.4.11 Cross Reference....................................................................... 15

3.4.12 Set Relay 1 Mode...................................................................... 16

3.4.13 Set Relay 2 Mode...................................................................... 16

3.4.14 Set Alarm Level 1...................................................................... 17

3.4.15 Set Alarm Level 2...................................................................... 17

3.4.16 Sounder Enable ........................................................................ 17

3.4.17 Set Alarm Hysteresis................................................................. 18

3.4‘FGD14’ INDICATIONS.................................................................................19

3.5SENSOR REPLACEMENT.............................................................................. 21

4Trouble Shooting 22

5Specification 24

5.1 HYDROCARBON.......................................................................................... 24

5.2 CARBON DIOXIDE ....................................................................................... 25

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 2

5.3 OXYGEN ....................................................................................................26

5.4 TOXIC........................................................................................................ 26

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 3

1 INTRODUCTION

The FGD14 is a self-contained unit designed to detect environmental conditions by

fitting suitable sensors. It also provides the user with local and remote indication of

alarm / fault conditions.

The FGD14 can be fitted with a display unit that allows non-intrusive calibration /

configuration via concealed push buttons and local readout of gas levels.

A remote keypad can be temporarily fitted to gain access to the calibration /

configuration data when the unit is supplied without a display.

The FGD14 is fitted with two relays, which are linked to user definable alarm set

points.

The FGD14 may be connected to an interface unit that will allow direct connection to a

PC.

1.1 Sensors

The unit can be fitted with a range of sensor modules allowing it to be tailored to

individual needs.

1.1.1 Infrared

The infrared sensors use the proven non-dispersive infrared principle (NDIR) to detect

and monitor the presence of gases. This technique relies upon the target gas having a

unique, well-defined absorption signature within the infrared region of the

electromagnetic spectrum.

There are currently two IR sensors: -

1) Carbon Dioxide

2) Hydrocarbon.

1.1.2 Oxygen

The oxygen type fitted is the ‘4’ series type.

1.1.3 Toxic

The toxic type fitted is the ‘4’ series 3 electrode type.

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 4

2 INSTALLATION

IMPORTANT

It is important that the instrument has been installed and powered for a minimum of 10

minutes before it is used to monitor the gases concentration in the environment.

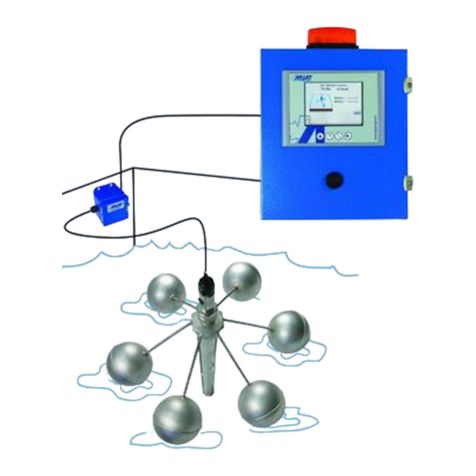

2.1 Siting the ‘FGD14’

Mounting positions for detector heads need to be considered individually, some points

for consideration are:

•Sensors for detecting gases that are lighter than air should be positioned at a

high level.

•Sensors for detection of gases heavier than air should be located as low as

practically possible.

•Ensure all sensors are mounted to allow calibration and maintenance to be

carried out as required.

•Ensure the proposed site will not interfere with movement of existing

equipment, e.g. cranes, doors etc

•Install all cables neatly and securely.

•Avoid siting the sensors adjacent to potential sources of radio frequency

interference, e.g. radio transmitters, control switchgear, motors etc.

•Avoid mounting the instrument where it may be subjected to sudden transients

in ambient temperature (e.g. above a heater/radiator).

2.2 Power Supply Options

The FGD14 is available with one of two power supply options.

2.2.1 Mains Powered

A universal power supply is fitted that operates in the range of 85-265Vac, 47-400 Hz.

This allows worldwide use without the need to configure for location specific mains

voltage requirements.

2.2.2 DC Powered

Alternatively a DC power supply can be installed capable of accepting voltages in the

range of 8-30V DC.

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 5

2.3 Wire Termination

All connections should be made according to the diagram below. It is advised that

‘Bootlace Ferrules’ or ‘flat blade crimps’ be used for tidy and reliable connections of

wires into the Detector Head connectors.

Note: The yellow mains cover must be removed to gain access to the mains input

connector.

Isolate the mains supply before removing cover.

Ensure that the protective cover is securely replaced after terminating the mains input

Note:

When a DC Power Supply is fitted within the FGD14, the terminals marked L and N on

the above diagram will be identified as +Ve and –Ve.

Mains Fuse

Mains

Connector

Terminals for

connection of

Remote indicator

unit

Power

Supply Fuse

Sensor

module

Remote

keypad

connector

Ext. 0V

Rx

Tx

Ext.5V

Pwr LED

Alm

LED

Buzzer

NC

NO

COM

NC

NO

COM

Relay 2

Relay 1

Status Scientific Controls

E N L

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 6

2.3.1 Remote Indicator Connection

To gain access to the terminals within the remote indicator assembly, remove the

screw located at each corner of the assembly when viewed from below (4 in total).

The units should then be wired as follows:

FGD14

Remote Indicator

Ext5V

5V

Pwr LED

PWR

Alm

ALM

Buzzer

BUZ

A cable tie is provided within the remote indicator assembly to strain relieve the

terminals.

PWR

ALM

BUZ

5V

Ext. 0V

Rx

Tx

Ext.5V

Pwr LED

Alm

LED

Buzzer

NC

NO

COM

NC

NO

COM

Relay 2

Relay 1

E N L

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 7

3 MENU SYSTEM

Important

Whenever the menu system is entered the instrument will cease to measure

current gas levels. However normal operation is always returned following a

period of keypad inactivity (or when the menu system is exited).

3.1 Display Unit

In order to gain access to the calibration switches and test points, release the screw

situated between the letters A and T of the chrome STATUS label on the Detector

Head front panel. The screw does not need to be completely removed, only release it

far enough so that the STATUS label can rotate revealing the calibration switches. The

buttons are designated as follows:

3.2 Menu Mode Selection

Several calibration modes exist in the detector head and these are accessible via the

instruments simple menu system. To select a calibration mode follow this procedure:

•Press the MENU button and C: 1 appears on the display.

•Press UP or DOWN until the required calibration mode is displayed on the

screen.

•Press ENTER to select the calibration mode.

•To exit the calibration mode press MENU.

While the instrument is in a calibration mode –any data displayed on the screen will

alternate between the cal number and the reading.

The following features are available via the ‘FGD14’ menu system: -

Cal number

Function

Enabled

Section

1

Zero Sensor

Yes

3.3.2

2

Span Sensor

Yes

3.3.3

3

Set Sensor F

Yes

3.3.5

6

Set Display Mode

Yes

3.3.6

7

Display Firmware version

Yes

3.3.7

8

Restore

Yes

3.3.8

9

View Engineer/Diagnostics Data

Yes

3.3.9

10

Sensor Frequency

Yes

3.3.10

13

Set Relay 1 Mode

Yes

3.3.12

UP DOWN ENTER MENU

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 8

14

Set Relay 2 Mode

Yes

3.3.13

15

Set Alarm Level 1

Yes

3.3.14

16

Set Alarm Level 2

Yes

3.3.15

26

Sounder enable

Yes

3.3.16

27

Alarm hysteresis

Yes

3.3.17

Note: The MENU numbers have gaps, this is to maintain compatibility with

other products that have different features.

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 9

Alarm Test

The FGD14 is equipped with an alarm test function. During alarm the relays, Leds and

sounder will operate, see section 3.4

In order to gain access to the alarm test switch see section 3.1.

When the FGD14 is operating normally press the UP button to activate the alarm

system. The alarm will continue to operate whilst the UP button is pressed and for a

further 5 seconds when it is released.

3.3 Calibration

The infrared sensors used within the Status Scientific Controls ‘FGD14’ Detector

Heads do not respond linearly with respect to gas levels to which they are exposed.

The FGD firmware contains complex mathematical formulae to allow a linear response

to be calculated and indicated on the instrument display.

Care should be taken to ensure that calibration procedures are followed and any notes

included are read and understood. Failure to adhere with the recommendations within

this manual may seriously impair the instruments ability to accurately indicate the gas

levels to which it is being exposed.

3.3.1 Calibration Gas Flow Rates

Most gas sensors including the infrared sensors are sensitive to pressure transients

and therefore it is important that the flow rate of gas into the sensor housing is not

excessive during calibrations. Care must also be taken to ensure the exhaust from the

sensor housing is not restricted. The recommended flow rate of calibration gases is

500 - 750cc/min.

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 10

3.3.2 Zero Sensor

This is a calibration feature. It allows the instrument to determine the sensor output

under zero gas conditions.

•Apply target free gas to the sensor inlet and allow enough time for the sensor

to respond and all gas to be purged (typically 2 minutes dependent upon flow

rate).

•Select calibration mode C: 1 (refer to section 3.2) and press ENTER.

•Press ENTER to perform the ZERO calibration. Pressing MENU instead of

ENTER aborts the calibration (the ZERO factor will still be displayed on exit).

•Press MENU –the display will show the ZERO factor for the instrument before

returning to its standard mode of operation.

The ZERO factor should be recorded on any calibration certificates.

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 11

3.3.3 Span Sensor

This is a calibration feature. It allows the instrument to determine the sensor output

when it is exposed to a know concentration of gas.

•Apply a known concentration of Hydrocarbon gas (typically 20% LEL pentane)

to the sensor inlet and allow enough time for the sensor to respond. I.e. until

the reading remains constant.

•Select calibration mode C: 2 (refer to section 3.2) and press ENTER.

•Using the UP and DOWN buttons, adjust the displayed reading so that it

matches the calibration gas concentration.

•Press ENTER to perform the SPAN calibration. Pressing MENU instead of

ENTER aborts the calibration (the SPAN factor will still be displayed on exit).

•Press MENU –the display will show the SPAN factor for the instrument before

returning to its standard mode of operation.

The SPAN factor should be recorded on any calibration certificates.

3.3.4 Calibration Factors

During the ZERO sensor and SPAN sensor calibrations a factor is displayed that

allows the calibration personnel to have confidence with their calibration.

The ideal ZERO and SPAN factors are as follows: -

Sensor

Factor

MIN

TYP

MAX

Notes

HC

ZERO

0.800

1.000

1.200

SPAN

TBA

1.70

TBA

CO2

ZERO

0.800

1.000

1.200

SPAN

TBA

0.45

TBA

Oxygen

ZERO

0

0

20

SPAN

TBA

0.3

TBA

Non-linearised

SPAN

TBA

2559

TBA

Linearised

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 12

3.3.5 Set Sensor FSD

This option is used to match the sensor’s operating range with the electronics so that

over-range conditions can be detected.

•Select calibration mode C: 3 (refer to section 3.2) and press ENTER.

•Using the UP and DOWN buttons, adjust the displayed reading so that it

matches the desired FSD.

•Press ENTER to accept the new FSD. Pressing MENU instead of ENTER

aborts the feature.

•Press MENU to return the instrument to its standard mode of operation.

3.3.6 Set Display Mode

Menu mode C: 6

•Select calibration mode C: 6 (refer to section 3.2) and press ENTER.

•Using the UP and DOWN buttons, adjust the display to match the number of

decimal places required.

•Press ENTER to accept the new setting. Pressing MENU instead of ENTER

aborts the feature.

•Press MENU to return the instrument to its standard mode of operation.

Note: increasing the display resolution will not make the sensor more accurate.

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 13

3.3.7 Display Firmware Version

Menu mode C: 7

This option is not available in this version –it is used for compatibility with other

products.

3.3.8 Restore

This feature is used to restore all the settings to the factory default settings. Warning

all current settings and sensor calibration will be lost –use with extreme caution

The information that can be displayed using this feature is usually only required during

initial assembly and testing of the detector head

•Select calibration mode C: 8 (refer to section 3.2) and press ENTER.

•The display will show HC.

•Press UP to select the different types of sensor.

•Press ENTER to restore the factory default settings for the selected sensor

type. Pressing MENU instead of ENTER leaves the unit without change.

•Press MENU to return the instrument to its standard mode of operation.

3.3.8.1 Sensor types

MENU TYPE RANGE COMMENTS

HC Infrared 0-100%LEL General hydro carbons

CO2L Infrared 0-5%Vol Carbon Dioxide

CO2A Infrared 0-2%Vol Carbon Dioxide

CH4L Infrared 0-100%LEL Methane

CH4H Infrared 0-100%Vol Methane

Elt1 Oxygen 0-25%Vol

Elt2 Toxic 0-1ppm Positive output sensor

Elt3 Toxic 0-1ppm Negative output sensor

Elt4 Toxic 0-20ppm

Elt5 Toxic 0-50ppm

Elt6 Toxic 0-200ppm

Elt7 Toxic 0-500ppm

Elt8 Toxic 0-1000ppm

Elt9 Toxic 0-9999ppm

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 14

3.3.9 View Engineer/Diagnostics Data

This feature is a view-only feature. No configuration changes are possible from within

this menu.

This information is for the use of Status Scientific Controls.

•Select calibration mode C: 9 (refer to section 3.2) and press ENTER.

•The display will alternate between the current value and code C: 9x: where x

is: 0 Sensor reading.

1 Calibration temperature, degC.

2 Sensor temperature, degC.

3 Detector AtoD counts.

4 Reference AtoD counts.

5 Fractional absorbance, IR only.

•The mode of operation can be selected by pressing the UP button.

•Press MENU to return the instrument to its standard mode of operation.

3.3.10 Sensor Frequency

Menu mode C: 10

This option is not available in this version –it is used for compatibility with other

products.

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 15

3.3.11 Cross Reference

This option is used to allow the user to calibrate the sensor with a commonly available

gas (e.g. methane or propane) but use the unit to detect a different gas (e.g. methanol

or acetone etc.). This is achieved by adjusting the cross-reference factor according to

the difference in signal that is detected for the calibration gas compared to the target

gas.

•From the menu system select menu option: C: 12 and press ENTER.

•Using the INCREASE and DECREASE buttons, set the required cross-

reference factor.

•Press ENTER to store the new value.

Note:

Pressing MENU rather than ENTER exits the cross-reference feature

without saving any changes.

•Press MENU to close the menu system.

Infrared sensor

Note: Oxygen sensors.

Cross reference = 0, oxygen sensor is linearised

Cross reference not 0, oxygen sensor is not linearised

Target gas

Calibration gas

Cross Reference Factor

Methane

Methane

1.00

Propane

Propane

1.00

Toluene

Methane

1.30

Ethanol

Propane

1.20

IPA

Propane

1.72

Hexane

Propane

1.00

Acetic Acid

Methane

2.00

Methanol

Propane

1.00

Acetone

Methane

1.50

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 16

3.3.12 Set Relay 1 Mode

The unit is fitted with a relay that is operated in conjunction with the alarm level. The

user can select if the relay is normally energised, E’ or normally de-energised, ‘d’ when

the unit is not in an alarm condition.

•Select calibration mode C: 13 (refer to section 3.2) and press ENTER.

•The display will show the following:

oE:r Normally energized, rising alarm

od:r Normally de-energized, rising alarm

oE:F Normally energized, falling alarm

od:F Normally de-energized, falling alarm

•The mode of operation can be changed by pressing the UP button.

•Press ENTER to accept the new relay mode of operation. Pressing MENU

instead of ENTER leaves the unit without change.

•Press MENU to return the instrument to its standard mode of operation.

3.3.13 Set Relay 2 Mode

The unit is fitted with a relay that is operated in conjunction with the alarm level. The

user can select if the relay is normally energized, ‘E’ or normally de-energised, ‘d’

when the unit is not in an alarm condition.

•Select calibration mode C: 14 (refer to section 3.2) and press ENTER.

•The display will show the following:

E:r Normally energized, rising alarm

d:r Normally de-energized, rising alarm

E:F Normally energized, falling alarm

d:F Normally de-energized, falling alarm

•The mode of operation can be changed by pressing the UP button.

•Press ENTER to accept the new relay mode of operation. Pressing MENU

instead of ENTER leaves the unit without change.

•Press MENU to return the instrument to its standard mode of operation.

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 17

3.3.14 Set Alarm Level 1

•Select calibration mode C: 15 (refer to section 3.2) and press ENTER.

•Using the UP and DOWN buttons, adjust the displayed reading so that it

matches the desired alarm set point.

•Press ENTER to accept the new alarm level. Pressing MENU instead of

ENTER aborts the feature.

•Press MENU to return the instrument to its standard mode of operation.

3.3.15 Set Alarm Level 2

•Select calibration mode C: 16 (refer to section 3.2) and press ENTER.

•Using the UP and DOWN buttons, adjust the displayed reading so that it

matches the desired alarm set point.

•Press ENTER to accept the new alarm level. Pressing MENU instead of

ENTER aborts the feature.

•Press MENU to return the instrument to its standard mode of operation.

3.3.16 Sounder Enable

The sounder has three modes of operation:

Always off

Always on

Timed.

The display shows OFF, On or a number between 1 and 600. The timed mode is in

seconds.

This option is used to enable or disable the sounder. Note the Leds and display

operate normally.

•Select calibration mode C: 26 (refer to section 3.2) and press ENTER.

•Set the option to OFF, On or timed by pressing the UP / DOWN buttons.

•Press ENTER to accept the change. Pressing MENU instead of ENTER aborts

the feature.

•Press MENU to return the instrument to its standard mode of operation.

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 18

3.3.17 Set Alarm Hysteresis

Hysteresis is applied during alarm checking to stop the alarm relays chattering when

the gas level is at the alarm set point. The hysteresis level is expressed as a

percentage of the alarm setting. For example if the alarm setting is 10% vol. CO2and

the hysteresis setting is 1% then the alarm relay would be activated at 10% gas and

de-activate at 9.9% gas.

•Select calibration mode C: 27 (refer to section 3.2) and press ENTER.

•Using the UP and DOWN buttons, adjust the displayed reading so that it

matches the desired alarm hysteresis level.

•Press ENTER to accept the new level. Pressing MENU instead of ENTER

aborts the feature.

•Press MENU to return the instrument to its standard mode of operation.

STATUS SCIENTIFIC CONTROLS

FGD14 Environmental Monitor

TD06/026

Issue:

2.9

Change note:

1882

Page 19

3.4 ‘FGD14’ Indications

Start up Conditions

The FGD starts up with the following conditions:

The GREEN power led on the remote indicator flashes.

The LCD shows:

All segments.

Firmware version.

Sensor type.

‘----‘ flashes for remaining start up time.

The GREEN power led on the remote indicator is continuously lit.

Alarm Condition

If the FGD14 detects gas levels in excess of the preset alarm level, an alarm is raised.

This is indicated by:

The RED LED on the front panel of the FGD14 flashes and the sounder will be

heard.

The RED LED on the Remote Indicator Unit flashes and the sounder will be

heard.

The internal Relay will change state.

The alarm condition will continue to be indicated until the detected gas level falls

below the alarm set point.

Other manuals for FGD14

1

Table of contents