Hanwell IM4772 iSense User manual

IM4772 –iSense

Instruction Manual

Doc No. IM4772-7

Page 2 of 14

iSense

Contents

1Introduction.................................................................................................................................................... 4

2Inventory........................................................................................................................................................ 5

3Product Description....................................................................................................................................... 6

3.1 Product Options....................................................................................................................................6

3.2 System Pre-requisites........................................................................................................................... 6

3.2.1 Hanwell Software.............................................................................................................................. 6

3.3 Wall Mounting Instructions....................................................................................................................6

3.4 Vehicle Mounting ..................................................................................................................................6

3.5 Adding iSense to Synergy .................................................................................................................... 7

3.6 Sensor operation ..................................................................................................................................7

3.7 Alarm Handling.....................................................................................................................................7

4Setting Up the iSense Hardware................................................................................................................... 8

4.1 Removing the Front Panel....................................................................................................................8

4.2 Connecting the Aerial ........................................................................................................................... 8

4.3 Connecting the Batteries ...................................................................................................................... 9

4.4 Connecting Vehicle Power Supply ....................................................................................................... 9

4.5 Operating Environment.........................................................................................................................9

5Sensor Input Wiring.....................................................................................................................................10

5.1 Connecting a Probe –Thermistor Example........................................................................................11

5.2 Connecting a Probe –JO91 Current Clamp Example........................................................................ 12

Doc No. IM4772-7

Page 3 of 14

iSense

Document History

Document Number: IM4772

Issue

No.

Issue Date

Changes

By

1

18 July 2010

First release.

MSH

2

23 December 2010

Adds information on redirector service and USB

configuration utility

MSH

3

28 September 2011

Add 3-channel thermistor connections

MSH

4

8 October 2014

Update for Synergy. Radiolog GPRS no longer

supported

CRB

5

18 September 2015

Update for Alarm Handling

RAB

6

11 November 2015

Mounting instructions added

RAB

7

30 May 2017

Vehicle usage instructions

CRB

Doc No. IM4772-7

Page 4 of 14

iSense

1 Introduction

Hanwell instruments offer a range of battery powered devices which can send their data to Synergy via GPRS

rather than low power radio. Data sent via GPRS is collected and stored on the IMC Remote Data Service,

from where your Synergy installation will retrieve it. Synergy then handles all data presentation and alarm

functionality in the normal way.

The devices log data on board and periodically send this logged data to the IMC Remote Data Service. This

send rate should normally be set low to save battery power, but in the event of an alarm the device will go into

a much faster transmission sequence. In the event of poor network coverage the device will retain data

packets and retry the send in due course

Synergy collects data associated with your iSense sensor(s), by making an outgoing TCP/IP connection to the

IMC Remote Data Service. As this connection is made to a standard HTTP port on the IMC Remote Data

Service, the system operates with the vast majority of network and Firewall configurations.

The device comes preconfigured with a SIM card fitted, so all that it is normally necessary to do is to connect

the sensor wiring (if required) and fit the battery.

A battery life of up to 3 years is achievable if the normal send rate is limited to once every 12 hours.

The actual desired send rate, logging rate and alarm levels will be sent from Synergy when first signal has

been received.

On first power up the device will send data every 5mins for 30minutes to verify correct operation.

It is also possible to have a remote radio system sending data to a CR2 which then transfers all of this

information via GPRS; in this configuration only one SIM card will be required.

Doc No. IM4772-7

Page 5 of 14

iSense

2 Inventory

Your iSense box should contain the following as standard:

1x iSense unit

1x Knuckle joint antenna (G205)

1x Battery Pack* (G213)

* If you have ordered an externally power unit then you will also either have a desktop power supply or 24V

DC truck power adaptor pre-fitted, instead of a battery.

WARNINGS

A battery pack must NOT be fitted when the external supply is used.

The desktop power supply is not rated for outdoor use, if you wish to use this outdoors then enclose

the whole in a suitable plastic or fibre glass enclosure

Use only the supplied mains adaptor with these devices.

Doc No. IM4772-7

Page 6 of 14

iSense

3 Product Description

3.1 Product Options

Extended antenna for low signal areas: AM36913

Standard input types include Thermistor, RH, 0...1V, 0...5V, 0...10V, 4...20mA, Current Clamps and Pulse

Counting.

Please ask for input options not listed above, as many sensor types can be accommodated.

3.2 System Pre-requisites

3.2.1 Hanwell Software

Synergy: Version 1.4.4 or above.

3.3 Wall Mounting Instructions

1. Use the three holes in the mounting box as a drilling template, ensuring that the keyhole is uppermost.

2. Screw the box mounting box to the wall.

3. Insert the iSense unit into the mounting box.

3.4 Vehicle Mounting

IMC strongly recommend that the iSense is mounted inside the vehicle body; in any case, the iSense unit

needs to be protected from extremes of temperature changes, and wind force.

The iSense unit has 4 mounting holes, adjacent to the lid fixing screw holes on each corner; these are

accessed by removing the lid; the unit should be mounted with 4mm diameter bolts, or equivalent self-tapping

screws.

Where radio reception inside the vehicle is likely to be affected by bodywork etc. use a GSM aerial mounted

externally to the vehicle body, this connects to the brass coloured aerial connector mounted on the iSense

side, (do not use excessive force tightening the aerial connection, finger tight is adequate).

See Connecting Vehicle Power Supply for vehicle power connection details.

Doc No. IM4772-7

Page 7 of 14

iSense

3.5 Adding iSense to Synergy

The iSense must be added to Synergy using the Family Type iSense; see Synergy User Manual ‘Adding

Sensors’, for full details on adding sensors to Synergy.

Note: Do NOT try to use the iSense with RadioLog, and do NOT attempt to configure the iSense with the

legacy iSenseConfig Utility or iSense USB Configurator.

3.6 Sensor operation

The devices will log data on-board at the pre-set log interval, and in due course send these to the IMC

Remote Data Service. This send process will occur under the following circumstances:

After the ‘SendInterval’

OR 300 logged points are available

OR 12hours has elapsed

OR the measurement is in alarm

In the event of communications failure the device will buffer up to 250k of data and gradually send this after

communications is restored, and in reverse time order. If and when this happens at each wake up the device

will send its current packet plus the most recent three packets whose sending was not successful

If the measurement goes into alarm then the unit will start to transmit every 15minutes for a period of up to 2

hours. At this time it will revert to its programmed behaviour. No alarm will be re-triggered until three logs have

been within the alarm limits.

The device sends its battery voltage with each message; this can be viewed via Synergy.

3.7 Alarm Handling

It is possible to set level alarms on each individual iSense channel. It is important to remember that as the

device only calls in, then these values can only be changed on a standard connect cycle. This cycle will

happen at some time later –possibly many hours later –after the Synergy change.

Prior to an alarm the sensors are sampled at the nominal interval and sent periodically, but if an alarm

condition is detected it will transmit this within the following 4 minutes. Thus the maximum iSense response

time to an alarm is (nominal logging interval +4 min).

Assuming that the GSM network is up and running perfectly then there will be up to a further 8 minutes before

it appears on screens because of redirector and Synergy delays. Any provider network delays are outside of

our control and may be added to this time.

The device will continue to send data rapidly for 2 hours (every 15 minutes) after the initial transition and then

revert to normal mode. If the alarm condition persists then this will start the sequence again.

To cope with the system delays you should set the alarm reactivation time on the PC to a minimum of

30 minutes, and not manually reset it prior to this or you risk seeing the same alarm reported twice.

Doc No. IM4772-7

Page 8 of 14

iSense

4 Setting Up the iSense Hardware

4.1 Removing the Front Panel

The iSense unit is fastened by four screws that are situated in each corner on the front of the device. By using

a screwdriver to unscrew these four screws the front panel will lift off from the rest of the device. See Figure 1

below for details:

Figure 1 iSense GPRS Unit Front Panel

Once the front panel has been removed the battery pack will be visible on its reverse side. This now leaves

the back panel open and the iSense circuit board accessible.

4.2 Connecting the Aerial

There are two types of aerials which can be attached to this unit, either the extended or the knuckled joint.

Choose one that will better suit the environment that this device will be situated in and simply screw it into the

Aerial connection found on the top of the iSense. The Aerial should be positioned to ensure a good RF signal,

(do not use excessive force tightening the aerial connection, finger tight is adequate).

Doc No. IM4772-7

Page 9 of 14

iSense

4.3 Connecting the Batteries

The battery pack is held in place against the front panel of the iSense unit by two Velcro fasteners. Simply

peel the Velcro apart to release the battery pack (see Figure 2). A new pack can then be fastened in place

using the same Velcro sleeves.

The connection of the new battery pack to the iSense circuit board is done by inserting the battery plug from

the pack into the battery terminal, located on the circuit board.

Figure 2 Connecting the Batteries to the iSense Circuit Board

4.4 Connecting Vehicle Power Supply

The vehicle power supply connects to terminals 7 and 8 on the PCB connector inside the iSense unit.

Unscrew and remove the lid, connect the vehicle supply cable as below:

Yellow/Red wires, iSense +ve, connect to terminal 8

Blue/Green wires, iSense -ve, connect to terminal 7

Black/Blue wires, Vehicle –ve, connect to vehicle negative

Brown wire, vehicle +ve, connect to vehicle positive

Vehicle power should be sourced from as clean a supply as possible; the inline fuse is 250mA, input range is

+15V to +30V.

If required, replacement fuse is IMC part number G097, 20MM 250mA anti surge fuse.

4.5 Operating Environment

Maximum temperature ranges are:

Operating range with battery 0C to +40C.

Operating range with external power supply -20C to +55C.

Operating range with vehicle power supply 0C to +55C.

Storage temperature range, (without battery), -40C to +80C.

Note: The above ranges apply to the iSense unit itself, these do not apply to input probes, check probe

operating ranges as these will vary from probe to probe.

Doc No. IM4772-7

Page 10 of 14

iSense

5 Sensor Input Wiring

In the following section of this document a table has been included which contains a list of all the possible

input sensor types that can be connected to the iSense device. The majority of these sensors will be

connected via the sensor connection terminal (JP1). This terminal has six pins with pin 1, 3 and 5 being

positive, while 2, 4 and 6 are negative.

The Thermistor/RH sensor differs from the other devices as it connects to the 5 Pin Lemo socket (JP5). Both

of these areas of the iSense are shown in Figure 3 below.

Input Type

JP1 Pin Connection

Channel Type

1 channel pulse counter

Pin 1(+) & 2(-)

channel 1

2 channel pulse counter

Pin 1(+) & 2(-)

channel 1

Pin 3(+) & 4(-)

channel 2

1 channel pulse & sync

Pin 1(+) & 2(-)

sync

Pin 3(+) & 4(-)

channel 1

2 channel pulse & sync

Pin 1(+) & 2(-)

sync

Pin 3(+) & 4(-)

channel 1

Pin 5(+) & 6(-)

channel 2

Single Thermistor

Pin 3(+) & 4(-)

channel 1

Dual/Triple Thermistor

Pin 1(+) & 2(-)

Pin 3(+) & 4(-)

channel 1

channel 2

Pin 5(+) & 6(-)

channel 3

Current Clamp

Pin 1(+) & 2(-)

channel 1

Pin 3(+) & 4(-)

channel 2

Pin 5(+) & 6(-)

channel 3

Thermistor and Digital

Pin 1(+) & 2(-)

Pin 3(+) & 4(-)

Thermistor

Digital

Input Type

JP5 Pin Connection

Channel Type

Thermistor/RH

5 Pin Lemo

n/a

Figure 3 Sensor Input Wiring

Doc No. IM4772-7

Page 11 of 14

iSense

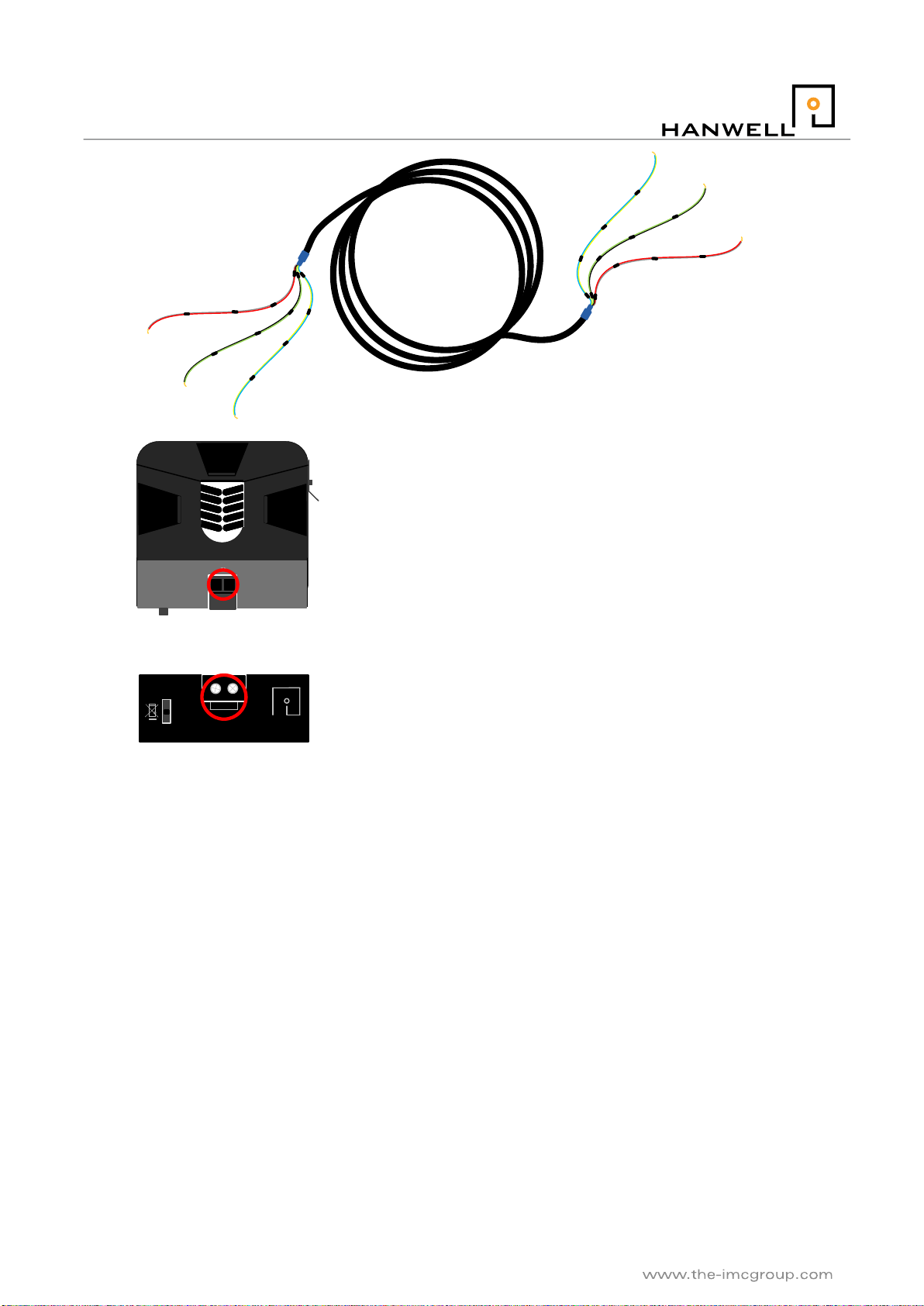

5.1 Connecting a Probe –Thermistor Example

For this example a thermistor probe is used to demonstrate how to connecting one of the accompanying

devices to the unit.

The thermistor probe can be found coiled with the metal probe attached to one end and two exposed wires

(white and red) on the other.

Figure 4 Loosening the Input Glands

Figure 5 Opening Terminals 3 and 4

To attach the probe to the circuit board, loosen the input glands (Figure 4 above), thread the exposed wires up

the gland until there is enough length for the wire to reach the top of the circuit board, tighten the gland.

Using a screwdriver, press down on the terminal release lever to open terminals 3 and 4 and thread in to

these openings the red and white (respectively) exposed wires (Figure 5). If another probe is needed to be

fitted then follow the same procedure but open terminals 5 and 6 and thread in the new red and white wires.

Doc No. IM4772-7

Page 12 of 14

iSense

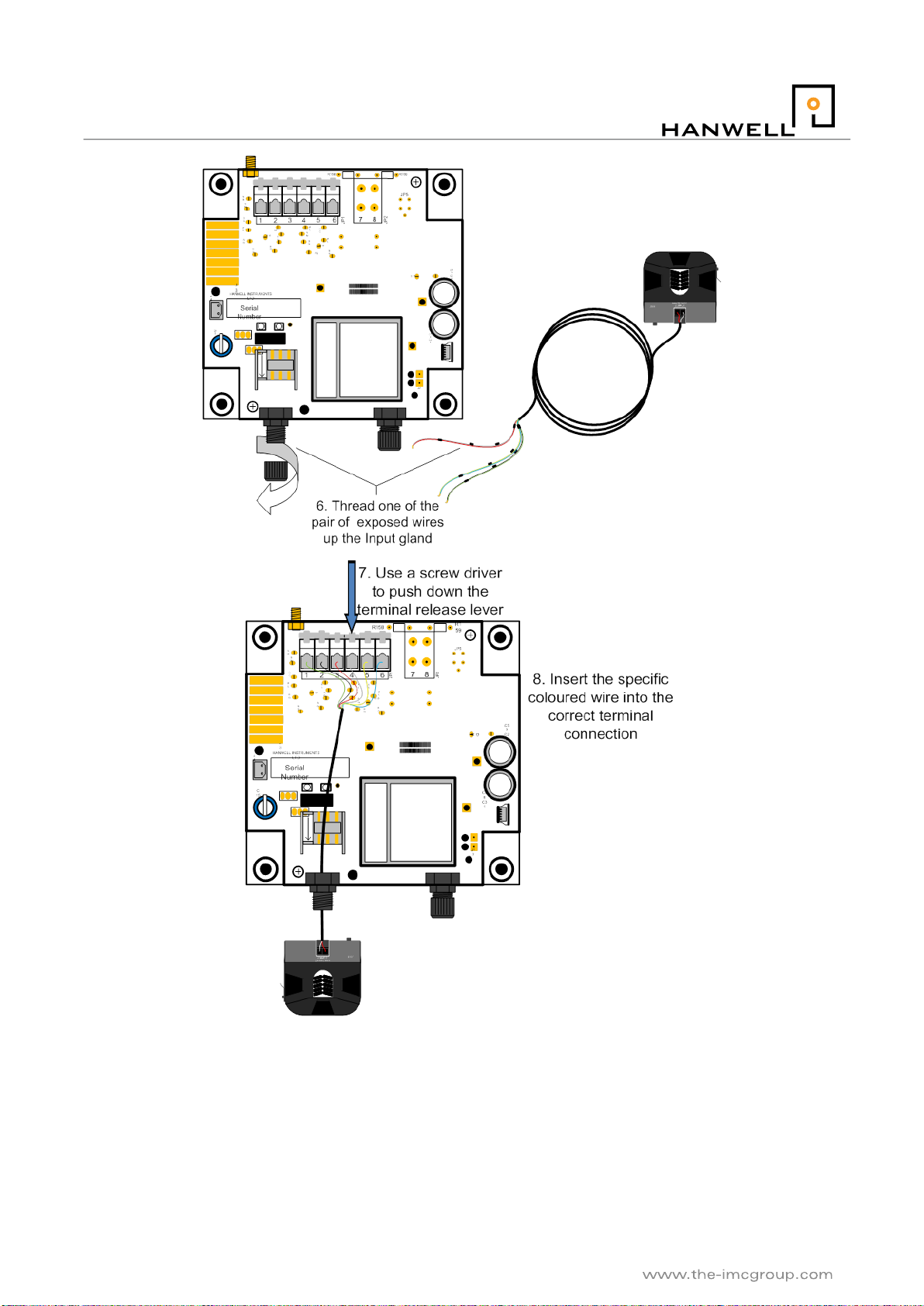

5.2 Connecting a Probe –JO91 Current Clamp Example

For this example a current clamp is used to demonstrate how to connect one of the accompanying devices to

the unit (Fig. 6). A J091 is illustrated. Other (DC only) clamps are connected in a similar manner.

Channel No.

+ve

-ve

1

Green (pin1)

Black (pin2)

2

Red (pin3)

White (pin4)

3

Yellow (pin5)

Blue (pin6)

Any unused pairs should be twisted together.

J091 OUTPUT

www.hanewll.com J091 OUTPUT

www.hanewll.com

1. Lift the latch found on the side

of the unit and open the

released clamp.

2. Thread the single core cable

through the middle of the clamp

and then secure the latch.

Figure 6 Connecting a JO91 –1

Doc No. IM4772-7

Page 13 of 14

iSense

Figure 7 Connecting a JO91 –2

V093

J091 OUTPUT

www.hanewll.co

m

HANWELL

MONITORING & CONTROL

-+

Amperage Range

120

60

30

0-5VDC

3. Thread one of the V093 coloured wires into the correct output

terminal situated on each of the clamps to be used.

4. The bottom of the clamp indicates which side of the terminal

is positive/negative. Use this in conjunction with the table on

page 29 to connect the correct coloured VO93 wire.

5. Use the screws found here to tighted the threaded wire to the clamp.

Ch. 1

Ch. 2

Ch. 3

Ch. 2

Ch. 1 Ch. 3

Doc No. IM4772-7

Page 14 of 14

iSense

Figure 8 Connecting a JO91 –3

Table of contents