Staubli Cam Motion 1781 Operating instructions

Cam motion – Type 1781

User and maintenance manual

F.143.489.04-C - 04/05/2015

1781 B1 DRC10 - English (Translation of the original manual)

© Stäubli 2013

O/ 94KGA1

The royalties of these drawings and all appendices submitted personally to the recipient are reserved

at all times. They cannot be copied, reproduced, or translated into other languages, communicated or

rendered accessible to third parties without the express written authorisation of STÄUBLI.

2/62 © Stäubli 2013 – F.143.489.04-C 1781 B1 DRC10

History

Hermann STÄUBLI began his career in a Horgen (Switzerland) firm, where he performed maintenan-

ce on weaving machines. His technical skills were noticed by another industrial entrepre-

neur, Rudolf Schelling. Together, they opened a construction and repair machine shop. Then,

in 1892, the "Schelling & Stäubli" company was created on the banks of Lake Zurich. Very rapidly, the

firm became specialised in the weaving industry, and particularly dobbies, for which numerous pa-

tents were produced.

Following the death of Rudolf Schelling, Hermann STÄUBLI took control of the company with his

brother, Robert Stäubli-Kaspar. They created a new subsidiary in France in order to be closer to their

customers.

In 1909, STÄUBLI Frères located in Faverges and their 30 employees began producing dobbies.

Still today, STÄUBLI develops and manufactures its cam motion and their corresponding harness mo-

tions.

1781 B1 DRC10 © Stäubli 2013 – F.143.489.04-C 3/62

4/62 © Stäubli 2013 – F.143.489.04-C 1781 B1 DRC10

TABLE OF CONTENTS

1- FOREWORD....................................................................................................................7

1.1- Warranty..................................................................................................................................7

1.2- Pictograms/terminology...........................................................................................................7

2- DESCRIPTION.................................................................................................................9

2.1- Intellectual property..................................................................................................................9

2.2- Characteristics.........................................................................................................................9

2.2.1- Cam motion characteristics.............................................................................................9

2.2.2- Compliance with regulations............................................................................................9

2.3- Identification.............................................................................................................................9

2.4- STÄUBLI standards...............................................................................................................10

2.4.1- Screw tightening torques...............................................................................................10

3- SAFETY..........................................................................................................................11

3.1- General safety instructions....................................................................................................11

3.2- Operating safety instructions.................................................................................................11

3.3- Maintenance safety instructions............................................................................................11

4- FIRST USE.....................................................................................................................13

4.1- Prior to initial start-up.............................................................................................................13

4.1.1- Filling the cam motion....................................................................................................13

4.1.2- Transmission lubricating................................................................................................13

4.1.3- Check the operating conditions.....................................................................................14

4.2- Start-up..................................................................................................................................14

4.2.1- Check oil level...............................................................................................................14

4.2.2- First oil change..............................................................................................................14

5- OPERATION..................................................................................................................15

5.1- Operating conditions..............................................................................................................15

5.1.1- Installation of the cover..................................................................................................15

5.2- Limits of use...........................................................................................................................16

5.3- Shed adjustment....................................................................................................................17

5.4- Frame height adjustment.......................................................................................................18

5.4.1- "DRC10" .......................................................................................................................18

5.4.2- Disassembly/reassembly of central frame link..............................................................19

5.5- Immobilised lifting units..........................................................................................................19

5.5.1- Cam motion immobilised lifting units.............................................................................19

5.5.2- Immobilised lifting units of the harness motion..............................................................21

5.6- Weave change.......................................................................................................................22

5.6.1- Speed reducing ratio change.........................................................................................22

5.6.2- Removing/Replacing the complete cam shaft...............................................................23

5.6.3- Removal / replacement of the bevel wheel....................................................................27

5.6.4- Removal / replacement of the bevel gear......................................................................28

Table of contents

1781 B1 DRC10 © Stäubli 2013 – F.143.489.04-C 5/62

5.6.5- Cams disassembly........................................................................................................29

5.7- Indexing the cams..................................................................................................................31

5.7.1- Definition of the cam indexing weave............................................................................31

5.7.2- Indexing preparation......................................................................................................31

5.7.3- Indexing case B1...........................................................................................................33

5.7.4- Fixing the cams.............................................................................................................36

6- MAINTENANCE.............................................................................................................41

6.1- General..................................................................................................................................41

6.1.1- Programmed maintenance............................................................................................41

6.1.2- Table of equivalent oils and greases.............................................................................41

6.1.3- Frame attachments........................................................................................................43

6.2- Programmed maintenance procedure...................................................................................43

6.2.1- Check oil level...............................................................................................................43

6.2.2- Verification of the oil level in the pump reservoir...........................................................44

6.2.3- Clean the filter...............................................................................................................46

6.2.4- Oil change.....................................................................................................................47

6.2.5- Clean the drive shaft......................................................................................................49

6.2.6- Cleaning of the levers....................................................................................................50

6.2.7- Lubrication of clamping loop joints................................................................................50

6.2.8- Lubrication of harness motion stabilisers......................................................................51

6.2.9- Maintenance of the links of frame clamping loops "DRC10".........................................52

6.2.10- Lubrication of the harness motion lever shafts..............................................................56

7- APPENDICES................................................................................................................59

7.1- Special tools...........................................................................................................................59

8- PROGRAMMED MAINTENANCE.................................................................................61

Table of contents

6/62 © Stäubli 2013 – F.143.489.04-C 1781 B1 DRC10

1 - FOREWORD TMA05-APP001.1

You have just acquired a new cam motion developed by STÄUBLI and we wish to thank you for

placing your confidence in our brand name.

This cam motion has been manufactured with utmost care and we are confident that it will provi-

de you complete satisfaction.

The purpose of this manual is to enable the technical weaving personnel to install, adjust and

maintain cam motions in optimal operating condition.

IMPERATIVE

Read this manual carefully.

Respect the instructions provided herein.

Communicate all the information included in the manual to the personnel concerned.

1.1 - WARRANTY TZA05-GAR001.1

The warranty conditions are stipulated in our general terms of sale. Refer to the sales conditions

which deal with elements not covered by the warranty.

ATTENTION

The use of parts other than genuine STÄUBLI parts is forbidden throughout the entire

service life of our products, as this might seriously damage these products or adversely

affect their service life.

Our guarantee is valid only if our products are:

- fitted with genuine STÄUBLI parts.

- operated and maintained in strict compliance with our specifications.

This manual is not a contractual document and STÄUBLI reserves the right to modify it without

notice.

STÄUBLI cannot be held liable for omissions of technical or editorial nature or for accidental da-

mage or damage resulting from erroneous interpretation of the contents of this manual.

1.2 - PICTOGRAMS/TERMINOLOGY TMA05-TMG001.1

IMPERATIVE

An instruction which informs the reader of the possible risks of injury or death faced by the

user. This instruction is applicable in terms of industrial safety.

ATTENTION

An instruction which informs the reader of risks which may result in equipment damage.

This instruction is applicable to the quality of the work.

Lubrication with a grease gun

Lubrication applied with a brush

1 - Foreword

1781 B1 DRC10 © Stäubli 2013 – F.143.489.04-C 7/62

Lubrication with oil

Housing

Maximum number of lifting units that can be installed in the cam motion.

Open shed position

Position of the cam motion enabling the frames to be placed in movement depending

on whether the weave is in the high or low position. This position corresponds to the

stop position of the frames, enabling the weft to be inserted.

Closed shed position

Position of the cam motion enabling the fames to be placed in movement at cross-shed

position. The other frames remain in high or low position.

Levelling of the harness frames

Position of the cam motion enabling all of the frames to be placed in cross-shed

position using the leveller.

1 - Foreword

8/62 © Stäubli 2013 – F.143.489.04-C 1781 B1 DRC10

2 - DESCRIPTION TMD10-DTC002.1

The assembly you have acquired consists of the following elements:

- A cam motion.

- A transmission.

2.1 - INTELLECTUAL PROPERTY TMD10-PPI001.1

STÄUBLI cam motion type machines and the optional products delivered with the machines are

protected by trademarks, patents and patent applications.

STÄUBLI is a registered trademark.

All copyright violations will be prosecuted.

2.2 - CHARACTERISTICS TMD10-CRT001.3

2.2.1 - CAM MOTION CHARACTERISTICS TMD10-CRT002.2

The cam motion can accommodate up to 10 levers on an 11-frame shaft.

The cams are available with ratios of 4, 5 or 6 picks, which enables the production of fabrics with

a repeat of 2, 3, 4, 5 or 6 picks.

The speed ratio of the cam motion's cam shaft in relation to that of the weaving machine may be

1 to 4, 1 to 5 or 1 to 6, depending on the gears used in the control housing.

The cams can be symmetrical (enabling a weft or a warp effect, according to how they are as-

sembled), or asymmetrical (one single warp or weft effect possible, per asymmetric cam).

The cam motion is equipped with a hydraulic leveling system, which allows:

-to bring the warp threads to their minimal tension, when the weaving machine is at a standstill,

by placing the levers at cross-shed position.

-to facilitate program changes by separating the rollers from the cams.

2.2.2 - COMPLIANCE WITH REGULATIONS TMD10-CRT004.1

This cam motions complies with the provisions in directive 2006/42/CE concerning quasi-machi-

nes.

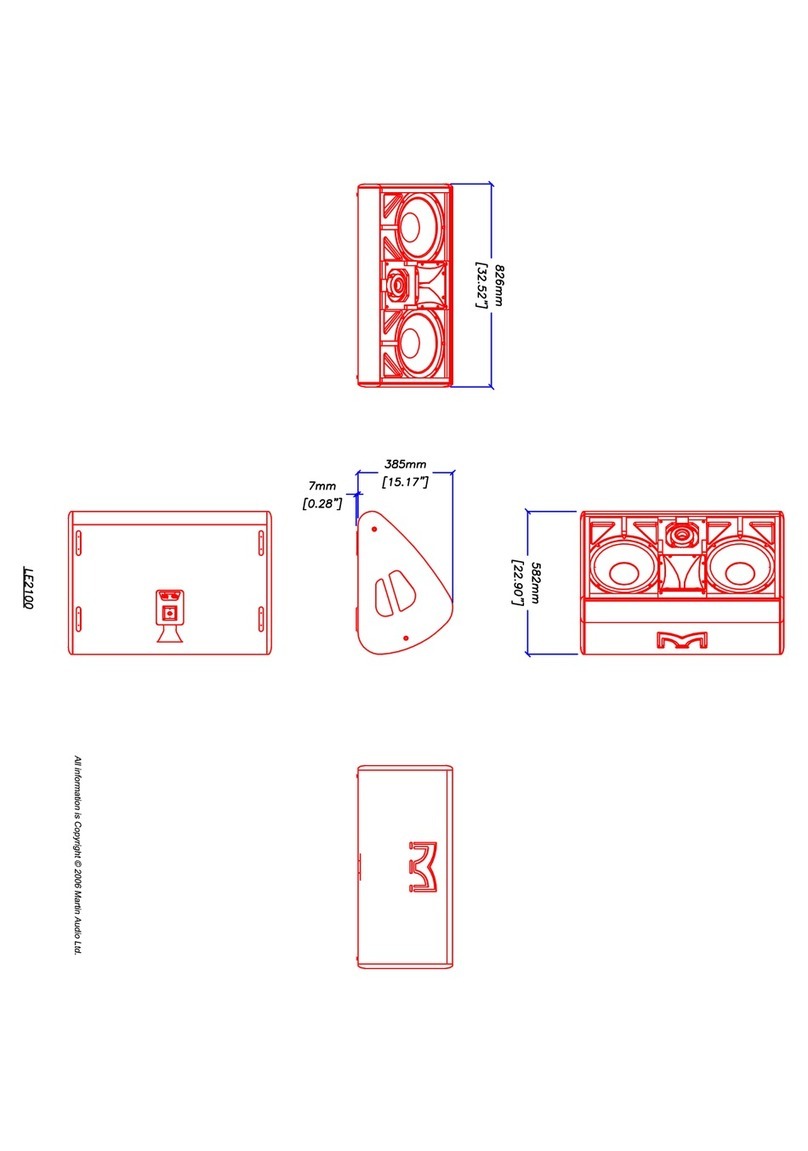

2.3 - IDENTIFICATION TMD10-IDF001.1

For all inquiries, order for spare parts, or service request, please indicate the type and serial

number of the cam motion concerned, located on the nameplate.

STAUBLI FAVERGES SCA

74210 FAVERGES FRANCE

MADE IN FRANCE

Type:

Machine N°: Date :

2

1

3 4

1 : Indication of the cam motion type

2 : Serial number of the cam motion

3 : Specific information relative to the type of cam

motion

4 : Date (month - year)

2 - Description

1781 B1 DRC10 © Stäubli 2013 – F.143.489.04-C 9/62

2.4 - STÄUBLI STANDARDS .

2.4.1 - SCREW TIGHTENING TORQUES TZD10-CSV002.2

ATTENTION

The resistance of the screws and the efficiency of the tightening torques can only be

guaranteed by using the tightening torque values defined in the following tables or the

tightening torque values indicated in the specific chapters of this manual.

Tightening torques have a tolerance of ± 7%.

2.4.1.1 - Characteristic parts TZD10-CSV006.1

Description Torque in Nm H (mm) Ø

Oil drain valve 77 32 G3/4"

H

Ø

Drain plug 77 32 G3/4"

H

Ø

Outside cover retaining

screw 16,7 6 / 27 M16

Ø

H

Ø

H

2 - Description

10/62 © Stäubli 2013 – F.143.489.04-C 1781 B1 DRC10

3 - SAFETY TZS15-SCT001.1

3.1 - GENERAL SAFETY INSTRUCTIONS TMS15-SCT002.1

All actions performed on the cam motions must be carried out in strict compliance with the safety

regulations currently in force in the country concerned.

IMPERATIVE

Only skilled and authorized persons should carry out these operations.

3.2 - OPERATING SAFETY INSTRUCTIONS TMS15-SCT004.1

Refer to the safety instructions stipulated by the weaving machine manufacturer.

3.3 - MAINTENANCE SAFETY INSTRUCTIONS TMS15-SCT005.3

IMPERATIVE

Maintenance must be performed by technically-proficient and certified personnel.

Wear protective gloves when performing maintenance operations.

All adjustments, testing and maintenance operations mentioned in this manual must be carried

out while the weaving machine is stopped.

IMPERATIVE

Disconnect the electrical power supply to prevent any untimely start-up.

However, the operations that require the weaving machine to be turned on, only slow or

step operation is authorized.

The oil is very hot during operation:

-Do not uncover the cam motion if the inside temperature is greater than 40°C.

-Allow the cam motion to cool down before removing the cover.

-Wear protective gloves before opening and when performing oil change operations.

3 - Safety

1781 B1 DRC10 © Stäubli 2013 – F.143.489.04-C 11/62

3 - Safety

12/62 © Stäubli 2013 – F.143.489.04-C 1781 B1 DRC10

4 - FIRST USE TZI20-PMU001.1

4.1 - PRIOR TO INITIAL START-UP TZU35-APM001.1

4.1.1 - FILLING THE CAM MOTION TMU35-RAU003.3

Prerequisites:

-Installation of the cover. (See "Installation of the cover", page 15)

Tools / Servicing materials:

-Recommended oil.

Oil quantity (litres)

10

Procedure:

1

IMGT3990

Fill the cam motion with new oil, spraying all the components (See "Table of equivalent oils and

greases", page 41).

4.1.2 - TRANSMISSION LUBRICATING TMU35-LUB003.1

4.1.2.1 - Oil the stablising group TMU35-LUB001.1

(See "Lubrication of harness motion stabilisers", page 51)

4.1.2.2 - Lubricate the joints of the frame attachments TMU35-LUB002.2

(See "Grease", page 42)

DRC10 : (See "Maintenance of the links of frame clamping loops "DRC10"", page 52)

4 - First use

1781 B1 DRC10 © Stäubli 2013 – F.143.489.04-C 13/62

4.1.3 - CHECK THE OPERATING CONDITIONS TMU35-CFO001.1

The maximum speed of the cam motion is a function several parameters:

-Cam profile.

-Frame travel.

-Maximum reed space.

-The weight of the frames.

-The weight of the heddles.

-The number of frame links.

-The weave.

-The number of levers in movement.

ATTENTION

Each time one of these parameters is changed, the speed of the weaving machine must

be checked to ensure that it is compatible with the manufacturer's data.

ATTENTION

Never exceed the speeds recommended by the manufacturer of the weaving machine on

which the cam motion is installed.

All excessive speed shall be considered as an operating fault or equipment overload and

the consequences are therefore not covered under the guarantee.

4.2 - START-UP TMU35-MIR001.1

4.2.1 - CHECK OIL LEVEL TMU35-MIR002.1

(See "Check oil level", page 43)

4.2.2 - FIRST OIL CHANGE TMU35-MIR003.1

After 500 hours of operation (3 weeks maximum).

(See "Programmed maintenance", page 61)

(See "Table of equivalent oils and greases", page 41)

4 - First use

14/62 © Stäubli 2013 – F.143.489.04-C 1781 B1 DRC10

5 - OPERATION TMU35-CLU001.2

5.1 - OPERATING CONDITIONS TMU35-CLU002.1

Do not leave the cam motion uncovered while operating to prevent lint from entering. This could

damage the cam motion.

The temperature of the weaving room must be between 15°C and 35°C.

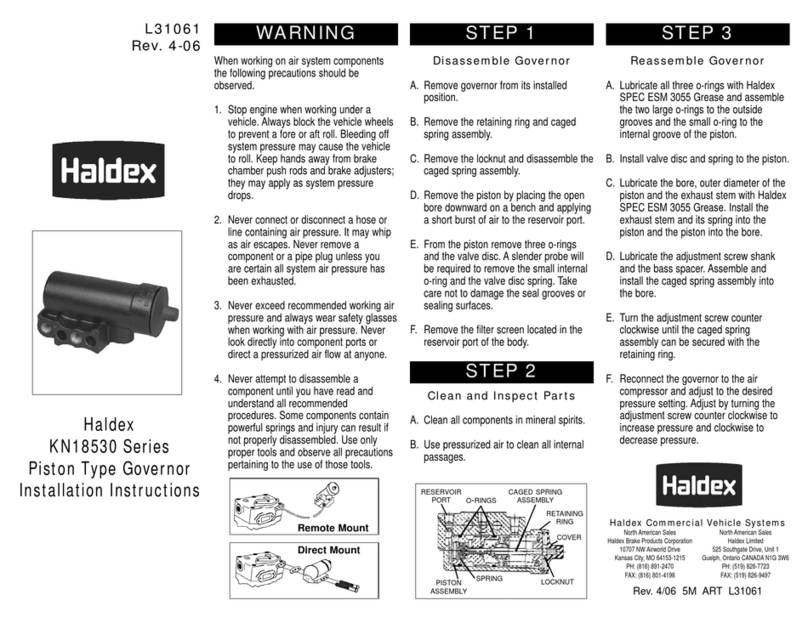

5.1.1 - INSTALLATION OF THE COVER TMU35-MTC001.4

Tools:

-Torque wrench.

Description Torque in Nm H (mm) Ø

Outside cover retaining screw 16,7 6 / 27 M16

Ø

H

Ø

H

2

4

5

1 (16,7 Nm)

3

IMGT4345

Removal:

-Unscrew the screws (1).

-Remove the cover (2).

-Remove the cover (3).

5 - Operation

1781 B1 DRC10 © Stäubli 2013 – F.143.489.04-C 15/62

-Remove the cover (4).

-Remove the part (5).

Installation:

-Replace the cover (4).

-Replace the cover (3).

-Replace the part (5).

-Replace the cover (2).

-Tighten the screws (1) to 16.7 Nm of torque.

Note :

The clips (6) must be correctly positioned:

-At dimension 45 mm.

- Opposite the drive gear and pinion (8).

45 mm

6

8

IMGT3996

The amount of time the cover is open must be as short as possible.

5.2 - LIMITS OF USE TMU35-CLU003.1

The maximum speed of the cam motion is a function several parameters:

-Cam profile.

-Frame travel.

-Maximum reed space.

-The weight of the frames.

-The weight of the heddles.

-The number of frame links.

-The weave.

5 - Operation

16/62 © Stäubli 2013 – F.143.489.04-C 1781 B1 DRC10

-The number of levers in movement.

ATTENTION

Each time one of these parameters is changed, the speed of the weaving machine must

be checked to ensure that it is compatible with the manufacturer's data.

ATTENTION

Never exceed the speeds recommended by the manufacturer of the weaving machine on

which the cam motion is installed.

All excessive speed shall be considered as an operating fault or equipment overload and

the consequences are therefore not covered under the guarantee.

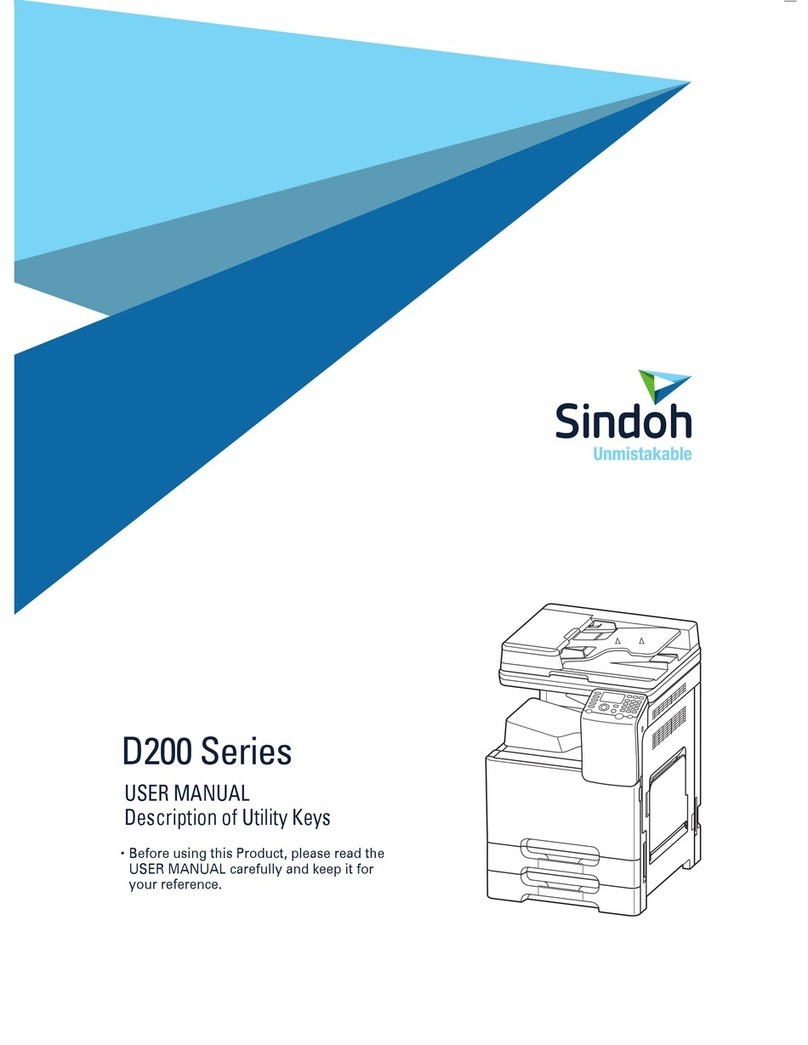

5.3 - SHED ADJUSTMENT TTI20-COR001.3

2

1

3

(M7-22Nm)

A

IMGT3972

The shed adjustment is performed by adjusting the position of the clamping loop (3) on the le-

ver (1). This position is determined by dimension A provided by the weaving machine manufactu-

rer.

Procedure:

-Loosen screw (1).

-Adjust the position of the clamping hoop.

-Tighten the screw (1) to the recommended torque value.

5 - Operation

1781 B1 DRC10 © Stäubli 2013 – F.143.489.04-C 17/62

5.4 - FRAME HEIGHT ADJUSTMENT TTI20-RGL011.1

5.4.1 - "DRC10" TTI20-RGL010.4

1 (M5 - 8 Nm)

IMGT3973

The height of the frame can be adjusted as required.

Procedure:

-Loosen screw (1).

-Adjust the position.

-Tighten the screw (1) to the recommended torque value.

5 - Operation

18/62 © Stäubli 2013 – F.143.489.04-C 1781 B1 DRC10

5.4.2 - DISASSEMBLY/REASSEMBLY OF CENTRAL FRAME LINK TZU35-DPC001.2

5.4.2.1 - "DRC10" TZU35-DPC002.1

Disassembly:

IMGT4178

- Loosen screw (1).

- Remove the central frame attachment (2).

Note :

This procedure is valid for all central frame attachments.

- Remove the end frame attachments (3).

Note :

There is no need to loosen the adjusting screws of the end frame attachments (3).

- Remove the frame.

Reassembly:

- Position the frame.

- Lock the end frame attachments (3).

- Lock the position of the central frame attachment (2).

- Torque down the screw (1) (to a torque of 8 Nm).

Note :

This procedure is valid for all central frame attachments.

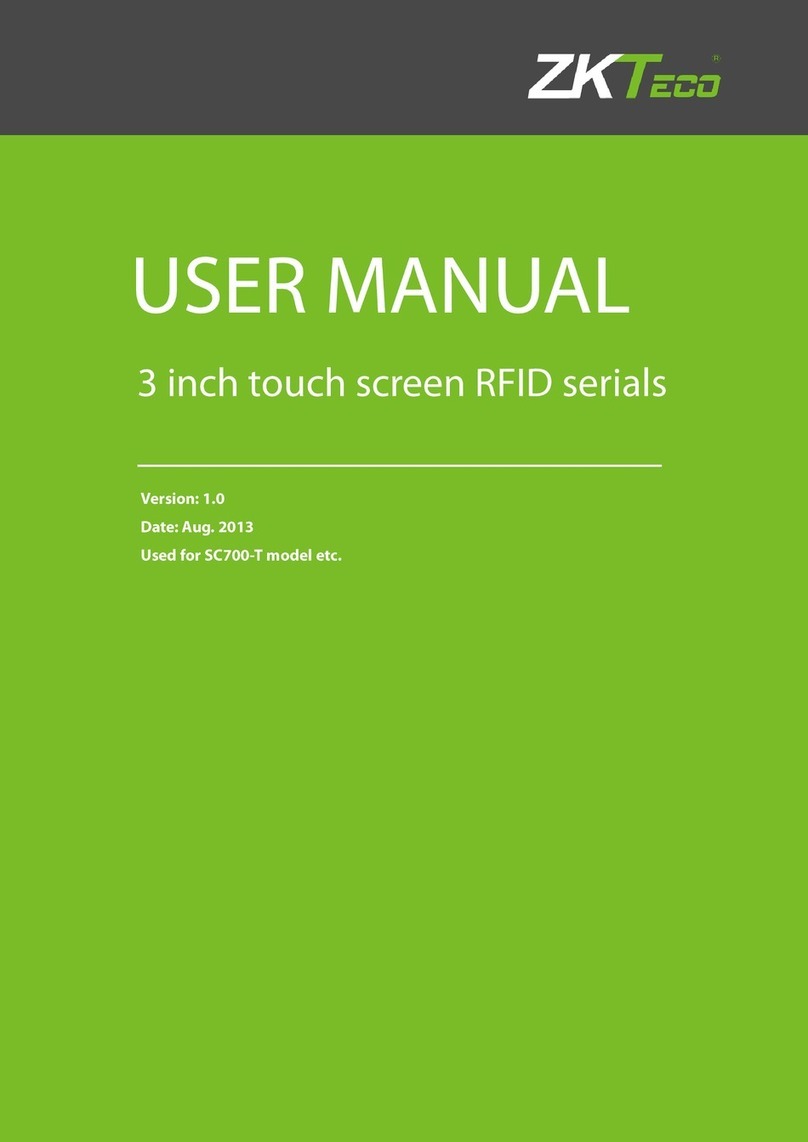

5.5 - IMMOBILISED LIFTING UNITS TMU35-RGL001.1

5.5.1 - CAM MOTION IMMOBILISED LIFTING UNITS TMU35-RGL002.3

Tools / Servicing materials:

-Not applicable

5 - Operation

1781 B1 DRC10 © Stäubli 2013 – F.143.489.04-C 19/62

Procedure:

2

5

3

1

4

B

A

IMGT4357

IMGT4358

- After the last weave cam or before the first weave cam:

• Install the immobilisation disc (1) facing the lever (2).

• Place the clamping loop (5) in low position.

- Other immobilised lifting units:

• Lock the immobilised levers together with the immobilisers (4).

5 - Operation

20/62 © Stäubli 2013 – F.143.489.04-C 1781 B1 DRC10

Table of contents