SICK RFH620-1001201S01 User manual

OPERATING INSTRUCTIONS

Special Version

RFH620-1001201S01

Radio Frequency Interrogator

(13.56 MHz)

Operating Instruction

RFH620

8013171/ZO93/2017-08-08 ©SICK AG •Germany •All rights reserved • Subject to change without notice 3

Software Versions

Software/Tool Function Version

RFH620-1001201S01 Firmware S 0.60

Copyright

Copyright © 2009 -2017

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Trademarks

WindowsTM is a registered trademark or trademark of the Microsoft Corporation in the

USA andother countries.

AdobeTM ReaderTM is a trademark of the Adobe Systems Incorporated.

Operating Instructions

RFI341 Radio Frequency Interrogator

48013171/ZO93/2017-08-08 ©SICK AG • Germany • All rights reserved • Subject to change without notice

Figures and Tables

Contents

1 Notes about this Document ................................................................................... 8

1.1 Purpose ...................................................................................................... 8

1.2 Target Groups............................................................................................ 8

1.3 Deep of information .................................................................................. 8

1.4 Symbols Used............................................................................................ 8

2 Safety Information............................................................................................... 10

2.1 Authorised User....................................................................................... 10

2.2 Intended use............................................................................................. 11

2.3 Electrical Connection and Replacement.................................................. 11

2.4 Start-up, Operation and Configuration .................................................... 11

2.2 General Safety Instructions and Protective Measures ............................. 12

2.3 Quick stop and quick restart .................................................................... 12

3.1.1 2.3.1 Switching off the RFH620...........................................................................12

3.1.2 2.3.2 Switching the RFH620 back on ...................................................................12

2.4 Environmental Conditions....................................................................... 12

3.1.3 2.4.1 Energy requirements....................................................................................13

3.1.4 2.4.2 Disposal of the device after decommissioning.............................................13

3 Product Description............................................................................................. 14

3.1 Setting up the RFH620 ............................................................................ 14

3.1.5 3.1.2 Device view .................................................................................................14

3.2 Included in delivery................................................................................. 16

3.1.6 3.2.1 Contents of the CD-ROM 2049555 .............................................................16

3.3 Device versions ....................................................................................... 16

3.4 System Requirements ...................................................................................... 17

3.5 Product features and functions (overview) ...................................................... 17

3.5 RFH620 method of operation .......................................................................... 18

3.5.1 Reading / Writing configuration...............................................................................19

3.5.2 Object trigger control ...............................................................................................19

3.5.3 Increment configuration ...........................................................................................19

3.5.4 ISO/IEC 15693 configuration ..................................................................................19

3.5.5 Reading operation mode (object related)..................................................................20

3.5.6 Data Processing........................................................................................................20

3.5.7 Output format...........................................................................................................21

3.5.8 Network / Interface / IOs..........................................................................................21

3.5.9 Data interfaces..........................................................................................................21

3.5.10 Digital Inputs..........................................................................................................21

3.5.11 Digital Outputs.......................................................................................................22

3.6 Indicators and control elements ....................................................................... 22

3.5.1 User Interface...........................................................................................................22

3.5.2 LEDs on the RFH620 housing .................................................................................23

Operating Instruction

RFH620

8013171/ZO93/2017-08-08 ©SICK AG • Germany • All rights reserved • Subject to change without notice 5

4 Installation............................................................................................................24

4.1 Overview of installation sequences..................................................................24

4.2 Installation preparations...................................................................................24

4.2.1 Components to be installed ...................................................................................... 24

4.2.2 Accessories .............................................................................................................. 25

4.2.3 Mounting device ...................................................................................................... 25

4.3 Installation location..........................................................................................26

4.4 Installation of the RFH620...............................................................................26

4.4.1 Installing the RFH620.............................................................................................. 26

5 Electrical Installation...........................................................................................27

5.1 Overview of installation sequences..................................................................27

5.2 Electrical installation preparation ....................................................................27

5.3 Electrical connections and cables.....................................................................28

5.3.1 Electrical connections .............................................................................................. 28

5.3.2 RFH620 connections................................................................................................ 28

5.3.2 RFH620 connections................................................................................................ 29

5.4 Performing electrical installation .....................................................................29

5.4.1 Connecting the power supply for the RFH620......................................................... 30

5.4.2 Wiring serial data interface ...................................................................................... 30

5.4.3 Wiring CAN interface.............................................................................................. 32

5.4.3 Wiring Ethernet interface......................................................................................... 32

5.4.4 Wiring switching inputs ........................................................................................... 32

5.5 Pin assignment and wire colour assignment of the assembled cables..............33

5.4.1 Pin assignment of the assembled cables................................................................... 33

5.4.2 Pin assignment of the assembled cables with an open end....................................... 34

6 Startup and configuration ...................................................................................35

6.1 Overview of the startup procedure...................................................................35

6.2 SOPAS-ET configuration software..................................................................35

6.2.1 Functions of the SOPAS-ET configuration software for the RFH620 ..................... 35

6.2.2 System requirements for the SOPAS-ET configuration software ............................ 35

6.2.3 Installing the SOPAS-ET configuration software .................................................... 36

6.2.4 Default setting for SOPAS-ET configuration software ............................................ 36

6.3 Establish communication with the RFH620.....................................................36

6.3.1 Connecting data interface......................................................................................... 36

6.3.2 Starting the SOPAS-ET configuration software....................................................... 37

6.3.3 Starting the SOPAS-ET configuration software....................................................... 38

6.3.4 Carrying out a scan .................................................................................................. 38

6.4 First startup ......................................................................................................39

6.4.1 Overview of the startup procedure ........................................................................... 39

6.4.2 Configure the RFH620............................................................................................. 40

6.4.3 Permanently load changed parameter sets into the device ....................................... 41

6.4.4 Save, display and print the current parameter set..................................................... 41

6.5 Default settings ................................................................................................41

6.5.1 Resetting the default setting in the RFH620 ............................................................ 41

Operating Instructions

RFI341 Radio Frequency Interrogator

68013171/ZO93/2017-08-08 ©SICK AG • Germany • All rights reserved • Subject to change without notice

Figures and Tables

7 Maintenance during operation ........................................................................... 43

7.1 Checking the incremental encoder................................................................... 43

7.2 Replacing RFH620 .......................................................................................... 43

7.2.1 Removing the RFH620 ............................................................................................43

7.2.2 Replacing the RFH620.............................................................................................43

8 Troubleshooting................................................................................................... 44

8.1 Overview of errors and malfunctions which could occur ................................ 44

8.1.1 Installation error.......................................................................................................44

8.1.2 Electrical installation error .......................................................................................44

8.1.3 Configuration error...................................................................................................44

8.1.4 Malfunctions during operation .................................................................................44

8.2 Detailed malfunction analysis.......................................................................... 44

8.2.1 LEDs on the RFH620...............................................................................................44

8.2.2 System information ..................................................................................................45

8.3 Status protocol ................................................................................................. 45

8.3.1 Displaying the status protocol using the SOPAS-ET configuration software ..........45

8.4 SICK Support .................................................................................................. 45

9 Technical Data ..................................................................................................... 46

9.1 Datasheet of RFH620 RFID device ................................................................. 46

9.2 Reading Diagrams ........................................................................................... 47

9.3 RFH620 dimensional drawings ............................................................... 47

10 Appendix .............................................................................................................. 48

11.1 Appendix overview........................................................................................ 48

11.2 Configuration the RFH620 with command strings ........................................ 48

11.3 Order information for the RFH620 and the accessories ................................ 49

11.3.1 Order information for the RFH620 RFID device ...................................................49

11.3.2 Accessories: Mounting devices ..............................................................................49

11.3.3 Accessories: Connection modules..........................................................................49

11.3.3 Accessories: cables for Ethernet Version ...............................................................51

11.3.4 Accessories: ISO/IEC 15693 compliant Transponder ............................................52

11.3.5 Accessories: SD Card.............................................................................................52

11.4 Dimensional drawing accessories.................................................................. 53

11.4.1 Dimensional drawing fixing bracket no. 2048551..................................................53

11.5 Glossary......................................................................................................... 53

11.6 EC Declaration of Conformity....................................................................... 54

Operating Instruction

RFH620

8013171/ZO93/2017-08-08 ©SICK AG • Germany • All rights reserved • Subject to change without notice 7

Tables & Figures

Table 2-1 Required qualification for starting up the RFH620........................................10

Table 3-1: Variant of the RFH620.............................................................................14

Table 3-2: Device view of the RFH620 (Ethernet version).......................................15

Table 3-3: RFH620 delivery......................................................................................16

Table 3-4: Variants of the RFH620 ...........................................................................16

Table 3-5: Overview of the RFH620 product features and functions........................17

Figure 3-6: HF Technology – principle overview ......................................................18

Figure 3-7: Methods of operation in a conveyor system.............................................18

Figure 3-8: reading operation mode for the RHF620 in stand-alone operation ..........20

Table 3-9: data interface function..............................................................................21

Table 3-10: LED indications .................................................................................23

Table 4-1: Example: Fixing the RFH620 with the angle with adapter plate no.

2048551 25

Table 5-1: Ethernet version: Electrical connections at the RFH620 with connector

unit 28

Chapter 1Operating Instructions

Radio Frequency Identification RFI341 Interrogator

88013171/ZO93/2017-08-08 © SICK AG • Germany • All rights reserved • Subject to change without notice

Notes On This Document

1Notes about this Document

1.1 Purpose

This document provides instructions for technical staff on the installation and operation

of the RFID special device RFH620 with two integrated LED’s in the front side:

This document contains information about:

•Mounting and electrical installation

•Start-up

•Use and configuration

•Replacing

A step-by-step approach is taken for all tasks.

1.2 Target Groups

The target groups for this user guide are:

•Operating electricians

•Technicians and engineers

1.3 Deep of information

This document contains all the required information for installation, electrical

installation and operation of the RFID device at the installation location. The factory

default setting (basic configuration) of the RFID device is prepared for the use as a

stand-alone device. Configuration of the RFID device for the application-specific

reading conditions and operation is carried out using the SOPAS-ET configuration

software on a WindowsTM PC, or – if available – via an external middleware. The

SOPAS-ET configuration software contains an online help system to facilitate

configuration.

1.4 Symbols Used

To gain easier access, some information in this documentation is emphasised as follows:

NOTICE!

Warnings are provided to prevent injury to operating personnel or serious damage to the

RFID Interrogator.

¾Always read warnings carefully and observe them at all times.

A

TTENTION

Operating Instructions Chapter 1

RFI341

8013171/ZO93/2017-08-08 ©© SICK AG • Germany • All rights reserved • Subject to change without notice 9

Notes On This Document

Warning notice!

A warning notice indicates real or potential danger. This should protect you against

accidents. The safety symbol next to the warning notice indicates why there is a risk of

accident, e.g. due to electricity. The warning levels (DANGER, WARNING,

CAUTION) indicate the seriousness of the risk.

¾Carefully read and follow the warning notices!

Note Notes provide information on special features or characteristics.

Explanation Explanations provide background information on technical aspects.

Recommendation Recommendations provide advice on how to carry out a task more effectively

This symbol refers to additional technical documentation.

WARNING

Chapter 2Operating Instructions

Radio Frequency Identification RFI341 Interrogator

10 8013171/ZO93/2017-08-08 © SICK AG • Germany • All rights reserved • Subject to change without notice

Safety Information

2Safety Information

This chapter deals with your safety and operator safety in the operational area.

¾Read this chapter carefully before using the RFID device.

2.1 Authorised User

For correct and safe functioning, the RFID device must be installed, operated and

maintained by sufficiently qualified staff.

Repairs to the RFID device should only be carried out by qualified and authorised SICK

service staff.

¾The operating instructions should be made available to the end user.

¾The end user should be briefed and urged to read the operating instructions by the

technicians.

The following qualifications are required for different activities:

Task Qualification

Installation,

maintenance

¾Practical technical training

¾Knowledge of current health and safety regulations at

the workplace

Electrical installation,

device replacement

¾Practical electrical training

¾Knowledge of current electrical safety regulations

¾Knowledge of start-up and operation of the device in

each operational

¾area (e. g. conveyor system)

Startup, configuration ¾Basic knowledge of the WindowsTM operating system

¾Basic knowledge of designing and setting up

(addressing) Ethernet

¾connections for connecting the bar code system to the

Ethernet

¾Basic knowledge of working with an HTML browser (e.

g. Internet ExplorerTM) for using the online help

¾Basic knowledge of data transfer

¾Basic knowledge of bar code technology

Operation of the device

in each operational area

¾Knowledge of start-up and operation of the device in

each operational area (e. g. conveyor system)

¾Knowledge of the software and hardware environment

in each operational area (e. g. conveyor system)

Table 2-1 Required qualification for starting up the RFH620

Operating Instructions Chapter 2

RFH620

8013171/ZO93/2017-08-08 ©SICK AG • Germany • All rights reserved • Subject to change without notice 11

Safety Information

2.2 Intended use

The RFH620 RFID device is an intelligent sensor for the automatic recognition and

decoding of 13.56 MHz, ISO 15693 compliant RFID transponder signals e.g. placed on

objects in a conveyor system.

The RFID device enable the bi-directional communication with a host for, e.g., further

processing.

The intended use of the RFID device results from the following description of the

function:

¾In a reading station/situation the RFH620 could be installed in a holder, either on

the side of a conveyor system (side reading) or under it (reading from below)

¾In a writing station/situation the RFH620 gets the date to be written from the host

system

¾The LED’s in the front antenna panel could be switch by either the system

depending on the reading result or by the host via command language.

¾The RFID device transfers the reading data via the host interface to a superordinate

host computer for further processing.

¾The RFH620 could be configured/operated using the SOPAS-ET configuration

software that runs on a standard client PC provided by the customer or via

command language. Communication takes place using RS-232 or Ethernet.

Any warranty claims against SICK AG shall be deemed invalid in the case changes to

the RFH620, such as opening the housing, this includes modifications during

installation and electrical installation or changes to the SICK software.

2.3 Electrical Connection and Replacement

•Practical training in electrical technology

•Knowledge of the standard safety guidelines relating to electrical technology

•Knowledge regarding the operation of the devices in the relevant application (e.g.

conveyor belt)

2.4 Start-up, Operation and Configuration

•Knowledge regarding the operation of the devices in the relevant application (e.g.

conveyor belt)

•Knowledge of the software and hardware environment of the relevant application

•Basic understanding of data transfer methods

•Basic understanding of RFID technology

Chapter 2Operating Instructions

Radio Frequency Identification RFI341 Interrogator

12 8013171/ZO93/2017-08-08 © SICK AG • Germany • All rights reserved • Subject to change without notice

Safety Information

2.2 General Safety Instructions and Protective Measures

Read carefully the general safety instructions and observe them at all times. This also

applies to the warnings provided for the activities described in each chapter of this

document.

2.3 Quick stop and quick restart

The RFH620 can be switched on or off using the main switch for connection modules

CDB620 or CDM420.

3.1.1 2.3.1 Switching off the RFH620

¾Switch off the power supply to the RFH620 (the connection module)

- or -

¾Remove (pull out) the 15-pole D-Sub-HD connector of the RFID device

When the RFH620 is switched off, the following data is lost:

¾Application-specific parameter sets in the bar code scanner that were only saved

temporarily in the device

¾The last reading result of the bar code scanner

¾Daily operating hours counter of the RFH620

3.1.2 2.3.2 Switching the RFH620 back on

¾Switch on the power supply to the RFH620 (the connection module) back on

- or -

¾Connect the 15-pole D-Sub-HD connector of the RFH620

The RFH620 starts up using the most recent permanently saved configuration. The

daily operating hours counter is reset.

2.4 Environmental Conditions

The RFI341 is designed to cause minimum impact to the environment.

Operating Instructions Chapter 2

RFH620

8013171/ZO93/2017-08-08 ©SICK AG • Germany • All rights reserved • Subject to change without notice 13

Safety Information

3.1.3 2.4.1 Energy requirements

The RFH620 consumes typically < 4,5W with 24V DC ±10%.

3.1.4 2.4.2 Disposal of the device after decommissioning

SICK AG will not currently accept the return of any devices which can no longer be

operated or repaired.

-Inoperable or irreparable devices must be disposed of in an environmentally

friendly manner and in accordance with valid country-specific waste disposal

guidelines.

The design of the RFID device allows for its separation as recyclable secondary raw

materials and hazardous waste (electronic scrap).

Chapter 10 Operating Instructions

Radio Frequency Identification RFH620 Interrogator

14 8013171/ZO93/2017-08-08 © SICK AG • Germany • All rights reserved • Subject to change without notice

Appendix

3 Product Description

This chapter describes the design, the features and the functions of the RFH620 RFID

device. The RFID works at a frequency of 13.56 MHz and reads passive ISO/IEC

15693 tags.

¾For installation, electrical installation and startup assistance as well as for the

application specific configuration of the RFH620 using the SOPAS-ET

configuration software, please read this chapter prior to carrying out any of the

tasks.

3.1 Setting up the RFH620

The RFH620 consists of an integrated antenna and an electronic unit with an integrated

decoder. The RFID field enters via the black top plastic part of the housing. The

RFH620 (depending on the version) is electrically connected by a revolving connector

unit with two connections.

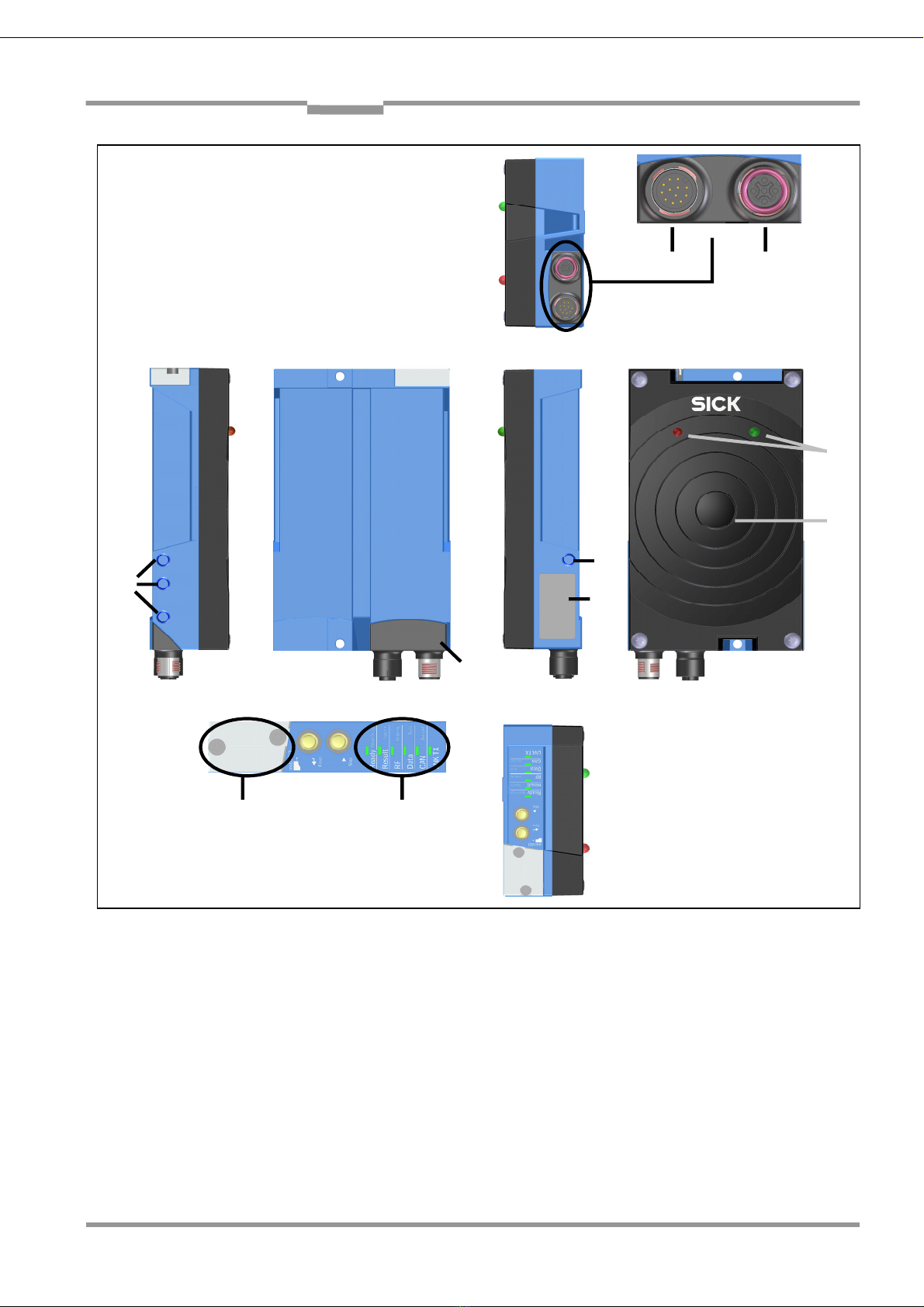

3.1.5 3.1.2 Device view

Table 3-1: Variant of the RFH620

Operating Instructions Chapter 10

RFI341

8013171/ZO93/2017-08-08 ©SICK AG • Germany • All rights reserved • Subject to change without notice 15

Appendix

Table 3-2: Device view of the RFH620 (Ethernet version)

1

1

2

3

4

5

6

78

1 – Blind hole taps M6

2 – Type plate

3 – LEDs for status indicator

4 – Antenna

5 – LEDs for signaling

6 – Revolving connector unit

7 – 12-pole M12 plug

8 – 4-pole M12 jack (Ethernet IF)

9 – Opening for SD card

9

Chapter 10 Operating Instructions

Radio Frequency Identification RFH620 Interrogator

16 8013171/ZO93/2017-08-08 © SICK AG • Germany • All rights reserved • Subject to change without notice

Appendix

3.2 Included in delivery

Delivery of the RFH620 includes the following components:

Pieces Components Comment

1 RFID Device RFH620

1 Notes on device with electrical

connection diagram as primary

information

Included in the device packaging of

the RFH620

1 CD-ROM "Manuals & Software

Auto Ident"

SICK Order No. 2049555

Table 3-3: RFH620 delivery

An overview of in-stock installation accessories, connection modules, cables and

connectors as well as sensors for reading pulses is available in chapter “Ordering

information for RFH620.

3.1.6 3.2.1 Contents of the CD-ROM 2049555

¾"SOPAS-ET Engineering Tool“: Configuration software for WindowsTM PCs with

integrated online help system (HTML files)

¾RFH620 operating instructions: PDF version in English

¾“Acrobat Reader“: Freely available PC software for reading PDF files

The current versions of publications and programs on the CD-ROM can also be

downloaded at www.sick.com.

3.3 Device versions

Delivery of the RFH620 includes the following components:

Type Order No. Description

RFH620-1001201S01 1046849 RFID device for proximity read range (up to 16cm) with

two in antenna plate integrated LEDs

Table 3-4: Variants of the RFH620

Operating Instructions Chapter 10

RFI341

8013171/ZO93/2017-08-08 ©SICK AG • Germany • All rights reserved • Subject to change without notice 17

Appendix

3.4 System Requirements

General system requirements are derived from the RFH620 technical data (see chapter

“Technical data”).

The requirements and conditions for Installation, electrical installation and “startup and

configuration” are summarised in the respective chapters.

3.5 Product features and functions (overview)

RFH620 RFID device ¾supports ISO/IEC 15693 (18000-3M1) compliant transponder ICs (mandatory and optional

command set)

¾Reading direction to front side

¾Large reading area to address high speed applications

¾International radio approval (CE&FCC)

User safety and convenience ¾Robust, compact metal housing, CE/FCC mark

¾Automatic self-test on system startup

¾Diagnosis tools for system setup and system (remote) monitoring

¾Operational data retrieval, error code display on request in case of errors

¾Activatable test string function (heartbeat) for signalling readiness for operation

¾Password protected configuration mode

¾Future proof due to firmware update (flash PROM) via data interface

¾Future-proof SOPAS-ET configuration software

¾Extended power supply range

Convenient operation/configuration ¾Configuration (online/offline) using the SOPAS-ET configuration software (incl. Help

system)

¾Status indicators via five LEDs

¾Beeper that can be switched off to confirm device functioning

Reading operation modi ¾Start/Stop operation

¾Free running reading method

Reading pulse ¾Pulse sources for start: switching inputs; data interface (command); automatic cycle; CAN

¾Pulse sources for stop: reading pulse source, switching inputs, command, timer, condition

Data processing ¾Manipulation of the output of the reading data via event-dependent evaluation conditions

¾Manipulation of the output strings through filter and output sort options

¾Switching the outputs via interface command language

Data communication ¾Host interface: two data output formats configurable, switchable to different physical

interfaces, parallel operation possible

¾Aux interface: fixed data output format, switchable to different physical interfaces, parallel

operation possible

Electrical interfaces ¾Host interface: RS-232, RS-422/485 (data format and protocol can be configured) and

Ethernet, or CAN

¾Aux interface: RS-232, (fixed data format, data transfer rate and protocol) and Ethernet

¾CAN interface for integration into the SICK-specific CAN-SENSOR network

¾One digital switching input on the device

¾Digital switching outputs connected with LEDs in front side

Connection technology (design) ¾Revolving connector unit on the device with two M12 circular connectors

¾Connection module CDB620/CDM420 for connection to the host computer (standalone)

and for integrating into the SICK-specific CAN-SENSOR network

¾Bus connection module CMF4001) in connection module CDM420 for connecting to field

bus systems

Table 3-5: Overview of the RFH620 product features and functions

Chapter 10 Operating Instructions

Radio Frequency Identification RFH620 Interrogator

18 8013171/ZO93/2017-08-08 © SICK AG • Germany • All rights reserved • Subject to change without notice

Appendix

3.5 RFH620 method of operation

The RFH620 is an intelligent sensor system for automatic and non-contact detection and

decoding of SISO/IEC15693 compliant transponders. In principle, the transponders can

be detected on any side of still or moving objects in a conveyor system. Several RFID

devices can be combined to allow detection of several sides in one passage (multi-side

reading).

The RFH620 creates a high frequency field to recognise transponders. The transponder

itself generate out of the field the power for operation and the data send from the RFID

device and respond data to the interrogator using field load modulation. The size of the

reading field depends mainly on the used transponder (size and Q-factor) and the

environment (metal objects).

Figure 3-6: HF Technology – principle overview

To control a process, external sensors could deliver information via the reading pulse,

the object distance and the conveyor speed (increment). The reading/writing results are

output to the RFH620 data interfaces and forwarded to a host/PC.

Figure 3-7: Methods of operation in a conveyor system

Operating Instructions Chapter 10

RFI341

8013171/ZO93/2017-08-08 ©SICK AG • Germany • All rights reserved • Subject to change without notice 19

Appendix

3.5.1 Reading / Writing configuration

The RFH60 is compliant with the ISO 15693 Standard. Via SOPAS tool standard

specific setting could be set.

In addition parameters could be set that e.g could be used to define reading window

conditions as well as conditions for the actions to be taken within.

3.5.2 Object trigger control

In order to start an object-related reading process, the RFH620 requires an appropriate

external signal (trigger source) for reporting an object in the reading area. The start

signal is emitted via an external reading pulse sensor (e. g. photoelectric reflex switch)

as standard. As soon as an object has passed the reading pulse sensor, a time window

opens in the RFH620 (“reading/writing gate“) for the reading/writing process.

Alternatively, a command activates the reading process via a data interface or the CAN-

SENSOR network. In Automatic mode, the RFID device generates the reading gate

internally with an adjustable mark-space ratio.

The reading pulse can be ended in a number of ways: With external triggering by the

reading pulse source or a command, internally by a timer or an evaluation condition to

be met.

The trigger source could be configured using the SOPAS-ET configuration software:

PROJECT TREE, RFH620, PARAMETER, READING CONFIGURATION, OBJECT

TRIGGER CONTROL, register tab START/STOP OF OBJECT TRIGGER

3.5.3 Increment configuration

The RFID device receives information about the conveyor speed from an external

incremental encoder, for example. The incremental encoder delivers pulses which are

used to determine the current conveyor speed.

The conveyor speed results from the number of impulses and the resolution of the

external incremental encoder.

The increment source and the resolution/speed can be configured using the SOPAS-ET

configuration software: PROJECT TREE, RFH620, PARAMETER, INCREMENT

CONFIGURATION, register tab INCREMENT

3.5.4 ISO/IEC 15693 configuration

The RFH620 is compliant with the ISO 15693 Standard. All mandatory and optional

command set as defined in the standard are supported. All transponders that comply full

with the standard could be used in a customer application. A actual list of supported

transponder IC’s could be requested via SICK sales channel.

Chapter 10 Operating Instructions

Radio Frequency Identification RFH620 Interrogator

20 8013171/ZO93/2017-08-08 ©SICK AG •Germany •All rights reserved

Appendix

3.5.5 Reading operation mode (object related)

There is only one object in the reading field during start/stop operation, i.e. all the read

data should be unambiguously assigned to the object. The start and stop of the reading

process control one/two reading pulse sensors at the beginning and at the end of the

reading field as standard. The distance between each sensor is determined by the size of

the reading field. The reading process can be alternatively controlled with command

strings via the data interface. The output of the reading results is carried out either at the

end of the reading pulse (the rear edge of the object has left the end of the reading field)

or during the reading pulse if certain configurable conditions have been fulfilled.

Figure 3-8: reading operation mode for the RHF620 in stand-alone operation

The reading operation mode can be configured using the SOPAS-ET configuration

software: PROJECT TREE, RFH620, PARAMETER, DATA PROCESSING, register

tab TRACKING

3.5.6 Data Processing

The output time in the reading process with regard to the reading pulse start can be

configured using the SOPAS-ET configuration software: PROJECT TREE, RFH620,

PARAMETER, DATA PROCESSING, OUTPUT CONTROL

Furthermore, the evaluation conditions and filters and sorters for data output to the host

computer can be configured: PROJECT TREE, RFH620, PARAMETER, DATA

PROCESSING, EVALUATION CONDITION

PROJECT TREE, RFH620, PARAMETER, DATA PROCESSING, FILTER/SORTER

FOR OUTPUT

Operating Instructions Chapter 10

RFI341

8013171/ZO93/2017-08-08 ©SICK AG •Germany •All rights reserved 21

Appendix

3.5.7 Output format

The reading result (decoded codes) is displayed via selectable physical interfaces. Two

different output formats (telegrams) can be defined for this task, one format for "No

Read" and one for the heartbeat (signalisation of readiness).

Note The output formats can be configured using the SOPAS-ET configuration

software: PROJECT TREE, RFH620, PARAMETER, DATA PROCESSING,

OUTPUT FORMAT

3.5.8 Network / Interface / IOs

All important interfaces for displaying the reading results are available on the RFH620.

Several RFID devices can be connected to each other via the CAN bus in the SICK-

specific CAN-SENSOR network.

The network parameters can be configured using the SOPAS-ET configuration

software: PROJECT TREE, RFH620, PARAMETER, NETWORK / INTERFACE /

IOS, tab pages NETWORK OPTIONS

3.5.9 Data interfaces

The following data interfaces are available on the RFH620:

Data interface Function

Host interface

(RS-232 or RS-422/485

and Ethernet host port)

¾Preparation of the reading result for further

processing by the host processor

Auxiliary interface (RS-232

and Ethernet aux port)

¾Reading diagnosis or host interface monitoring

CAN ¾Networking several bar code scanners

Table 3-9: data interface function

The data interfaces can be configured using the SOPAS-ET configuration software:

PROJECT TREE, RFH620, PARAMETER, NETWORK / INTERFACE / IOS,

SERIAL

PROJECT TREE, RFH620, PARAMETER, NETWORK / INTERFACE / IOS,

ETHERNET

PROJECT TREE, RFH620, PARAMETER, NETWORK / INTERFACE / IOS, CAN

3.5.10 Digital Inputs

The external sensor for the object triggering (photoelectric reflex switch) and the

incremental encoder, e.g., can be connected to the digital switching inputs.

The digital inputs can be configured using the SOPAS-ET configuration software:

PROJECT TREE, RFH620, PARAMETER, NETWORK / INTERFACE / IOS,

DIGITAL INPUTS

Table of contents

Other SICK Other manuals

Popular Other manuals by other brands

Bavarian Demon

Bavarian Demon AXON Product information

Aqua Medic

Aqua Medic CO2 reactor+ Operation manual

Alfalaval

Alfalaval Toftejorg MultiJet 65 instruction manual

Aqua Medic

Aqua Medic Kauderni CF Operation manual

NewLine

NewLine Anita instruction manual

Alfalaval

Alfalaval Gunclean Toftejorg T-82 instruction manual

ALLOMATIC

ALLOMATIC TK-1000 Hardware installation instructions

Advanced Card Systems

Advanced Card Systems ACR321 user manual

Perfect Aire

Perfect Aire 4PADP95 user manual

Night Stick

Night Stick XPP-5462GX Dicata instruction manual

Aqua Medic

Aqua Medic Light Computer Operation manual

globalwater

globalwater FL16 user manual