STAVIOR Smart Sterilizer Series User manual

DISINFECTION LOGIC CONTROLLER

UVC-DLC08

User Manual

[English]

2 www.stavior.com

Contents

PROPER AND SAFE USE OF THE DLC CONTROLLER 4

IMPORTANT SAFETY PRECAUTIONS 5

FIRST TIME SETUP 6

THE DLC CONTROLLER PARTS 6

INSTALLATION 7

DLC CONTROLLER OPERATIONS 8

HOW DOES IT WORK 8

SPECIFICATIONS 8

MAINTENANCE, CLEANING AND SERVICING 10

CLEANING INSTRUCTIONS 10

TROUBLESHOOTING 10

PART REPLACEMENT AND SERVICING 11

FREQUENTLY ASKED QUESTIONS 11

⨻UV Radiation hazard! To prevent

possible injury, read the instructions

carefully and pay attention to all the

warnings before using the Sterilizer.

PROPER AND SAFE USE OF THE DLC CONTROLLER

The appliance is designed with built-in safety features, but it’s important to follow all safety

precautions prior to using the equipment. Make the safety instructions available to everyone who

has access to the unit. This controller must be used in conjunction with the UVC-HAS Series

Modules.

●Never Open the DLC Controller

●Do not disassemble the product as there

are no user serviceable parts inside.

●Handle the DLC Controller gently and

carefully as the equipment is

●Any fault or malfunction of the DLC

Controller should be reported to the

3 www.stavior.com

sensitive.

Original Equipment Manufacturer.

●Only a well qualified technician or

engineer should be using or

operating this controller after

properly understanding the safety

aspects and operational concepts of

the DLC Controller

●Protect yourself all the times from any

kind of Electric Shock.

IMPORTANT SAFETY PRECAUTIONS

To reduce the risk of fire, electric shock, injury, follow the precautions diligently:

1. Read all instructions in the User Manual carefully before using the appliance.

2. Install or replace DLC Controller according to the instructions provided in the “Installation”

section.

3. Only qualified technicians or engineer should install or operate the DLC Controller

4. Do not operate the unit if the electric cord or plug, cables, buttons, etc are loose or damaged.

5. Mount the Unit as per the Installation Instruction of the manual.

6. Ensure this Unit is Installed in a neat, clean, dry environment without dust.

7. Do not store or use this appliance outdoors.

8. Keep the unit away from moisture or wet environment.

9. Place the unit at locations away from heated surfaces.

FIRST TIME SETUP

THE DLC CONTROLLER PARTS

1. Lamps Phase Output (1 - 8)

2. Lamps Neutral (Output) (1 - 8)

3. MCB

4. Door Switch Sensor

5. Input 230 V AC

4 www.stavior.com

INSTALLATION STEPS

1. Please note the installation has to be performed by a trained technician

2. Remove all packing material and accessories.

3. Install the DLC Controller at a height of at least 1.5 meters above the ground.

4. Use Steel Bolts if mounting on concrete surfaces.

5. Ensure the wiring connection is properly secured, connected with correct polarity.

6. The controller shall be installed in an area that’s easily accessible.

7. The Controller should be installed away from heat generating sources, wet environment,

dusty environment, or other High Voltage Sources.

8. Use input voltage 230 V and Frequency: 50/60Hz.

9. Connecting wires –Yellow (Phase), Black (neutral), Green (Earthing)

PRECAUTIONS TO BE TAKEN

Avoid the following situations:

●Avoid mounting the DLC Controller near heat sources, such as heating vents, air

conditioning units, High Voltage Sources etc.

DLC CONTROLLER OPERATION

HOW DOES IT WORK

The Disinfection Logic Controller Unit controls the UVC Module switching and scheduling

operations lamp as per desired times and durations. The UV Lamps are connected through the 8

Pin output (Phase) & 8 Pin Output (Neutral) and the lamp switching operations and on/off duration

are controlled by the internal programming and relay circuit.

The Unit operates on 230 V AC Input connected through a 3 Pin Socket. The Main Power Switch

on the Front Door is used to switch on/off the power supply to the Controller. The UV Power switch

adds an additional layer of security to control the switching of UVC lamps. An Indicator light is

provided adjacentto the Main Power switch along with an Alarm to indicate/warn personnel safety.

A green light means it is safe for the people to enter the AHU or control room. As soon as the UV

Power Switches ON, the indicator turns RED and the UV Lamps switch ON, indicating a hazard

for any personnel entering the UV Lamps area. A 2 pin door switch is also provided that activates

alarm when the door is open while the UV Lamps are ON.

The LCD Display on the panel helps understand the status of the UV Lamps. The programming

features can be set / configured with the help of the knob adjacent to the LCD display.

DLC Settings Configuration

5 www.stavior.com

The LCD Display along with the rotary knob encoder is used to configure the Controller to operate

in conjunction withthe UVCModules. The screenof the LCD appears as shown below for 1 second

while the device is booting up.

LCD Booting Status

Then the LCD Home screen appears as shown below

LCD Home Screen

The Date and Time are pre-configured and are kept accurate with the help of an internal real-time

clock. Therefore no reconfiguration of the date is required. When you single click the knob while

the cursor bar is resting on the “Date & Time” option, the following information will be displayed.

Rotating the knob slightly clockwise, moves the cursor bar “DOWN” in steps, likewise moving the

knob anti clockwise will move the cursor bar “UP” in steps.

To go back to the previous menu, move the cursor bar to the “Back” option and single click (or)

Double click from wherever the cursor bar is located.

The next option in the settings home screen is “STATUS” option. This indicates the status of all

the 8 lamps, on/off condition.

The next option is the “Life Span” option. When you single click this option it will display 2 sub

categories.

Module Life : Rotate the knob to get the cursor on “Module Life” and single click. That will show

the Life of all the 8 UV Lamps. It indicates how many hours the lamps have been burning. The

below information appears in the LCD Display.

6 www.stavior.com

Module Reset : This option is used to reset the actual number of hours of operation of each lamp,

then it shows 9000 hours of total operation as balance. This is used when you replace a faulty or

failed lamp with a new one. A confirmation message will be displayed saying “ Reset Successful”

for every reset done.

The next option of set up is the “MODE” option. This is used to bring the lamps into Automatic

Mode (or) Manual mode of switching on/off. The LCD displays the information as shown below.

Automatic : If the Auto mode is off, then the lamps need to be switched on off controlled manually

with no reference to real time clock. If the Auto mode is ON then the lamps are automatically

switched on/off based on the time configured already.

To change the configured timings, move the knob clockwise in steps to place the cursor bar on the

desired lamp that you intend to change the timings of. Single click the knob. It will take you to the

time setting screen as shown below.

If the symbol before the numeral is displayed as a colon, then we can change the numerals in

single digits. If a greater than symbol is displayed before the numeral, then we can change the

numerals in steps of 10 digits.

Manual : When the manual mode is selected, there is no option to choose the switching on/off of

the lamps by real time clock.

7 www.stavior.com

It is totally manual depending on the user how long he intends to keep it on or off. The display will

be as shown below. Use the knob to reach the desired lamp and turn it on or off manually.

The next option is the Settings option. The LCD will display the sub categories as shown below.

Use the knob to move to the INFO option, and it displays the information related to this DLC

Controller, manufacturer, Year of manufacturing etc.

Door Switch : Move the cursor bar to reach the door switch option. Single click to edit the setting

as “Enable” or “Disable”

Wifi Setting : Use the knob to reach the Wifi Settings option. Single click to edit the setting as

“Enable” or “Disable”

SPECIFICATIONS

Dimensions

200 x 255 x 95 Cm

Materials :

PVC - 100 % Shock Proof

Power Source :

230 V

Frequency :

50/60 Hz

Power Consumption :

60 Watt

Control Panel

Consist of the following :

1. Microprocessor based control panel with LCD Display.

2. Individual Lamp run hours for timely and easy replacement.

3. Individual lamp On/Off/Error Indicator.

4. Over Current Protection Circuit.

5. Lamp change reminder on Display.

6. Suitably rated RCBO for ON/Off of incoming Mains power

Safety

The operation of the UV lamp shall be interlocked through AHU door

panel lock and shall be independent of the AHU operation. The system

shall be interlocked with the AHU door panel so that it will be ON ONLY

WHEN AHU DOOR IS CLOSED and OFF when AHU DOOR IS

8 www.stavior.com

OPEN.

MAINTENANCE, CLEANING AND SERVICING

CLEANING INSTRUCTIONS

●Clean/Wipe the DLC controller with a soft cloth and a mild detergent solution.

●Wipe off the cleaning agents immediately with a lint-free cloth moistened with water.

●Allow the device to completely dry before operating again.

●Dust off any loose particle or lint on the device a lens cleaning brush.

TROUBLESHOOTING

If you experience trouble with the DLC Controller then you can refer the user manual.

If the DLC Controller still does not work properly, contact the manufacturer representative as soon

as possible.

Trouble

Possible Cause

Possible Remedy

DLC Controller

wont start

●230V AC Electric power input

failure to the device

●Check the power supply from the

nearby power source is on/off

●MCB Tripped

●Try resetting the MCB

Lamps won’t glow

●UVC Switch is off

●MCB is switched off

●Turn ON UVC Switch

●Turn ON MCB

PART REPLACEMENT AND SERVICING

There are no user serviceable parts inside this unit. The device needs to be inspected/replaced by

the manufacturer in case of failure/faulty operation. Please use a qualified service engineer to

replace and check the operation the DLC Controller.

FREQUENTLY ASKED QUESTIONS

Q. Is this controller designed particularly for a specific model ?

A. No. This controller can be used for any model of UVC-HAS Series Air Stream sterilizers: UVC-

HAS30, UVC-HAS60, UVC-HAS50, UVC-HAS100, UVC-HAS160, UVC-HAS90, UVC-HAS180,

UVC-HAS220, UVC-HAS300, UVC-HAS330, UVC-HAS660 and UVC-HAS1300

Q. How many Air Stream modules can be connected to a single controller ?

9 www.stavior.com

A. You can connect upto 8 UVC-HAS Modules. Note that not all of the Modules need to be of the

same model.

Q. Can the air stream modules be configured to be ON for 24 hours through the controller ?

A. The air stream modules can be configured to operate pretty much round the clock using the

manual mode on the controller.

Q. What to do in case the DLC controller is faulty ?

A. There are no user serviceable parts inside this unit. Please contact the manufacturer or

distributor as soon as possible.

HEAD OFFICE REGD. OFFICE

Cenaura Technologies Pvt Ltd Cenaura Technologies Pvt Ltd

No 201, Sree Homes, Plot No 51, FT-3G, Block A, Jain Srikar Auroville,

MB Society, Madhapur, Khanamet, Madhapur,

Hyderabad - 500084 Hyderabad - 500084

www.stavior.com

+91 79933 51666

The design and specifications are subject to change without prior notice for product improvement.

Consult with the sales agency or manufacturer for details.

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

Steca

Steca Tarom 4545 Installation

Mitsubishi Electric

Mitsubishi Electric TC-24A Instruction book

Bernard

Bernard SQ Series Installation, start-up and maintenance instructions

Toa

Toa DI-1616 Specifications

BERGHOF

BERGHOF DC2004 User handbook

Analog Technologies

Analog Technologies ATLS500MA103 quick start guide

NXP Semiconductors

NXP Semiconductors PN7120 quick start guide

Computherm

Computherm WPR-100GC operating instructions

Auber Instruments

Auber Instruments WS-1500EPM Operation & instruction manual

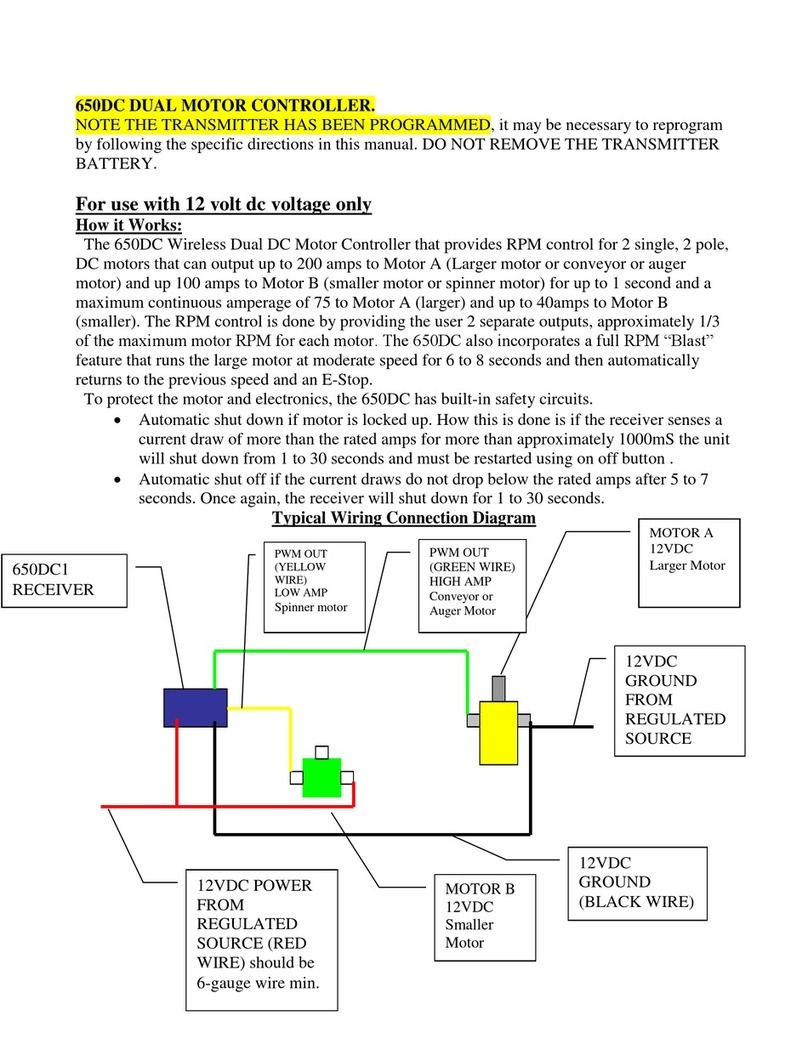

Control All Wireless

Control All Wireless 650DC user guide

Emerson

Emerson FRANSEL REGAL 3 instruction manual

Tempco

Tempco TPC20058 user manual