Steadypass BOAT SPEED CONTROL SYSTEM User manual

1

STEADYPASS

THE BOAT SPEED CONTROL SYSTEM

Thank you for your purchase!

SteadyPass system is designed to control (decrease) boat’s throttle to maintain preset speed per GPS or

RPM.

2

What’s in the box:

1. Head unit with wingnuts. Fits in opening with diameter 87-90mm.

2. Mating power cable (white). Use yellow for tach input.

3. Short and long temperature sensors

4. Servo assembly in white PVC tube

5. Adapter plate pre-fab: connecting servo cable to OEM throttle rod

6. Two nylon nuts to mount adapter plate: should fit OEM throttle rod

7. Allen wrench for servo fitting

8. 3-pin 6 meter extension cable for servo

9. GPS antenna

10. Misc electrical connectors

Good To Know Facts:

Kit body is not waterproof, but reasonably water resistant.

Device power is provided by standard 12v boat power: kit comes assembled in 3.5” enclosure, with

power leads (black(negative), red(12v) and yellow (tach input).

Power polarity is important!

Tachometer: connect to signal lead on your tach, which would likely be grey (for older analog units).

This signal typically comes off negative coil lead.

Servo install: Fit cap firmly to PVC tube (it is removed for shipment purposes)

Assembly needs to be fixed in a place without direct heat/water/etc exposure. Will need to adjust

bowden cable to guarantee correct idle position and smooth operation.

Servo connection: 3 wire lead, provides servo power, ground and PWM signal (standard for RC

servo). Servo connects directly to head unit with extension 3-wire cable. Starting July 2019 –cable

is included

Optional: temp sensors, air and water. Early kits have one 4-pin connector for both sensors. Wiring

diagram provided. August and later 2019 kits –have separate connectors for water/air. Cable

extension may be required depending on boat. 5meter cable is included. 10 meter is optional.

3

Installation:

To be added drawing: MECHANICAL CONNECTION DIAGRAM

1. Unpack, inspect, make sure all parts are present.

2. Connect all parts together and power up from any 12v DC power supply to confirm all is functioning

as intended after shipping:

a. Connect GPS antenna to head unit

b. Connect servo with cable to head unit

c. Connect temperature sensors (optional)

d. Connect 12v DC power to head unit –screen should light up.

e. Enter menu, select “Test Servo” mode – verify servo is moving smooth.

3. Work up a plan and connect Bowden cable to your throttle body: most challenging.

NOTE: Cable is connected IN SERIES, not in parallel to factory throttle rod. Steady Pass is

NOT supposed to move throttle rod or throttle handle at helm. It is designed to add “slack”

- releasing throttle body arm and decreasing speed to target.

NOTE1: Some throttle bodies will have weak return spring, and require additional spring.

NOTE2: Every boat is a bit unique in dimensions but overall idea is outlined below

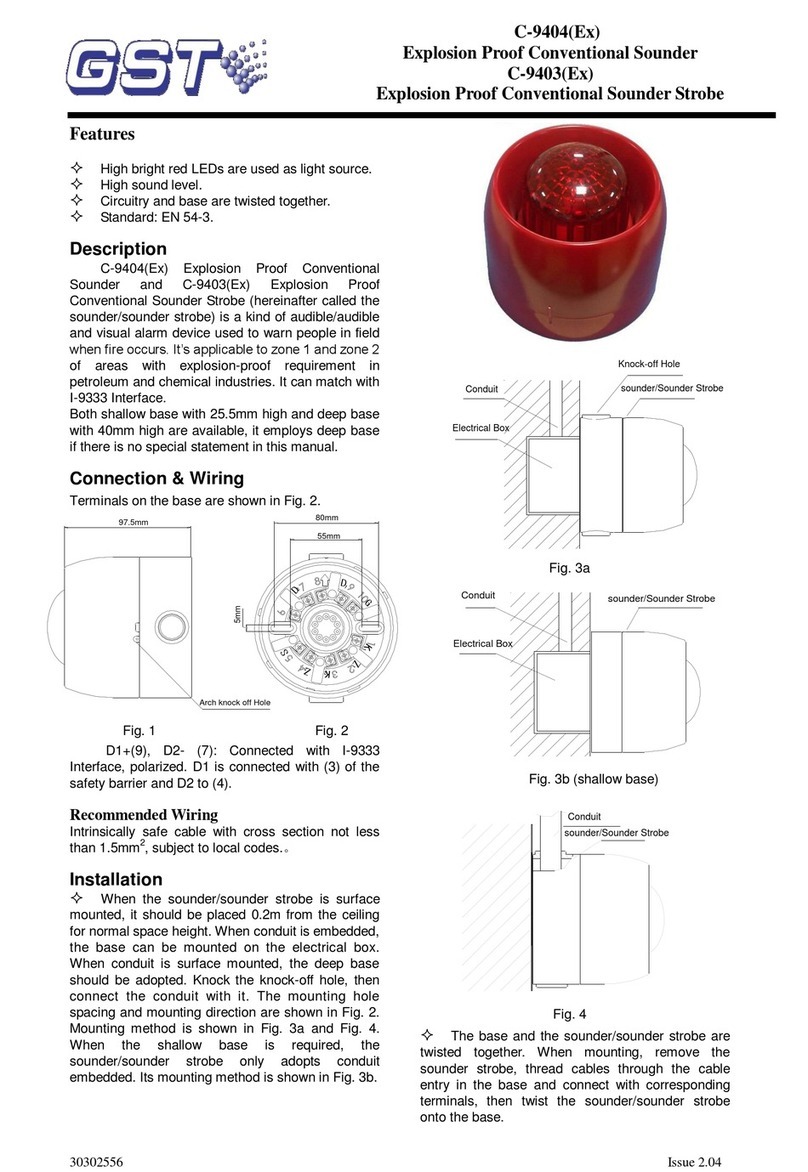

a. Disconnect throttle rod from throttle body, and remote elbow assembly from throttle rod –

keep any removed parts. (See picture 1)

b. For most boats - OEM Throttle rod assembly mount (outer shell) needs to be moved back,

to allow space for Steady Pass connection. Your boat approach may vary –examples below.

(See picture 2)

c. Connect tip of original throttle rod thru plate-adapter (connecting plate) to outer shell of

Bowden cable, secure with nylon nuts on both sides of plate. (See picture 3)

d. Connect tip (elbow assembly, on the core of Bowden cable) to throttle arm (where throttle

rod was connected originally). (Also on picture 3)

e. Cable guide is needed. Not provided. May be as simple as cable tie. Good example on

Picture 4

f. With Steady Pass fully retracted (Bowden cable tip pressed against Bowden shell –can

adjust in menu AND mechanically by repositioning cable tip) adjust position of throttle rod

shell and Bowden cable to correct idle throttle configuration. When throttle control lever is

in idle –your throttle body arm must be in idle. Verify with engine running in neutral.

4

5

4. Place head unit into a “3.5” standard opening on the dash

5. Connect 12v power to your preference –ignition controlled ACC power or to a separate switch (unit

does not shut down itself, and must be powered down to avoid battery drain when not in use)

6. Connect Tachometer signal wire in parallel to your boat tachometer signal.

7. Run servo control wire from head unit to servo –3 pin connector does not have orientation key, but

will not cause any harm when plugged in wrong. If you don’t see servo moving – simply rotate 3 pin

connector 180 degrees.

8. Mount GPS antenna and connect to head unit. GPS will work ok even when mounted under non-

metal dash surface, but is most accurate when mounted on the open space with clear sky view.

Double sided tape works great for mounting.

9. Install optional temperature sensors

10. Adjust servo range (instructions later in document) and verify correct operation of servo:

a. Put helm throttle handle to ¾ power, enter menu (long press) and enter option “Test Servo”

on Steady Pass. Travel must be smooth and continuous.

6

b. Enter menu “Max Throttle”setting –servo will retract and must apply light pressure to

Bowden cable, very light intermittent buzzing is ok, cable connector tip needs to be pulled

in firm against outer shell of Bowden cable, but must not cause servo stall. Rotate knob

while in menu to change default servo position.

c. Enter menu “Min Throttle”setting –servo is extended, and Bowden cable allows throttle

body to close, decreasing throttle. Adjust to remove servo overextension: with Helm

Throttle handle in FULL POWER –SteadyPass cable must extend but remain under tension

Pictures will best describe install, and we are continuously working on install aids

Pic1 Left: Bowden cable fitted with L-bracket to throttle cable and is in “Min Throttle” (de-throttle) position.

Tip of Bowden cable core is connected to throttle body arm. Cable guide on the right. Additional spring on

the left

Pic2 Right: Flat bracket used where throttle rod base had enough adjustment. Cable is in “non-activated”

position

Usage:

Steady Pass has 3 modes of operation: OFF, RPM and SPEED

Steady Pass works by decreasing throttle within mechanical limits of installation. So it will NEVER go

faster than you set by throttle lever.

To change mode: Single short (but firm) press on knob.

Mode –shown in upper right corner.

oOFF mode: device does not perform any servo movements, only displays current speed and

time.

oRPM and SPEED modes –rotate knob to set desired RPM/SPEED setting.

During correct operation –driver accelerates moderately above desired speed, to allow throttle

range for Steady Pass to use. Once current speed exceeds target sett –you will see “power” value

7

decrease in upper left corner, which indicates servo movement to decrease throttle. This is helpful

at BETA testing stage to confirm correct operation.

Note –MPH and KPH speed options are available –change thru menu.

Note –Current SPEED setting will be saved when entering menu. Upon next startup –unit will

default to saved Speed value. There is also a separate line item in menu.

Menu:

SteadyPass has single menu with setting for acceleration and

response rate, time zone, cylinder and default speed settings.

To enter and to exit menu –press and hold control knob for

about 5 seconds.

Min Throttle (max servo) –position of servo fully

extended. This adds maximum slack to throttle linkage –

and so drops throttle by maximum amount

Max Throttle(min servo) –default, “no action” position of

device. When all set correctly –with device powered on

and mechanical throttle control at idle –engine should

not exceed idle RPM. But there should be no extra slack.

TEST servo: use this to test servo setting, and especially

–test installation to make sure Bowden cable and linkage

is moving freely without stalls.

Servo mode: for custom reverse action installation

(typically not used)

Engine Cylinders –multiplier for RPM calculation,

typically set number of cylinders on your engine.

Time zone offset –set your time zone to display local

time as calculated from GPS acquired GMT time.

Startup Target Speed: Value that unit will use on

startup next time. Current value (before entering

menu) is automatically saved and show.

Unit of measure: MPH or KPH

Temp Sensor: Choose Celsius or Fahrenheit

Contrast: LCD setting. Typically not used.

Coefficients: Proportional , Integral, Derivative –part of

PID routine. We are working on tuning manual

oProportional –helps boat to reach target

speed.

oIntegral –helps to even out overshoot and undershoot.

oDerivative –last to adjust, helps to minimize oscillations after reaching target speed.

oWhen in doubt –use defaults.

8

Servo range setting verify before each season.

It is very important to verify/set servo range before operation. It is done by entering menu (long press

knob) and adjusting MAX/MIN throttle settings so that servo is not pressing against mechanical limits and

does not stall at end points.

Start by setting correct min/max limits in menu while servo is in your hands, before installing into

the boat.

Typical values for linear servo are 950 in “max throttle”, 1950 in “min throttle”. Servo min/max

limits are slightly different for every servo.

Menu has 3 lines for setup: Min throttle, Max throttle, TEST.

oWhen in menu for one of the values –servo will position itself to the current number shown

on screen.

Set up “Min Throttle”(max servo value position) : This is position of maximum de-throttle.

oPut help throttle handle to FULL power.

oEnter menu by long press, then enter “min throttle”menu –servo will move to extended

position

oWhen in menu –rotate knob to find optimal position.

oBowden cable must allow throttle body to close, decreasing throttle. Adjust to remove

servo over-extension: SteadyPass cable must remain under tension

oNote, depending on your throttle body –it may not fully close. It is ok.

Set Up default position –“Max Throttle”(min servo value)

oPut Help Throttle Handle to IDLE

oEnter “Max Throttle”menu

oServo is retracted fully but must not stall.

oThis is done AFTER installation, because setting depends on bend radius of Bowden cable

oRotate knob to remove ALL cable slack, with LIGHT pressure of cable tip against cable outer

shell

Verify setting by entering “TEST MODE” in device menu – servo should continuously cycle without

stops.

9

Updated servo and unit assembly.

Shown below: 3D printed body, two temp sensors (need to extend cables), power harness, short extender

for servo (need to splice in 20 awg cable to fit boat size), servo in enclosure

Don’t forget to

verify travel is

smooth across full

servo range when

installed!

August and later 2019 have separate sensors with connectors installed.

Temperature sensors have individual 3-pin connectors.

Power and tachometer input is below:

10

Please read and agree:

The SteadyPass Boat Speed Control system is designed solely for use with water ski and wakeboard boats

operating under calm conditions with supervision, with driver in full control at all times, also utilizing a

spotter and all other safety crew and requirements applicable to water sports and general boating.

Steadypass Boat Speed Control system should not be used for any other purpose or under any other

conditions. Your decision to proceed with installation is conditional upon you assuming all and any risk and

losses related to use of this system.

Both purchaser and/or anyone utilizing the Steadypass Boat Speed Control system acknowledges that their

purchase and or use of this device is conditional upon them releasing and forever discharging Opportunity

LLC and Steadypass Boat Speed Control team from any and all liability for any injuries or losses or any other

claims, demands, losses or causes of action, whether occurring prior to, during, or subsequent to or directly

or indirectly connected with the use of the Steadypass Boat Speed Control System, and whether caused by

any persons negligence or otherwise. In other words –while by mechanical design Steadypass is not able to

increase speed above what boat operator sets by mechanical handle –please proceed at your own risks.

Power and Tach input

By color:

•Yellow – Tach gauge

•Black – Ground

•Red – Power (+12v)

Table of contents

Popular Marine Equipment manuals by other brands

Raymarine

Raymarine EV-100 installation instructions

Furuno

Furuno IF-1002 Operator's manual

Raymarine

Raymarine i50 Depth Installation and operation instructions

Humminbird

Humminbird PiranhaMAX 155 Installation and operation manual

Nera

Nera Saturn BM Marine Operator's manual

Magnadyne

Magnadyne M5100CD Installation and operation manual