SteamandGo SAGS3 User manual

1

GARMENT STEAMER

INSTRUCTION MANUAL

MODEL NO.: SAGS3

PLEASE READ ALLINSTRUCTION CAREFULLY BEFORE USI

2

3

Dear customer:

Thanks for choosing our garment steamer. For your convenience of operating the steamer

correctly, please read the instructions carefully before operation.

(No further notice in case of changing of technical parameter)

The picture is only for reference.

Catalogue

Brief introduction ---------------------------------------------------------2

Safety reminder---------------------------------------------------------3

Accessory Drawings-----------------------------------------------------4—5

Installation of operation --------------------------------------------------------6—7

Installation of the clothes rack--------------------------------------------8

Method of steaming---------------------------------------------------------9

Excrete the remaining water in the machine----------------------------10

Maintenance and descaling operation------------------------------------10

Storage--------------------------------------------------------------------------11

Please read the user manual carefully before operation and keep it for future consulting.

4

Brief introduction

As a high-grade ironing appliance, the product is applicable to such places as home, hotel.

It has compact and light weight design, save storage space. It provides massive high

temperature steam, can easily remove wrinkles in short time. It heats up just in short time.

Large water tank can steam 40 minutes continuously.

Inspection should be made before operation

Get rid of blockage if it exists in the steam pipe and inlet & outlet water pipe. If the power

line has been damaged, instead of taking apart on your own, make the repair or

replacement at a specified maintenance point or by a professional.

I Feature

·1300W high-power, 35S rapid steam generation and heating

·1400ml large capacity water tank, to meet the ironing demand for a long time

·98 ℃high temperature steam, remove wrinkle, does not hurt the clothes

·Intelligent temperature controller, quality fuse, automatic overheat protection without

water, safe and reliable

·3 section telescopic pole design, free to adjust the height

·360-degree rotating racks can be folded, easy for storage

·At the bottom of the drain valve, drain directly, easy to operate

II Thermostat

Thermostat fixed on the heater controls it operating in a safe range of temperature and

prevents danger caused by high temperature effectively.

III Thermal fuse

The thermal fuse will be burned out when temperature of heater rises too high which

prevent danger automatically.

Warning:

Steam pipe nozzle should not be too low, otherwise it will lead to noise and small steam; if

the power line is damaged, in order to avoid danger, it must be maintained or replaced in

designated maintenance points specified by our company instead of replacing it by users.

No electricity during water injection and cleaning period.

5

Safety reminder

·Don’t use the product before reading the instructions.

·Careful with hot condensed water from steam vent before operation.

·Move vertically to avoid plane ironing which can lead to spray head’s spraying.

·Don’t put it (or be exposed to) in water or liquid.

·Operate the machine with care and keep it away from children

·Don’t add hot water into the water tank, which can cause the deformation of the water

tank.

·Pay attention to the safety of plug, socket and power and don’t pull or draw the plug.

·Don’t let the plug touch the heating part and store it after the body cools down and water

has been drained.

·Drain off the water and pull out the plug for the long-term idling.

·Notify professionals for maintenance in case of part damage. Incorrect maintenance may

cause injury, fire alarm and electric shock.

·Don’t touch heat-emitting place or steam spray head. Pour the excess water carefully to

avoid injury.

·Let the body cool down after operation

·Pull out the plug when the machine is not in use

·Do not pull out the steam pipe during operation.

·If the power line is damaged, make the replacement at the maintenance point.

·Don’t start power first and add water later to avoid dry burning.

·The product is subject to indoor operation.

·To avoid danger the product is not suitable for children and the disabled.

·This appliance is not intended for use by persons(including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

·Children should be supervised to ensure that they do not play with the appliance,

·If the supply cord is damaged, it must be replaced by the manufacturer, its service agent

or similarly qualified persons in order to avoid a hazard.

·Care should be taken when using the appliance due to the emission of steam.

·Unplug the appliance during filling and cleaning.

6

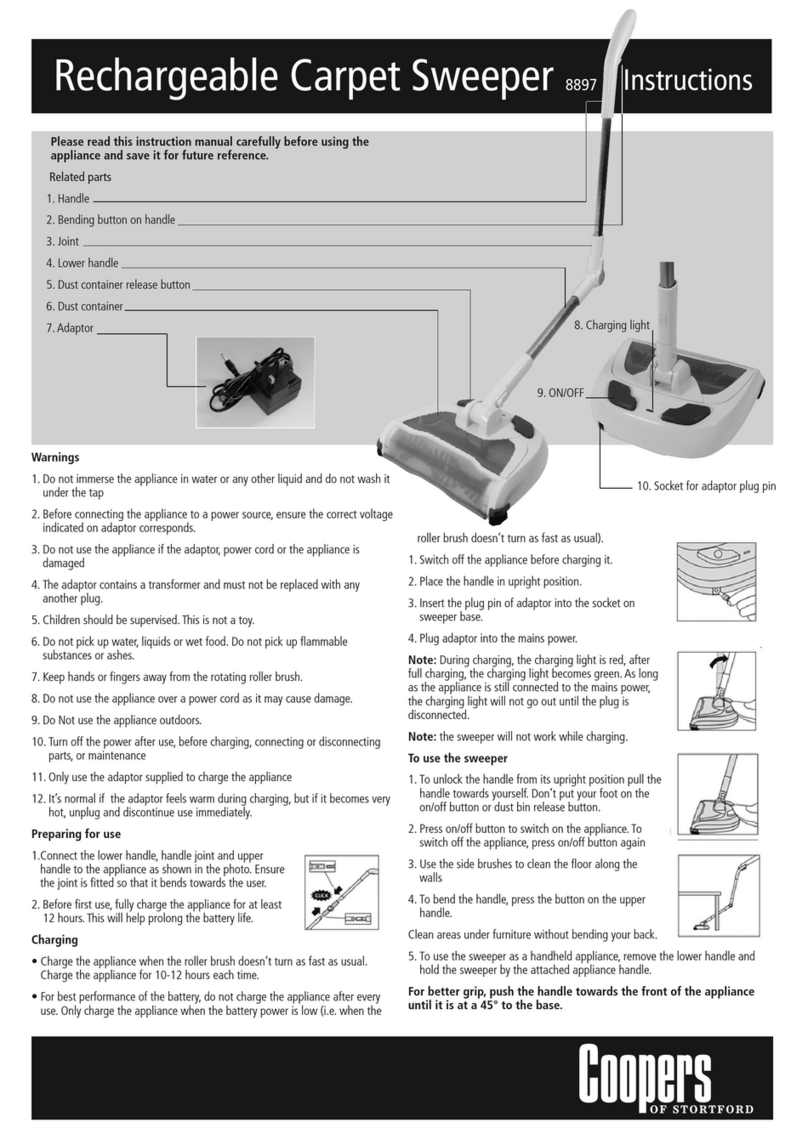

Accessory schematic diagram

Part number

Name

1

Main body

2

Water tank

3

Steam pipe

4

Spray head

5

Fabric brush

6

Hanger with hook

7

Supporting pole

8

Trousers clamp

7

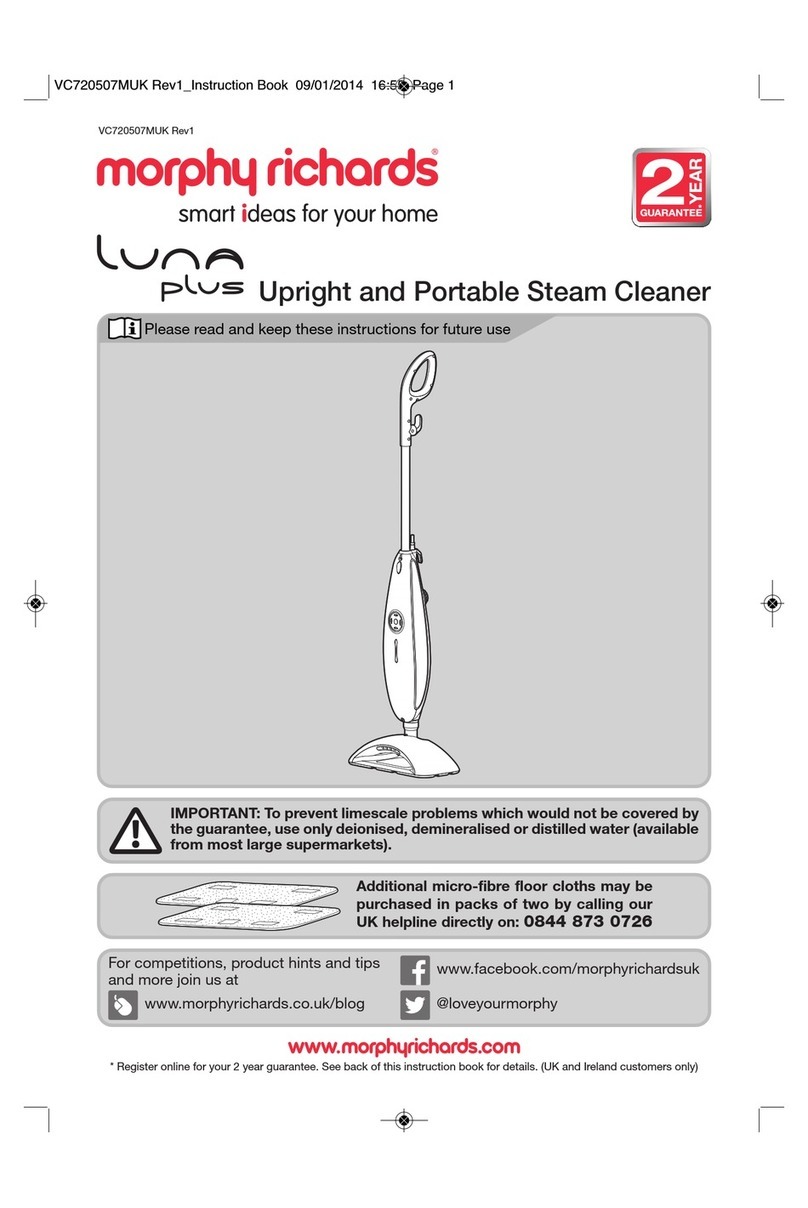

Accessory schematic diagram

Part number

Name

9

Switch

10

Boiler

11

Steam pipe connector

12

Supporting pole hole

13

Drainage cap

14

Base

8

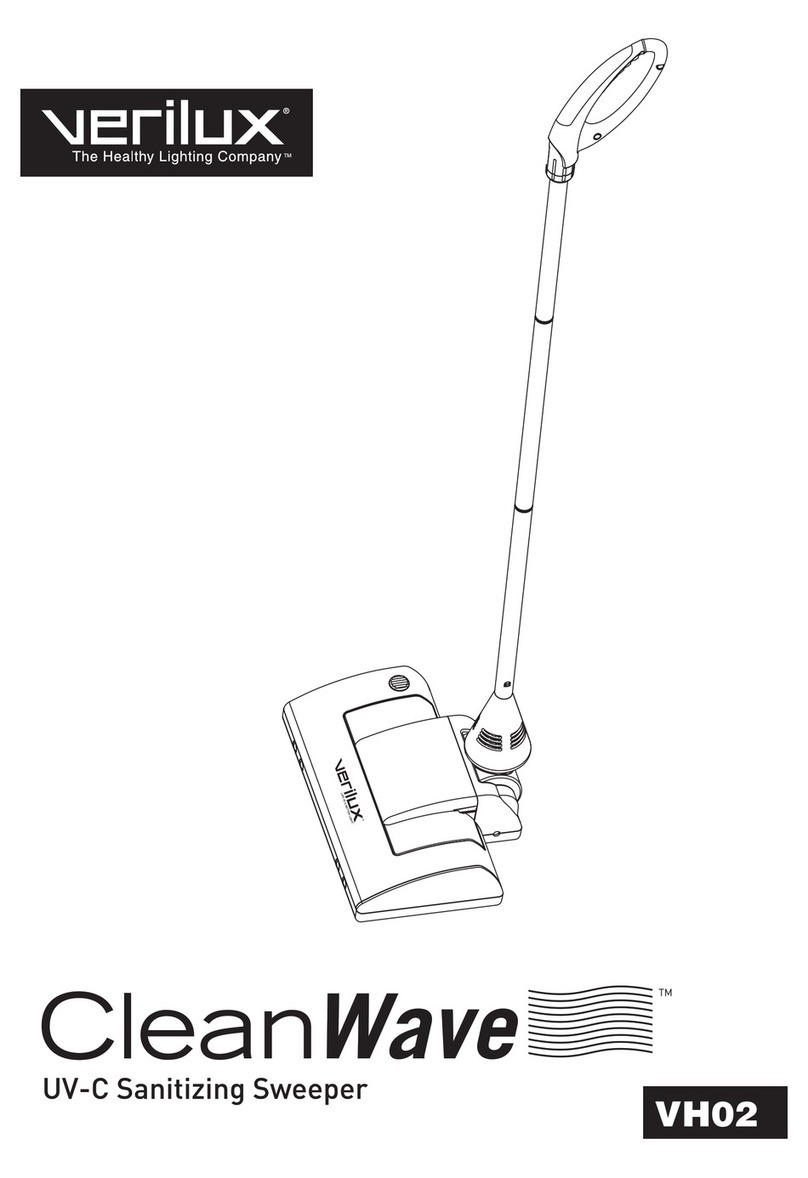

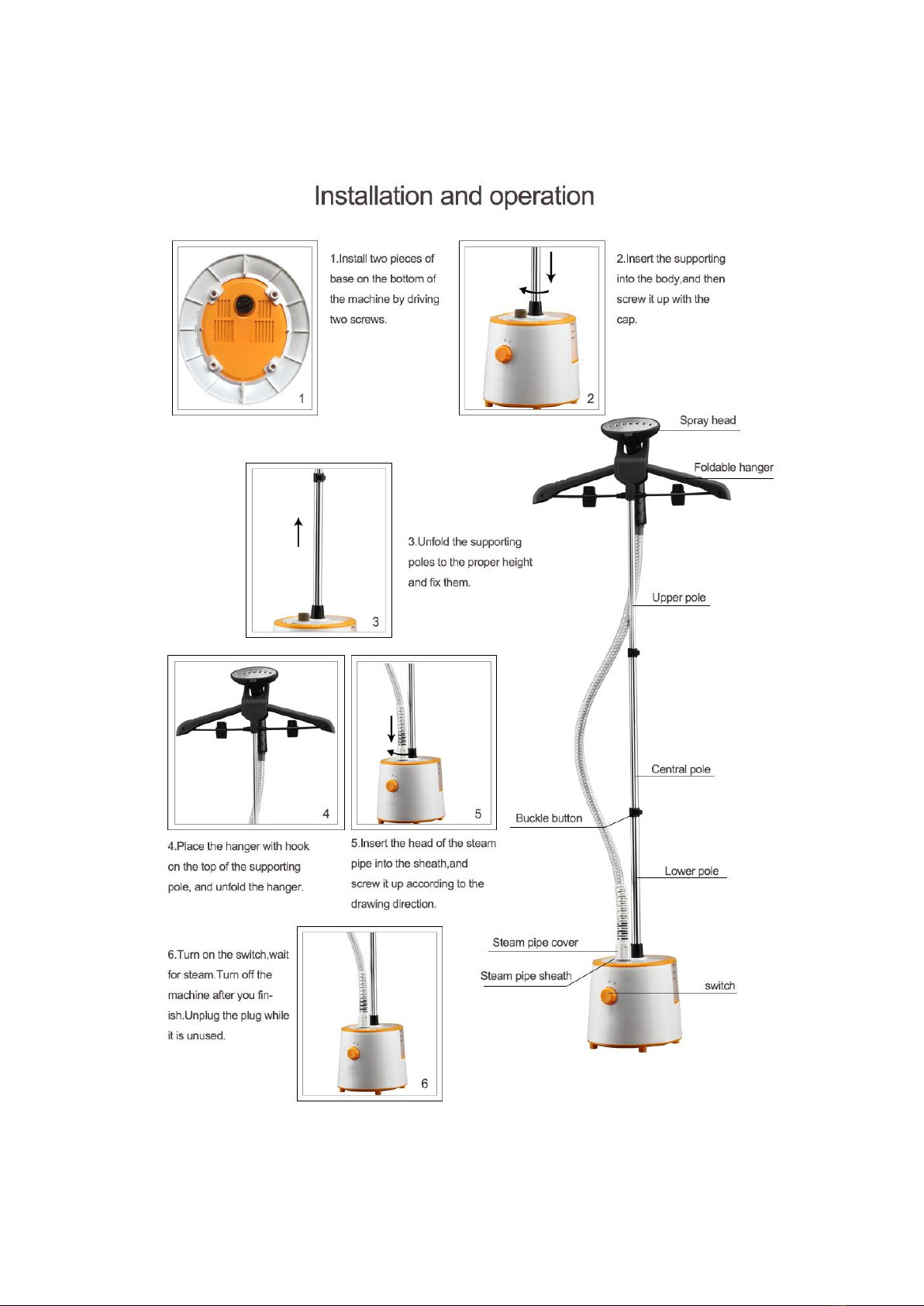

Installation and operation

1、Install two pieces of base on the bottom of the machine by driving two screws. It

provides stability of the machine.

2、Insert the supporting pole into the body, and then screw it up with the knob.

3、Unfold the supporting poles to the proper height and fix them.

4、Place the hanger with hook on the top of the supporting pole, and unfold the hanger.

5、Insert the head of the steam pipe into the sheath, and screw it up according to the

drawing direction .

6、Turn on the power, turn the switch to the ‘1’ level and the indication light will be on, and

wait for the steam. Turn the switch to “0”, then the steamer turns off. Unplug the plug while

it is unused.

Spray head

Foldable hanger

Upper pole

Central pole

Lower pole

Switch

Buckle button

Steam pipe cover

Steam pipe sheath

9

10

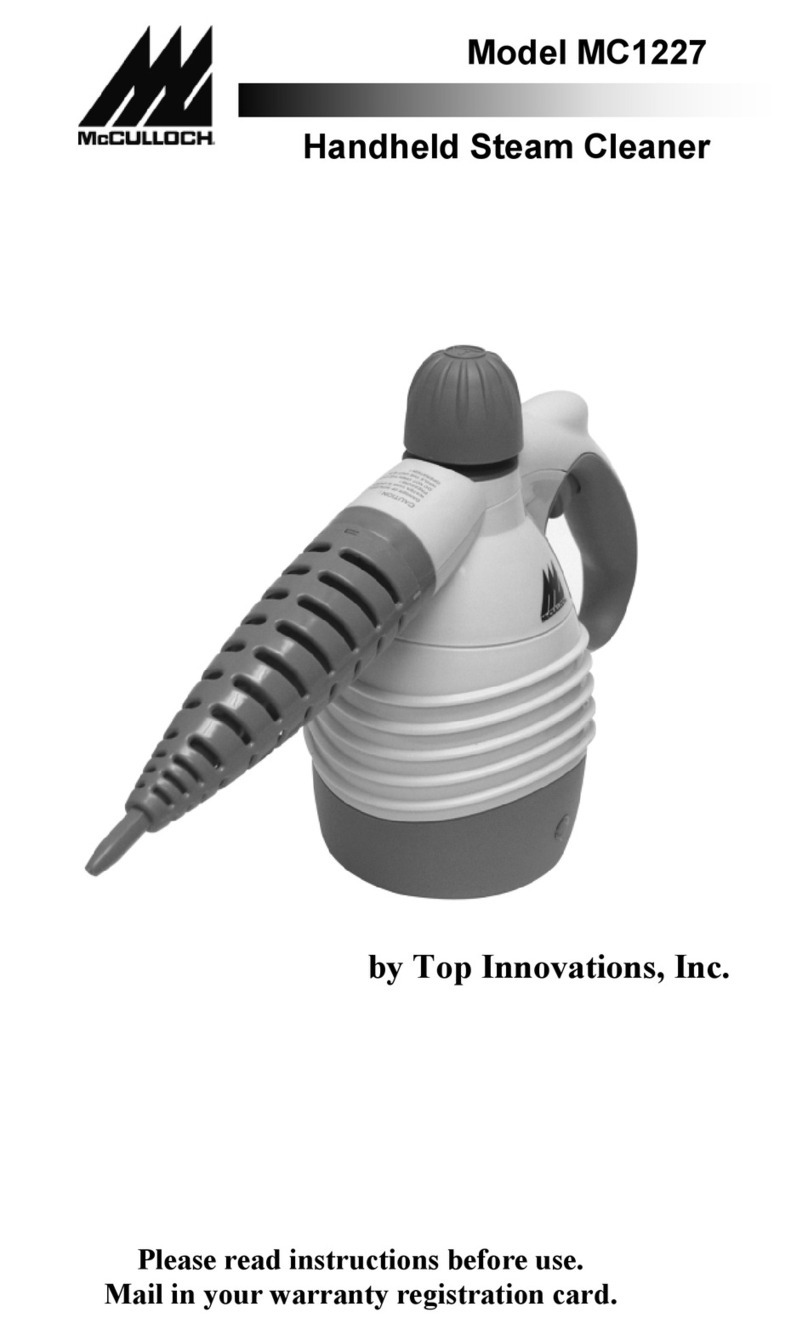

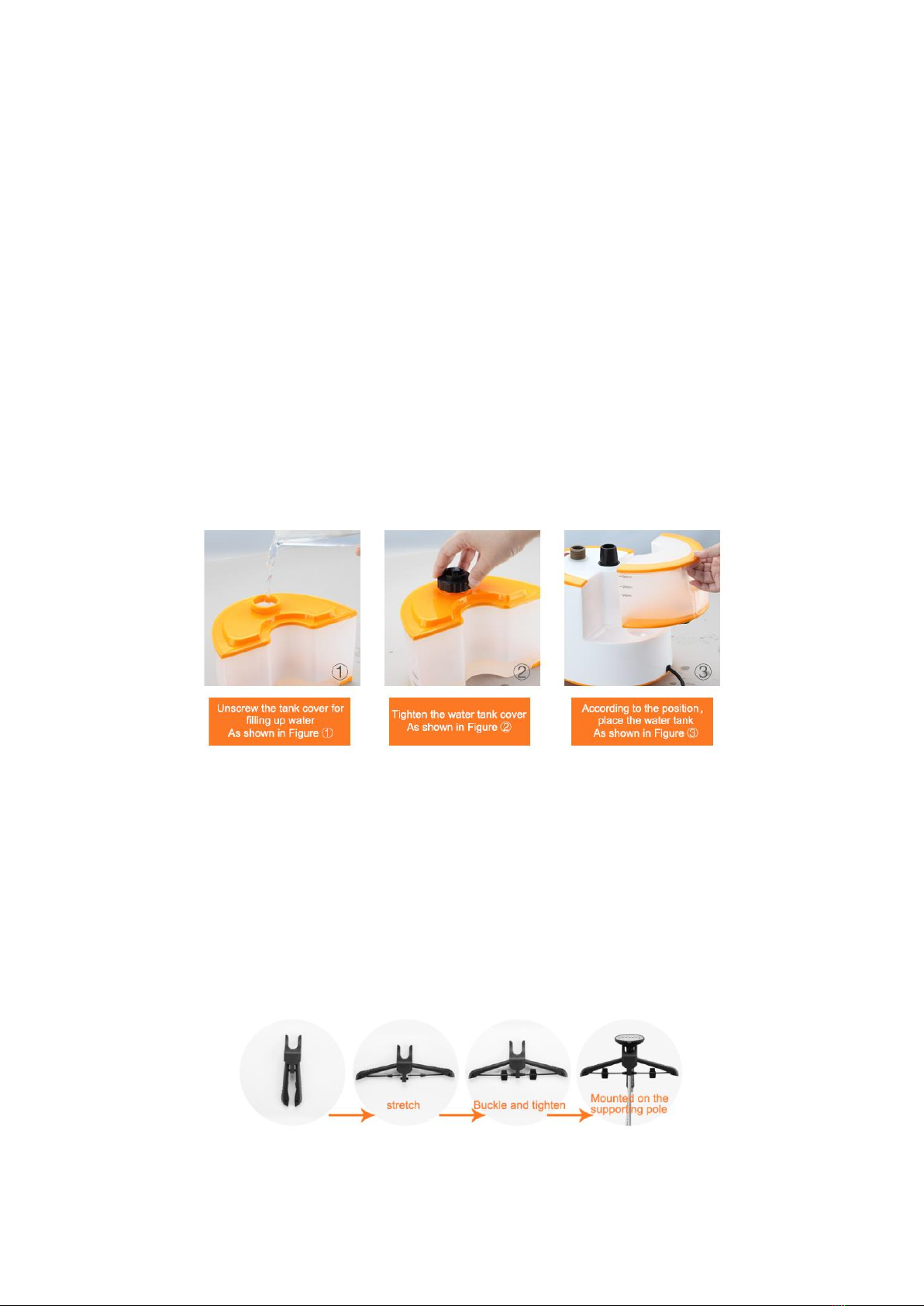

Instructions of operation

1:Please make sure the power switch is off before start working.

2:Take out the water tank,turn off the tank nut on the bottom, fill the water into the

tank(see picture 1), then tighten the nut(see picture 2). Pay attention to that only can fill

cold water, not hot water. In order to extend the life of the machine, we suggest that you

may use the water that does not contain minerals or distilled water. Put back the water

tank, and make sure that the position is installed correctly. (see picture 3)

3: Connect the plug with the power socket.

4:Turn on the switch, the steamer starts to work when the power indicator is turned on,

steam will come out from the spray head in short time.

5: Turn off the switch after finishing steaming, the power indicator will be turned off, the

machine stops working. Disconnect the plug from the power socket.

Usage of two clamps

Two clamps can fix shirts, or trousers etc.

Installation of the hanger with hook.

Firstly, unfold the hanger and buckle up the two small poles to the middle to form the

hanger shape. Place the two small clamps on the small poles. Then attach the hanger to

the top of the supporting pole. Then place the spray head on the hook.

11

Method of Steaming:

1: The effect of high temperature steam is to soften clothes fiber. If only rely on the steam

from the spray head is hard to steam clothes smoothly. Gently pull the clothes surface flat

and use the steam to soften clothes fiber is the key to steam the clothes.

2: Attach the spray head to the clothes surface closely, move the spray head up and down

gently. Steam the area you need, meanwhile fix the clothes surface flat and smooth by

pulling.

3: Hold the side of clothes when steaming the bottom of clothes. Steam up and down,

right and left. Be careful of the steam from the spray head. Wearing a glove is

recommended.

4: Press the spray head a bit harder down on the collar, keep the spray head on the collar

a little longer.

5: The same way to steam the sleeve like steaming the collar.

6: Then steam the other side.

12

Excrete the remaining water in the machine

In order to avoid that the user not to use the garment steamer for long time, the water

inside will go bad, or provide environment for bacteria to grow. So, there is a drainage cap

on the bottom, you can excrete redundant water after turn off the cap. To avoid the water

come out from the outlet when using next time, please tighten the cap after the water is

out.

Maintenance and descaling operation

Water contains mineral substance, which can result in sediment accumulation in the

appliance and impact the heating efficiency and spurt of steam. The sediments shall be

often cleaned and removed (warm tip: please do the descaling operation once a week if

using frequently). The following ways are suggested for descaling:

1: Firstly, turn off the power switch and pull up the plug so as to make this machine

complete cooling.

2: Make sure the appliance is completely cool. Take the appliance outdoor, as the water

will come out from the appliance. Then open the drainage cap on the bottom of the

appliance (see picture), place a full filled water tank on the appliance, so the water will

flush the boiler and take out the sediment out. If the sediments are not completely cleaned,

repeat above process until the boiler is cleaned.

3: If anything blocks the steamer output, do not use the appliance until the output is

cleaned. The blockage may increase the pressure inside of the appliance. Use small

pincers or other suitable tools to take the blockage out.

13

Storage

1: Please make the telescopic pole to the shortest, then remove the hose and put it aside.

2: Take the water tank, and pour out remaining water and clean up, then put back.

3: Please open the drainage cap on the bottom and pour out remaining water.

4: Clean the hose joint with clean water, make the hose around on the telescopic pole. Put

the spray head on the hook.

5: Put the machine in a dry place

14

Trouble-shooting

Facts

Reason

Solution

Out of work

completely

1.Electrical fault;

2. Attaching plug gets loose;

3.Fuse burns out;

4.Power light doesn’t work

Check and maintain by

professional staff

Big noise inside the

steam pipe with little

steam out

steam pipe gets bended under

horizontal level

Raise up steam pipe to let

condensate water backflow into

the machine

Spray head leakage

1.Spray head fracture

2. Operate flatwise

1.Replace spray head

2.Move the spray head up and

down vertically

Leakage in steam pipe

joint

1.Sealing ring aging

2. Linking joint looses

1. Replace sealing ring

2.Frap linking joint of steam pipe

Water in tank outflow

Tank fractures or has holes

Replace the tank

Hot water generates

inside the tank

Water pipe blocked

Eliminate the dirt or blockage

Steam is too small

1. voltage low

2. pipeline blocked by scale

1.Assemble voltage stabilizer

2.Eliminate the dirt or blockage

Tank deformation

1. Hot water added into the water

tank.

2. Other chemical added into the

water tank.

1. Use continually

2.Replace the tank

Power light works but

no steam comes out

1. Steam generator burns out

2.Inside components fail.

Check and maintain by

professional staff

15

Parameters:

Rated voltage:110V Steam discharge:35g/min

Rated Frequency:50/60Hz Height of whole machine:155cm

Output power:1300W Length of supporting pole:120cm

Water tank capacity:1.4L Steam pipe length:145cm

Packing list

NO.

Parts

Quantity

No.

Parts

Quantity

1

Body

1

7

Clamp

2

2

Water tank

1

8

Instruction

Manual

1

3

Spray head

1

9

Warranty

Card

1

4

Supporting

pole

1

10

glove

1

5

Hanger with

hook

1

11

Base

1

6

Fabric Brush

1

12

Screws for

the base

2

Table of contents

Other SteamandGo Steam Cleaner manuals