Steamist DSC-425 User manual

3

START

STOP

TIME

TEMP

SENSOR HEAT

2

1

6

TIME / TEMP

4 5

Installation and Operating Instructions

C US

®

02/09 Pub. No. 120-F

- 1 -

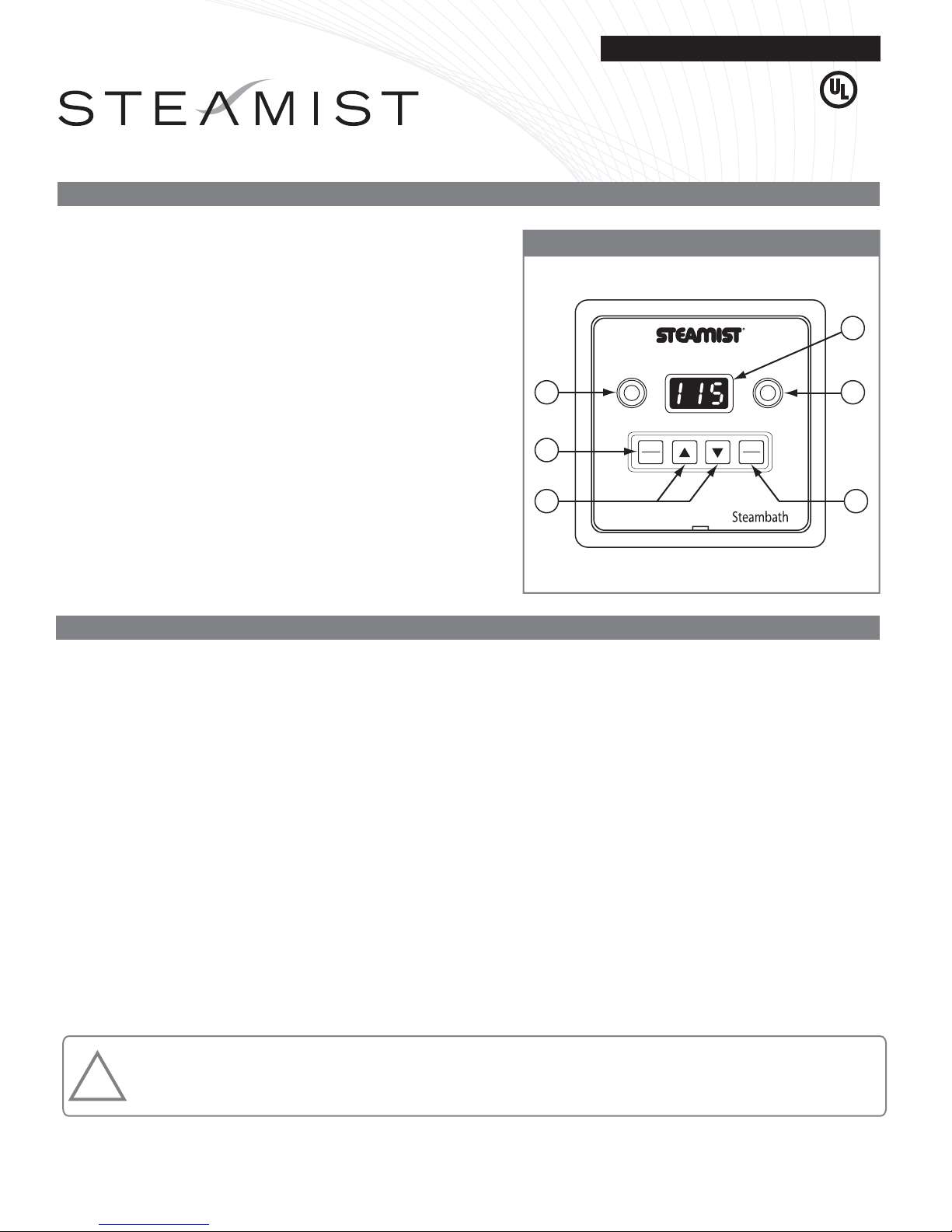

Control Features

1. Temperature Sensor: Measures temperature inside

steamroom.

2. Temperature/Timer Display: Counts down remaining

minutes and shows programmed minutes, set temperature,

and room temperature.

3. Heat Light: Indicates the generator is producing steam when

illuminated. The heater in the generator and the heat light

will cycle ON/OFF as the temperature is maintained

automatically in the steamroom.

4. Increase/Decrease, Temperature and Timer Set Keypads:

Press for a second to view the previously selected time/temp.

Press and hold to program the desired minutes or setpoint

temp.

5. Start/Stop Keypad: Press to start programmed cycle, press

again to cancel cycle.

6. Time/Temp Keypad: Press to select between time and

temperature.

Steambath Control

Installation Instructions

Model: DSC-425

DSC-425 Digital Timer and Digital Temperature Control

IMPORTANT: This control MUST be installed inside the steam-

room for proper operation of the system.

The Digital ON/OFF Elapsed Timer/Temp Control is designed

to be connected and operated only with the Steamist SM

Steambath Generator and cannot be used with any other

equipment.

CAUTION: All electrical connections must be performed by a

licensed electrician in accordance with Local and National

Electrical Codes. Power must be OFF until all wiring is complete.

1. Remove the cover from the Steambath Generator. Insert

multi-conductor cable with strain relief (provided) through

cabinet knockout and secure the cable to the top of the

steambath generator leaving 8" of cable inside the generator.

Remove the protective covering labeled “Remove Before

Installation” from the Telco Jack found on the Circuit Board.

Remove protective cap from plug and insert Steamist cable

into Telco Jack; check that the orientation of the plug properly

aligns with the jack. A snap will indicate the plug is installed

correctly (see Figure 1). Close and secure Generator cover.

NOTE: The DSC-425 Control should be stored in the

protective box until the wall is completed and is ready

to be installed.

2. Select a mounting location inside the steamroom for the

DSC-425 Control, 4 feet above the floor, convenient to

the bather. Do NOT locate in direct line of shower head

spray or above steamhead (see Figure 6). Mount 2

metal, gangable switch boxes, twinned together (not

provided) in this location. Do NOT use a 4x4 electrical

box.

WARNING: Elderly persons, pregnant women, or those suffering from heart disease, high blood pressure, diabetes, or

who are otherwise not in good health, do not use this device unless directed to do so by a physician. Also, do not use

steambath while under the influence of alcohol. For additional Important Safety Information, please see a separate

instruction sheet Pub. No. 199.

!

IMPORTANT: The DSC-425 Controls will only function with one of the following Steamist Generator models: SM-46, SM-79, SM-4,

SM-5, SM-7, SM-8, SM-11, SM-12, SM-15, System-18, System-24, System-30, with or without the InstaMist feature.

®

Protective Covering

“Remove Before

Installation”

Modular Jack Plug

Knockout for

Strain Relief

To Control

¾" Conduit

Coupler

Gasket

Control Cable

to Generator

Installation and Operating Instructions

IMPORTANT: Test Control for operation before installing

face plate.

6. To install Face Plate, peel back the (2) paper liners on

Base Plate to expose adhesive surfaces. Attach Face

Plate to the control.

7. Clean the face and Base Plate Assembly with a damp

cloth after installation to remove all dust, dirt, grime, etc.

Figure 1 Model: DSC-425

Figure 2 - Back of Control

02/09 Pub. No. 120-F

- 2 -

3. Carefully route the other end of the multi-conductor control

cable from the Steambath Generator to the DSC-425 inside

the steamroom. Route multi-conductor cable through a ¾"

conduit to protect the cable from damage and to facilitate

replacement if necessary.

4. Using the knockout either on top or bottom of the switch box,

secure cable with a strain relief fitting (provided). It is

suggested that the strain relief fitting be installed from inside

the switch box so cable may be adjusted. Allow approximately

10" - 12" of cable to extend into the box beyond the strain relief

fitting. Protect control cable by placing it inside the switch box

during construction, with the protective cap installed over the

end (see Figure 3).

5. After the walls are finished you are now ready to wire and

install the DSC-425 Control Digital On/Off Elapsed

Time/Temp.

CAUTION: Electrical Power to the Steambath Generator must be

OFF before making connections.

a) Locate Telco Jack at female coupler, on back of control.

Remove the protective covering labeled “Remove Before

Installation.” Remove protective cap from cable and plug

into jack. Check that the orientation of the plug properly

aligns with the jack. A snap will indicate the plug is installed

correctly (see Figure 2).

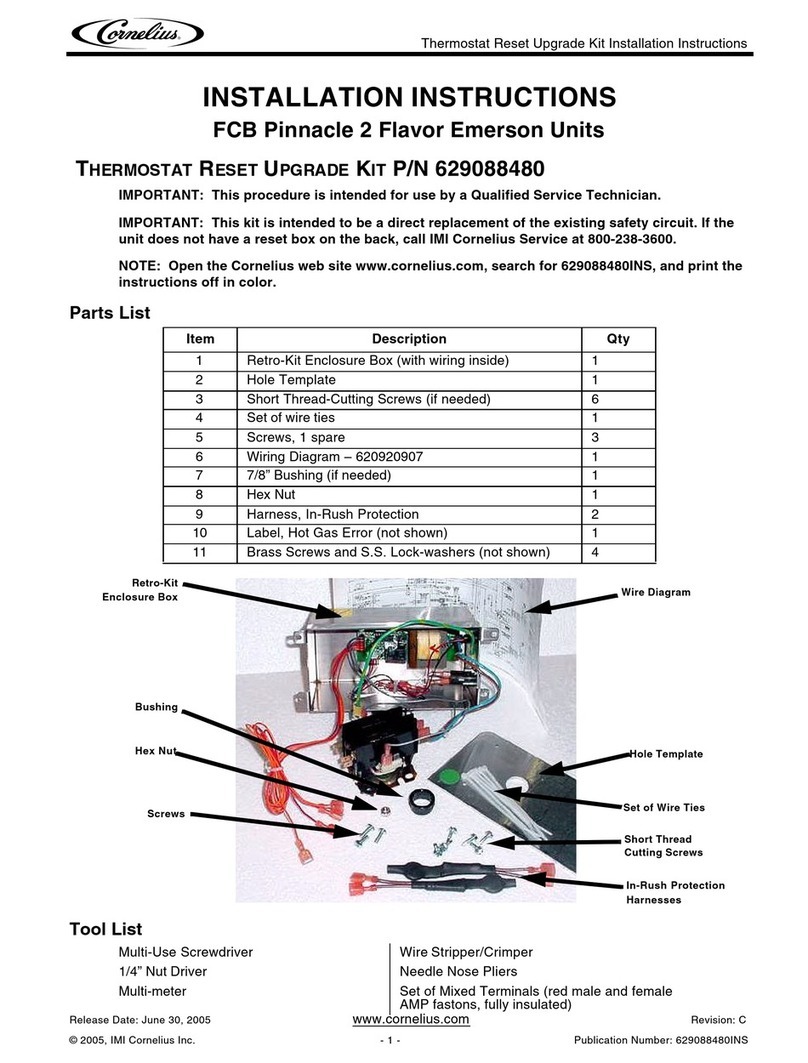

b) Mount Base Plate Assembly to the switch box using No.

6-32 x 2" S/S SCREWS (supplied in the plastic mounting

hardware bag).

IMPORTANT: DSC-425 Control MUST be mounted inside

the steamroom. Silicone sealant (supplied) MUST be used

to form a watertight seal to the wall.

Face Plate

Base Plate

#6-32 x 2" Long

Stainless Steel

Screw, 4 Places

Double-Sided

Adhesive Tape

2 Places

Reverse

Strain Relief

Coupler

IMPORTANT: Run the Control Cable through a ¾" Conduit.

To Generator

ENOCILIS

RAELC

.

ZO

.

LF2

/

1t

e

N02

5

13

.

o

N

me

t

I

.

A

.S.

UNI

EDAM

1/2"

Aromatherapy

Reservoir

Back Plate

O-Ring MUST

seal to inside of

the Back Plate

Cover Plate

Center Hub

3/4" NPT

(Brass Pipe)

Must use

sealant tape

Apply silicone around

the back edge of Back

Plate to seal and

prevent movement

3/8" Hex Key

Hole

Apply silicone

around the steam

pipe to form a

watertight seal

Apply a small amount

of silicone to prevent

movement IMPORTANT:

Install top first

MUST be vertical

After inserting the top,

snap in the bottom

Figure 5

the steamhead O-ring is fully seated into the Back Plate. If

the nipple is sticking out too far the O-ring will not make a

proper seal and the nipple must be adjusted.

5. Apply a small amount of silicone at the back center point of

the Cover Plate. This will aid in preventing movement of

this plate (see Figure 5).

6. Place the Cover Plate over the Center Hub. This is

accomplished by first hooking the top and then snapping

the bottom into place.

7. Adjust the Back Plate and Cover Plate to line up squarely,

and clean excess silicone with rubbing alcohol.

Installation and Operating Instructions

Figure 3 Model: DSC-425

02/09 Pub. No. 120-F

- 3 -

IMPORTANT: Apply Silicone around the edge of the control to

form a watertight seal to the wall (see Figure 4).

Cleaning Instructions: Use a damp cloth and mild soap. Do

NOT use abrasive cleaners which might scratch the surface or

the base of the control.

Installation Instructions for Steamhead & Center Hub

1. Make sure the 3/4" nipple protrudes beyond the tile

approximately 1/2" (see Figure 5).

2. Wrap the nipple with pipe sealant tape.

3. Put a bead of silicone around the outer edge of the Back

Plate (see Figure 5) and center the Back Plate over the

pipe in an upright position. While holding it in place screw

the Center Hub onto the nipple, using a ⅜" Hex Key to

tighten.

4. The Center Hub MUST be aligned with the four walls in the

vertical and horizontal position (see Figure 6). Make sure

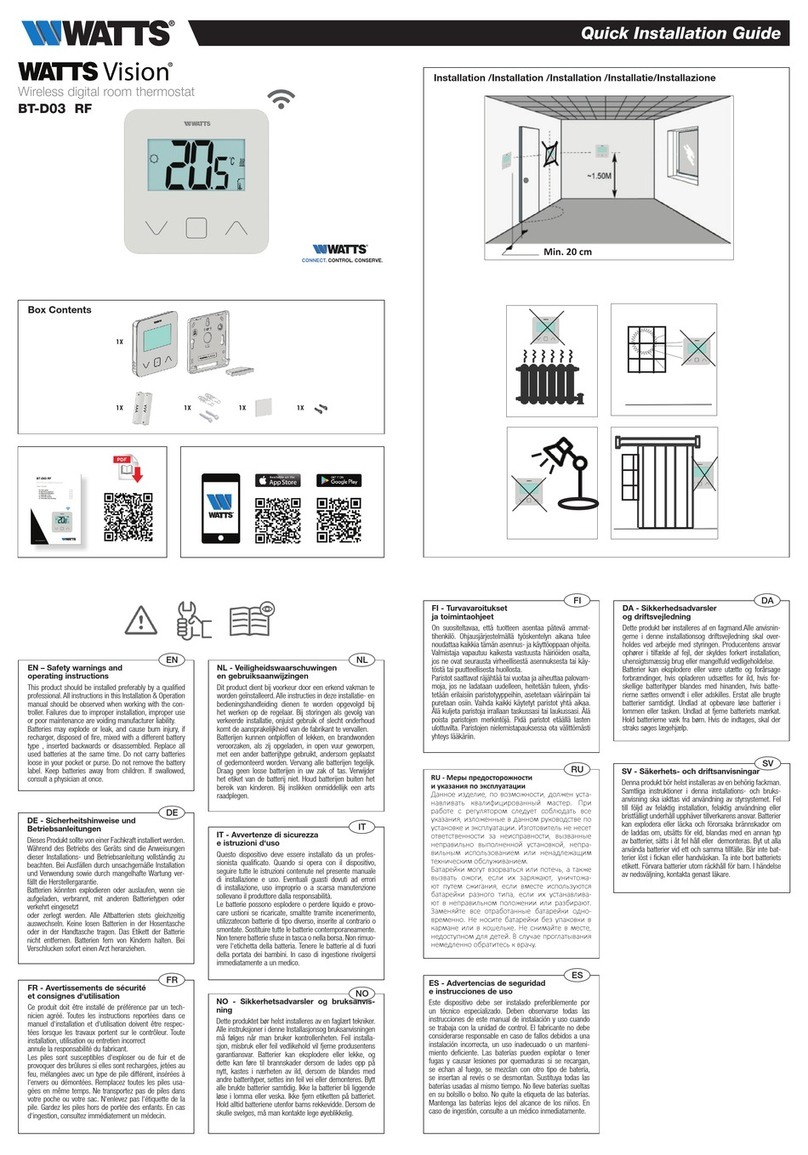

Figure 4

All Instructions must be given to the homeowner for future use.

START

STOP

TIME

TEMP

SENSOR HEAT

Typical location of the DSC-425

Control. Locate away from the

direct line of shower spray and do

NOT locate above steamhead.

Steamhead Installation

Steamhead should be mounted 18"

above the finished floor or 6" above

the rim of the tub as far from the

bather as possible

Installation and Operating Instructions

IMPORTANT: Although the control is low voltage, power to the

generator must be switched off before servicing electrical

connections.

Operation: Simply press the Start/Stop keypad to begin the

previously programmed cycle. Pressing the Start/Stop keypad a

second time will cancel the cycle. After a cycle is started it will

take a few minutes for the Steam Generator to heat up and begin

producing steam.

During operation the display will flash between the remaining

time for 15 seconds and the ambient temperature for 45

seconds. A colon (:60) is displayed to indicate time, and no colon

indicates temperature. The heat light will cycle on and off as the

temperature is maintained.

Programming: There are several ways to program this control.

Adjustments can be made while the system is active and while it

is off. At any time the time or temperature is displayed, it can be

Operating Instructions

Additional Features

Model: DSC-425

Figure 6

02/09 Pub. No. 120-F

- 4 -

adjusted by simply pressing the Up or Down keypad. To

display the time or temperature, press the Time/Temp

keypad once or twice until it shows the setting to be

changed. All changes made to the temperature control are

stored in permanent memory until changed again. The

temperature range is 50° to 130°F (10° to 55°C). The timer,

however, has both temporary and permanent memory. Any

adjustments made to the timer while the system is active

will be stored in temporary memory for that cycle only. Any

adjustments made to the timer while the system is off are

stored in permanent memory. The temporary memory

allows you to make adjustments to the time in accordance

to your needs for that day without affecting the permanently

stored time. The timer range is from :01 to :60 minutes

Cleaning Instructions:

Use a damp cloth and mild soap.

Do NOT use abrasive cleaners which might scratch the

surface or the base of the control.

Memory: The memory for both the time and temperature is

retained even if there is a power failure.

Fahrenheit/Celsius: The temperature display may be changed

to Fahrenheit or Celsius by simultaneously pressing and holding

the Up and Down keypad for 5 seconds while the system is off.

The display will show the current setting “F” or “C” and then

alternate when the change is complete.

Error Messages:

This control is programmed with a diagnostic

feature to help isolate any potential problems. Error messages

E0, E1, E2 and E3 indicate a problem internal to the

control. If this occurs, the contorl must be replaced or

repaired. Error messages E4, E5 and E6 indicate a

communication problem with the Steam Generator. If this

error occurs, check both ends of the control cable for clean,

dry and secure connections. Dirty contacts can be cleaned

with alcohol and a cotton swab or a toothbrush. This can

also happen if the control is not sealed and the cable

connections get wet.

East Coast Office: 25 E. Union Ave., East Rutherford, NJ 07073 • Tel: 800-577-6478 • Fax: 201-933-0746

West Coast Office: 315 W. Pondera St., Suite F, Lancaster, CA 93534 • Tel: 800-355-6478 • Fax: 661-940-1617

®