12

TO START ENGINE

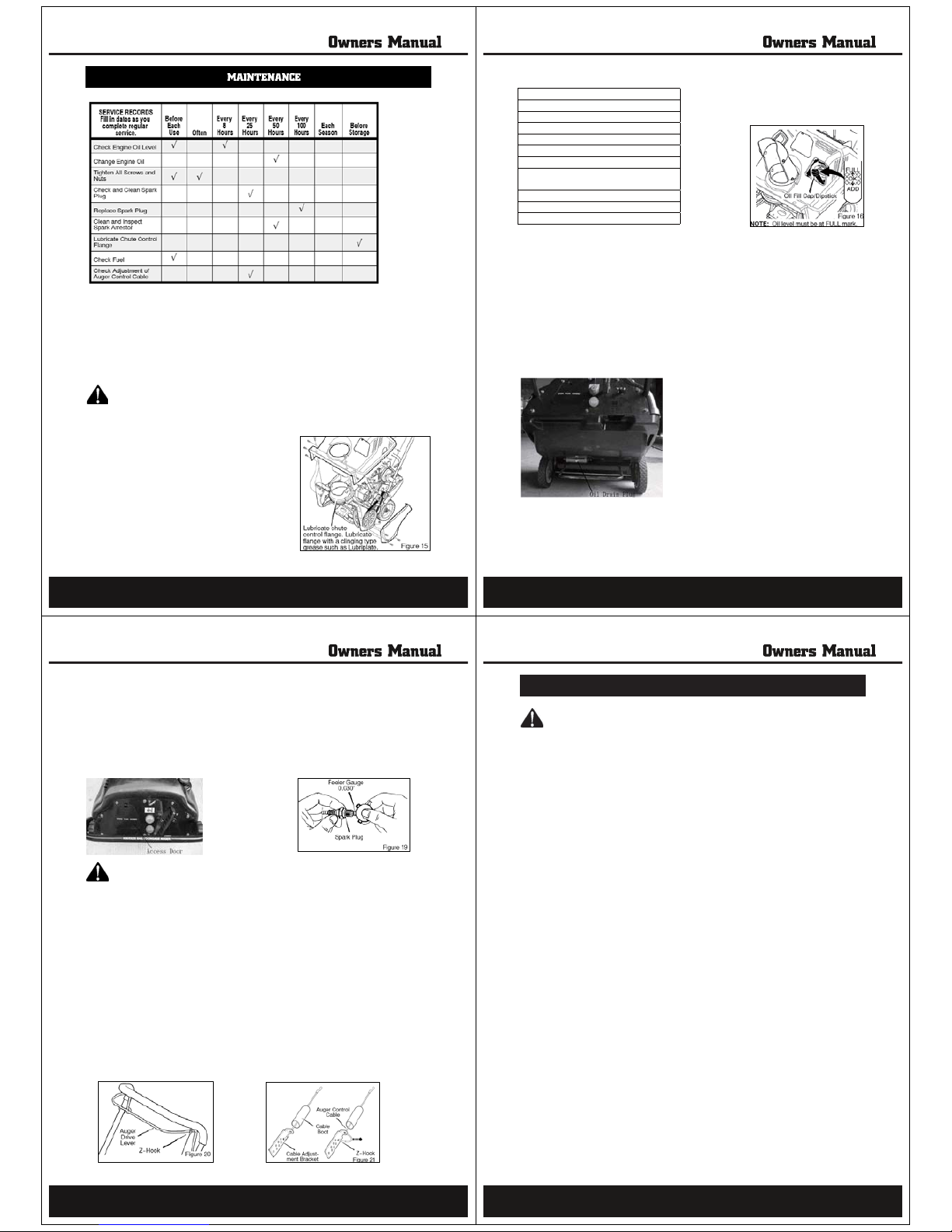

Be sure that engine oil is at FULL mark on the oil fill cap/dipstick.The snow thrower engine is equipped with a

120 volt A.C.electric starter and recoil starter. Before starting the engine, be certain that you have read the

following information.

If engine floods, set the choke to the OPEN/RUN position and crank until the engine starts.

WARNING: The electric starter is equipped with a three-wire power cord and plug designed to

operate on 120 volt AC house hold current. The power cord must be properly grounded at all times

to avoid the possibility of electric shock which can cause injury to the operator. Follow all

instructions carefully Make sure your house has a three-wire grounded system. If you are not sure, ask a

licensed electrician. If your house does not have a three-wire grounded system, do not use this electric

starter under any condition.

If your house has a three-wire grounded system but a three hole receptacle is not available to connect

the electric starter, have a three-hole receptacle installed by a licensed electrician.

WARNING: To connect a 120 volt power cord,always connect the power cord first to the switch

box located on the engine and then plug the other end into a three-hole grounded receptacle.

WARNING: To disconnect the power cord, always unplug the end connected to the threehole

grounded receptacle first.

How To Start A Cold Engine

1. Be sure auger drive and traction drive levers are in the disengaged (RELEASED) position.

2. Pull the choke knob to the CHOKE position.

3. (Electric Start) Plug the power cord into the

4. Push the primer button as specified below.Remove finger from primer button between pushes.

Push two times if temperature is 15 F (-9 C) or higher.

Push four times if temperature is below 15 F (-9 C).

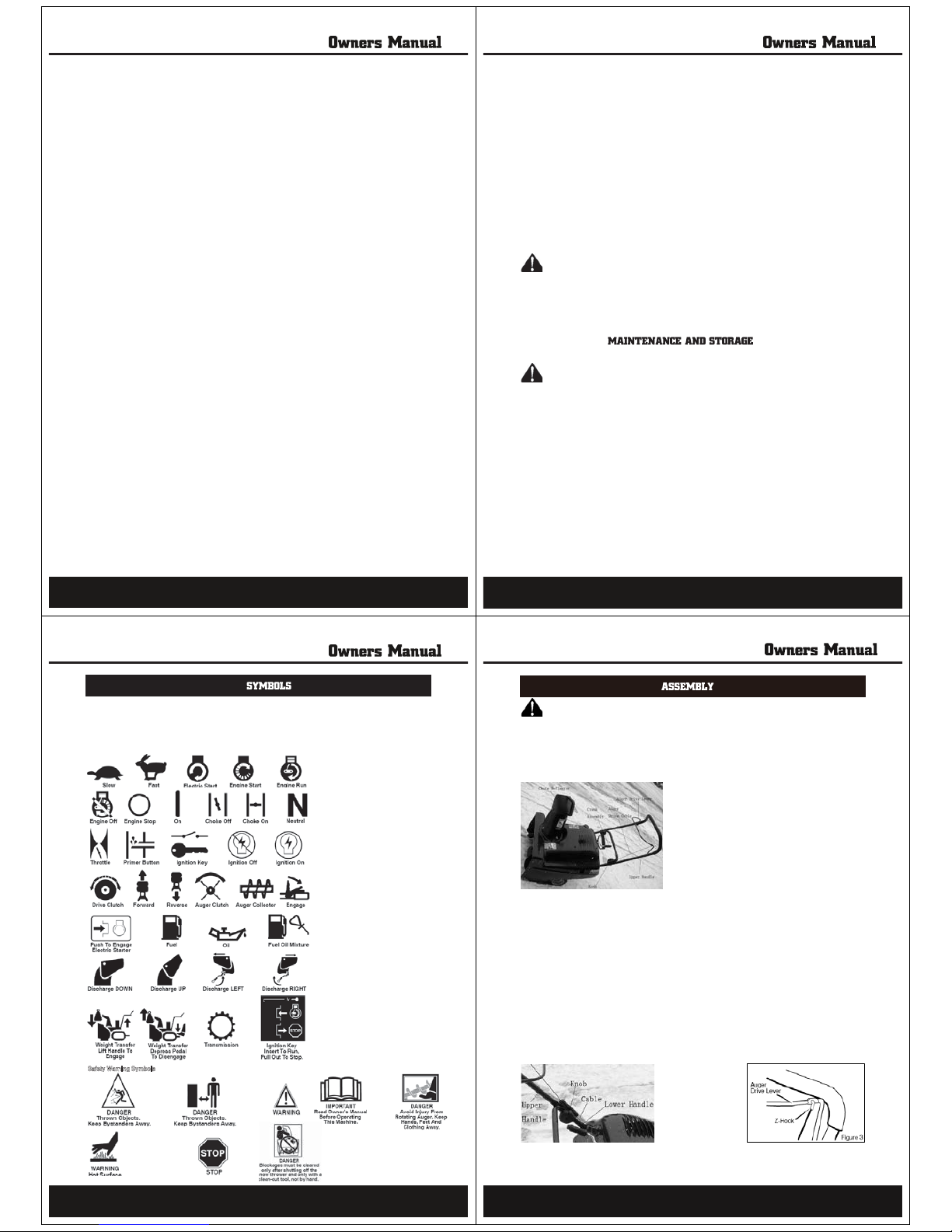

Figure 9

Primer Button

5. (Electric Start) Turn the key to the START position (see

Figure 10). To prolong the life of the starter, do not crank

for more than 5 seconds at a time. Wait one minute

between starts to allow the starter motor to cool.

6. (Recoil Start) Turn the key to the ON position (see

Figure 10). Slowly pull the recoil starter handle until resistance is felt and then pull rapidly to start the engine. Do

not allow the recoil starter handle to snap back. Slowly return the recoil starter handle.

starter

motor on the engine. Plug the other end of power

cord intoa three-hole, grounded 120 VOLT,

AC receptacle.

13

WARNING: Rapid retraction of the starter cord (kickback) will pull your hand or arm toward the

engine faster than you can let go of the starter cord. This can result in entangled hair or clothing,

broken bones, bruises, traumatic amputation or severe lacaration.

Do not crank the engine with the spark plug removed.Make sure the spark plug, muffler, fuel cap and hous-

ing are in place and firmly secured by the equipped fasteners.

When starting the engine, slowly pull the starter cord until resistance is felt. Then, rapidly pull the starter

cord.

Make sure components; such as impellors, pulleys or sprockets, are securely attached.

7. If the engine does not start in 5 or 6 tries, See Difficult Starting in the “Troubleshooting Table”.

Figure 11

Pull starter handle rapidly.

8. Allow the engine to warm up for several minutes. As the engine warms up, adjust the choke knob toward the

RUN position. Wait until the engine runs smoothly before each choke adjustment.

NOTE: Do not lose the safety/ignition key. Keep the safety/ignition key is a safe place. The engine will

not start without the safety/ignition key.

How To Start A Warm Engine

If restarting a warm engine after a short shutdown, leave the choke lever in the off position and do not push the

primer button. If the engine fails to start, follow the Cold Start instructions.

WARNING: Never run engine indoors or in enclosed,poorly ventilated areas. Engine exhaust conta-

ins CARBON MONOXIDE, AN ODORLESS AND DEADLY GAS. Keep hands, feet, hair and loose

clothing away from any moving parts onengine and snow thrower.

Engine parts, especially the muffler, become extremely hot. Severe thermal burns can occur on con-

tact. Allow the engine to cool before touching.

Never allow children to operate the snow thrower.Never allow adults to operate the snow blower with-

out proper instruction.

Keep the area of operation clear of all persons, particularly small children and pets.

Never leave the snow blower unattended while the engine is running. Anyone operating the engine or

equipment must carefully read and understand the operating instructions.

IMPORTANT: After each use of the snow blower, stop the engine, remove the safety/ignition key, remove

all accumulated snow from the snow blower and wipe clean. Store the snow blower in a

protected area.

NOTE: Never cover snow blower while engine and exhaust area are still warm.

9. (Electric Start) First disconnect power cord from receptacle. Then, disconnect the power cord from the starter

motor.

If after following the preceding instructions, your engine fails to start, have the engine checked by a Service Centre.

Frozen Starter

If the starter is frozen and will not turn the engine, follow the steps below.

1. Pull as much starter rope as possible out of the starter.

2. Release the starter handle and let it snap back against the starter. Repeat until the engine starts. Warm

engines will cause condensation in cold weather. To prevent possible freeze--up of recoil starter and engine

controls, proceed as follows after each snow removal job.

1. With engine off, allow engine to cool for several minutes.

2. Pull starter rope very slowly until resistance is felt, then stop. Allow the starter rope to recoil. Repeat three

times.

3. With the engine not running, wipe all snow and moisture from the carburetor cover in area of controls and

levers. Also, move the choke control and starter handle several times.

WARNING: Never run engine indoors or in enclosed, poorly ventilated areas. Engine exhaust

contains CARBON MONOXIDE, AN ODORLESS AND DEADLY GAS. Keep hands, feet, hair and loose

clothing away from any moving parts onengine and

snow thrower.

1. Engine parts, especially the muffler, become extremely hot. Severe thermal burns can occur on

contact. Allow the engine to cool before touching.

2. Never allow children to operate the snow thrower. Never allow adults to operate the snow thrower

without proper instruction.

3. Keep the area of operation clear of all persons, particularly small children and pets.

4. Never leave the snowthrower unattended while the engine is running. Anyone operating the engine

or equipment must carefully read and understand the operating

instructions.

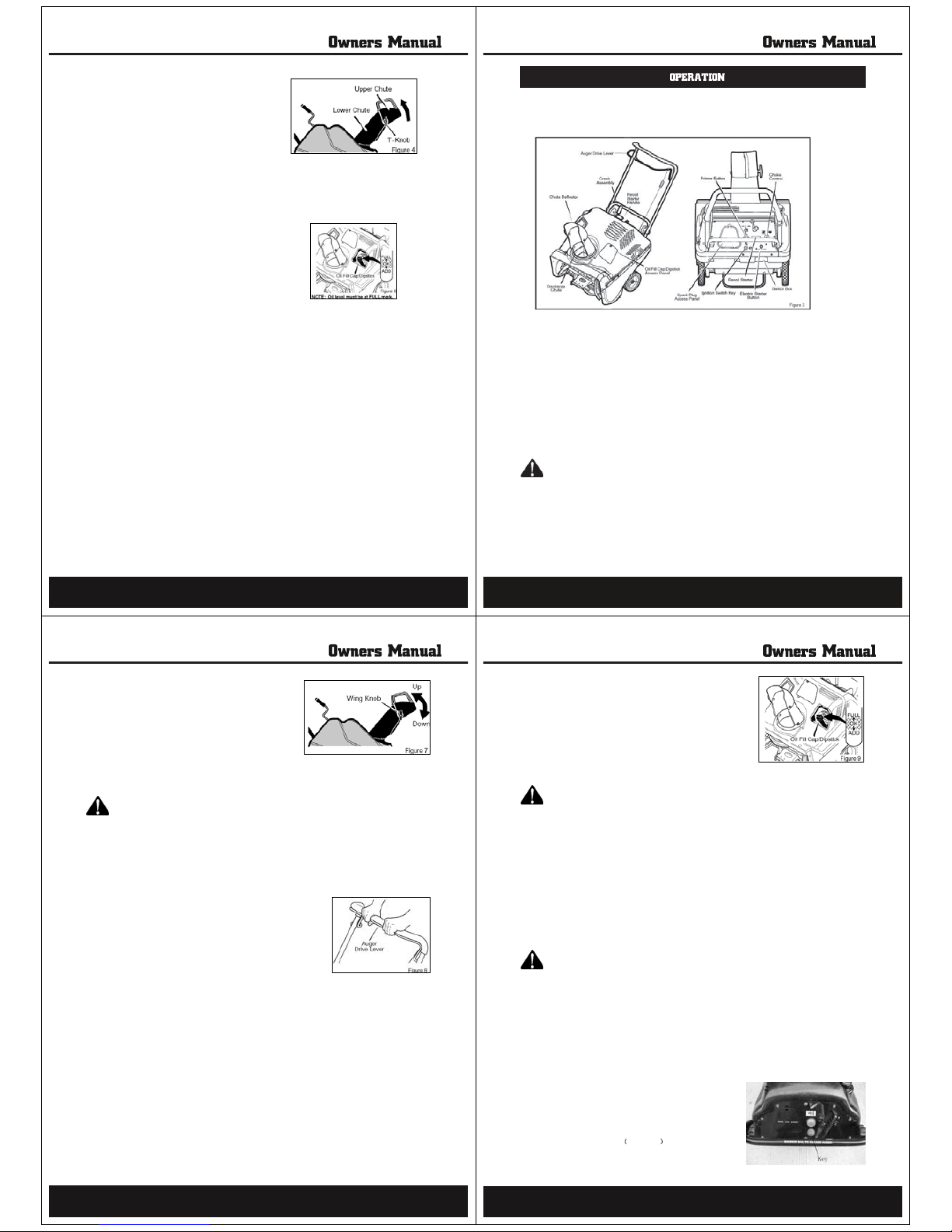

HOW TO CLEAR A CLOGGED DISCHARGE CHUTE

WARNING: Hand contact with the rotating impeller inside the discharge chute is

the most common cause of injury associated with snow throwers. Never use your hand to clean out the

discharge chute.

To Clear The Chute:

1. SHUT OFF THE ENGINE!

2. Wait 10 seconds to be sure that the impeller blades have stopped rotating.

3. Always use a clean-out tool, not your hands.

Use a clean-out tool to remove snow from the auger housing.

1. Release the auger drive lever.

2. Pull out the key.

3. Disconnect spark plug wire.

4. Do not place your hands in the auger or discharge chute. Use a clean-out tool to remove snow or debris.

WARNING: Blockage must be cleared only after shutting off the snow thrower and only with a

clean-out tool, not by hand.

14

SNOW THROWING TIPS

1. When the handle is raised, the auger blades will engage the ground and the snow thrower will move forward.

When the auger drive lever is released, the auger blades will stop.

2. Most efficient snow throwing is accomplished when the snow is removed immediately after if falls.

3. Let the engine (motor) and the snow thrower adjust to outdoor temperature before starting to clear snow.

4. For complete snow removal, slightly overlap each previous path.

5. Whenever possible, discharge the snow down wind.

6. The distance the snow will be discharged can be adjusted by moving the discharge chute deflector. Raise

the deflector for more distance or lower the deflector for less distance.

7. In windy conditions, lower the chute deflector to direct the discharged snow close to the ground where it is

less likely to blow into unwanted areas.

8. For safety and to prevent damage to the snow thrower, keep the area to be cleared free of stones, toys and

other foreign objects.

9. When clearing snow from crushed rock or gravel driveways, do not allow the auger blades to contact the

driveway. Move the handle down to slightly raise the auger blades.

10. The forward speed of the snow thrower is dependent on the depth and weight of the snow. Experience will

establish the most effective method of using the snow thrower under different conditions.

11. After each snow throwing job, allow the engine to run for a few minutes. The snow and accumulated ice will

melt off the engine.

12. Clean the snow thrower after each use.

13. Remove ice, snow and debris from the entire snow thrower. Flush with water to remove all salt or other

chemicals. Wipe snow thrower dry.

DRY AND AVERAGE SNOW

1. Snow up to eight inches deep can be removed rapidly and easily by walking at a moderate rate. For snow or

drifts of a greater depth, slow your pace to allow the discharge chute to dispose of the snow as rapidly as the

auger receives the snow.

2. Plan to have the snow discharged in the direction the wind is blowing.

WET PACKED SNOW

Move slowly into wet, packed snow. If the wet, packed snow causes the auger to slow down or the discharge

chute begins to clog, back off and begin a series of short back and forth jabs into the snow. These short back

and forth jabs, four to six inches, will “belch” the snow from the chute.

SNOW BANKS AND DRIFTS

In snow of greater depth than the unit, use the same “jabbing” technique described above. Turn the discharge

chute away from the snow bank. More time will be required to remove snow of this type than level snow.

15