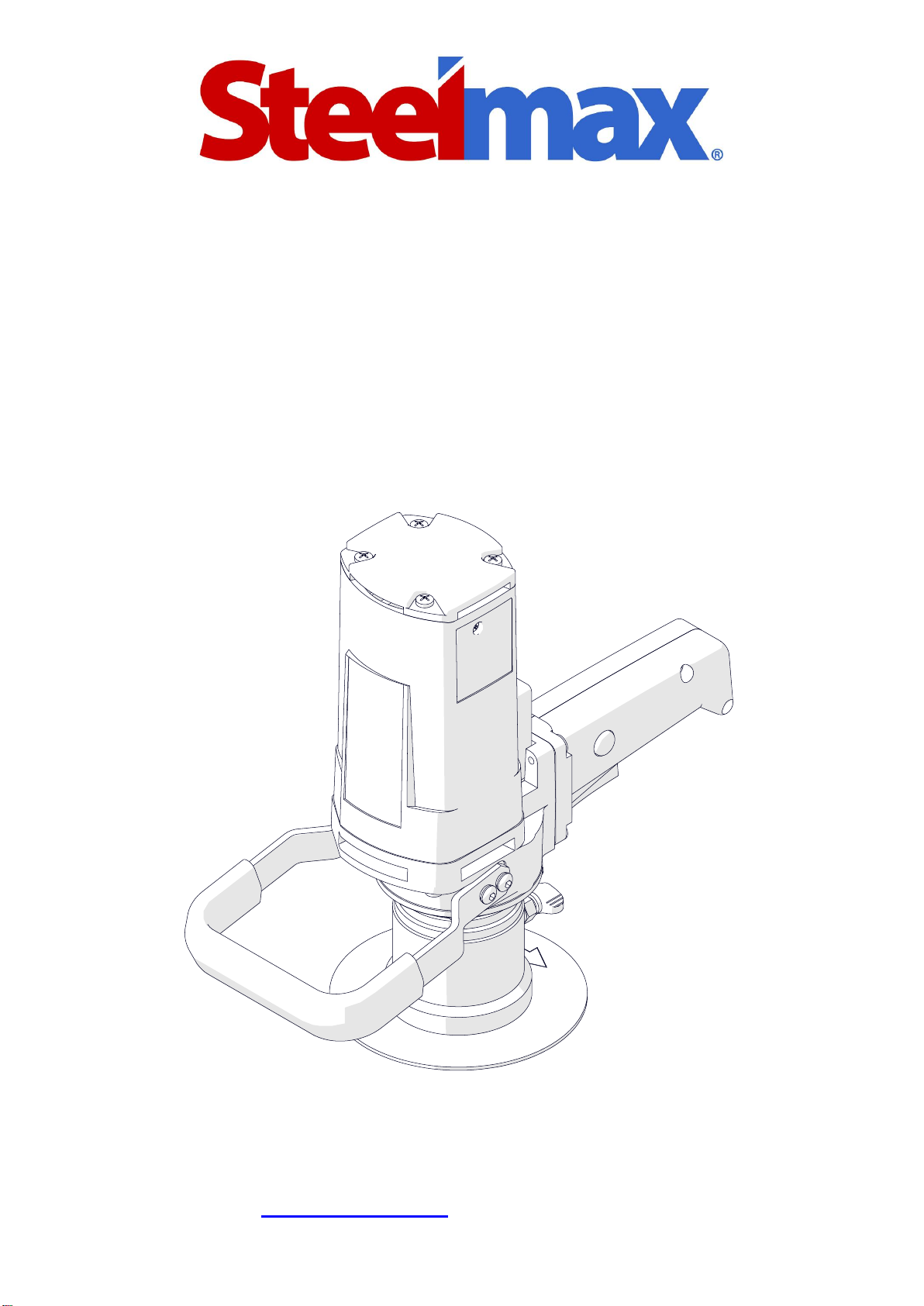

SteelMax BM-7 User manual

The tools of innovation.

15335 E. Fremont Drive, Centennial, CO 80112

1–87STEELMAX, FAX 303–690–9172

www.steelmax.com [email protected]

OPERATOR’S MANUAL

B

BM

M-

-7

7

BEVELING MACHINE

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Equipment included ................................................................................................... 4

1.4. Dimensions................................................................................................................ 5

1.5. Design ....................................................................................................................... 6

2. SAFETY PRECAUTIONS.................................................................................................. 7

3. STARTUP AND OPERATION........................................................................................... 9

3.1. Installing and removing the cutting inserts.................................................................. 9

3.2. Installing and removing the milling head ...................................................................10

3.3. Adjusting the bevel width ..........................................................................................12

3.4. Adjusting the guide for beveling with radius ..............................................................12

3.5. Operating..................................................................................................................13

3.6. Replacing the brushes ..............................................................................................14

4. ACCESSORIES...............................................................................................................15

4.1. Radius insert positioner.............................................................................................15

4.2. Anti-scratch guide sticker..........................................................................................16

4.3. Milling tools...............................................................................................................16

5. SPARE AND WEARING PARTS......................................................................................17

6. WIRING DIAGRAM..........................................................................................................18

7. DECLARATION OF CONFORMITY.................................................................................19

8. EXPLODED DRAWINGS AND PARTS LIST....................................................................20

9. WARRANTY CARD..........................................................................................................24

BM-7

BM-7 Operator’s Manual

3

1. GENERAL INFORMATION

1.1. Application

The BM-7 is a beveling machine designed to bevel plates and pipes made of steel or

aluminum alloys.

Depending on the milling head, the machine allows you to bevel at the angle of 30°

or 45°. The minimum workpieces thickness is 1.5 mm (1/16″). The maximum bevel

width is 7mm (9/32″). The included milling head allows you to bevel at the angle of

45°. Radius inserts allow you to bevel with a radius of 2, 3, 4, or 5 mm. The minimum

diameter of a hole to be machined is 35 mm (1-3/8″).

An optional milling heads allow you to machine holes with diameters of at least

22.5 mm (7/8″). A sticker protects aluminum workpieces from scratches.

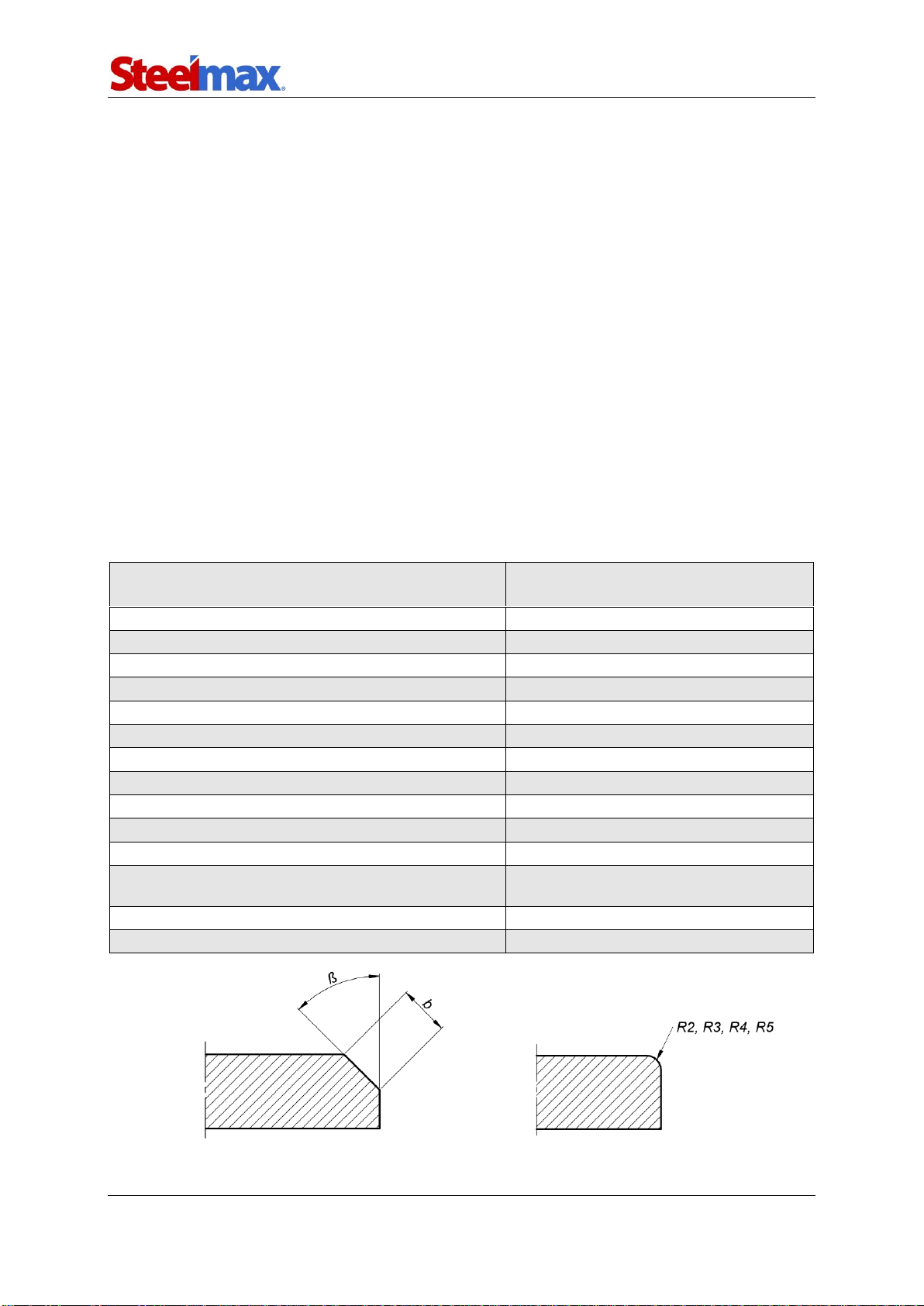

1.2. Technical data

Voltage

1~ 110–120 V, 50–60 Hz

1~ 220–240 V, 50–60 Hz

Power

1080 W

Rotational speed without load

6200 rpm

Rotational speed with load

3200 rpm

Protection level

IP 20

Protection class

I

Maximum bevel width (b)

7 mm (9/32″, Fig. 1)

Bevel angle (ß, depends on the milling head)

30° (option), 45° (Fig. 1)

Minimum workpiece thickness

1.5 mm (1/16″)

Minimum hole diameter

22.5 mm (7/8″, option), 35 mm (1-3/8″)

Edge radius

2 mm, 3 mm, 4 mm, 5 mm (Fig. 1)

Noise level

More than 70 dB

Vibration level

Machine harmful for health.

Take periodic breaks during work.

Required ambient temperature

0–40°C (34–104°F)

Weight

6.1 kg (13 lbs)

Fig. 1. Bevel dimensions

BM-7

BM-7 Operator’s Manual

4

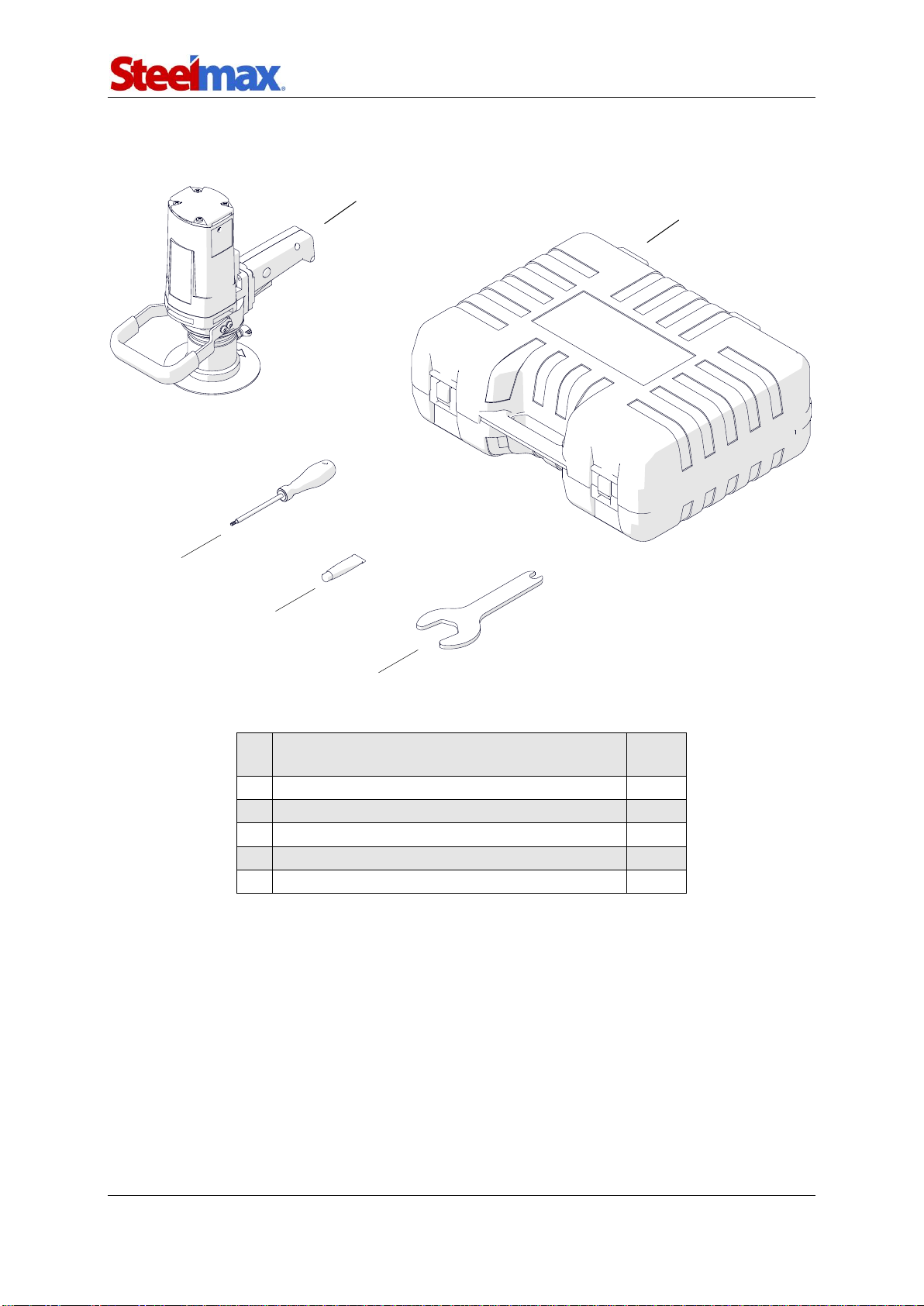

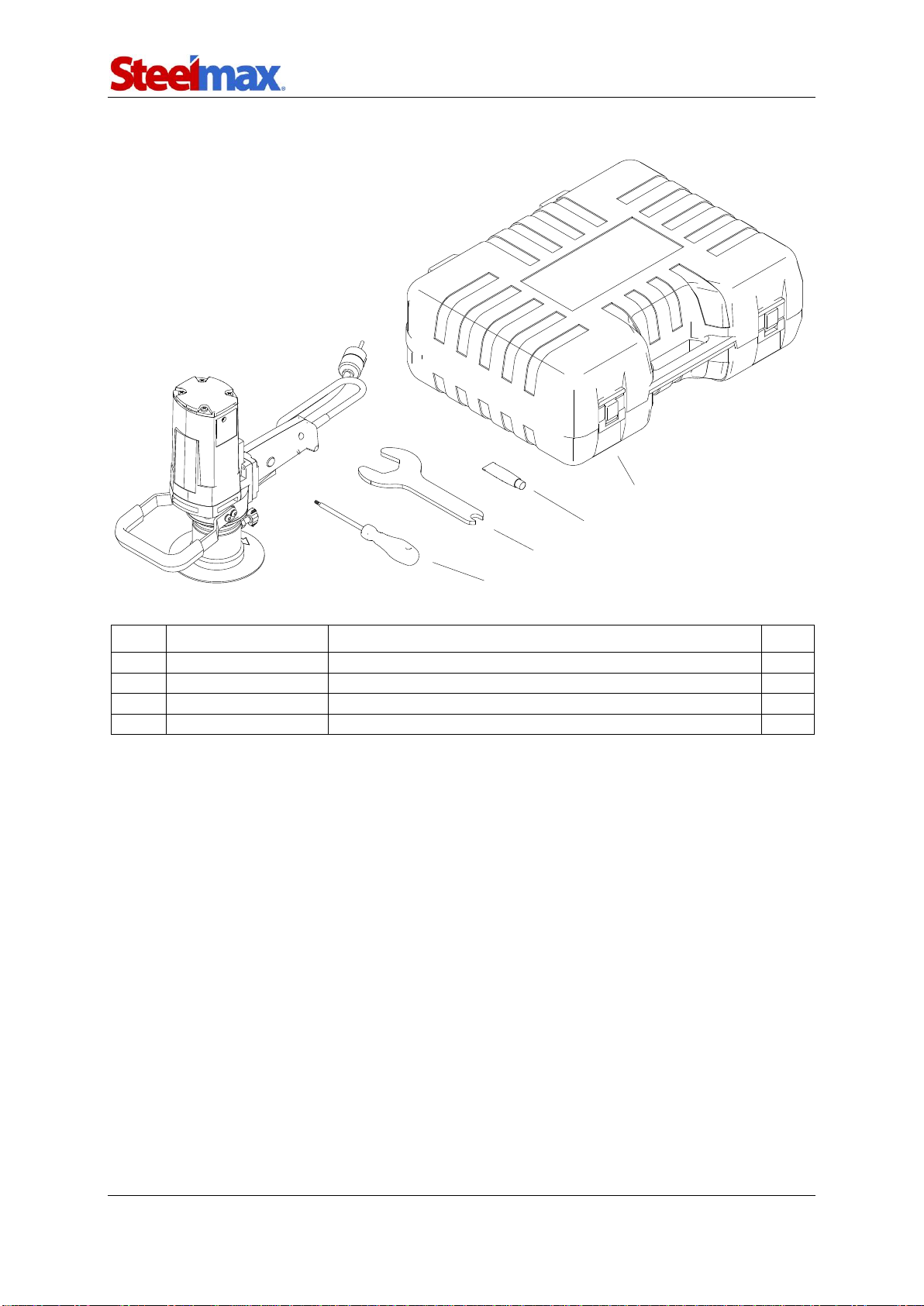

1.3. Equipment included

1

Beveling machine (includes 45° milling head

with Ø35 mm roller, without cutting inserts)

1 unit

2

Plastic box

1 unit

3

Special flat wrench

1 unit

4

Grease for screws 5 g (0.2 oz)

1 unit

5

Torx T15 screwdriver

1 unit

–

Operator’s Manual

1 unit

3

1

2

4

5

BM-7

BM-7 Operator’s Manual

5

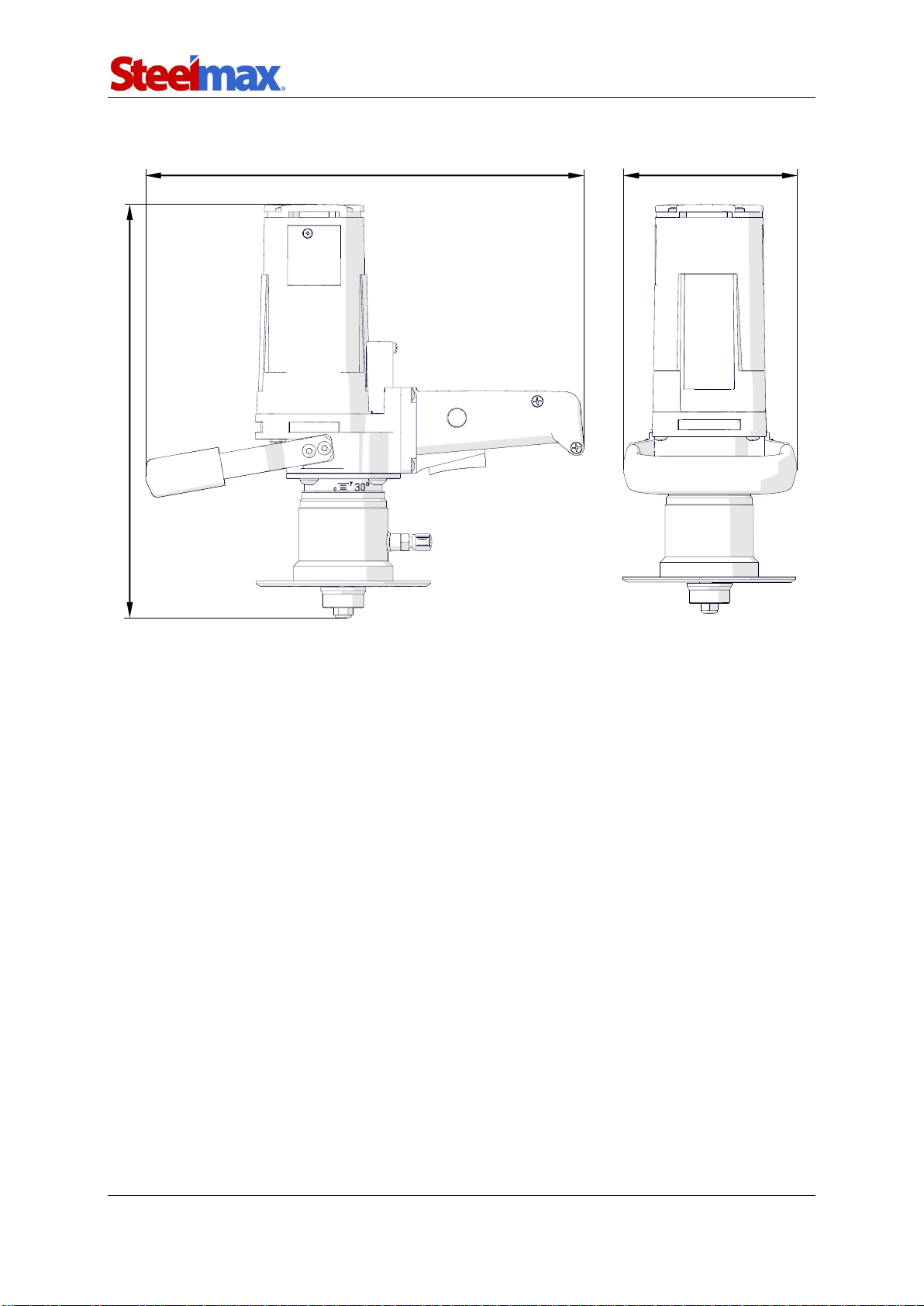

1.4. Dimensions

339 mm (13-11/32″)

319 mm (12-9/16″)

135 mm (5-5/16″)

BM-7

BM-7 Operator’s Manual

6

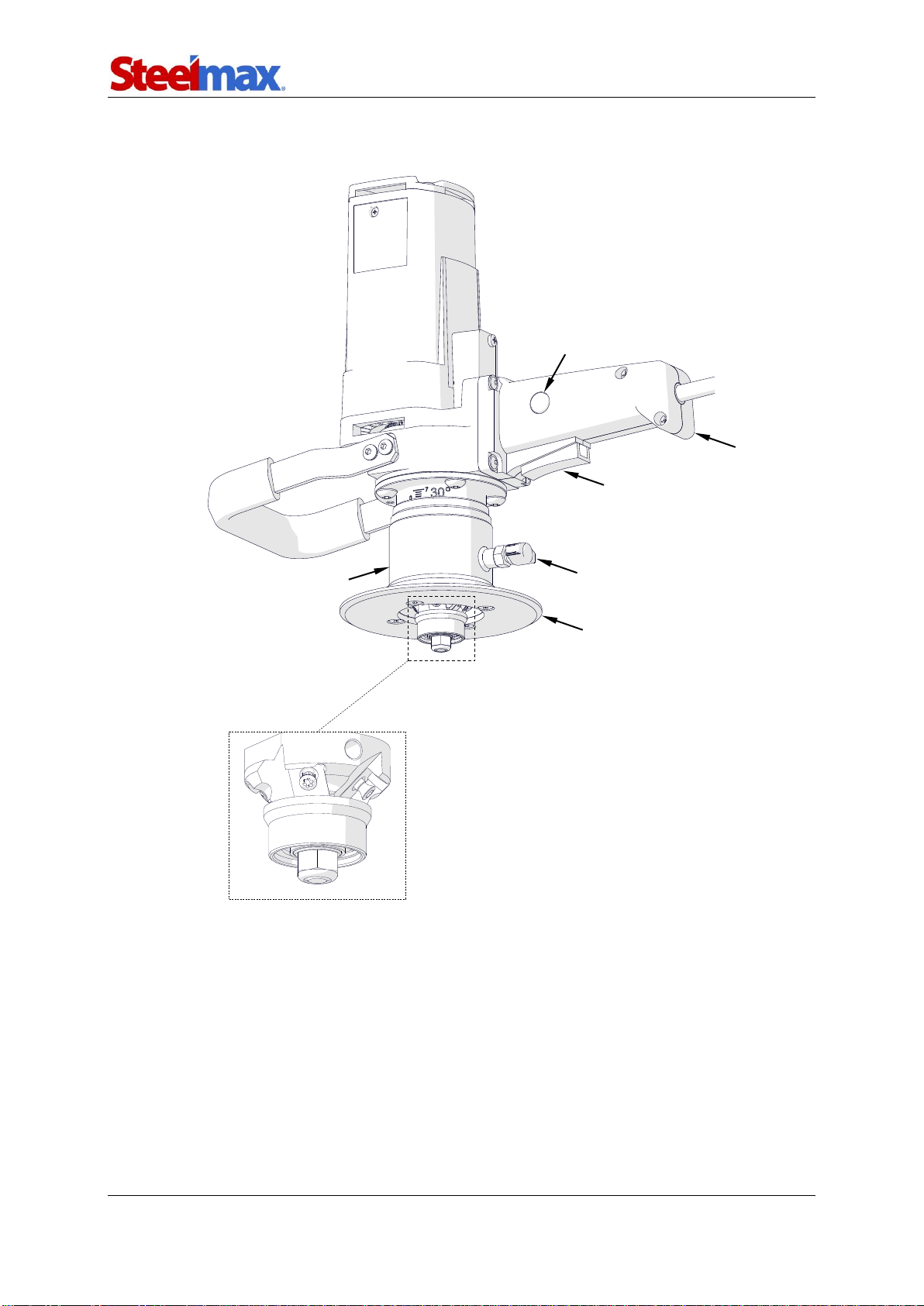

1.5. Design

45° milling head with Ø35 mm roller

Handle

ON/OFF switch

Clamping screw

Guide

Sleeve

Switch lock

BM-7

BM-7 Operator’s Manual

7

2. SAFETY PRECAUTIONS

1. Before use, read this Operator’s Manual and complete a training in occupational

safety and health.

2. Use only in applications specified in this Operator’s Manual.

3. Make sure that the machine has all parts and they are genuine and not damaged.

4. Make sure that the specifications of the power source are the same as those

specified on the rating plate.

5. Do not carry the machine by the cord and do not pull the cord. This can cause

damage and electric shock.

6. Keep untrained bystanders away from the machine.

7. Before each use, ensure the correct condition of the machine, power source,

power cord, plug, control parts, and tools.

8. Before each use, make sure that no part is cracked or loose. Make sure to

maintain correct conditions that can have an effect on the operation of the

machine.

9. Keep the machine dry. Do not expose the machine to rain, snow, or frost.

10. Keep the work area well lit, clean, and free of obstacles.

11. Do not use near flammable materials, or in explosive environments.

12. Use only tools specified in this Operator’s Manual.

13. Do not use tools that are dull or damaged.

14. Make sure that the cutting inserts and the milling head are correctly attached.

Remove wrenches from the work area before you connect the machine to the

power source.

15. Do not use the machine so that the milling head is up.

16. If the cutting edge of an insert is worn, turn all inserts by 90°. If all cutting edges

are worn, install new inserts specified in this Operator’s Manual.

17. Use eye and ear protection, non-skid footwear, and protective clothing. Do not use

loose clothing.

18. Do not touch chips or moving parts. Do not let anything catch in moving parts.

19. After each use, clean the machine and the milling head with a dry cotton cloth

and no chemical agents. Do not remove chips with bare hands.

20. Maintain the machine and install/remove parts and tools only after you unplug the

machine from the power source.

BM-7

BM-7 Operator’s Manual

8

21. Repair only in a service center appointed by the seller.

22. If the machine falls, is wet, or has any damage, stop the work and immediately

send the machine to the service center for check and repair.

23. If you are not going to use the machine, remove it from the work area and keep it

in a safe and dry place.

24. If you are not going to use the machine for an extended period, put anti-corrosion

material on the steel parts.

BM-7

BM-7 Operator’s Manual

9

3. STARTUP AND OPERATION

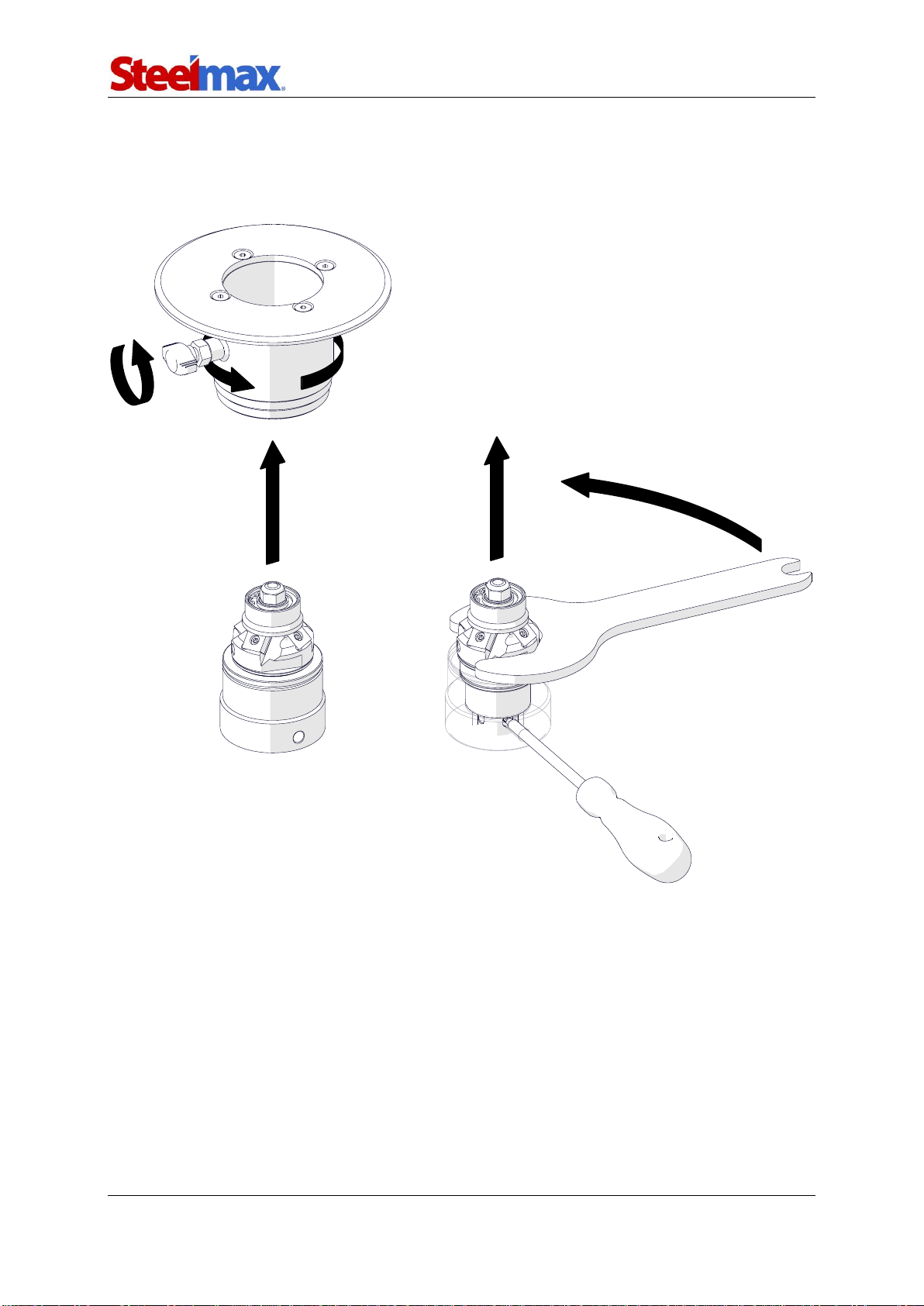

3.1. Installing and removing the cutting inserts

Unplug the power cord. Loosen the screw (1) and then turn the sleeve (2) to lower it

as far as possible and get access to the milling head. Use the special wrench (3) to

loosen the roller, and then use the screwdriver (4) to remove the cutting inserts. Clean

the sockets.

To change the cutting edge, turn the inserts by 90°, push them to the sockets, and

tighten the inserts and the roller. If all cutting edges are worn, install new inserts. Make

sure that the bottom of each insert is in full contact with the socket (5).

Each week clean the threads of the mounting screws for inserts and put the

supplied grease on the threads.

2

1

CORRECT

INCORRECT

5

3

4

BM-7

BM-7 Operator’s Manual

10

3.2. Installing and removing the milling head

Unplug the power cord. To remove the milling head, continue in the sequence that

follows.

1

2

4

5

3

6

BM-7

BM-7 Operator’s Manual

11

To install the milling head, continue in the sequence that follows.

1

2

3

4

5

6

BM-7

BM-7 Operator’s Manual

12

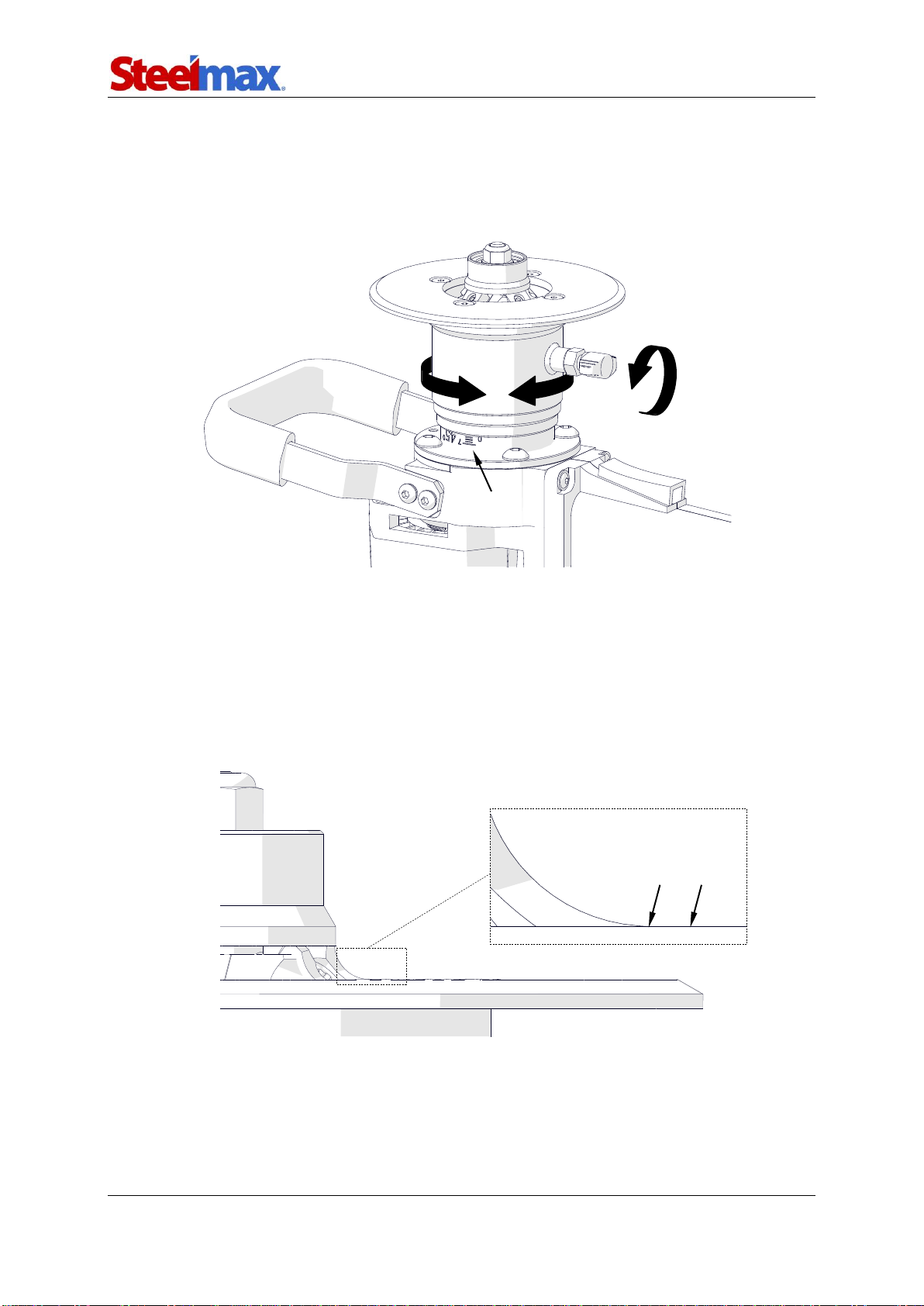

3.3. Adjusting the bevel width

Unplug the power cord. Loosen the clamping screw (1) and turn the sleeve (2) so

that the scale (3) shows the required bevel width. Tighten the screw.

3.4. Adjusting the guide for beveling with radius

Unplug the power cord. Then, loosen the clamping screw and turn the sleeve to set

the surface (1)on the height of the end of the cutting edge (2). You can also use an

optional radius insert positioner to set the guide correctly. Tighten the screw. Bevel a

test edge, and if necessary adjust the position of the guide again.

2

1

1

2

3

BM-7

BM-7 Operator’s Manual

13

3.5. Operating

Install the required milling head with cutting inserts, and set the required bevel width.

Connect the machine to the power source and put the machine on the left as in the

figure. Make sure that the workpiece is stable.

To start the motor, press and hold the switch lock (1) and the ON/OFF switch (2),

and then release the lock (1). Next, wait some seconds until the speed is at the

maximum. Press the machine to the workpiece with the two hands. Then, slowly slide

the machine toward the edge until the tool starts cutting. Move the machine from left

to right (4).

Bevel in two passes. Set the bevel width to a value that will allow the feed of

1 m/min without using too much force.

If there is vibration in the machine or if the cutting inserts are dull or damaged,

turn off the machine. Then, turn the cutting inserts by 90° to change the cutting edges.

If all cutting edges are worn, install new inserts.

Replace inserts before they become dull to prevent the overloading. Also, take

periodic breaks during work. This prevents overheating and damage to the windings.

After the work is finished, release the ON/OFF switch to turn off the motor. Then,

wait until the rotation stops, and unplug the power cord.

Clean the machine with a dry cotton cloth and no chemical agents.

4

1

3

2

BM-7

BM-7 Operator’s Manual

14

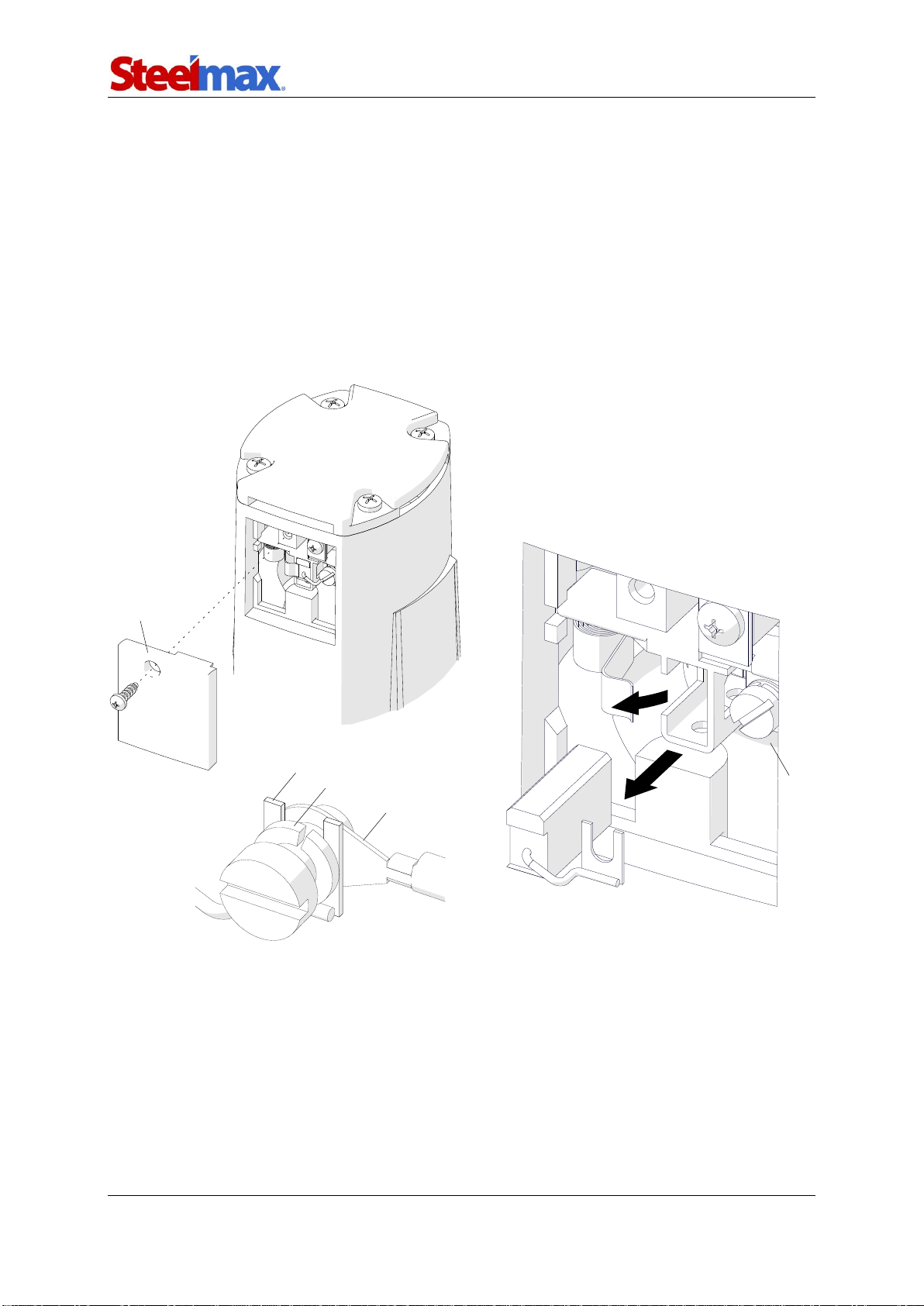

3.6. Replacing the brushes

Check the condition of the carbon brushes every 100 work hours. To do this, unplug

the power cord, and remove the cover (1). Next, loosen the screw (2), pry off the

spring (3), and remove the brush (4). If the length of the brush is less than 5 mm

(0.2″), replace the two brushes with new ones.

To install, continue in reverse order. Make sure to put the terminal of the brush

wire (5) between the washer (6) and the terminal of the motor wire (7). Then, let the

motor operate with no load for 20 minutes.

1

2

3

4

7

6

5

BM-7

BM-7 Operator’s Manual

15

Part number:

UST-0509-16-00-00-0

R2

R3

R4

R5

4. ACCESSORIES

4.1. Radius insert positioner

Allows the guide to be set correctly for beveling with a radius of 2, 3, 4, or 5 mm.

Unplug the power cord. Then, lower the sleeve to get access to the cutting inserts.

Next, put the positioner from the top (1) so that the edge marked with a given radius is

aligned with the edges of three cutting inserts with the same radius (2). Turn the

sleeve (3) until the guide is in contact with the positioner (4).

2

4

1

3

BM-7

BM-7 Operator’s Manual

16

4.2. Anti-scratch guide sticker

Self-adhesive guide sticker protects aluminum workpieces from scratches. After you

remove the sticker, clean the guide with petroleum ether.

4.3. Milling tools

Part number

Part name

GLW-0540-09-00-00-0

30° milling head (includes: Ø35 mm roller, mounting screws for inserts;

4 cutting inserts required)

PLY-000391

Cutting insert for steel (sold per 10 in a set);

for GLW-0540-08-00-00-0 and GLW-0540-09-00-00-0

PLY-000423

Cutting insert for aluminum (sold per 10 in a set);

for GLW-0540-08-00-00-0 and GLW-0540-09-00-00-0

PLY-000360

R2 cutting insert (sold per 10 in a set); only for GLW-0540-08-00-00-0

PLY-000159

R3 cutting insert (sold per 10 in a set); only for GLW-0540-08-00-00-0

PLY-000160

R4 cutting insert (sold per 10 in a set); only for GLW-0540-08-00-00-0

PLY-000161

R5 cutting insert (sold per 10 in a set); only for GLW-0540-08-00-00-0

GLW-0540-16-00-00-0

45° milling head (includes: Ø22.5 mm roller, mounting screws for inserts;

3 cutting inserts required)

PLY-000282

Cutting insert (sold per 10 in a set) for GLW-0540-16-00-00-0

Part number:

NKL-0540-15-00-00-0

BM-7

BM-7 Operator’s Manual

17

5. SPARE AND WEARING PARTS

Part number

Part name

GLW-0540-08-00-00-0

45° milling head (includes: Ø35 mm roller, mounting screws for inserts;

4 cutting inserts required)

RLK-0540-08-02-00-0

Ø35 mm roller for GLW-0540-08-00-00-0 and GLW-0540-09-00-00-0

RLK-0540-16-02-00-0

Ø22.5 mm roller for GLW-0540-16-00-00-0

SRB-000289

Mounting screw for insert

for GLW-0540-08-00-00-0 and GLW-0540-09-00-00-0

SRB-000311

Mounting screw for insert for GLW-0540-16-00-00-0

WKT-000005

T15P screwdriver for mounting screws

SMR-000005

Grease for mounting screws (5 g, 0.17 oz)

SCZ-000009

Carbon brush 115 V / 230 V

BM-7

BM-7 Operator’s Manual

18

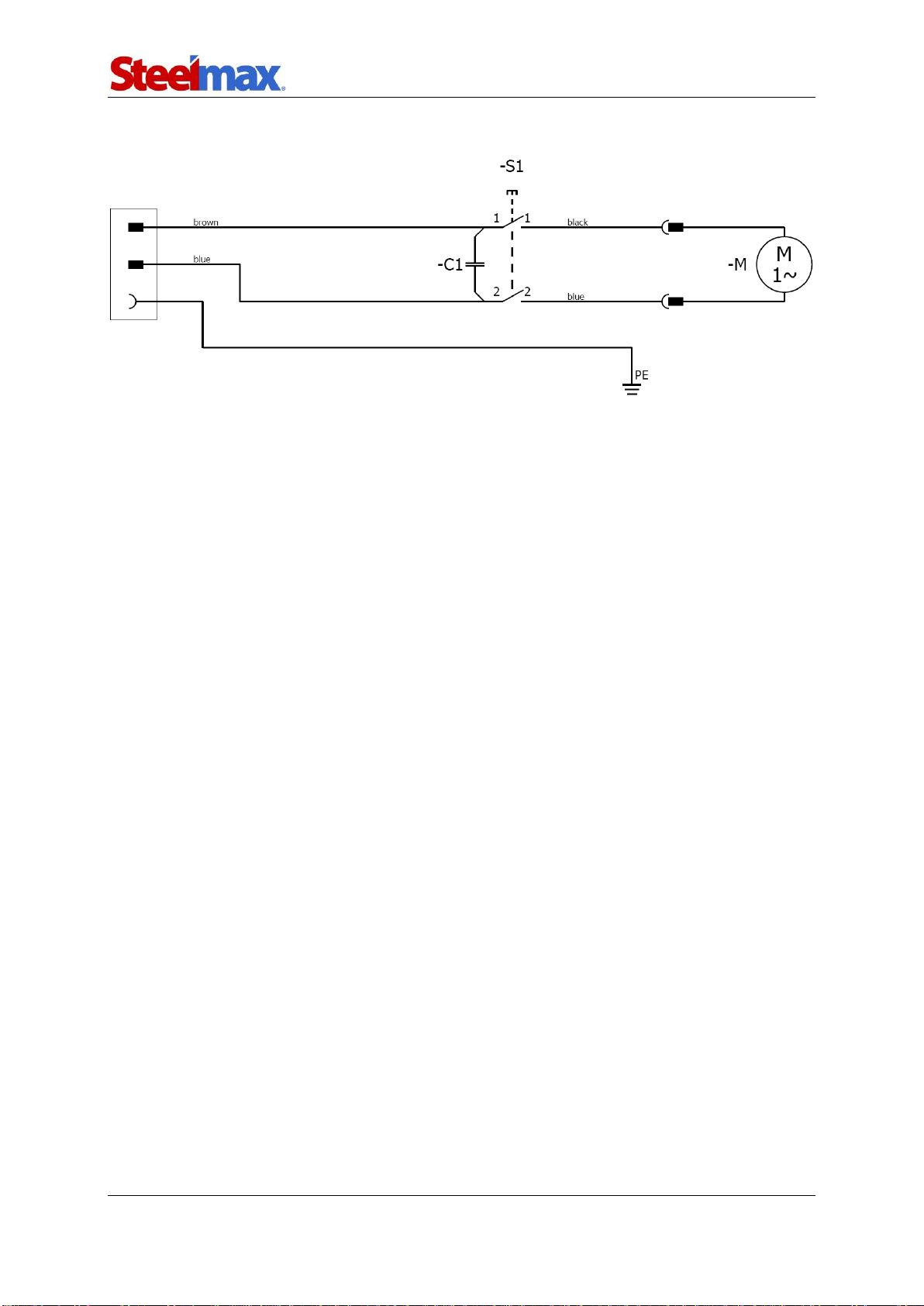

6. WIRING DIAGRAM

BM-7

BM-7 Operator’s Manual

19

7. DECLARATION OF CONFORMITY

Declaration of Conformity

PROMOTECH sp. z o.o.

ul. Elewatorska 23/1

15-620 Białystok

Poland

We declare with full responsibility that:

BM-7 Beveling Machine

is manufactured in accordance with the following standards:

•EN 60745-1

•EN 55014

•EN ISO 12100

and satisfies regulations of the guidelines: 2014/30/EC, 2014/35/EC, 2006/42/EC.

Person authorized to compile the technical file:

Marek Siergiej, ul. Elewatorska 23/1, 15-620 Białystok, Poland

Białystok, 17 October 2018 ___________________________

Marek Siergiej

CEO

BM-7

BM-7 Operator’s Manual

20

8. EXPLODED DRAWINGS AND PARTS LIST

4

2

3

1

ITEM

PART NUMBER

DESCRIPTION

Q-TY

1

WKT-000005

T15P TORX PLUS SCREWDRIVER

1

2

KLC-0540-07-00-00-0

SPECIAL FLAT WRENCH

1

3

SMR-000005

GREASE FOR SCREWS

1

4

SKR-000012

PLASTIC BOX

1

Table of contents

Popular Tools manuals by other brands

Farm King

Farm King 1370 Assembly manual

Peachtree Woodworking Supply

Peachtree Woodworking Supply Multi-joint spacing system instruction manual

Mooney

Mooney M20J Pilot operating handbook

KRAFTWERK

KRAFTWERK 3843 Using instructions

SUHNER ABRASIVE

SUHNER ABRASIVE LLC 4-TOP Technical document

Nitrous Express

Nitrous Express 11107 instructions