2Peachtree Woodworking

Fine Woodworking Accessories

P.O. Box 921487

Norcross GA, 30010

spacing system

™

Instruction Manual

Introduction

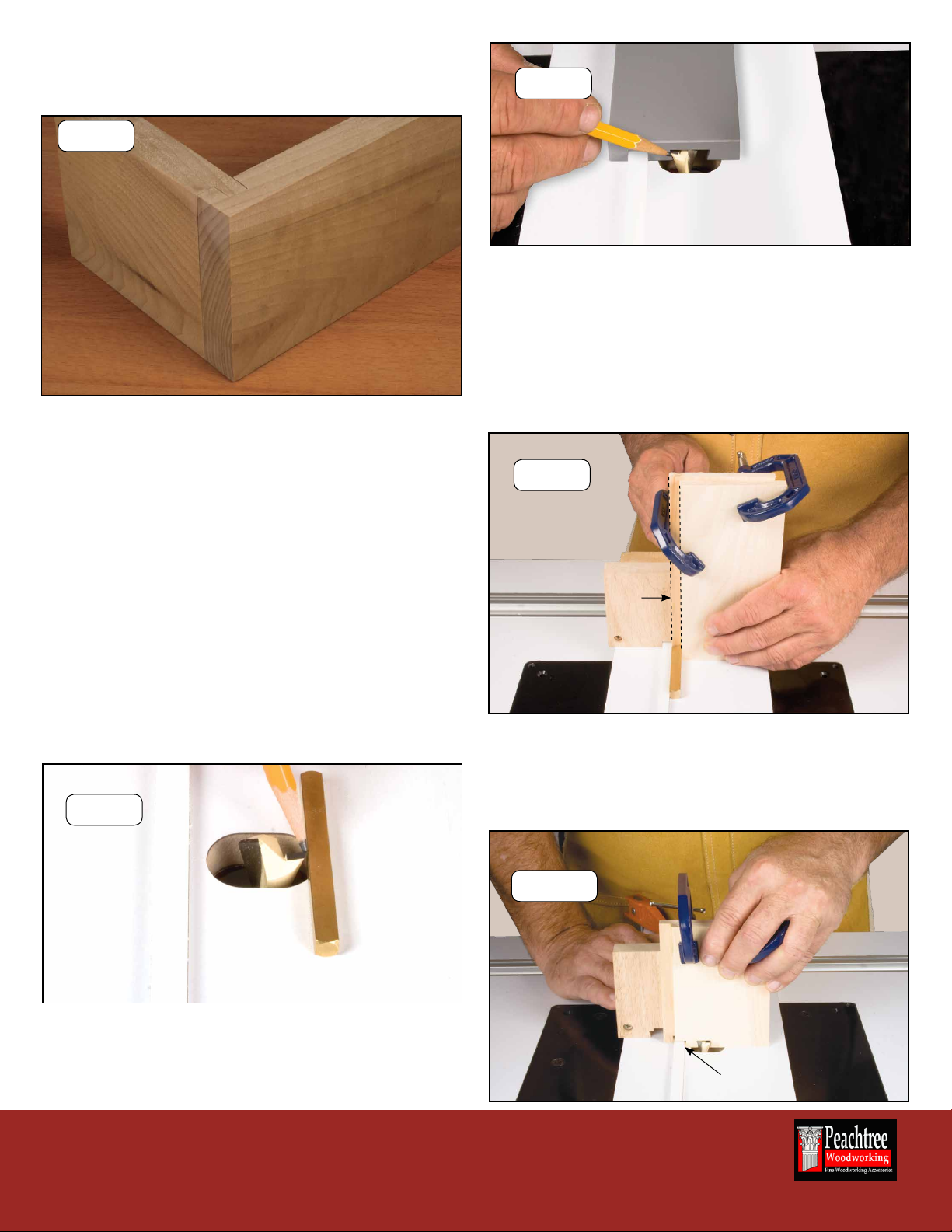

e Multi-Joint™spacing system takes a simple approach to making box joints, rabbet joints, spline joints, and sliding

dovetails. Unlike other spacer jigs, the Multi-joint™ has an MDF core base laminated on both sides so that it stays at and

does not warp. The 24” length makes it easy to clamp onto just about any router table top when making joints with the Multi-

joint system™. e hardest part about cutting these types of joints is spacing each cut exactly the same distance apart from one

another. With our Multi-joint™ fence spacing system and brass set-up bars, it will give you the exact spacing between two

cuts or fifty cuts. The bit, fence and the space between the bit and fence are all the same size. The only thing that needs to

be set up is the space between the router bit and fence. at’s what makes this system so easy to use. e Multi-Joint™system

works with precision guide bars made from U.H.M.W. for smooth operation. Instead of moving the fence for each cut, you will

move the stock on to each guide bar for endless repeatability. Unlike other template jigs you have seen, our jig will work with

two dierent thickness stock as well as two dierent widths. is means the type of projects you can create are endless. Let us

show you how your new Multi-joint™system works! Please note: all router bits required to use this system are sold separately,

due to your Multi-joint™system uses the most common type router bits that most woodworkers already own.

Read and follow all safety instructions

Caution:

Please read, understand and follow all manufacturers instructions, guidelines and owners manuals that come with

your power tools. Peachtree Woodworking Supply Inc. and its subsidiaries assume no liability for accidents or

injuries caused by improper use of this product.

Safety Tips

Creating unique joints that look like they have been hand cut will add curb appeal or distinction to any of your

projects. To get the best performance and results out of your Multi-joint™, we recommend the following tips:

1. Always wear safety glasses, hearing protection and dress properly. No loose clothing, hair, draw strings or

jewelry that might get caught in moving parts.

2. Keep work area clean. Messy work areas invite injuries.

3. Make deeper or larger cuts in multiple passes and NEVER use dull cutters. Forcing a deep cut in one pass

or using a dull cutter can result in injury. Inspect cutters for damage or chips in carbide.

4. Make sure router bit is properly installed in router and do not exceed the recommended rpm

5. Keep all safety guards in place.

6. Always unplug your tools before changing cutters

7. Secure you work. Always use at least two clamps to hold your stock. Make sure the clamps do not

interfere with the cutters.

8. Make sure the jig is clean with no build up or debris for smooth operation.

9. is system is designed for use on router tables only, do not use with a free hand router set-up.

10. Follow all manufacturer safety guidelines provided with you router.

11. Support wider stock properly so that it does not shi or change the position of the jig

spacing system

™

Package Contents

1 Ea. 1/4” spacer fence

1 Ea. 3/8” spacer fence

1 Ea. 1/2” spacer fence

1 Ea. short gray set-up block

1 Ea. long gray set-up block (sub-fence)

3 Ea. right angle fence

5 PC brass set-up bars