Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

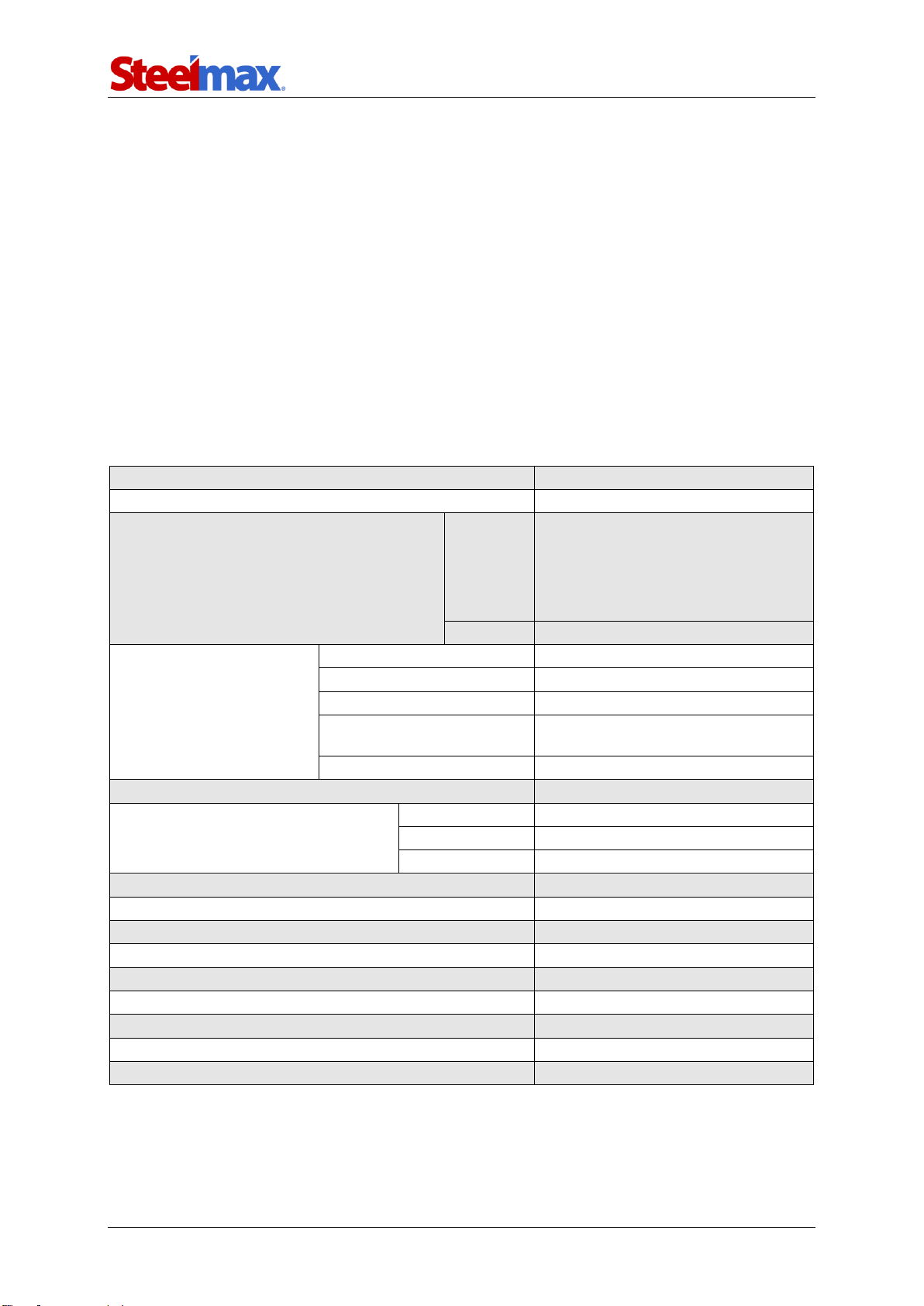

1.2. Technical data............................................................................................................ 3

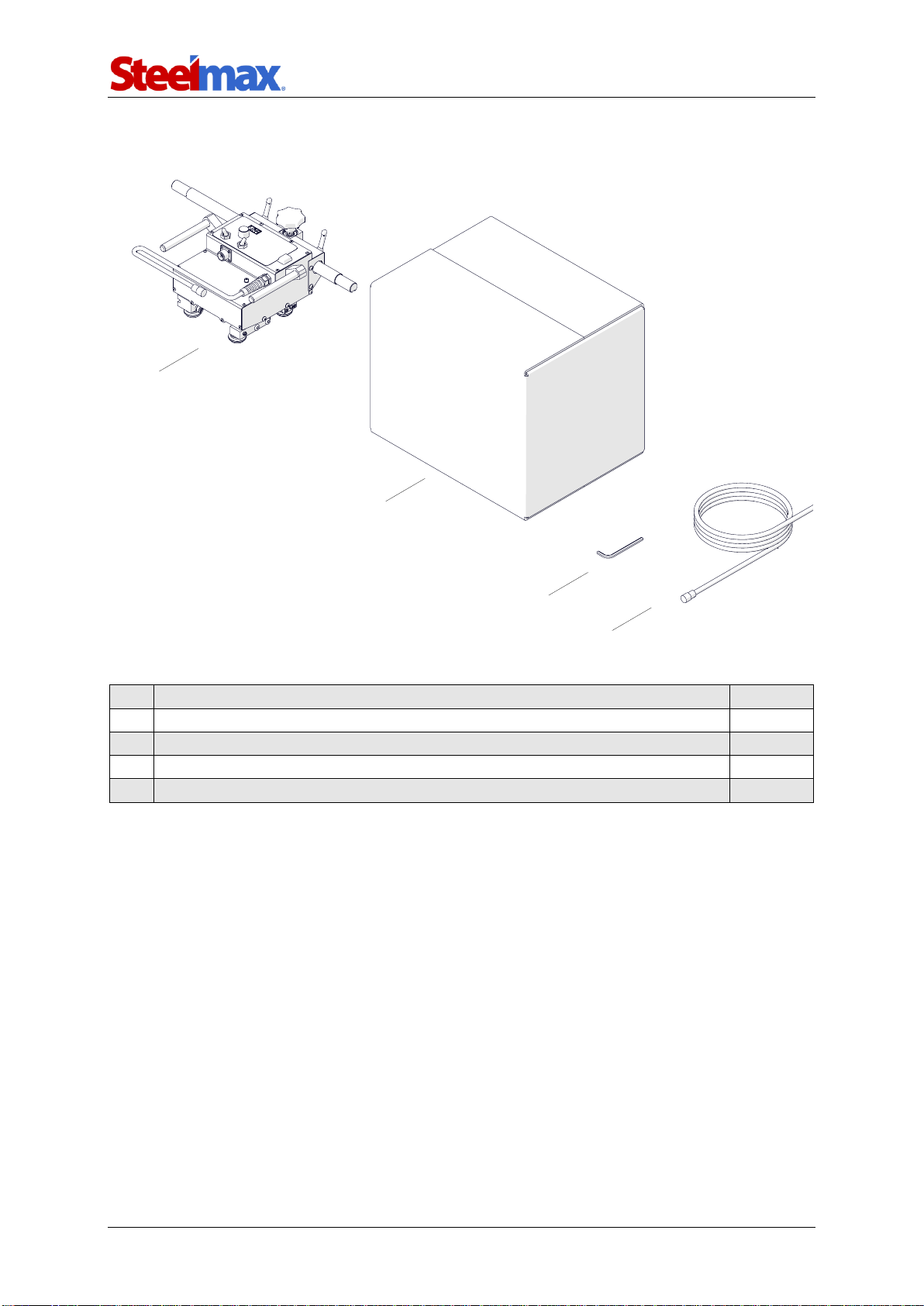

1.3. Equipment included ................................................................................................... 4

1.4. Dimensions................................................................................................................ 5

1.5. Design ....................................................................................................................... 6

2. SAFETY PRECAUTIONS.................................................................................................. 7

3. STARTUP AND OPERATION........................................................................................... 9

3.1. Assembling the hi-flex, semi-flex, or rigid track........................................................... 9

3.2. Assembling the ring track..........................................................................................11

3.3. Positioning on a straight track...................................................................................13

3.4. Positioning on a curved track....................................................................................15

3.5. Preparing..................................................................................................................16

3.6. Connecting to the welding or plasma cutting circuits.................................................18

3.7. Operating..................................................................................................................19

3.8. Adjusting the pressure of rollers................................................................................20

3.9. Troubleshooting........................................................................................................21

4. MAINTENANCE...............................................................................................................22

5. ACCESSORIES...............................................................................................................23

5.1. MIG/MAG welding set...............................................................................................23

5.2. SAW welding set.......................................................................................................23

5.3. Oxy-fuel cutting set...................................................................................................24

5.4. Plasma cutting set.....................................................................................................24

5.5. Hi-flex track...............................................................................................................25

5.6. Semi-flex track..........................................................................................................26

5.7. Rigid track.................................................................................................................26

5.8. Rack adjustment tool.................................................................................................26

5.9. Magnetic units...........................................................................................................27

5.10. Semi-flex track support............................................................................................32

5.11. Vacuum track system..............................................................................................33

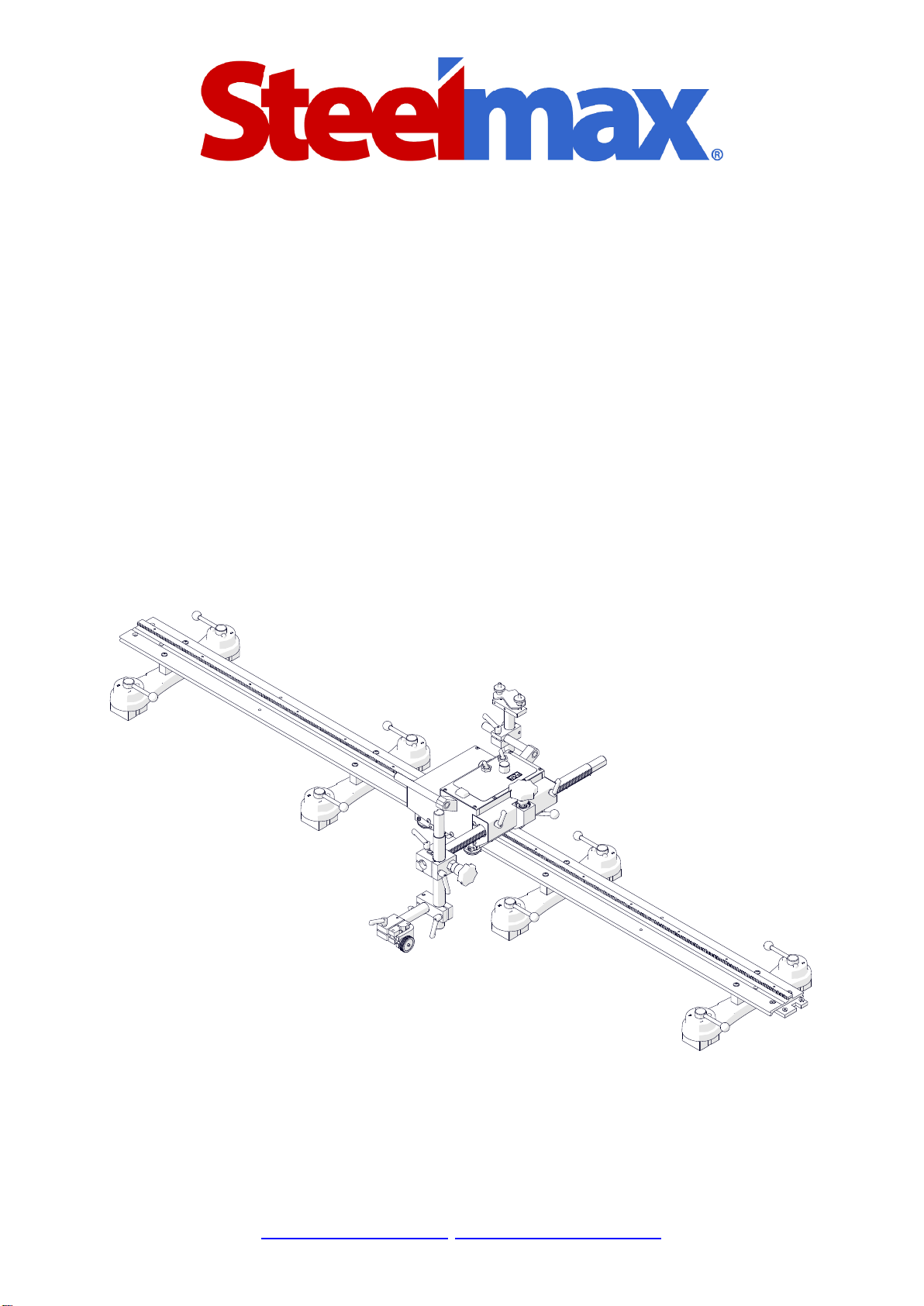

5.12. Ring tracks..............................................................................................................34

5.13. Ring track supports and bracket..............................................................................36

5.14. Rack........................................................................................................................37

5.15. Torch holders, clamps, and rods.............................................................................38

5.16. Cutting torch holders...............................................................................................40

5.17. Gas manifold (for oxy-fuel cutting)...........................................................................42

6. WIRING DIAGRAM..........................................................................................................44

7. EXPLODED VIEWS AND PARTS LIST............................................................................45

8. DECLARATION OF CONFORMITY.................................................................................49

9. WARRANTY CARD..........................................................................................................50