SteelMax Rail Runner 2 User manual

The tools of innovation.

15335 E. Freemont Drive, Centennial, CO 80112

1–87STEELMAX, FAX 303 –690 –9172

www.steelmax.com [email protected]

OPERATOR’S MANUAL

WELDING CARRIAGE

R

Ra

ai

il

l

R

Ru

un

nn

ne

er

r

2

2

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 4

1.3. Equipment included ................................................................................................... 5

1.4. Dimensions................................................................................................................ 6

1.5. Design ....................................................................................................................... 7

2. SAFETY PRECAUTIONS.................................................................................................. 8

3. STARTUP AND OPERATION..........................................................................................10

3.1. Assembling the hi-flex, semi-flex, and rigid track.......................................................10

3.2. Assembling the ring track..........................................................................................12

3.3. Positioning on a straight track...................................................................................14

3.4. Positioning on a curved track....................................................................................16

3.5. Preparing and connecting.........................................................................................17

3.6. Connecting to the welding circuits.............................................................................18

3.7. Operating..................................................................................................................19

3.8. Adjusting the pressure of rollers................................................................................25

3.9. Adapting for seam tracking (option)...........................................................................26

3.10. Troubleshooting ......................................................................................................30

4. MAINTENANCE...............................................................................................................31

5. ACCESSORIES...............................................................................................................32

5.1. Seam tracking attachment.........................................................................................32

5.2. Tracking sensor tips..................................................................................................32

5.3. Motorized vertical slide..............................................................................................33

5.4. 0.5 m (1.5 ft) signal cable..........................................................................................33

5.5. Hi-flex track...............................................................................................................34

5.6. Semi-flex track..........................................................................................................35

5.7. Rigid track.................................................................................................................35

5.8. Rack adjustment tool.................................................................................................35

5.9. Contact block............................................................................................................36

5.10. Magnetic units........................................................... Error! Bookmark not defined.

5.11. Semi-flex track support............................................................................................37

5.12. Vacuum track system..............................................................................................43

5.13. Ring tracks..............................................................................................................44

5.14. Ring track supports and bracket..............................................................................46

5.15. Torch holders, clamps, and rods.............................................................................47

5.16. Transport attachment..............................................................................................49

5.17. Pendulum oscillator.................................................................................................49

6. WIRING DIAGRAM..........................................................................................................52

7. EXPLODED DRAWINGS AND PARTS LIST....................................................................56

8. DECLARATION OF CONFORMITY.................................................................................67

9. WARRANTY CARD..........................................................................................................68

Rail Runner 2

Rail Runner 2 –Operator’s Manual

3

1. GENERAL INFORMATION

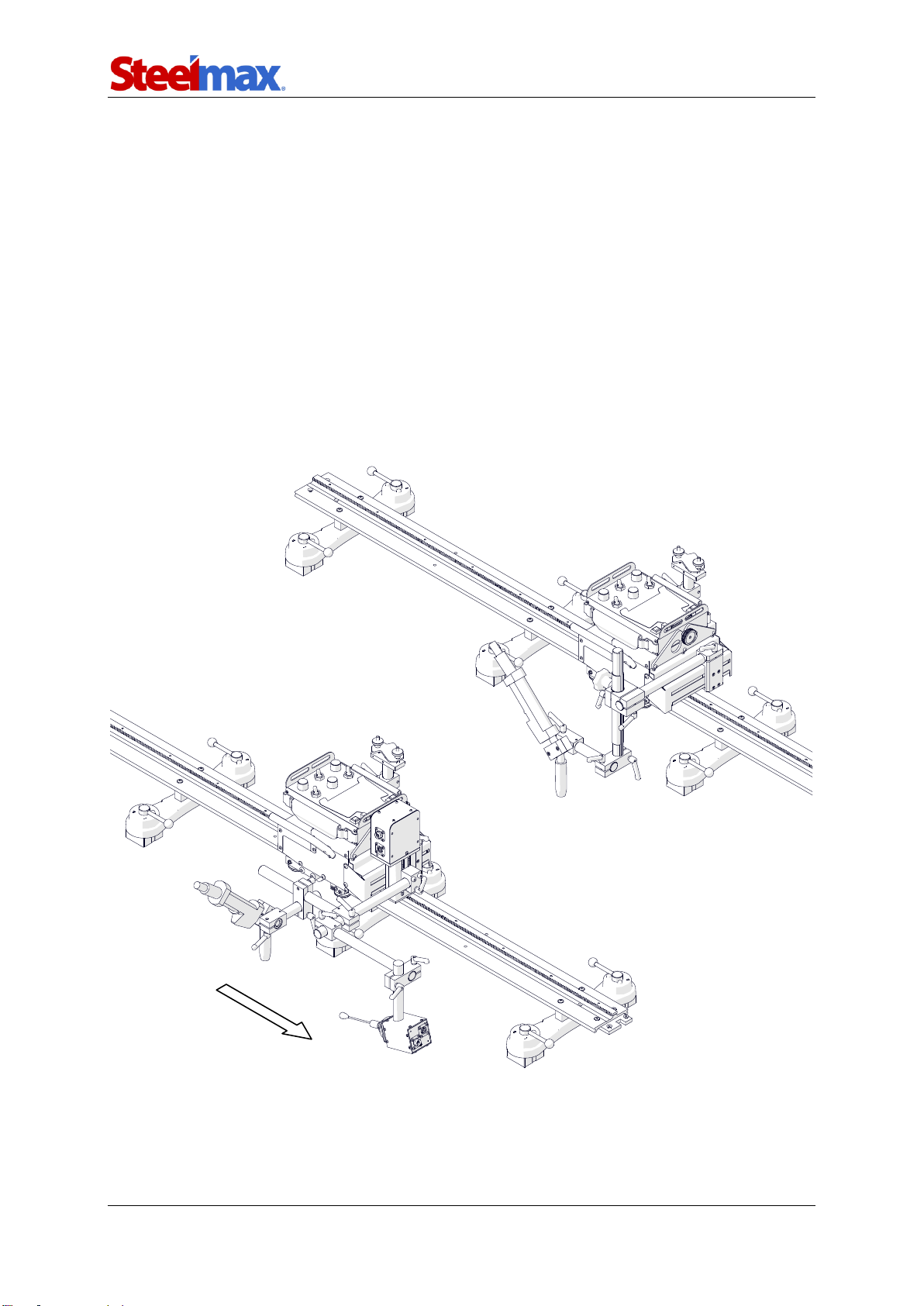

1.1. Application

The Rail Runner 2 is a track carriage designed to cut and to make butt and fillet

welds with or without oscillation. The carriage allows MIG/MAG, oxy-fuel, or plasma

torches. The track is clamped with magnetic units to ferromagnetic surfaces that are

flat or curved.

Accessories allow using torches with a larger diameter, guiding the carriage on a

hi-flex, semi-flex, rigid, or ring track, and tracking the welding seam. Using a vacuum

track system allows the track to be clamped to surfaces that are non-ferromagnetic.

Two intended configurations are shown in the figure that follows.

Basic configuration

Configuration with seam tracking in two axes

(requires an optional tracking attachment and

a motorized vertical slide)

Travel direction

Rail Runner 2

Rail Runner 2 –Operator’s Manual

4

1.2. Technical data

Voltage

1~ 230 V, 50–60 Hz

1~ 115 V, 50–60 Hz

1~ 42 V, 50–60 Hz (60 V DC)

Power

120 W

Welding position

(according to EN ISO 6947 and

AWS/ASME)

Horizontal

PA/1F/1G

PB/2F

PC/2G

PD/4F

PE/4G

Vertical

PF/3G

PG/3F (contact your dealer)

PG/3G

Diameter

of round workpiece

Ring tracks (OD)

200 mm (8″) – 3 m (10 ft)

Hi-flex tracks (OD)

Minimum 1.5 m (5 ft)

Hi-flex tracks (ID)

Minimum 3.4 m (11 ft)

Custom rolled tracks (OD)

3–10 m (10–32 ft)

(contact your dealer)

Semi-flex tracks (OD)

Minimum 10 m (32 ft)

Torch type

MIG/MAG, oxy-fuel, plasma

MIG/MAG torch diameter

16–22 mm (0.63–0.87″)

Minimum workpiece thickness for magnetic clamping

5 mm (0.2″)

Horizontal pulling force

400 N (88 lbs)

Vertical pulling force

300 N (66 lbs)

Horizontal speed

0–300 cm/min (0–120 in/min)

Vertical speed

0–300 cm/min (0–120 in/min)

Oscillation type

Linear

Weld path

Straight, triangle, trapezoid, square

Oscillation width

0.2–11.8 cm (0.1–4.5″)

Oscillation speed

10–300 cm/min (5–120 in/min)

Oscillation dwell time at center and on ends

0–5 s

Maximum oscillator pulling force

100 N (22 lbs)

Allowed ambient temperature

0–45°C (32–113°F)

Maximum allowed ambient humidity without conden-

sation

80%

Protection level

IP 23

Weight

10 kg (22 lbs)

Rail Runner 2

Rail Runner 2 –Operator’s Manual

5

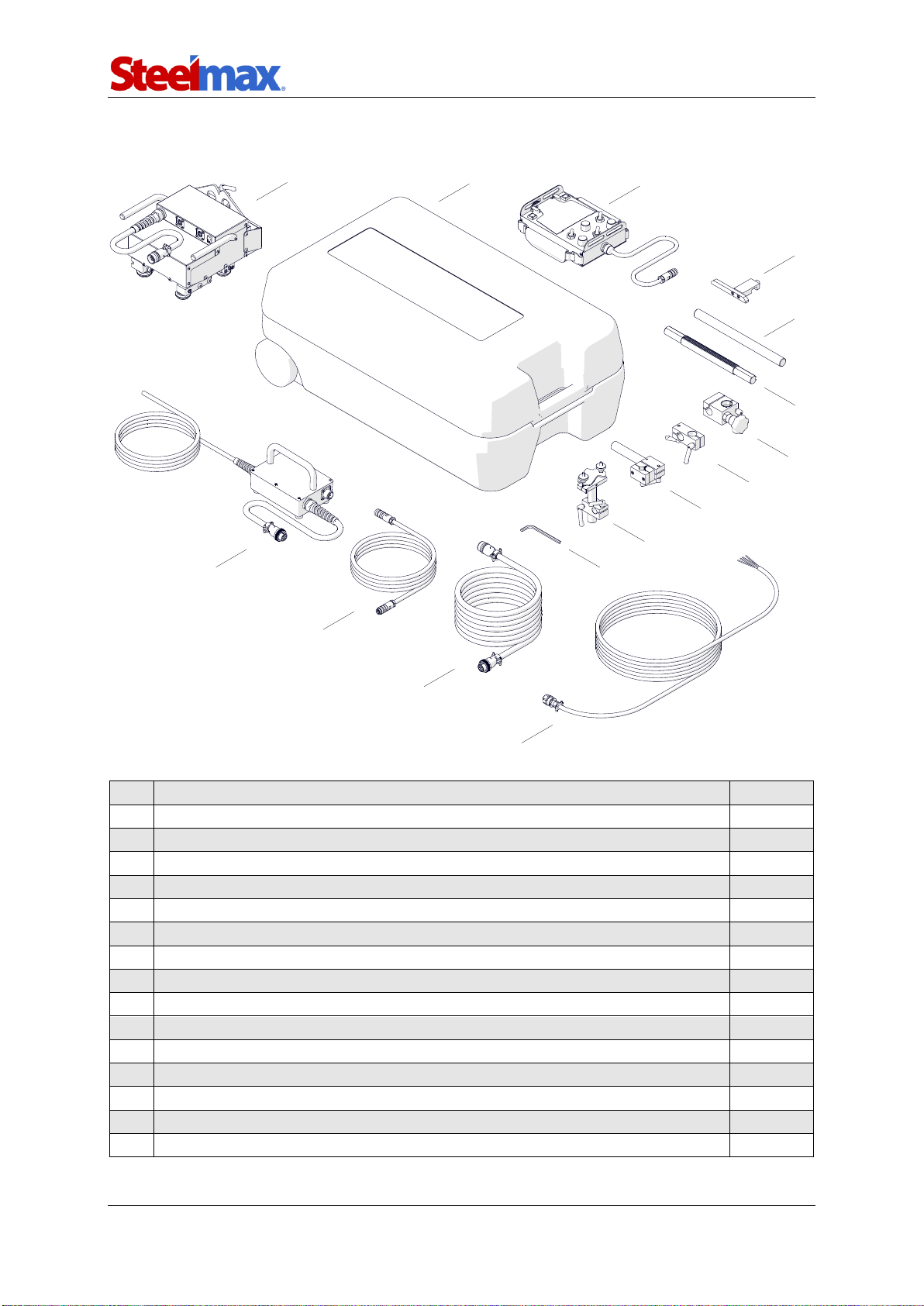

1.3. Equipment included

1

Carriage

1 unit

2

Plastic box

1 unit

3

Remote control

1 unit

4

Contact block

1 unit

5

300 mm (12″) rod

1 unit

6

300 mm (12″) rack with 180 mm (7″) adjustment

1 unit

7

Rack holder

1 unit

8

Clamping block with levers

1 unit

9

Short rod torch holder with clip

1 unit

10

Cable anchor

1 unit

11

6 mm hex wrench

1 unit

12

6.5 m (21 ft) arc ignition cable

1 unit

13

5 m (17 ft) power cable

1 unit

14

3 m (10 ft) remote control cable

1 unit

15

Power supply*

1 unit

–

Operator’s Manual

1 unit

* 230 V, 115 V, or 42 V depending on the order

12

1

3

4

7

8

9

10

11

13

14

15

5

6

2

Rail Runner 2

Rail Runner 2 –Operator’s Manual

6

1.4. Dimensions

470 mm (18.5″)

195 mm (7.7″)

318 mm (12.5″)

267 mm (10.5″)

350 mm (13.8″)

73 mm (2.9″)

131 mm (5.2″)

354 mm (13.9″)

121 mm (4.8″)

Rail Runner 2

Rail Runner 2 –Operator’s Manual

7

1.5. Design

Arc ignition socket

Carrying handle

Power cord

Rod holder

Passive roller

Knob to attach the remote

control to the carriage

Power switch

Carriage / 3 m (10 ft) remote

control cable connection

Remote control / 3 m (10 ft) remote control cable /

tracking sensor / motorized vertical slide connection

5 m (17 ft) power cable connection

5 m (17 ft) power cable connection

Drive clutch knob

Pressing lever (pressing roll-

ers are loose in this position)

Pressing roller

Limit switch

Drive gear

Mounting bracket

Display guard

Rail Runner 2

Rail Runner 2 –Operator’s Manual

8

2. SAFETY PRECAUTIONS

1. Before use, read this Operator’s Manual and complete a training in occupational

safety and health.

2. Use only in applications specified in this Operator’s Manual.

3. Make sure that the carriage, power supply, remote control, and other equipment

have all parts. Make sure that all parts are genuine and not damaged.

4. Make sure that the specifications of the power source are the same as those spec-

ified on the rating plate.

5. Connect the carriage to the power supply by using the power cable. Connect the

power supply to a correctly grounded power source.

6. Do not carry the carriage, remote control, and other equipment by cords or cables.

Do not pull the cords or cables. This can cause damage and electric shock.

7. Keep untrained bystanders away from the carriage.

8. Before each use, ensure the correct condition of the carriage, power supply, re-

mote control, and other equipment, power source, cords, cables, connections, roll-

ers, and gear.

9. Before each use, make sure that no part is cracked or loose. Make sure to main-

tain correct conditions that can have an effect on the operation of the carriage.

10. Keep the carriage, power supply, remote control, and other equipment dry. Do

not expose them to rain, snow, or frost.

11. Keep the worksite well lit, clean, and free of obstacles.

12. Do not use near flammable materials, or in explosive environments.

13. Transport and position the carriage by using the carrying handles.

14. Install the carriage only on the supplied track.

15. Make sure that the gear and rollers are clean.

16. Connect the cords and cables only after you set the power switch to ‘O’.

17. Keep the sockets clean. Do not use high pressure during cleaning.

18. Install only torches whose diameter matches the diameter of the torch holder.

19. Hang the cables to decrease the load applied on the carriage.

20. Do not bend the hi-flex track to a radius less than 0.75 m (2.5 ft).

21. Do not bend the semi-flex track to a radius less than 5 m (16 ft).

22. Use the rigid track only on flat surfaces.

Rail Runner 2

Rail Runner 2 –Operator’s Manual

9

23. At heights, protect the carriage and the track from falling. To do this, use chains

(not included) to attach the leftmost and rightmost magnetic units of the hi-flex,

semi-flex or rigid track to a stable structure. To protect the carriage, attach a

chain to a carrying handle. Make sure that the chains are not loose.

24. Do not stay below the carriage or the track that is put at heights.

25. Use eye protection (helmet, shield, and screen), ear protection, gloves, and pro-

tective clothing. Do not use loose clothing.

26. Do not stop the carriage by hand. To stop, set the direction switch to ‘O’.

27. Do the maintenance only after you unplug the carriage from the power source.

28. Repair only in a service center appointed by the seller.

29. If the carriage falls, is wet, or has any damage, stop the work and promptly send

the carriage to the service center for check and repair.

30. Do not leave the carriage unattended during work.

31. If you are not going to use the carriage, remove it from the worksite and keep in a

safe and dry place.

Rail Runner 2

Rail Runner 2 –Operator’s Manual

10

3. STARTUP AND OPERATION

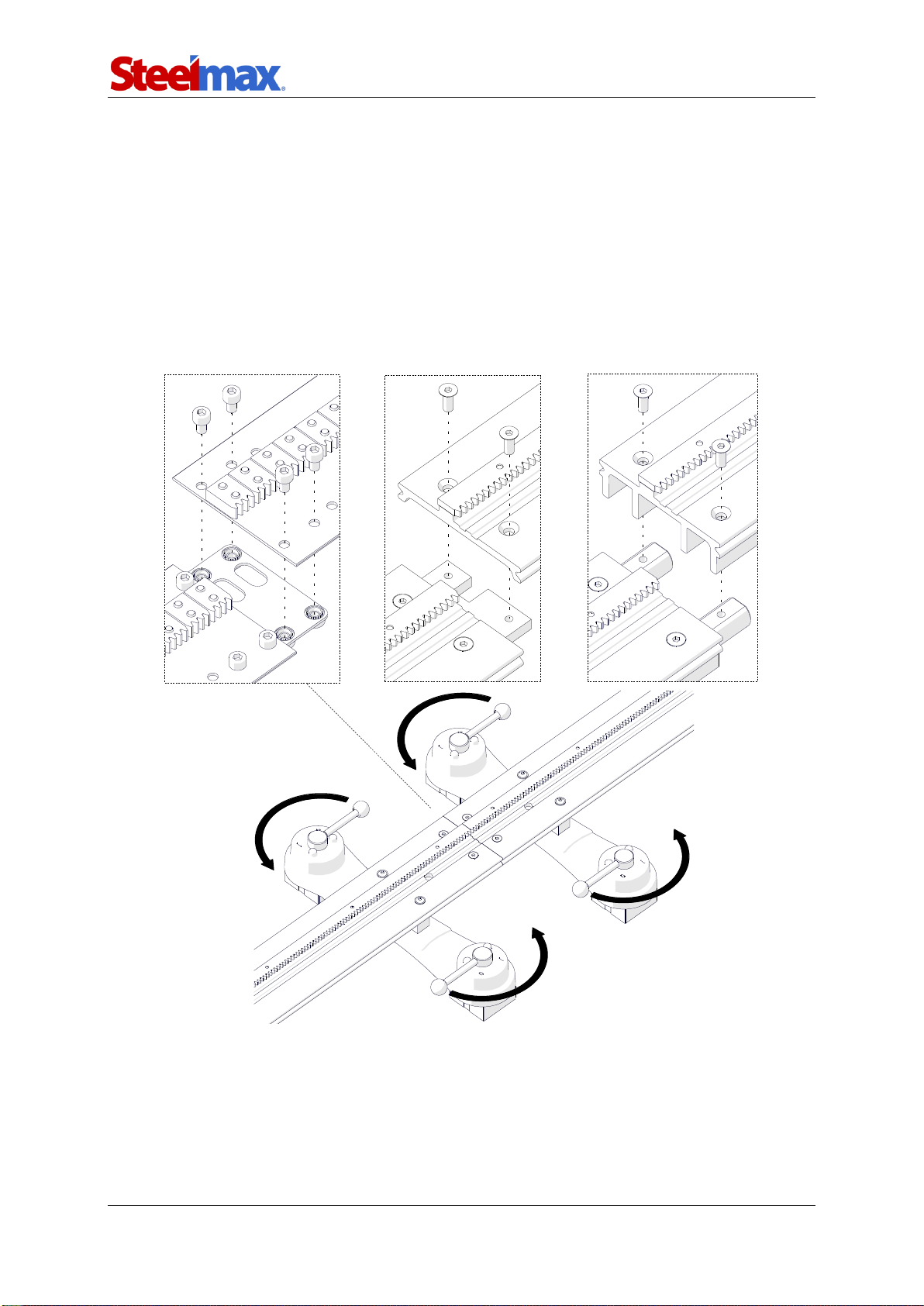

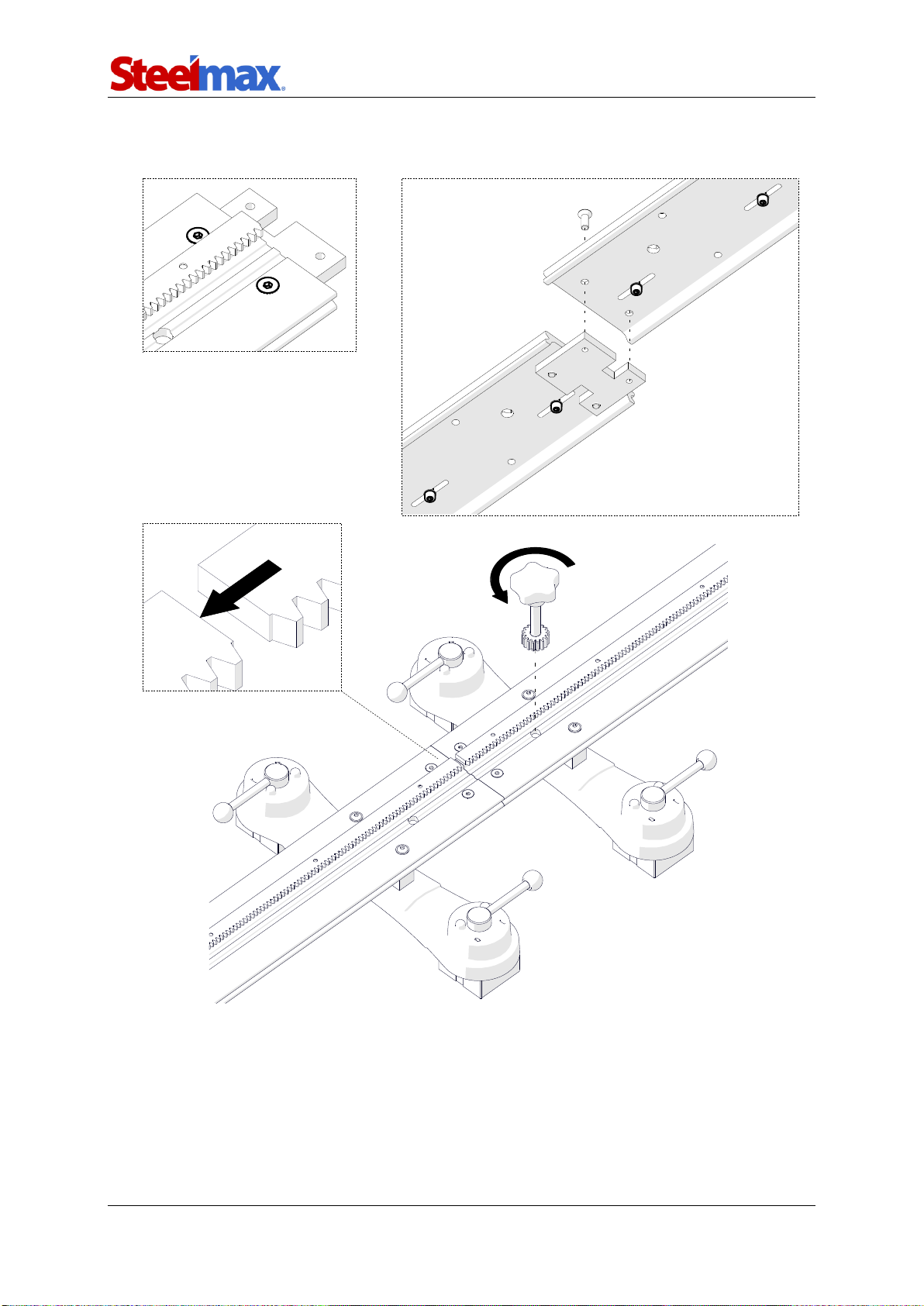

3.1. Assembling the hi-flex, semi-flex, and rigid track

Attach magnetic units to the rail, and put it on the workpiece. Use the 4 mm or 5 mm

hex wrench to attach more rails (1, Fig. 1). Then, set the levers of the magnetic units

to ‘I’ (2). This will clamp the track to the surface.

When working in PC/2G welding position, put the track so that the teeth of the

racks point down.

Fig. 1. Connecting the rails and clamping the magnetic units to the surface

If a semi-flex rail is put on a curve, before you attach more rails use the 4 mm hex

wrench to loosen the screws of the connecting plates (1, Fig. 2) and of the racks (2).

Next, attach the rails, clamp them with levers, and then tighten the connecting plates.

Put the rack adjustment tool (not included) into the hole (3), and rotate the tool to the

1

2

Rail Runner 2

Rail Runner 2 –Operator’s Manual

11

left (4) to remove the gap (5) between the racks. Then, tighten the leftmost screw and

the rightmost screw of each rack (2).

Fig. 2. Removing the gap between the racks of a semi-flex track

1

2

5

3

4

Rail Runner 2

Rail Runner 2 –Operator’s Manual

12

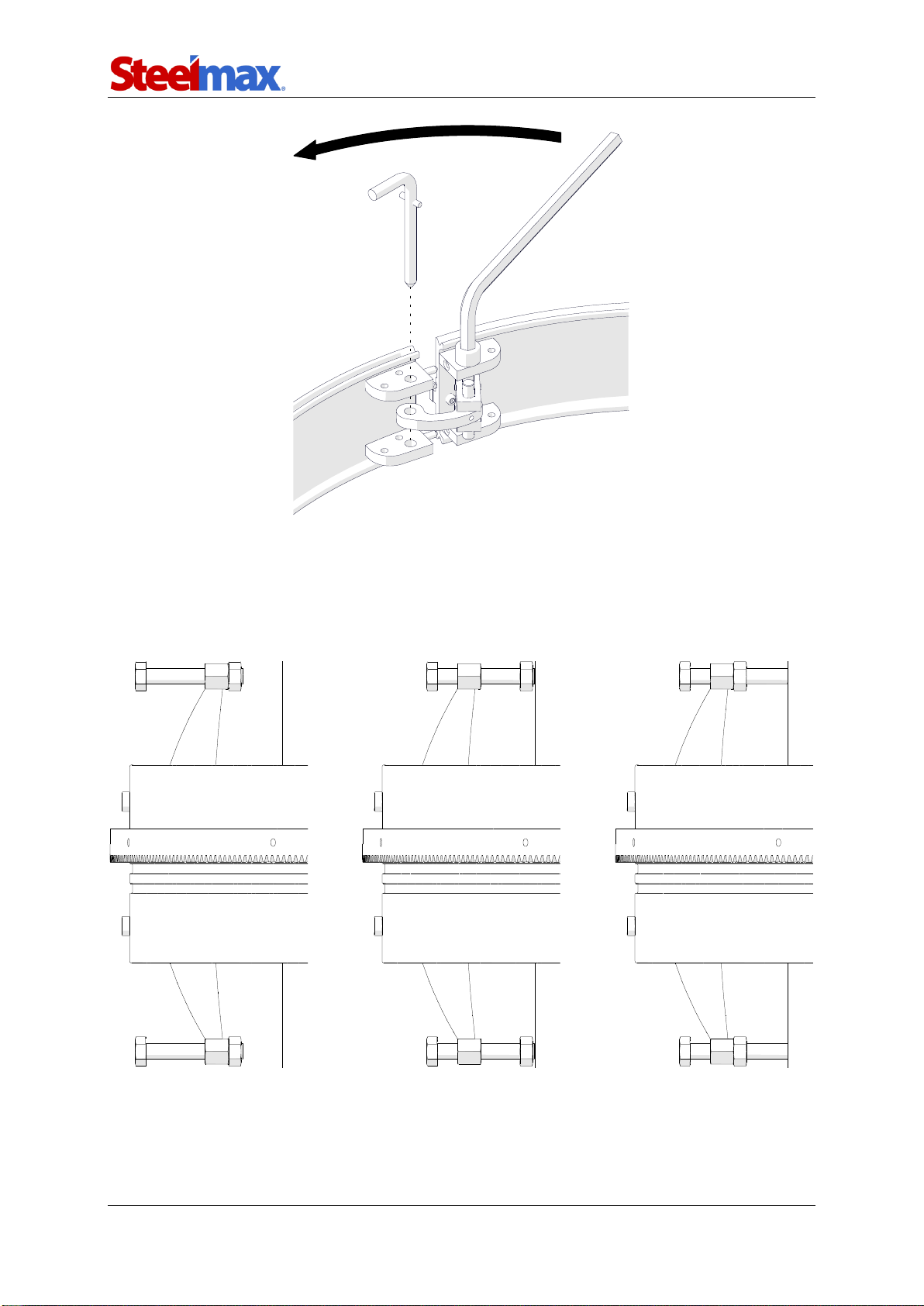

3.2. Assembling the ring track

Select the track that matches the outer diameter of the round workpiece. Use the

4 mm hex wrench to attach the supports to the rails (1, Fig. 3). Next, on all supports,

retract the bolts (2, or screws) as much as possible. To clamp the track to the work-

piece with a smaller diameter, you can use brackets (3). But this will decrease the

stiffness of the clamping.

Fig. 3. Connecting the supports to the rails

Put the workpiece vertically, and then put the rails onto the workpiece so that the

teeth of the racks point down. Next, for all rails, use the 12 mm hex wrench to set

the hinge as shown in Fig. 4. Then, put the lock pin through the holes (1), and then

rotate the wrench (2) to connect the rails.

1

2

2

Screw with plastic foot

25 mm (1″) adjustment range

Bolt

25 mm (1″) adjustment range

Screw with magnet

25 mm (1″) adjustment range

3

Rail Runner 2

Rail Runner 2 –Operator’s Manual

13

Fig. 4. Connecting the rails of the ring track

Use the 13 mm flat wrench to adjust the bolts (or the screws by hand) until they are

in contact with the workpiece (1, Fig. 5). Adjust each support equally to make the

track concentric to the workpiece. Lock the supports with the nuts (2) or levers.

Fig. 5. Attaching the ring track to the workpiece

1

2

2

1

Rail Runner 2

Rail Runner 2 –Operator’s Manual

14

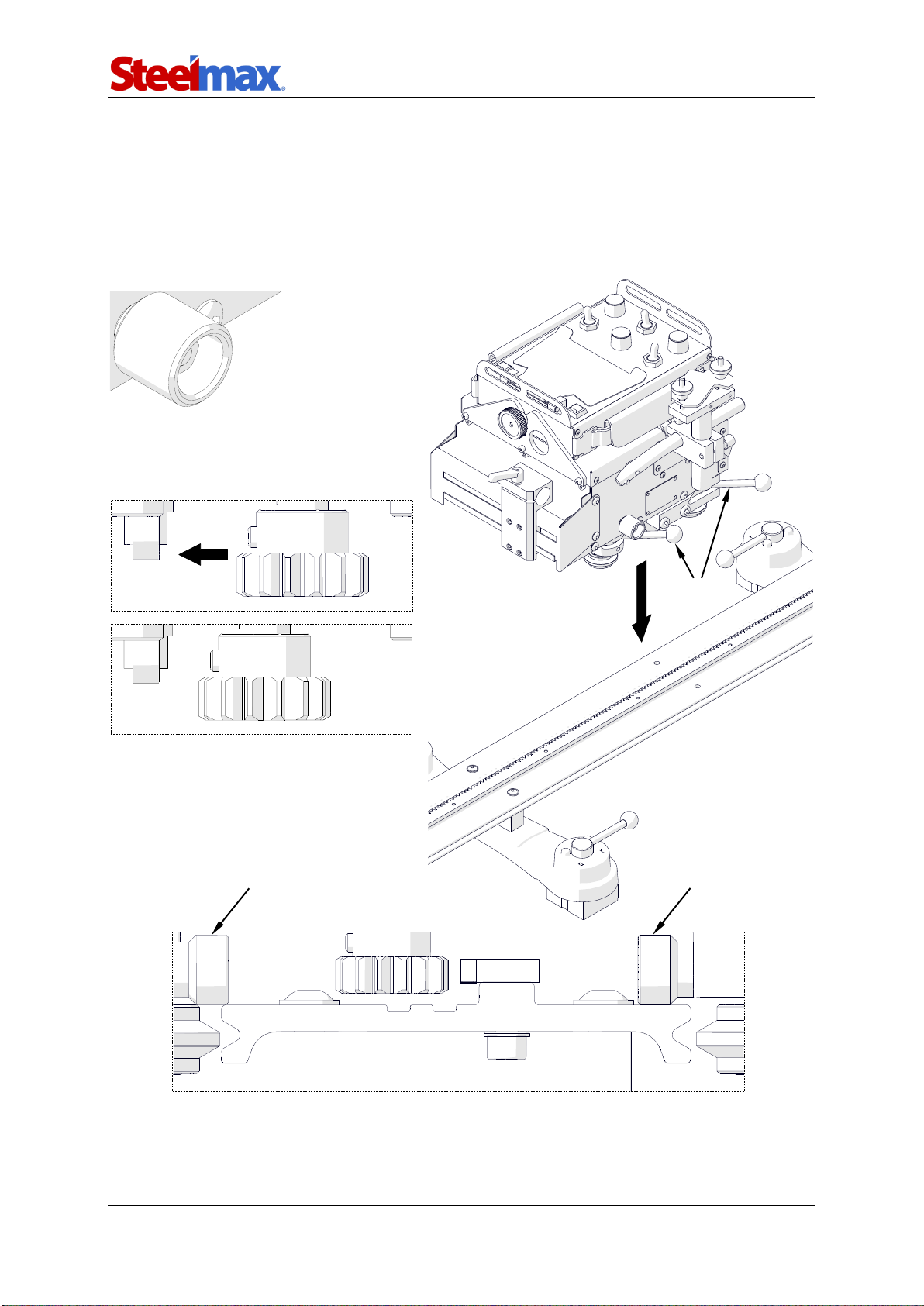

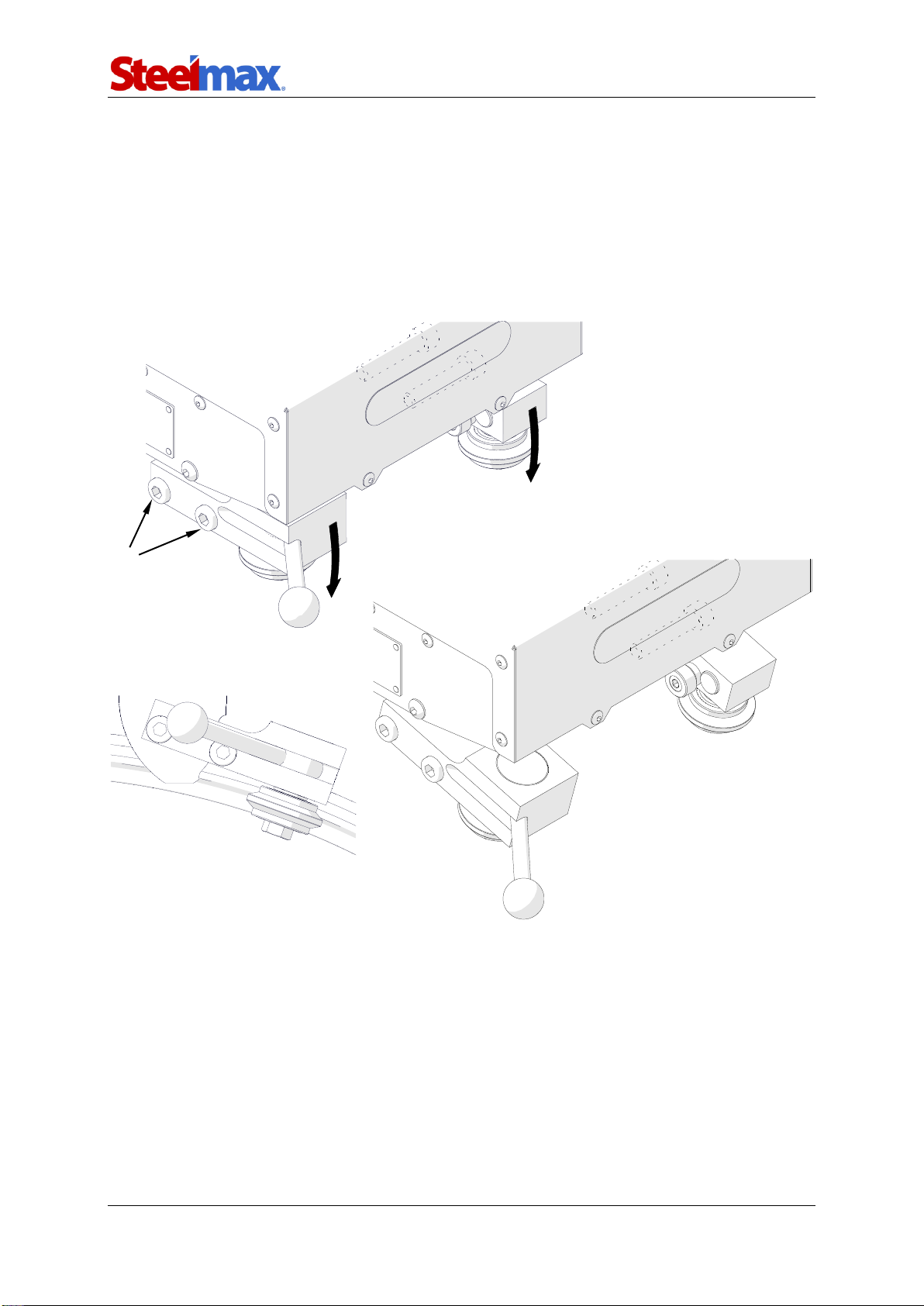

3.3. Positioning on a straight track

Set the power switch, arc ignition switch, oscillation switch, and direction switch to

‘O’. Next, set the levers to OFF (1, Fig. 6), and then loosen the knob (2) fully

to retract the gear (3). Then, put the carriage so that the mounting brackets are on

the rail (4, 5).

Fig. 6. Putting the carriage on a straight track

Mounting bracket

Mounting bracket

2

3

5

Gear retracted

1

4

Rail Runner 2

Rail Runner 2 –Operator’s Manual

15

Set the levers to ON (1, Fig. 7) to put the rollers into the grooves (2). Tighten the

knob (3) to engage the gear of the carriage with the rack of the rail (4). Keep a small

backlash between the gear and the rack. Move the carriage slightly back and forth to

make sure that there is a backlash.

Fig. 7. Engaging the carriage with the track

3

Not engaged

×

Engaged

✓

1

1

2

2

4

Rail Runner 2

Rail Runner 2 –Operator’s Manual

16

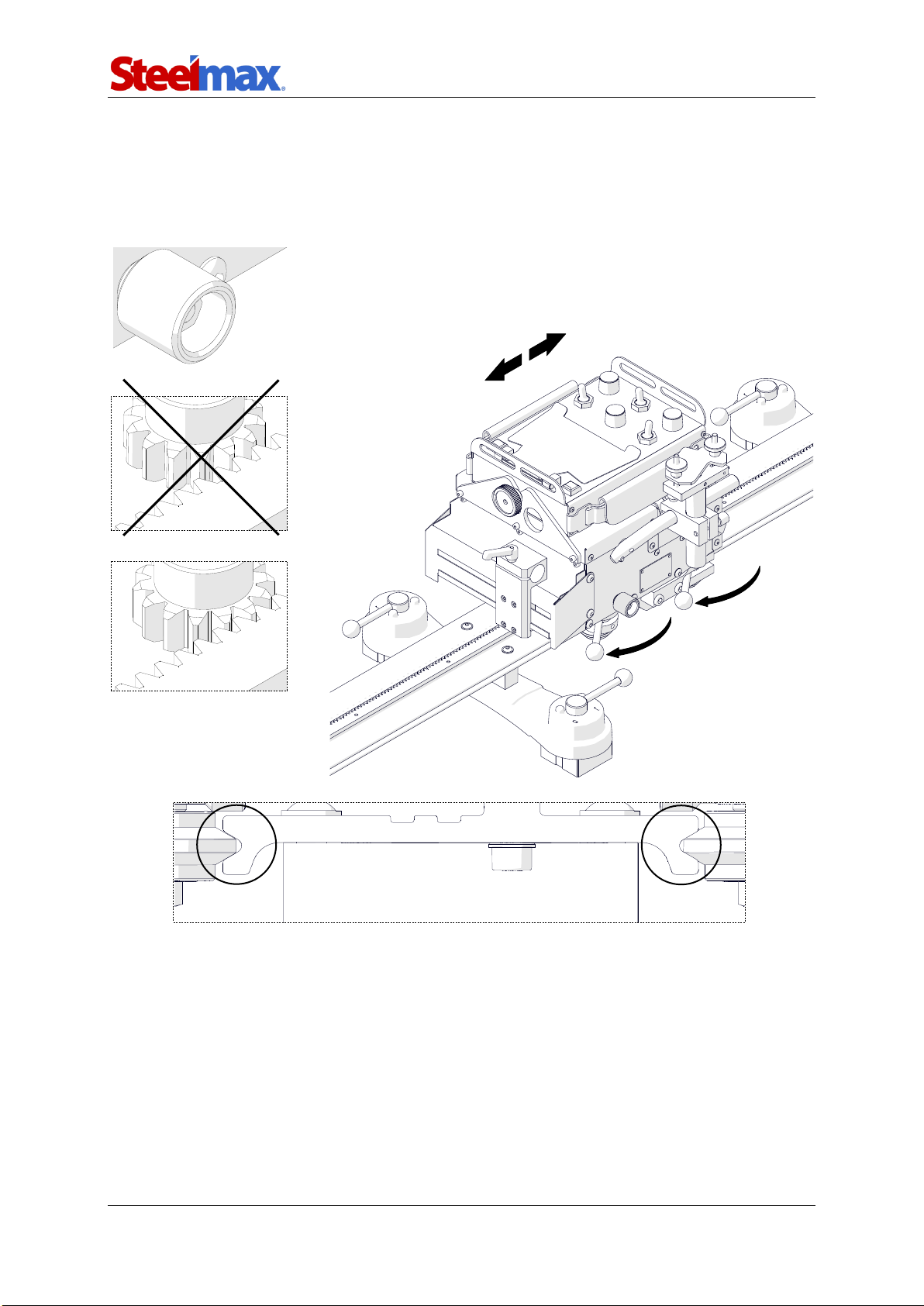

3.4. Positioning on a curved track

Use the 6 mm hex wrench to loosen four screws (1, Fig. 8), and then put the carriage

on the track. Rotate two roller brackets (2) to put the rollers into the grooves, and

then set the levers to ON (3). Next, move the carriage back and forth to make sure

that it moves smoothly. Then, tighten the screws (1) and use the knob (4) to engage

the gear with the rack as described in “Positioning on a straight track”.

Fig. 8. Rotating the rollers for a curved track

1

2

2

3

Rail Runner 2

Rail Runner 2 –Operator’s Manual

17

3.5. Preparing and connecting

At heights, protect the carriage and the track from falling. To do this, use chains

(not included) to attach the leftmost and rightmost magnetic units of the hi-flex, semi-

flex or rigid track to a stable structure. To protect the carriage, attach a chain to a

carrying handle. Make sure that the chains are not loose.

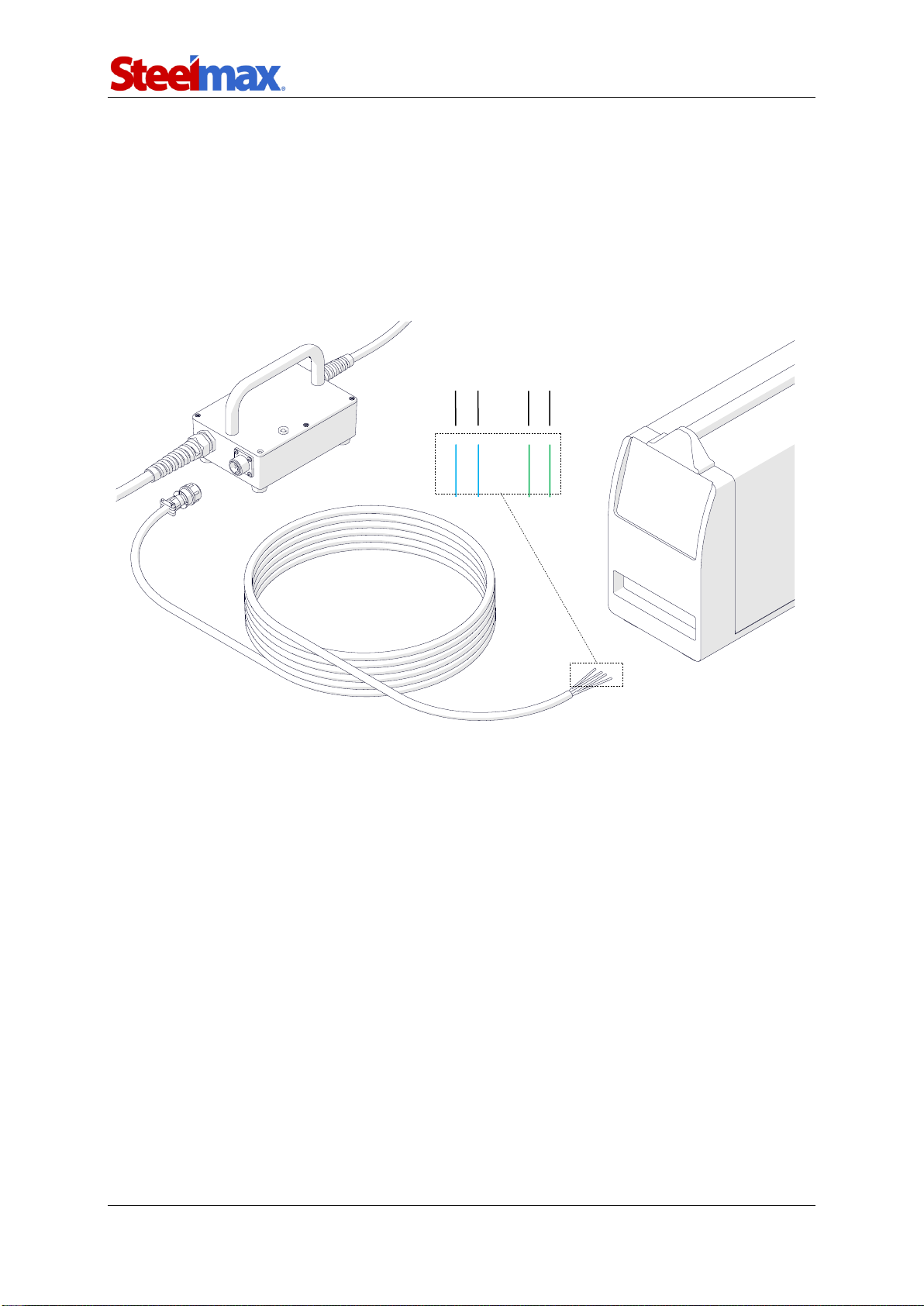

Connect the remote control to the carriage directly (1, Fig. 9), if the remote con-

trol will be put onto the carriage, or use the remote control cable (2). Then, use the

power cable to connect the carriage to the power supply (3). Next, connect the power

supply to the power source and put the torch and torch cables into the holders.

Fig. 9. Connecting the carriage

3 m (10 ft) remote control cable

5 m (17 ft) power cable

1

2

2

3

3

Rail Runner 2

Rail Runner 2 –Operator’s Manual

18

3.6. Connecting to the welding circuits

The carriage can control two torches by using the arc ignition cable plugged into the

arc ignition socket. To do this, refer to the diagram from Fig. 10 and connect one

blue-jacketed wire to one terminal of the welding circuit. Then, connect the other

blue-jacketed wire to the other terminal of the same circuit. To control the second

torch, connect the green-jacketed wires to the terminals of the second welding circuit.

Fig. 10. Connecting the arc ignition cable to welding circuits

Make sure that the arc ignition cable is connected correctly. To do this, turn on the

power of the carriage, and then set the arc ignition switch to TEST. This should ena-

ble the arc for a while.

Blue

Blue

Green

Green

Welding circuit 2

Welding circuit 1

Rail Runner 2

Rail Runner 2 –Operator’s Manual

19

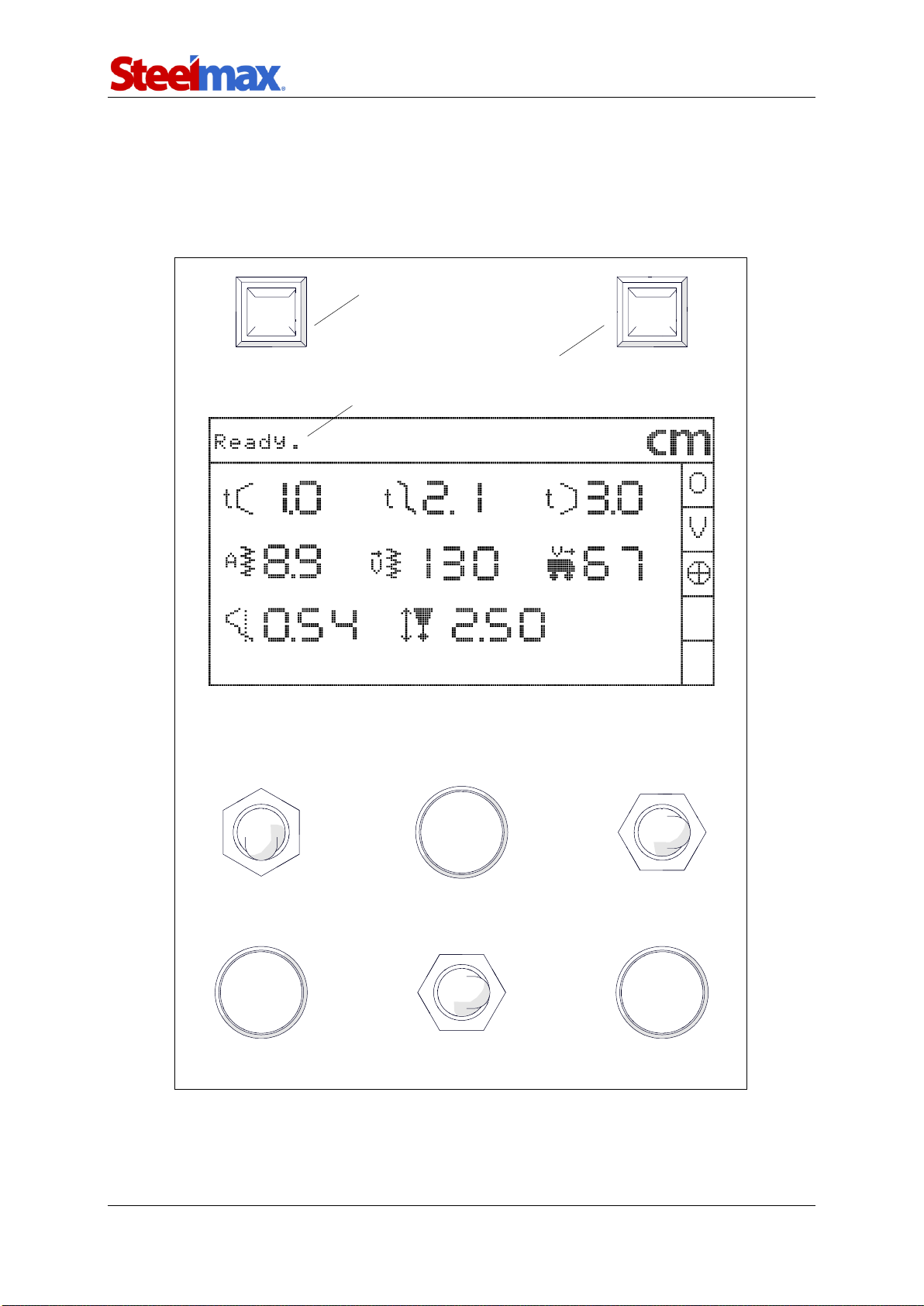

3.7. Operating

Set the power switch to ‘I’ to turn on the carriage. To pause loading to check the

firmware version, press and hold one of the navigation buttons. After you release the

button, the control system loads and the main screen from Fig. 11 shows.

Fig. 11. Control panel with the main screen displayed

Tab. 1 explains the symbols shown on the right of the main screen.

Operating mode

Arc ignition switch

(TEST/O/I)

Direction switch

(Forward/O/Backward)

F1

F3

F2

Oscillation switch

(TEST/O/I)

Navigation button 2

Navigation button 1

Rail Runner 2

Rail Runner 2 –Operator’s Manual

20

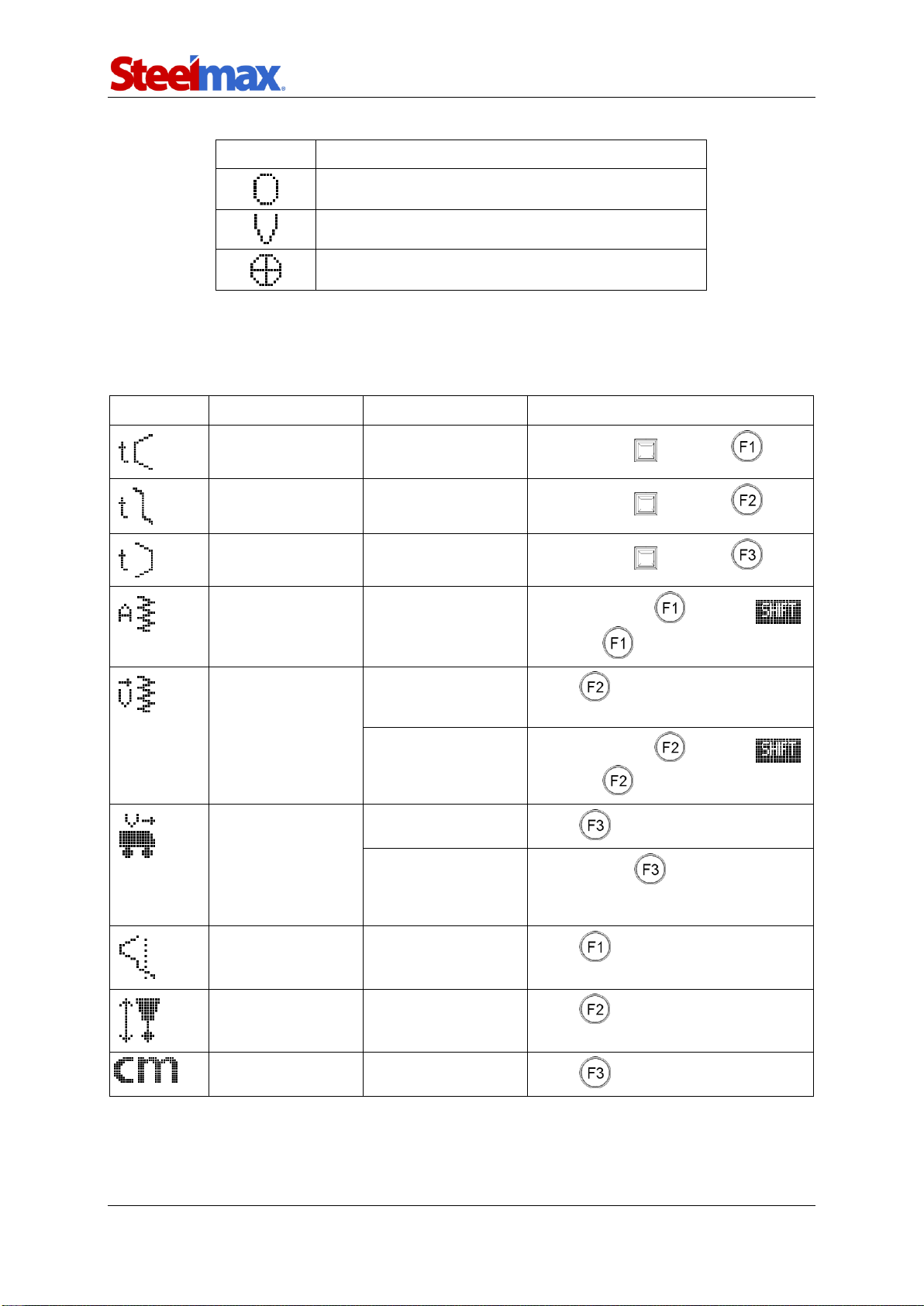

Tab. 1. Symbols of connected modules

Symbol

Description

Linear oscillator.

Motorized vertical slide (option).

Tracking sensor (option).

Use the knobs to set the required parameters (Tab. 2). Rotate to the right to increase

the value of the parameter. Rotate to the left to decrease the value.

Tab. 2. Parameters shown on the main screen

Parameter

Value

Description

Method of control

0–5 s

[step: 0.1]

Oscillation dwell time in

left position.

Press and hold and rotate

0–5 s

[step: 0.1]

Oscillation dwell time in

center position.

Press and hold and rotate

0–5 s

[step: 0.1]

Oscillation dwell time in

right position.

Press and hold and rotate

0.2–11.8 cm

0.1–4.5 in

[step: 0.1/0.01]

Oscillation width.

Press and release (activates )

and rotate

10–300 cm/min

5–120 in/min

[step: 5/1]

Oscillation speed

(when the vertical slide

is not connected).

Rotate

Oscillation speed

(when the vertical slide

is connected).

Press and release (activates )

and rotate

0–300 cm/min

0–120 in/min

[step: 1/0.5]

Carriage speed.

Rotate

Travel the carriage with

the maximum speed in

the direction set by the

direction switch.

Press and hold when the arc ignition

switch is set to ‘O’

From –9.9 to +9.9 cm

From –3.9 to +3.9 in

[step: 0.05/0.02]

Oscillation offset.

Rotate

From –2.5 to +2.5 cm

From –1 to +1 in

[step: 0.02/0.01]

Torch height (when the

vertical slide is con-

nected).

Rotate

cm

inch

Unit of measure.

Rotate in the correct setup screen.

Other manuals for Rail Runner 2

1

Table of contents

Other SteelMax Welding System manuals

Popular Welding System manuals by other brands

ASKAYNAK

ASKAYNAK MASTERMIG 420W user manual

EWM

EWM Taurus 451 Basic S FDG/FDW operating instructions

Lincoln Electric

Lincoln Electric MASTER LOAD IM575 Operator's manual

Lincoln Electric

Lincoln Electric Tomahawk 1000 Operator's manual

Air Liquide

Air Liquide SAFMIG 330 TRS PLUS Safety instruction for use and maintenance

HURNER

HURNER WeldControl EF 355 user manual