Steiel MA2000 User manual

STEIEL ELETTRONICA SRL

Viale Europa n° 24 -Z.I. Roncajette -35020 Ponte San Nicolò (PD) -ITALY

MA2000_IST_ING Rev.00 del 20-07-01 Page 1of 7

PANEL ALARM ACQUISITION SWITCHBOARD

MA2000

CONTENTS:

Foreword pag.1

Packing list pag.1

How it works pag.1

Installation pag.1

Level of safety pag.2

Guarantee pag.2

Technical features pag.2

Frontal pag.3

Back pag.3

Electrical connections pag.3-4

Inside of front panel pag.4

Date/time setting pag.4

Programming from front panel pag.5

Programmable data pag.5-6

Programming from a PC pag.6

Other functions pag.7

Troubleshooting pag.7

FOREWORD:

This device has been designed and tested in compliance with IEC publication 348: Safety Requirements for

Electrical Equipment for Measurement. More to the point “This device has been designed and tested in

compliance with IEC publication 348, and all criteria have been passed. The following instruction manual

contains information and procedures that need to be followed in order to ensure the safe operation and

maintenence of the device over time. The device has been designed for use inside premises, although it can

occasionally be exposed to temperatures between +5 and –10°C without a resulting loss in safety”.

The MA2000 switchboard and this manual are therefore in compliance with CEI 66/1 , 2, 3norms. The

switchboard is a “Class II device”.

PACKING LIST:

The MA2000 switchboard is supplied with the following:

1) 1 electronic unit

2) 2 brackets for fastening to panel

3) This instruction manual

4) Guarantee coupon (guarantee is for one year; see coupon for conditions)

HOW IT WORKS:

In a state of no alarm, the MA2000 excites all output relays (safety condition) and the words ‘NO ALARM’

appear on the display. A clock is always on, so current time also appears on the display. When an alarm is

recognised, the output relays are de-energised and the state of alarm (ALARM, SIREN and, possibly, SHUT)

is signalled; simultaneously, the triggering time is stored (this will appear on the display); the state of alarm is

also indicated by the flashing POWER-ON LED (normally a fixed light) and by the sound of an internal buzzer.

Any other alarms following the first one will also have the respective date and time stored, and will be displayed

in sequence. To switch off the state of alarm, all alarms need to be removed and identified using the ACK

button.

INSTALLATION:

This instrument has been designed for panel installation. Use the two brackets supplied for mounting. An

electrical control panel with transparent front door to protect the instrument from water sprinklers or other is

recommended. For further protection, use optional guard.

STEIEL elettronica s.r.l.

reserves the right to

make changes to the

switchboard or to this

manual without notice.

STEIEL ELETTRONICA SRL

Viale Europa n° 24 -Z.I. Roncajette -35020 Ponte San Nicolò (PD) -ITALY

MA2000_IST_ING Rev.00 del 20-07-01 Page 2of 7

SAFETY LEVEL:

The MA2000 switchboard has been designed and built in compliance with European Directive 89/336/EEC for

the electromagnetic compatibility.

The feeding transformer has been manufactured in compliance with EN60742 norms, EEC norms 73/23 (4kV

insulation between the primary and the secondary trasformers), and CEI norms 14.6 whereby it is defined a “

class II transformer”.

On the printed circuit, the minimum distance between the network and electronic power supply is greater than

3.3mm. This means that according to CEI EN 61010-1the MA2000 can be installed in areas of grade 2

pollution.

NB : output relay contacts have no filters or suppressors at all. It is the installer’s responsibility to dimension

and mount them.

Check that the electrical panel has been switched off prior to operating on the rear terminal boards!

GUARANTEE:

The switchboard has a 1-year guarantee from the date indicated on the delivery note or the date shown on the

guarantee coupon.

The instrument will be repaired under guarantee provided:

a) it has not been tampered with;

b) it comes with the guarantee coupon.

TECHNICAL FEATURES:

POWER SUPPLY: 230 or 115 or 24 V∼±10 % 50/60 Hz (please specify when

ordering)

ABSORBED POWER: max 3.7 VA

INTERNAL FUSE: F100mA 5*20

CASING: panel type, in NORYL, bracket mounting

DIMENSIONS: DIN 72 * 144 , depth 160 mm (including terminal brackets)

DRILLING TEMPLATE: 138 * 67 mm

WEIGHT: 800 g approx.

PROTECTION GRADING: IP 42 without protection, IP 54 with optional protection

CLIMATIC CONDITIONS: Storing temperature -20...+60 °C

Operating temperature -5...+50 °C

MAX humidity 90% without condensation

MICROCONTROLLER: 8 bit OTP, 8MHz, digital watch-dog, 8Kbytes ROM, 192bytes RAM,

128bytes EEPROM

NORMS OF REFERENCE: The switchboard has been designed and built in compliance with

EN 50081-, EN 61000-3-2, EN 61000-3-3, EN 50082-1, EN 61010-1

INPUTS: 12 alarm inputs, divided into two groups of six, with a single common

input, that accept voltage-free (12V –10mA) contacts, and with

galvanic separation from the microcontroller.

OUTPUTS: 6 independent outputs called ALL, SIREN and SHUT, 3 with

exchange potential-free contact, 3 with closing contact; max load 3A

@ 250V∼resistive

DISPLAY: 2-line, 16-character, backlit , high-contrast LCD

display. Green ‘ON’ LED (fixed light) / alarm (flashing light).

CONTROLS: 2 push buttons on the front panel (ACK and TEST), also present on

the rear terminal board for remote operating.

OPTIONS: RS232 serial line available inside the MA2000 for programming from

a PC using an adapter.

STEIEL ELETTRONICA SRL

Viale Europa n° 24 -Z.I. Roncajette -35020 Ponte San Nicolò (PD) -ITALY

MA2000_IST_ING Rev.00 del 20-07-01 Page 3of 7

FRONT PANEL:

The front panel of the switchboard features the following:

1) DISPLAY: 2-line, 16-character, backlit, high-contrast, alphanumeric, LCD display, which normally

displays the state of the alarms; during programming it displays the data stored and helps the

operator make changes.

2) POWER LED: light indicator showing the state of operation of the switchboard; a fixed light means

“regular operation, no alarm”, a flashing light means that there is something wrong or there is an alarm,

or that there is insufficient supply voltage.

3) ACK push button: alarm switch-off button: switches off the internal buzzer and the SIREN output.

4) TEST push button: when pressed, it simulates an alarm.

BACK:

ELECTRICAL CONNECTIONS:

POWER SUPPLY:

Check that the supply voltage corresponds to the unit rated value (max change ±10%). Next, power terminals

17 and 18. If present, connect the green/yellow ground wire to terminal 16. Though this connection is not

required for safety purposes, because this is a “class II device” it is however essential to eliminate any

electromagnetic interference from the power-supply line.

STEIEL ELETTRONICA SRL

Viale Europa n° 24 -Z.I. Roncajette -35020 Ponte San Nicolò (PD) -ITALY

MA2000_IST_ING Rev.00 del 20-07-01 Page 4of 7

OUTPUTS:

As can be seen from the diagram showing the back of the device, the outputs are available to terminals 1 to 15.

These are potential-free contacts that can stand a maximum of 3A resistive to 250V∼. As these contacts are

not protected by fuses or other, the installer should fit the panel with suitable protections for the components

controlled by the relays, and suitable arc eliminator systems (RC or varistors) in the case of inductive loads.

INPUTS:

Inputs are divided into two groups of six. Common inputs (pins 29 and 36) are short-circuited between each

other. Each input must be of the “potential-free contact” type and must be connected between the common and

the selected input. The input contact can be either NO or NC; it is possible to select during programming

whether or not to activate the alarm upon opening or closing the contact. The MA2000 switchboard supplies a

voltage of about 12 V and a current of approx. 10mA to each input

Warning! Supplying voltage to the inputs will burn them out!

KEYS:

It is possible to connect two additional ACK and TEST front panel push buttons to terminals 19 to 22.

INSIDE OF FRONT PANEL:

To remove the frontal:

1) Insert a small screwdriver between the front panel and the upper central part of the casing frame

2) lever with a screwdriver and pull out the front panel by a few millimetres

3) remove completely.

There are four more buttons inside the front panel. These are used for programming

1) NEXT key: for display selection and programming exiting

2) CAL key: for date/time setting, confirms data setting.

3) PLUS MINUS keys: for selected values increase/decrease both during date/time setting and during

programming.

View of front panel:

DATE/TIME SETTING:

MA2000 continuously displays date and time. When switched on for the first time, or for other reasons (for

example a change to DST), it may be necessary to change the date/time. This can be done during normal

operation, as follows:

1) Press CAL.

Display LCD 16*2

Ps +

Ps –

Ps CAL

Ps NEXT

Ps ACK Ps TEST

LED

STEIEL ELETTRONICA SRL

Viale Europa n° 24 -Z.I. Roncajette -35020 Ponte San Nicolò (PD) -ITALY

MA2000_IST_ING Rev.00 del 20-07-01 Page 5of 7

2) MA2000 will display REGOLAZIONE DATA/ORA (DATE/TIME set ) on the first line and the day of the

week will flash.

3) Press PLUS MINUS to select the day.

4) Press CAL or NEXT to confirm selection.

5) Time will now flash; select time using PLUS MINUS and press CAL to confirm.

6) Repeat steps 3, 4 and 5 to set minutes and seconds.

The time set is “buffered” by a lithium battery. This means that in the event of a power failure, the clock will

continue to work. The battery has an estimated life of about 2 years. If you notice that upon each power failure

the clock indicates the wrong time, send the MA2000 unit to Steiel for battery replacement (LITHIUM 3V

CR2032).

PROGRAMMING FROM FRONT PANEL

When programming, it is possible to “instruct” the MA2000 by setting the captions corresponding to the

various inputs, whether or not thery are NO or NC, and so on. To start programming procede as follows:

1) Make sure that a possible tripping of the output relays does not cause problems to the system (during

programming, alarms may trigger changing the contact from NO to NC).

2) Press NEXT.

3) PROGRAMMING appears on the MA2000 display, press CAL to confirm

4) Press CAL to confirm that you actually wish to enter the programming mode.

5) PASSWORD = 000 is then displayed.

6) Press PLUS MINUS to set correct password (e.g. 012) and press CAL to confirm.

7) If the password is correct, programming can begin and the values of the first input are displayed. A typical

display might be: PAR01 IN.01 NO NO SHUT DPSL01

8) The data displayed indicate: PAR01 = number of parameter being modified, IN.01 = number of relevant

input, NO = normally open (NC = normally closed), NO SHUT = the relevant input (no. 1 in the example)

does not generate an alarm on the SHUT relay (the alternative is SI SHUT), DPSL01 = alphanumeric

identification code for the relevant input.

9) Note that the cursor appears under the modifiable parameter (in the example PAR01 the value of which is

NO).

10) Press CAL to change the parameter; the value of the parameter will flash (in this example NA [normally

open] will flash). If you wish to change it press PLUS MINUS to set the new value and press CAL to

confirm; the value now enters the permanent memory (EEPROM) and will not be lost even in case the unit

is disconnected from the power supply.

11) Press NEXT to exit programming.

12) To see/change the other parameters, press PLUS MINUS (PARxx and cursor variations can be seen)

and repeat step 10 to change them.

13) Alternatively, if no buttons are pressed after 30 seconds the MA2000 automatically exits programming,

nevertheless saving the data set.

PROGRAMMABLE DATA

10 parameters can be programmed for each input:

1st parameter

NO/NC

determines whether the input

triggers the alarm upon closing

(NO) or upon opening (NC);

possible NO or NC values.

2nd parameter NO/SI SHUT determines whether this input

activates the SHUT output too;

possible values YES or NO.

3rd –10th parameter 1 to 8 characters for input name values; both numeric

(0-9) and alphabetic (a-z, A-Z)

values can be entered;

STEIEL ELETTRONICA SRL

Viale Europa n° 24 -Z.I. Roncajette -35020 Ponte San Nicolò (PD) -ITALY

MA2000_IST_ING Rev.00 del 20-07-01 Page 6of 7

The following is a table with all the parameters that can be set.

It is recommended that the last column be filled in with the data relative to the switchboard described in this

manual:

Value set

Par.01 NO/NC

Par.02 SHUT

Par.03 .. Par.10

Input 1

input name

Par.11 NO/NC

Par.12 SHUT

Par.13 .. Par.20

Input 2

input name

Par.21 NO/NC

Par.22 SHUT

Par.23 .. Par.30

Input 3

input name

Par.31 NO/NC

Par.32 SHUT

Par.33 .. Par.40

Input 4

input name

Par.41 NO/NC

Par.42 SHUT

Par.43 .. Par.50

Input 5

input name

Par.51 NO/NC

Par.52 SHUT

Par.53 .. Par.60

Input 6

input name

Par.61 NO/NC

Par.62 SHUT

Par.63 .. Par.70

Input 7

input name

Par.71 NO/NC

Par.72 SHUT

Par.73 .. Par.80

Input 8

input name

Par.81 NO/NC

Par.82 SHUT

Par.83 .. Par.90

Input 9

input name

Par.91

p

u

t

NO/NC

STEIEL ELETTRONICA SRL

Viale Europa n° 24 -Z.I. Roncajette -35020 Ponte San Nicolò (PD) -ITALY

MA2000_IST_ING Rev.00 del 20-07-01 Page 7of 7

Par.92 SHUT

Par.93 .. Par.100

input name

Par.101 NO/NC

Par.102 SHUT

Par.103 .. Par.110

Input 11

input name

Par.111 NO/NC

Par.112 SHUT

Par.113 .. Par.120

Input 12

input name

PROGRAMMING FROM A PC

This is only possible via the serial adapter and the software MA2000PROG already installed on your PC.

Procedure:

1) Make sure the MA2000 is turned off.

2) Insert the adapter onto the connector (please note: only by respecting the position of the pins is it

possible to insert the adapter in the correct way).

3) Insert the 9-pin CANNON connector on a free serial line of your PC (COMxx).

4) Turn on the MA2000.

5) Run the MA2000PROG program.

6) Check serial line parametre setting.

7) press EDITOR and follow the relative instructions.

OTHER FUNCTIONS:

During normal operation press NEXT once to enter the programming mode; further pressing NEXT

allows:

Once →PROGRAMMING (see relative subheading)

Twice →MANUAL TEST (controls all the functions of the MA2000)

Thrice →VARIABLE DISPLAYS (displays the MA2000’s internal data; the function is available exclusively to

STEIEL personnel)

TROUBLESHOOTING:

1) The instrument remains switched off even with the correct supply voltage:

a) internal fuse blown →replace

b) burnt power supply →send instrument to the

manufacturer for repair.

In case of fuse replacement, use a fuse with same size and current rating. Also find out the reason why

the original fuse blew:

a) incorrect power supply

b) power supply with peaks exceeding the nominal value by 15% .

It is forbidden to use makeshift fuses or to short-circuit the fuse holder!

Popular Switch manuals by other brands

RXTEC

RXTEC RX-PSE808G Quick installation guide

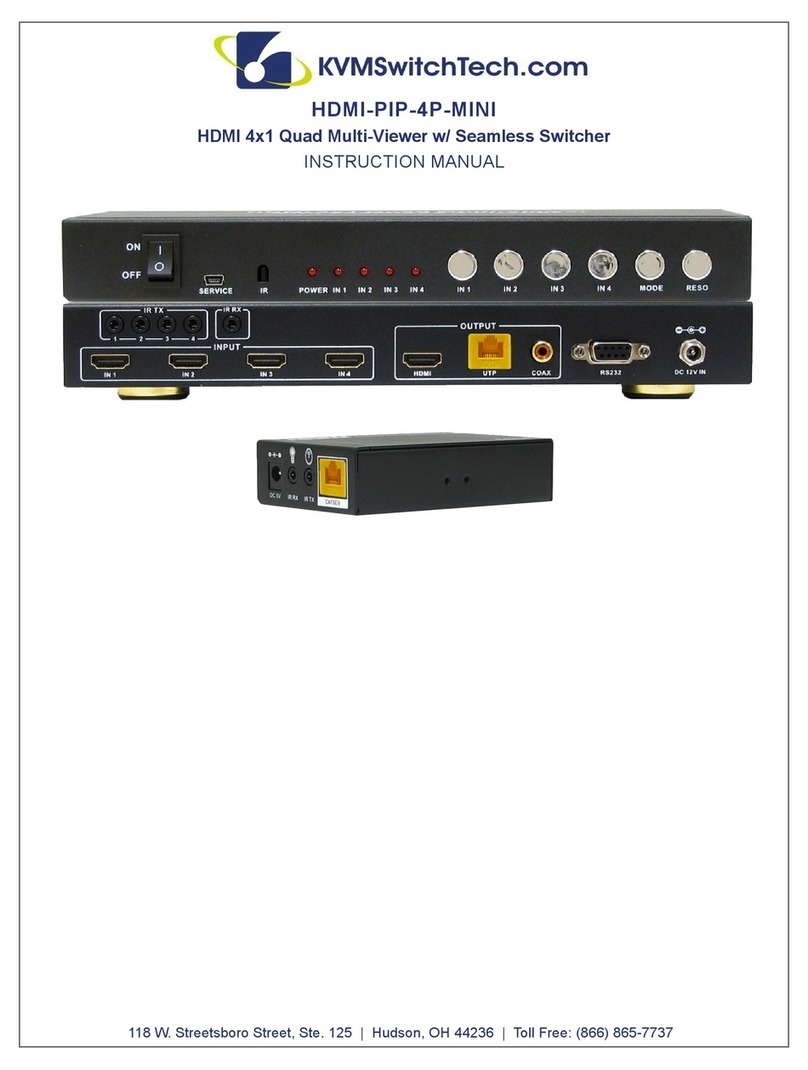

KVMSwitchTech

KVMSwitchTech HDMI-PIP-4P-MINI instruction manual

Atop

Atop EMG8510 Series Hardware installation guide

Cisco

Cisco Cisco Small Business Unmanaged Switch SR2016 datasheet

HP

HP FlexFabric 5950 Series Configuration guide

TRENDnet

TRENDnet TE-800plus Specifications