STEP ME800 Series User manual

ME800 High-voltage Inverter Operation Instruction

I

Shanghai Sigriner STEP Motor Co., Ltd

ME800 Series High Voltage Inverter

User Manual

Shanghai Sigriner STEP Electric Co.,Ltd

Shanghai, China

1560# Siyi Road, Jiading district, Shanghai

Postcode:201801

Hotline:400-821-0325

Shanghai Sigriner STEP Electric Co., Ltd.

II

II

ME800 Series High Voltage Inverter

Release state:Standard

Product version:V3.0

All Copyright reserved by Shanghai Sigriner STEP Electric

Co., Ltd.

The information in this document is subject to change without

prior notice. No part of this document may in any form or by any

means (electronic, mechanical, micro-coping, photocopying,

recording or otherwise) be reproduced, stored in a retrial system

or transmitted without prior written permission from Shanghai

Sigriner STEP Electric Co., Ltd.

ME800 High-voltage Inverter Operation Instruction

III

Foreword

ME800 series high voltage inverter is a new kind of inverter designed and manufactured by

Shanghai Sigriner STEP Electric Co., Ltd. The ME800 series high voltage inverter meets the

social requirements for energy saving and emission reduction. Thank you for your choice to

use our inverter. This manual contains the correct method which you must follow when

installing, operating and servicing the inverter. If ignored, physical injury or death may follow,

or damage may occur to the inverter and the motor. Read all the contents before you work

on the unit.

This manual only applies to ME800 series high voltage inverter produced by STEP.

The operating instruction is kept with the inverter properly, which is very convenient for use

at any time.

Summary

This manual is intended for personnel

This manual gives a comprehensive and systematic description about safety cautions,

installation, wiring, debugging, parameter setting, maintenance and so on. Read the manual

before working on the inverter to ensure safe and correct installation.

Audience

User

Engineering maintenance staff

Technical support staff

Content description

Supplement and modification may be made to the content of this instruction, please visit our

company website regularly for update. Website: www.stepelectric.com/sigriner

Signs and notices related to safety

This manual contains the following signs which relate to safety instructions. The instructions

are very important, please observe them strictly.

Shanghai Sigriner STEP Electric Co., Ltd.

IV

IV

Incorrect use can cause physical injury even death and damage to the equipment.

Incorrect use may cause minor/severe personal injury and damage to the equipment

Important

User must observe important notices.

ME800 High-voltage Inverter Operation Instruction

V

Contents

CHAPTER ⅠNOTICE FOR INVERTER USE....................................................................................1

1.1 SAFETY NOTICE .................................................................................................................................1

1.2 OUT OF BOX AUDIT.............................................................................................................................3

1.3 DESCRIPTION OF INVERTER MODEL .................................................................................................. 3

1.4 DESCRIPTION OF INVERTER NAMEPLATE...........................................................................................3

1.5 DISCARD AS USELESS NOTICE...........................................................................................................4

1.5.1 Capacitor handling ..................................................................................................................4

1.5.2 Plastic piece handling............................................................................................................. 4

CHAPTER ⅡOVERVIEW OF INVERTER .........................................................................................1

2.1 TECHNICAL CHARACTERISTICS..........................................................................................................1

2.1.1 High-quality input characteristics ..........................................................................................1

2.1.2 Low output harmonic...............................................................................................................2

2.1.3 High power factor .................................................................................................................... 3

2.1.4 Power failure and system continues to run..........................................................................3

2.1.5 High reliability and convenient maintenance.......................................................................3

2.1.6 Alarm and fault protection function .......................................................................................4

2.1.7 Selection of bypass function of power unit ..........................................................................4

2.1.8 Selection of system variable frequency/power frequency switching................................4

2.1.9 Soft start....................................................................................................................................4

2.1.10 Reducing motor abrasion and saving maintenance cost ................................................4

2.1.11 Rich user terminal interface.................................................................................................4

2.1.12 Friendly human-machine interface .....................................................................................5

2.2 FUNCTION BRIEF................................................................................................................................5

2.2.1 Frequency setting....................................................................................................................5

2.2.2 Operation Control Mode.........................................................................................................5

2.2.3 Acceleration and Deceleration Protection Function...........................................................6

2.2.4 Frequency Hopping Function................................................................................................. 6

2.2.5 Torque Lifting Function Controlled by V/F...........................................................................6

2.2.6 Configuration of Programmable User Terminal .................................................................. 6

2.2.7 Real Time Monitoring Function for Operating Parameters................................................7

2.2.8 Comprehensive Fault Inspection and Protection Function................................................7

2.2.9 Multi-level User Right Management...................................................................................... 7

2.2.10 Convenient Parameter Backup Function...........................................................................7

2.2.11. Communication Function .................................................................................................... 7

2.3 COMPOSITION AND WORKING PRINCIPLE OF INVERTER.................................................................... 7

2.3.1 Composition ............................................................................................................................. 7

2.3.2 Working principle................................................................................................................... 11

2.4 THE TECHNICAL PARAMETERS OF THE ME800 SERIES HIGH-VOLTAGE INVERTER........................ 14

2.5 SPECIFICATIONS AND DIMENSIONS.................................................................................................. 15

CHAPTER ⅢINSTALLATION AND WIRING.................................................................................... 1

Shanghai Sigriner STEP Electric Co., Ltd.

VI

VI

3.1 ACCEPTANCE CHECK.........................................................................................................................1

3.2 HANDLING..........................................................................................................................................1

3.3 INSTALLATION ....................................................................................................................................3

3.3.1 Requirements of operating environment..............................................................................3

3.3.2 Requirement of cabinet space............................................................................................... 3

3.3.3 Installation of cooling fan........................................................................................................4

3.4WIRING...............................................................................................................................................4

CHAPTER ⅣTOUCH SCREEN...........................................................................................................1

4.1 INTRODUCTION OF TOUCH SCREEN......................................................................................................1

4.2 OPERATION OF TOUCH SCREEN............................................................................................................ 1

4.2.1 Main interface of touch screen ..............................................................................................1

4.2.2 Password login interface of touch screen............................................................................4

4.2.3 Password modify interface of touch screen.........................................................................5

4.2.4 Power unit/IO status interface of touch screen ...................................................................5

4.2.5 Record interface ......................................................................................................................9

4.2.6 Parameter setting interface of touch screen......................................................................13

4.2.7 SOP setting interface............................................................................................................ 17

CHAPTER ⅤFUNCTION PARAMETER TABLE..............................................................................1

5.1 FUNCTIONAL GROUP CLASSIFICATION ................................................................................................. 1

5.2 FUNCTION LIST AND DESCRIPTION.......................................................................................................1

5.2.1 Basic parameters.....................................................................................................................1

5.2.2 Adjustment parameters .......................................................................................................... 3

5.2.3 Motor parameters.................................................................................................................... 3

5.2.4 Frequency control parameters............................................................................................... 4

5.2.5 Terminal function parameters................................................................................................ 5

5.2.6 Expand parameters............................................................................................................... 19

5.2.7 Display parameters ............................................................................................................... 20

5.2.8 Power unit parameters.......................................................................................................... 20

CHAPTER ⅥDEBUGGING PROCEDURES.....................................................................................1

6.1 INTRODUCTION................................................................................................................................... 1

6.2 PRE-POWER VISUAL INSPECTION ...................................................................................................... 2

6.3 INSULATION RESISTANCE INSPECTION .............................................................................................. 3

6.4 POWER UNIT AND COMMUNICATION TESTING....................................................................................4

6.5 TEST ON THE INVERTER WITHOUT MOTOR ........................................................................................5

6.6 TEST ON THE INVERTER WITH MOTOR............................................................................................... 6

6.7 IMPORTANT PARAMETERS SETUP INSTRUCTIONS.............................................................................. 8

6.7.1 Analog calibration....................................................................................................................8

6.7.2 Frequency hopping function description ..............................................................................9

CHAPTER ⅦALARM INFORMATION AND FAULT PROCESSING............................................1

7.1 FAULT NAME.......................................................................................................................................1

7.2 FAULT AND SOLUTIONS......................................................................................................................1

ME800 High-voltage Inverter Operation Instruction

VII

7.2.1 System fault and solutions.....................................................................................................1

7.2.2 Unit fault and solutions ........................................................................................................... 8

7.2.3 Bypass fault and solutions ................................................................................................... 10

7.2.4 Other faults and solutions..................................................................................................... 10

CHAPTER ⅧCOMMUNICATION PROTOCOL.................................................................................1

8.1 FUNCTION AND ADDRESS OF MODBUS.............................................................................................. 1

8.1.1 Explanation............................................................................................................................... 1

8.1.2 Modbus protocol...................................................................................................................... 1

8.2 PROFIBUS PROTOCOL........................................................................................................................6

8.2.1 Control word............................................................................................................................. 6

8.2.2 State word.................................................................................................................................8

APPENDIX A FAULT LIST......................................................................................................................1

APPENDIX B CUSTOMER COMPLIANT.............................................................................................1

APPENDIX C PRODUCT WARRANTY CARD....................................................................................1

APPENDIX D NOTICE TO CUSTOMER...............................................................................................1

ME800 High-voltage Inverter Operation Instruction

1-1

Chapter Ⅰ

Notice for inverter use

Chapter ⅠNotice for Inverter Use

1.1 Safety notice

Important

To ensure correct use, contents in this instruction must be known well before

installation, wiring, operation and maintenance inspection. Conditions of the machines

driven and the process as well as all related safety notices also should be understood

during use.

This series of high voltage inverter only applies to 3-phase high voltage induction motor.

If misused, unpredictable faults or dangers may follow.

The discarded elements and parts should be treated as industrial rubbish.

Wiring notice

Wiring operation must be executed in accordance with the related electric safety

operation standard under the guide of our professionals.

High voltage breaker for circuit protection must be provided on the power supply side of

high voltage inverter.

Wiring operation will be started only after the equipment body is mounted in place.

Ground wire must be connected reliably.

Phase of input power must be confirmed, and rated input voltage shall be consistent

with the rated voltage of inverter.

Transportation and storing notice

In all process of transporting, storing and installing the equipment in place, it can’t allow

the water into the inverter, or it will damage the equipment.

During lifting equipment, enough load bearing must be guaranteed, and its rise and fall

Shanghai Sigriner STEP Electric Co.,Ltd

2

1-2

Chapter Ⅰ

Notice for inverter use

shall be slow and gentle.

When moving, transporting and placing the equipment, its placement location shall be

level and smooth.

Don’t install inverter or put it into operation when its components are damaged.

Protective guard must be provided in the necessary position (marked with Danger High

Voltage), which cannot be moved away during equipment operation.

Don’t drop (leave) foreign matters such as wire residue, paper scrap, metal chip or tool

into inverter.

Storing notice

×Rainfall ×Outside ×Conductive dust ×Direct sunlight

×Flammability or explosive gas × Corrosive gas × Salt lampblack and dust, etc

Operation can be started only after no voltage is in the control circuit or main circuit.

Input and output HV cable must be connected following the directions, or it may cause

equipment damage will be caused.

Input and output HV cable will conform to the requirements of insulation and carrying

capacity, or it may cause the danger of short circuit once powered on.

Inverter shall be mounted on the flame retardant, such as metal support and cement

ground.

Inverter must be operated by HV electrician if high voltage passes through it. Doors

except for control cabinet shall not be opened after powering on.

ME800 High-voltage Inverter Operation Instruction

1-3

Chapter Ⅰ

Notice for inverter use

1.2 Out of box audit

Do not install inverter with damaged or missing parts, or it may cause fire and human injury

hazards.

When unpacking, please confirm carefully that there is damage during transportation, and

that model and specification in the nameplate is consistent with order requirement. If not

consistent or any part is missing, contact factory or supplier as early as possible.

1.3 Description of inverter model

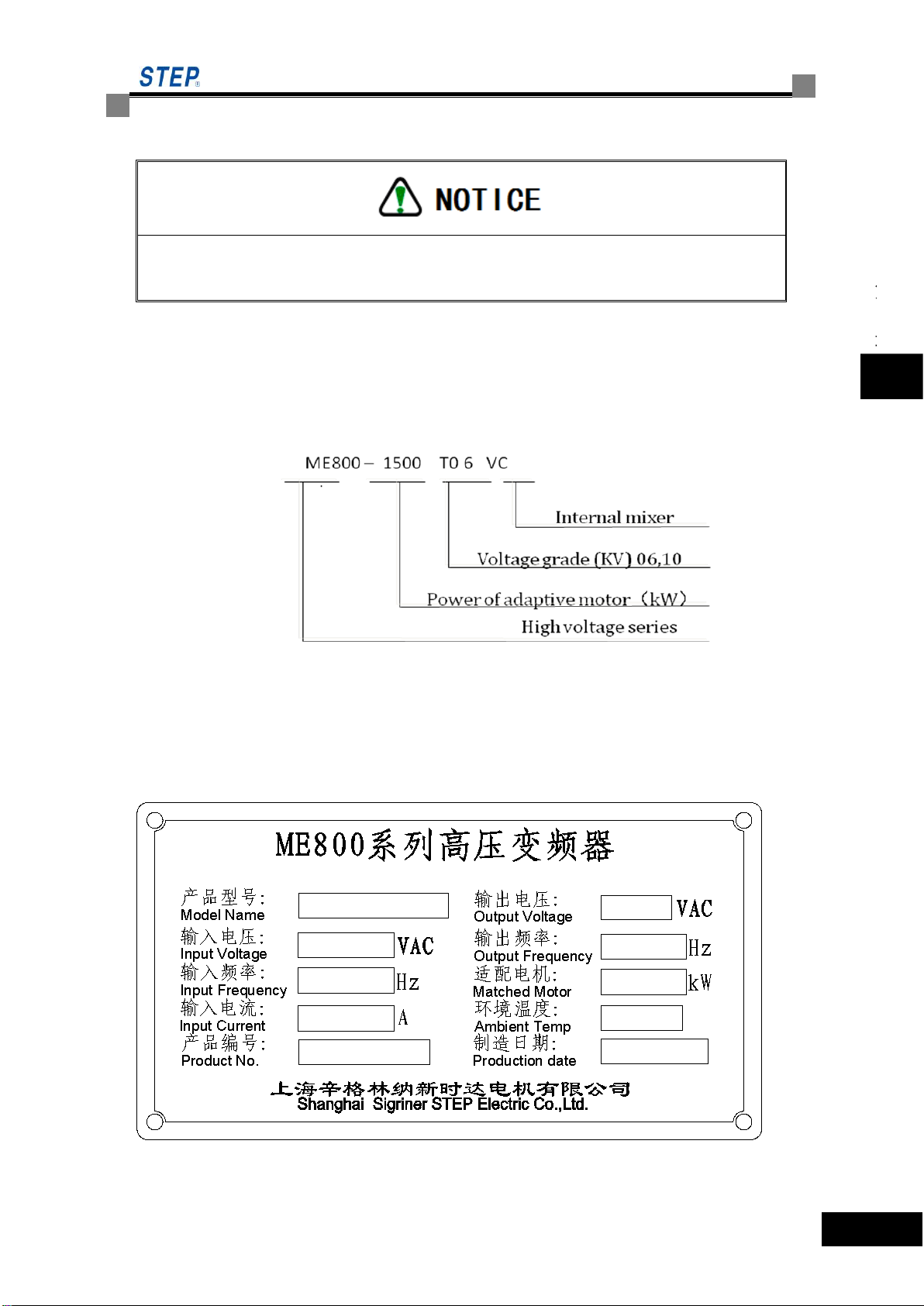

Fig.1-1 Description of inverter model

1.4 Description of inverter nameplate

For inverter nameplate, see Fig.1-2. Nameplate of inverter records inverter model,

specification, machine No and order No, etc.

Fig.1-2 Inverter nameplate

Shanghai Sigriner STEP Electric Co.,Ltd

4

1-4

Chapter Ⅰ

Notice for inverter use

1.5 Discard as useless notice

A discard as useless inverter needs to be handled as industrial refuse.

1.5.1 Capacitor handling

Electrolytic capacitors in main circuit and printed circuit board may explode while burning. It

is prohibited to burn them.

1.5.2 Plastic piece handling

There are many plastic pieces in inverter, and burning plastic piece will produce toxic gas.

Therefore, it is prohibited to burn them.

ME800 High-voltage Inverter Operation Instruction

2-1

Chapter II

Overview of Inverter

Chapter ⅡOverview of Inverter

2.1 Technical characteristics

As a new generation of high-high voltage inverter designed and manufactured by our company,

ME800 series HV inverter is able to suppress input harmonic current at the network side by the

shift-phase rectify transformer, and realize voltage overly by cascading multistage H bride

power unit, so as to obtain the perfect high voltage sine wave output. It will directly drive high

voltage motor, without any filter. ME800 series HV inverter applies to the standard high voltage

(3kV,6kV and 10kV)3-phase AC motor, with following characteristics:

2.1.1 High-quality input characteristics

ME800 series high voltage inverter applies shift-phase multiple rectification technology at the

power supply side, with small pollution to the harmonic on grid side and high power factor,

meeting GB 14549-9 and IEEE std 519-1992 in terms of voltage and current harmonic

distortion degree, without harmonic interference to other electrical equipment on the same grid,

as shown in Fig.2-1 and Fig.2-2.

Fig.2-1 Input 3-phase current wave form

Shanghai Sigriner STEP Electric Co.,Ltd

2

2-2

Chapter II

Overview of Inverter

Fig.2-2 Input 3-phase current total harmonic

2.1.2 Low output harmonic

Output side of ME800 series high voltage inverter uses phase-shift multiple pulse width

modulation technology with very small output harmonic, which is applicable to various motors

without any output filter device. Because of low output voltage distortion degree and good sine

degree of wave form, motor has low noise, small torque ripple and low heat productivity,

therefore scope of output cable length is wide.

Fig.2-3 Output current wave form of sine wave

ME800 High-voltage Inverter Operation Instruction

2-3

Chapter II

Overview of Inverter

2.1.3 High power factor

ME800 series high voltage inverter belongs to the constant voltage type, which will keep high

power factor within full speed range, and its full load power factor can be over 0.95, so as to

reduce low equipment utilization rate of the user power transformer and power factor

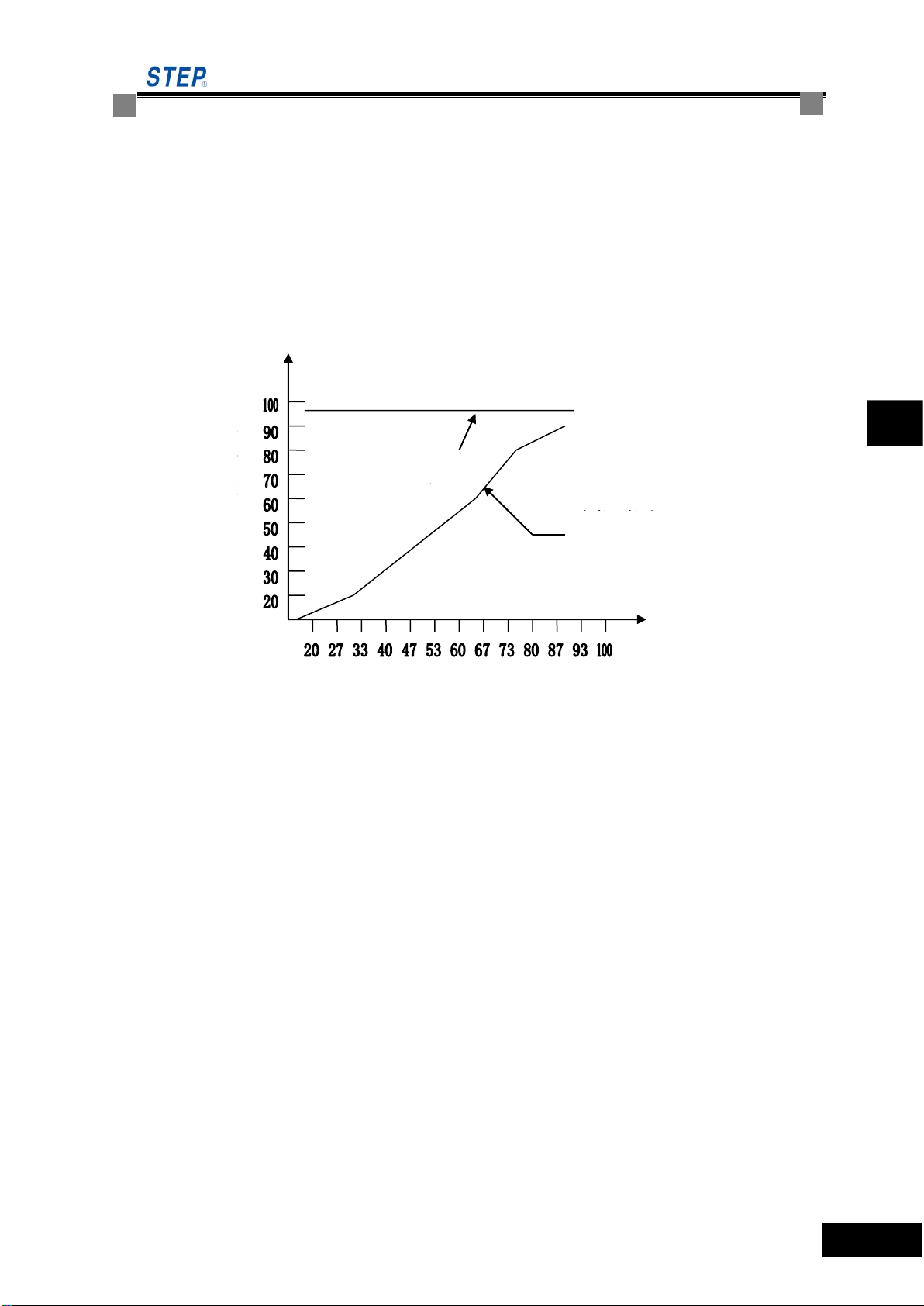

compensation problem of the user side caused by low power factor. Fig.2-4 shows power factor

comparison between high voltage inverter and phase control thyristor.

Fig.2-4 Power factor comparison between ME800 high voltage inverter and phase control thyristor

2.1.4 Power failure and system continues to run

During system operation, the Inverter can continue to run 1.2 seconds after instant power

failure of the grid (less than 1.2 seconds). During this time the system continues to run if power

on again to avoid the loss caused by unnecessary shutdown. Beyond the time, the system will

report the fault of power outages and then shutdown.

2.1.5 High reliability and convenient maintenance

IGBT power module of ME800 high voltage inverter has bigger voltage and current design

margin, whose trigger and overcurrent protection uses the special driver module circuit with

very high reliability. Control signal of inverter is transferred via optical fiber, realizing the reliable

electrical isolation of high and low voltage weak current.

ME800 series high voltage inverter adopts modular design, with perfect structural process

design and generality for the unit module with the same capacity. If any fault occurs, the simple

tool will be used to replace it within several minutes, conveniently and quickly.

Phase control thyristor

rectification inverter

ME800 high

voltage inverter

Power factor

Percentage rate

Shanghai Sigriner STEP Electric Co.,Ltd

4

2-4

Chapter II

Overview of Inverter

2.1.6 Alarm and fault protection function

ME800 series inverter provides the perfect alarm and protection function, with the fault

message relating to power unit and the complete machine, which will be viewed via remote

monitoring interface or site operator.

If any fault appears, inverter will automatically record its operation environmental message.

2.1.7 Selection of bypass function of power unit

When any power unit of the inverter fails, bypass it through bypass function and inverter will

operate for dated capacity, to greatly improve its reliability.

Warning: Before replacing the faulty power unit, it must be shutdown and cut off the drive

high-voltage input power.

2.1.8 Selection of system variable frequency/power frequency switching

If it is required by process or high voltage inverter fails, the user can manually or automatically

realize system variable frequency/power frequency switching by choosing function parameters.

2.1.9 Soft start

ME800 series high voltage inverter has the feature of soft start. Start time is set by user, with

the built-in functions of acceleration, overcurrent and speed limit to control impact current of

motor start, guarantee safe operation of motor and lengthen its service life. Overcurrent

shock-free quick start for the grid and motor can be realized. This function also will effectively

avoid motor faults such as cage bar breakage of the motor squirrel cage.

2.1.10 Reducing motor abrasion and saving maintenance cost

Such loads as fan and pump adopt ME800 high voltage inverter to adjust output through

adjusting motor speed, which will not only reach the objective of energy conservation, but

greatly reduce mechanical wear of the motor and its load, as well as save maintenance cost for

user.

2.1.11 Rich user terminal interface

ME800 series high voltage inverter is designed with rich I/O ports for users. Users can build

specific application system with these I/O ports (4-channel analog input, 4-channel analog

output and 16-channel switching input and 8-channel relay output) supplied by system; and

partial of terminals are programmable ones, so as to guarantee good system adaptability. Users

can also expand I/O port according to the actual needs.

ME800 High-voltage Inverter Operation Instruction

2-5

Chapter II

Overview of Inverter

2.1.12 Friendly human-machine interface

ME800 series high voltage inverter human-machine interface adopts touch screen and digital

keyboard, with the rich functions of setting, display and operating, as well as friendly

human-machine interface. Users can conveniently understand the running status message of

system via human-machine interface, and control high voltage inverter as required by process

control.

2.2 Function brief

2.2.1 Frequency setting

Given way of the operation frequency:

Given by panel

Given by communication (for remote monitoring interface)

Given by analog signal input

Given by multi-speed: the inverter can set several frequency sections and acceleration &

deceleration time, with switching among these frequency sections by terminal flexibly.

Choose the relative parameters within digital multi-velocity parameter to configure the

settings relating to operation frequency; Choose selection of frequency given way by

setting frequency/speed channel selection parameter.

2.2.2 Operation Control Mode

Start mode of inverter:

Normal start;

DC braking and restart (for the fan-type load, reverse rotation may be driven by load. Firstly

hold on the motor by DC braking, and then restart it, so as to avoid the huge impact current

during start).

Speed tracking start,The inverter firstly tracks the current speed of motor, then directly

starts on the basis of current speed.

Parking mode:

Deceleration and park,control the motor speed according to deceleration curve, until it

stops after zero frequency.

Inertia parking,Directly block PWM output, the motor stops as its own inertia.

Shanghai Sigriner STEP Electric Co.,Ltd

6

2-6

Chapter II

Overview of Inverter

DC braking and parking,quick braking and parking are realized by adding DC in motor coil.

Given ways for start and parking command of inverter:

Panel control

Terminal control

Communication control

Set the given way of start and parking command by touch screen

2.2.3 Acceleration and Deceleration Protection Function

No overcurrent appears to the protection motor during the accelerating process and no

overvoltage during the decelerating process. Once overcurrent or overvoltage alarm (protection

value hasn’t been reached yet) appears, the inverter will automatically keep the current

frequency unchanged, until the voltage or current returns to the normal level and accelerate or

decorate again.

2.2.4 Frequency Hopping Function

ME800 series inverter supports to set frequency hopping, 3 frequency hopping points are

available.

Frequency hopping: in order to avoid equipment damage such as motor caused by that the

inverter run at point of resonance of mechanical equipment, users can avoid this point of

resonance by setting frequency hopping.

Frequency hopping bandwidth: frequency width, when the inverter hops frequency, shall

not be too large, for example (0.5-2), or it may cause overcurrent or overvoltage.

2.2.5 Torque Lifting Function Controlled by V/F

ME800 series high voltage speed governing system provides low frequency torque lifting

function, the user may set torque lifting amplitude and speed scope that the torque needs to lift

within user-defined V/F parameters adopting the relevant parameter.

2.2.6 Configuration of Programmable User Terminal

ME800 series high voltage inverter provides rich terminal functions for users, in addition, it may

expand these I/O terminals as the user’s actual needs. The terminals may be programmable

ones, so as to guarantee the flexible system expandability and good adaptability.

ME800 High-voltage Inverter Operation Instruction

2-7

Chapter II

Overview of Inverter

2.2.7 Real Time Monitoring Function for Operating Parameters

ME800 series high voltage inverter is of the rich parameter monitoring functions.

Operation frequency, given frequency, current speed, input voltage, output voltage, input

current, output current, running speed, output frequency, terminal status, analog value, unit bus

voltage, unit temperature, unit optical fiber communication status, unit running status, unit

bypass state transformer temperature can be monitored under all conditions.

2.2.8 Comprehensive Fault Inspection and Protection Function

ME800 series high voltage inverter provides classification protection over 220 faults, and may

automatically send an alarm or report fault treatment and record according to severity of fault.

Users may view fault message via the operator or remote monitoring interface, and the system

will provide alarm prompt interface at the same time, to avoid element damage due to serious

fault.

In addition, system provides EEPROM detection function. When EEPROM error is detected, it

will be presented to the user by remote monitoring interface.

2.2.9 Multi-level User Right Management

ME800 series high voltage inverter provides three-level user right such as visitor, operator and

administrator, and provides the related rights according to user level, making the operation

become more safe and convenient.

2.2.10 Convenient Parameter Backup Function

Remote monitoring interface provides the convenient backup function for parameters and other

configuration message, the users can restore the backup parameters into the system by means

of simple operation.

2.2.11. Communication Function

ME800 series high voltage inverter provides the external Modbus (standard configuration) and

Profibus-DP (selective configuration) communication interface. The user may control and set

inverter with his own system via protocol.

2.3 Composition and working principle of inverter

2.3.1 Composition

The standard configuration of ME800 series inverter cabinet is different, which is based on the

Shanghai Sigriner STEP Electric Co.,Ltd

8

2-8

Chapter II

Overview of Inverter

inverter, model and quantity of units as well as other factors. But it is generally composed of the

following cabinet:

Transformer cabinet

System control cabinet

Power unit cabinet

System bypass cabinet(selective configuration)

Start cabinet(selective configuration)

Fig.2-5 is the appearance of typical ME800 inverter.

Fig.2-5 Appearance of ME800 Inverter

2.3.1.1 Transformer cabinet

Transformer part of ME800 inverter mainly includes phase-shift rectification transformer and its

cabinet. Input power line enters inverter from this cabinet and output power line to motor also is

led from here. Input and output power line applies both up and down incoming line. One or

several fans are also needed to cool the transformer. See Fig.2-6.

This manual suits for next models

70

Table of contents

Other STEP Inverter manuals