Safety regulation for the use

General safety rules

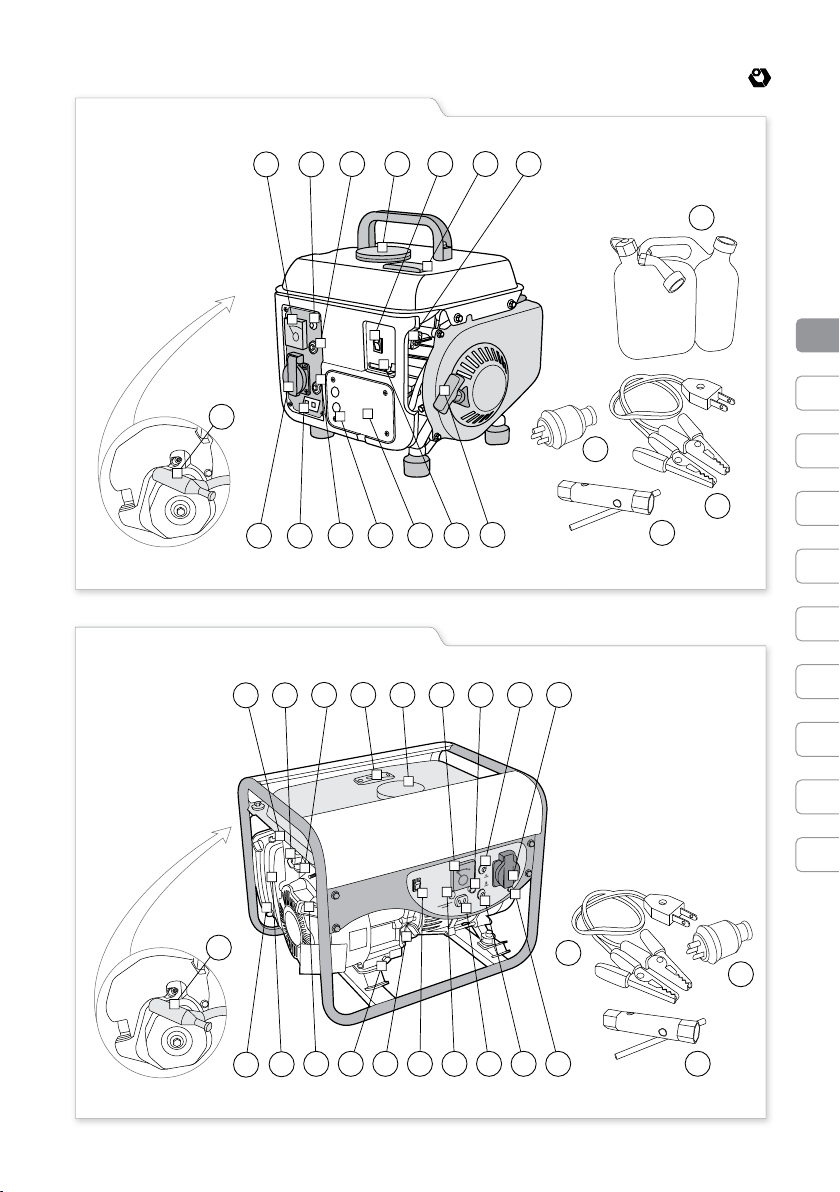

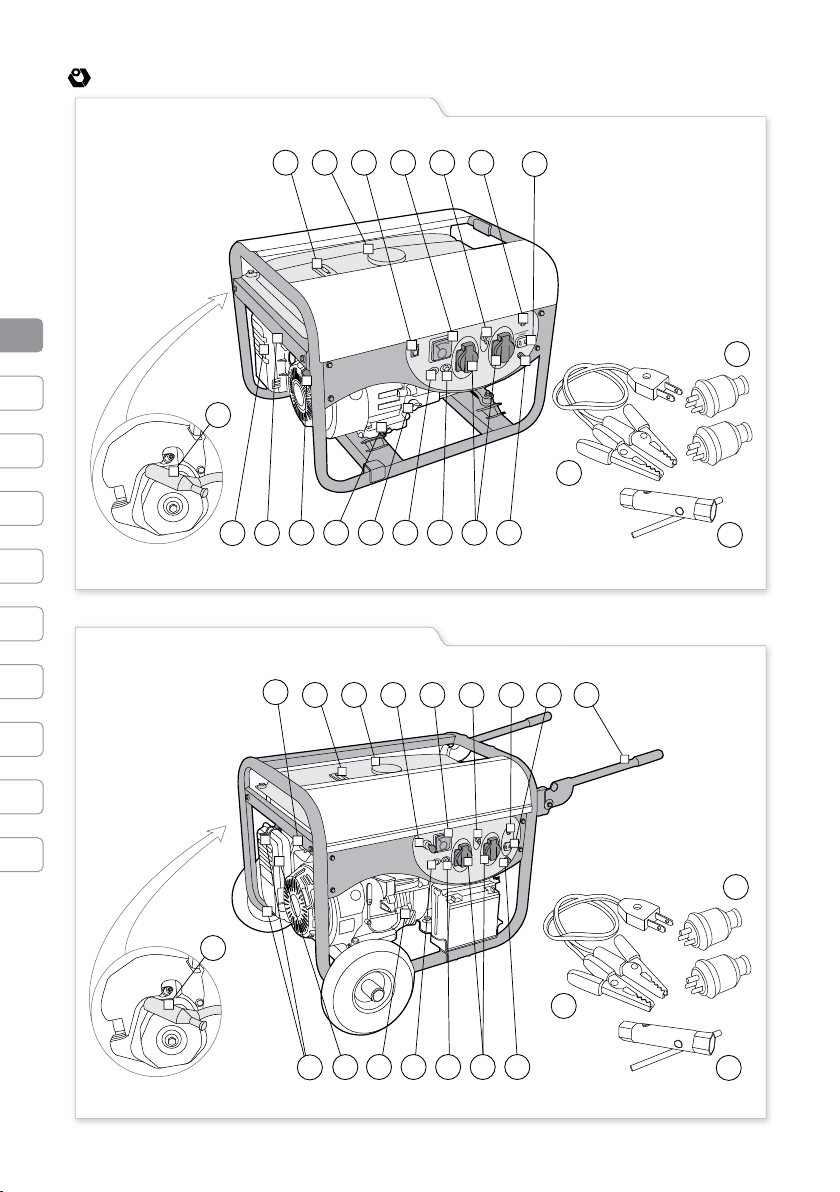

These models of gasoline generators (GN-850; GN-

1500; GN-3000; GN-6500) are designed to give safe

and dependable service if operated according to

the instructions.

The following listed safety instructions should serve

you for the right use and for the protection of your

own safety. Therefore please read this very carefully.

When passing this device to a third person, these

instructions must be handed out, too.

Retain this user manual and all other literature

supplied with your device for any future reference.

Comply with the safety information and the warning

on the appliance.

Be familiar with the controls and the proper use of

the appliance before attempting to operate it and

above all, make sure you know how to stop it in case

of emergency.

Following these simple instructions will also

maintain your device in good working order.

The appliance must be assembled correctly•

before use.

Only use the appliance for its designed•

purposes.

In addition to the design of the device there are•

safetydecalsthatmustbeconsideredandindications

about the safety equipment to use. Accident

prevention is dependent upon the awareness,

common sense, forethought, and proper training

of everyone involved in the operation, transport,

maintenance, and storage of the machine.

Never leave the machine unattended.•

Never allow children to use the appliance.•

Children should be supervised to ensure that they

do not play with the appliance.

Keep children and pets away. All onlookers•

should be kept at a safe distance away from the

appliance when it is in use. Stop using the machine

while people, especially children, or pets are

nearby.

The user is responsible for third parties while•

working with the appliance.

People who aren’t acquainted with the operating•

instructions, children, juveniles who have not yet

reached the minimum age for using this appliance,

and people under the inuence of alcohol, drugs or

medicationarenotallowedtousetheappliance.Local

regulations may restrict the age of the operator.

WARNING: The consumption of alcohol,

medication and drugs, plus states of illness, fever

and fatigue will aect your ability to react. Do not

use electric tools in any of these situations.

Make sure that all the protective devices are•

tted and are in good conditions.

Never operate the appliance with defective•

safety devices or guards, or without safety devices

in place.

Avoid any accidental starting: make sure the•

switch is“o” before plugging in.

Remove adjusting keys or wrenches before•

turning the tool“on”.

Do not use the tool if the switch does not turn•

to “ON” or “OFF”. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

Inspect the entire machine to look for loose•

parts (nuts, bolts, screws, etc.) and for any damage.

Check at frequent intervals if screws and bolts are

properly tight and to be sure the equipments is in

safe working condition. Repair or replace them, if

necessary, before using the machine. Serious injury

to the operator and to the bystanders could result if

there’s a damage to the machine.

While operating the appliance, dress properly.•

Do not wear loose clothing or jewelry that could

become caught by the moving parts of the unit.

Wear suitable working clothes, long trousers and

solid shoes. It is recommended that legs and feet

are covered, to protect from ying debris during

the operation. Do not operate the appliance when

barefoot or wearing open sandals. Long hair should

be tied back.

Keep handles dry clean and free from oil and•

grease.

WARNING: Use personal protective

equipment! The safety device and the

personal protective equipment to

protect your own health and the health of others

and ensure trouble-free operations of the device.

Use safety glasses, safety gloves, solid non-skid•

safety shoes and, if necessary, also an hardhat. Also

use a dust mask during pulverulent operations. If

the noise level exceeds 85 dB(A), ear protection is

obligatory.

Ensure that you have a good a stand, while you•

operate with the device. Keep proper footing and

balance at all times.

Do not start the device if it is in an inverted•

position or is not in the right working position.

Before use, all foreign bodies must be removed•

from the working area where the appliance is going