Steridose sterimixer User manual

Magnet Lowering Device

STD0023EN00

APPLIES TO: Steridose products Sterimixer®-Low-Shear drive units with Magnet Lowering Device.

CONTENTS

1 Important safety information 1

2 About the Magnet Lowering Device 2

3 Operation 2

4 Magnet Lowering Device product range 3

5 Sensor option for automation 3

6 Maintenance 3

7 Fitting the upgrade kit to existing drive units 3

8 Fitting the optional sensor kit to the Magnet

Lowering Device 7

Copyright © 2018 Steridose

Generated by Steridocs: November 22, 2018

1. IMPORTANT SAFETY INFORMATION

1.1. Introduction

1.1.1. Purpose of this manual

Read this manual carefully before installing and using

the product. Improper use of the product can cause per-

sonal injury and damage to property, and may void the

warranty.

+NOTICE: Save this manual for future reference

1.2. Safety terminology and symbols

1.2.1. Hazard levels and indications

The following symbols are used to indicate hazard levels.

DANGER:

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING:

Indicates a hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION:

Indicates a hazardous situation which, if

not avoided, could result in minor or moderate injury,

or, a situation that might lead to serious damage to the

product or components.

+NOTICE:

Indicates: A potential situation which, if not

avoided, could result in undesirable conditions or con-

tains tips to enhance the performance or facilitate the

installation of the product.

1.2.2. Hazard categories

Hazard categories can either fall under hazard levels or

let specific symbols replace the ordinary hazard level sym-

bols.

ELECTRICAL HAZARD:

www.steridose.com Installation & Operation | 1

INSTALLATION

& OPERATION

MANUAL

STRONG MAGNETIC FIELDS HAZARD:

CORROSIVE AGENTS HAZARD:

HAZARD FOR WEARERS OF CARDIAC PACE-

MAKER:

1.2.3. Other symbols used

In situations where confusion could arise, the icons below

are used to distinguish between the right and the wrong

procedure.

1.3. General safety

1.3.1. General statement

Undertaking any work covered by this manual may ei-

ther directly or indirectly create risks to the safety and

health of the person undertaking the work or the Sterim-

ixer/Sanimixer and/or its components while the work is

being undertaken.

It is the responsibility of the user to ensure that appro-

priate controls and precautions are identified and applied

in relation to the work covered by this document in ac-

cordance with relevant statutory, legal and industry re-

quirements to protect the health and safety of the persons

undertaking the work.

Neither this document, nor its use, in any way absolves

the user from their responsibility to ensure that the con-

trols and precautions referred to in this chapter are imple-

mented.

If, by undertaking any work covered by this document,

you become aware of any Steridose product design related

feature which could create risk to a person undertaking

work or to the Sterimixer/Sanimixer and/or its compo-

nents please contact Steridose immediately.

CAUTION:

You must observe the instructions con-

tained in this manual. Failure to do so could result

in physical injury, damage or delays.

1.4. User safety

WARNING:

This manual cannot replace specific knowl-

edge and adequately trained personnel needed for in-

stalling and handling equipment for professional use,

such as this product.

1.4.1. General safety rules

These safety rules apply:

• Always keep the work area clean

•

Pay attention to the risks presented by gas and vapors

in the work area

•

Avoid all electrical dangers. Pay attention to the risks

of electric shock or arc flash hazards

•

Always bear in mind the risk of pinching fingers,

electrical accidents and burn injuries.

1.4.2. Safety equipment

Use safety equipment according to the company and local

regulations.

1.4.3. Electrical connections

Electrical connections must be made by certified electri-

cians in compliance with all international, national, state

and local regulations. For more information about require-

ments see the relevant sections dealing specifically with

electrical connections (if applicable).

1.4.4. Hazardous liquids

The product is designed for use in liquids that can be

hazardous to your health.

WARNING:

Make sure that all personnel who work

with hazardous liquids use suitable protective equip-

ment.

1.4.5. Specific operational hazards

Specific operational hazards are listed under its respective

section.

1.4.6. Specific hazards while performing maintenance

Specific hazards while performing maintenance on the

product are listed under its respective section.

2. ABOUT THE MAGNET LOWERING DEVICE

The magnetic coupling between impeller and magnet ro-

tor is strong enough to pose a risk for damage to the bear-

ings during removing/installing the impeller. Therefore,

in conventional installations, the drive unit should be com-

pletely removed from the tank before removing/installing

the impeller, not vice-versa. The Steridose Magnet Low-

ering Device (LD) allows the user to break the magnetic

coupling without removing the drive unit from the vessel.

This is a significant ergonomic enhancement that reduces

service time and is particularly useful when working with

heavy drive units that can weight as much as 45 kg (100

lbs). Existing drive units can be retrofitted with this fea-

ture in the field, or the drive unit can be ordered with the

Magnet Lowering Device installed from the factory.

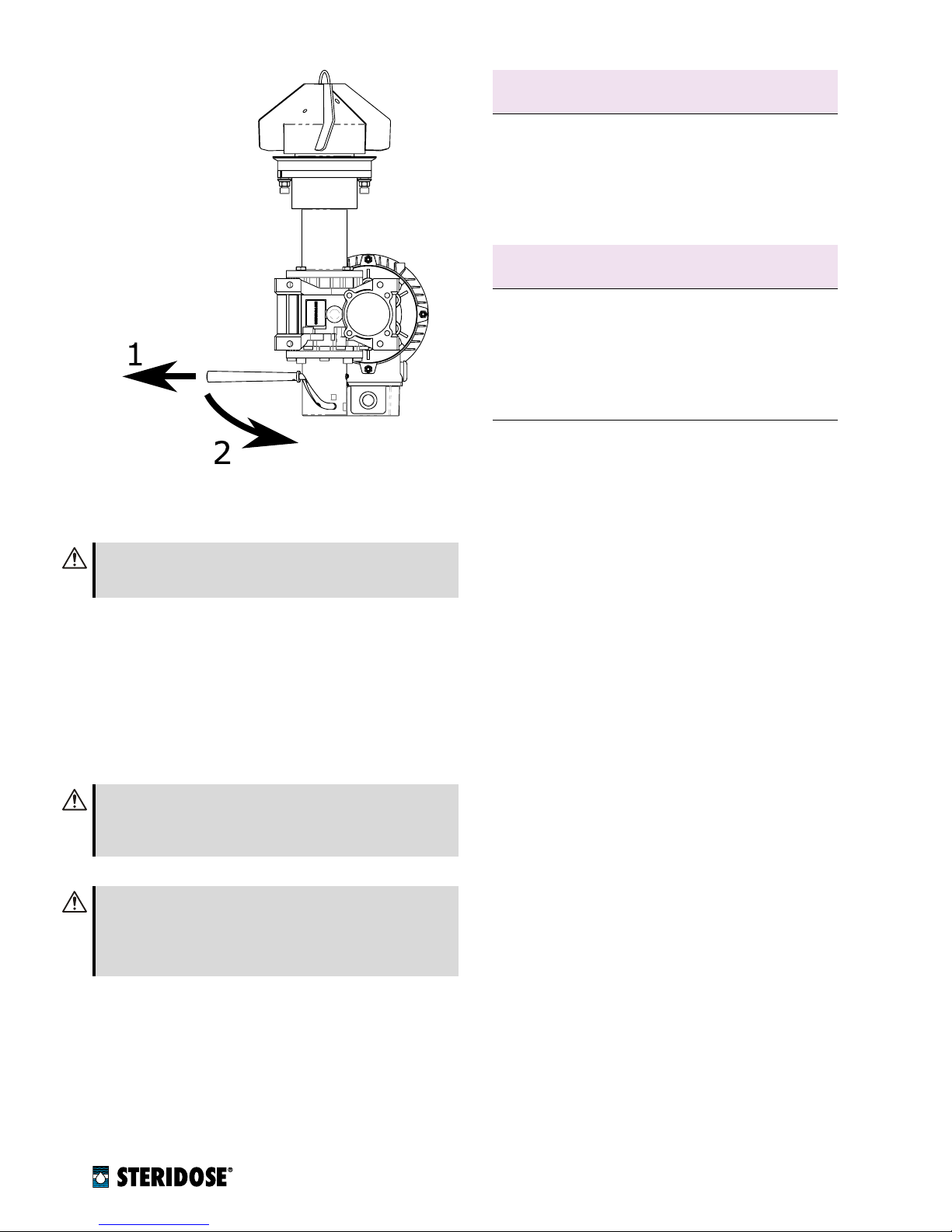

3. OPERATION

When installed on the drive unit the Magnet Lower-

ing Device can be operated as follows (see also figure

1):

2 | © Steridose www.steridose.com

nFigure 1

Operation of the Magnet Lowering Device: 1.

pull outwards, 2. slide along slot, 3. lock into position.

WARNING:

Make sure the drive unit is not running

and in automated installations make sure that lock-out

procedures have been followed.

1.

Pull the handle outwards to unlock it from its locked

position.

2.

Slide the handle through the S-shaped slot to move

the shaft and magnet rotor down/up.

3.

Make sure that when in its final position the handle

locks back into the locked position.

CAUTION:

Make sure that while operating the Magnet

Lowering Device there is enough room for the handle

and the operator’s hand to move freely without inter-

fering with pipes, tank legs or other objects.

CAUTION:

Keep fingers away from the S-shaped slot

when operating the Magnet Lowering Device, the mag-

netic forces present and the spring-loaded locking han-

dle might cause involuntary movements with risk for

pinching fingers.

See figure 2 for an example of a warning sign that can

be used to avoid incorrect installation/removal of the

impeller.

4. MAGNET LOWERING DEVICE PRODUCT

RANGE

The Magnet Lowering Device is available for non-ATEX

Sterimixer from size 85 and up. In order to accommodate

Mixer size

Delivered before 2018

Magnet Lowering Device

DU LD UPGRADE KIT a

85 113062

120/150 112393

120/190 112830

120H 112832

210 112834

Mixer size

Delivered in/after 2018

Magnet Lowering Device

DU LD KIT b

85 113121

120/150 112835

120/190 112836

120H 112837

210 112838

a

includes extended drive unit flange, extended shaft and lowering device

bincludes lowering device, assumes re-using shaft and flange

nTable 1

Part numbers for upgrade kits. Refer to sec-

tion 7 for details.

for the magnet rotor when in the lowered position, the use

of the Magnet Lowering Device requires the drive unit to

be equipped with the cooling jacket extension.

Retrofit kits are available that facilitate upgrading ex-

isting installations with this feature. Two different kits are

available depending on the original drive unit’s age, see

table 1. Fitting the upgrade kit is described in section 7.

5. SENSOR OPTION FOR AUTOMATION

The lowering device can be equipped with an optional

sensor that verifies that the Magnet Lowering Device is in

the raised position and that the mixer can be started. This

sensor included a LED which facilitates quick visual feed-

back (rotor up/down) during walk-around inspections of

the plant.

6. MAINTENANCE

The Magnet Lowering Device does not require special

maintenance.

7. FITTING THE UPGRADE KIT TO EXISTING

DRIVE UNITS

The upgrade kits (see table 1 for part numbers) come in

two versions:

DU LD UPGRADE KIT:

This kit must be used when up-

grading drive units that were delivered before 2018

(and after 2008, consult the factory for details). This

kit can also be used to upgrade drive units that do

not have the cooling jacket extension (adding the low-

ering device will change the space requirement of

the drive unit!). The kit includes extended drive unit

flange, an extended shaft, the mounting tool and the

lowering device (items 1, 2, 3, 4 in figure 3).

www.steridose.com Installation & Operation | 3

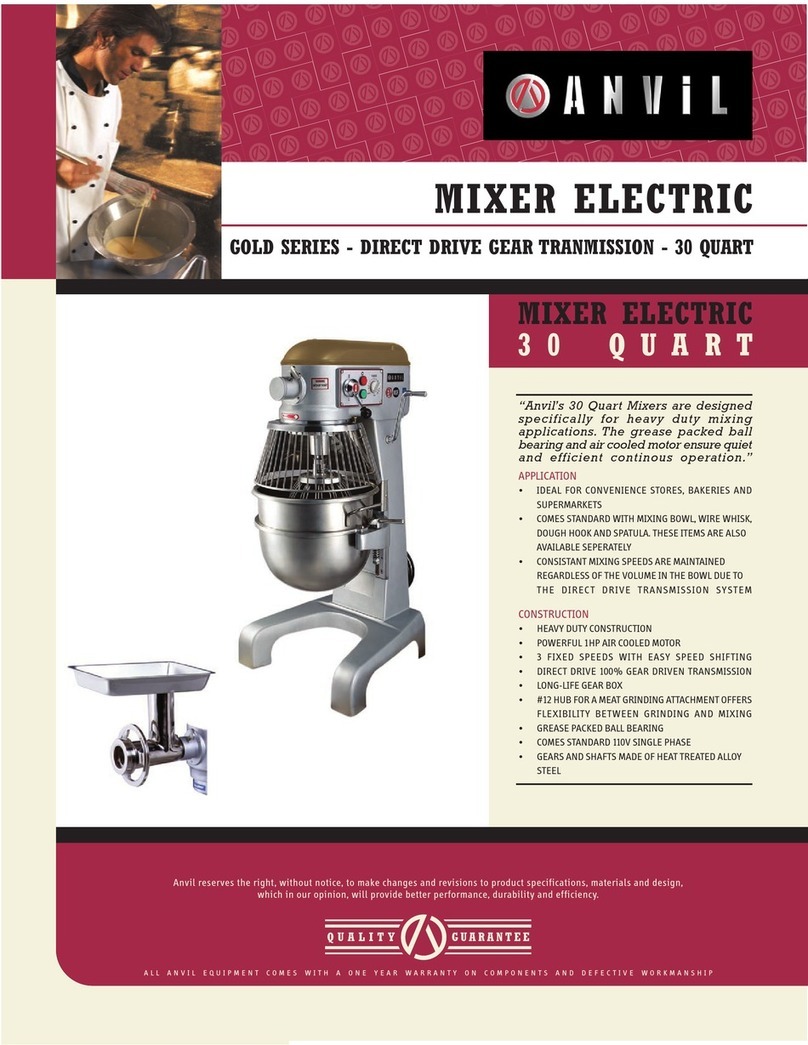

nFigure 2 Example of a sign for the correct use of the Magnet Lowering Device.

4 | © Steridose www.steridose.com

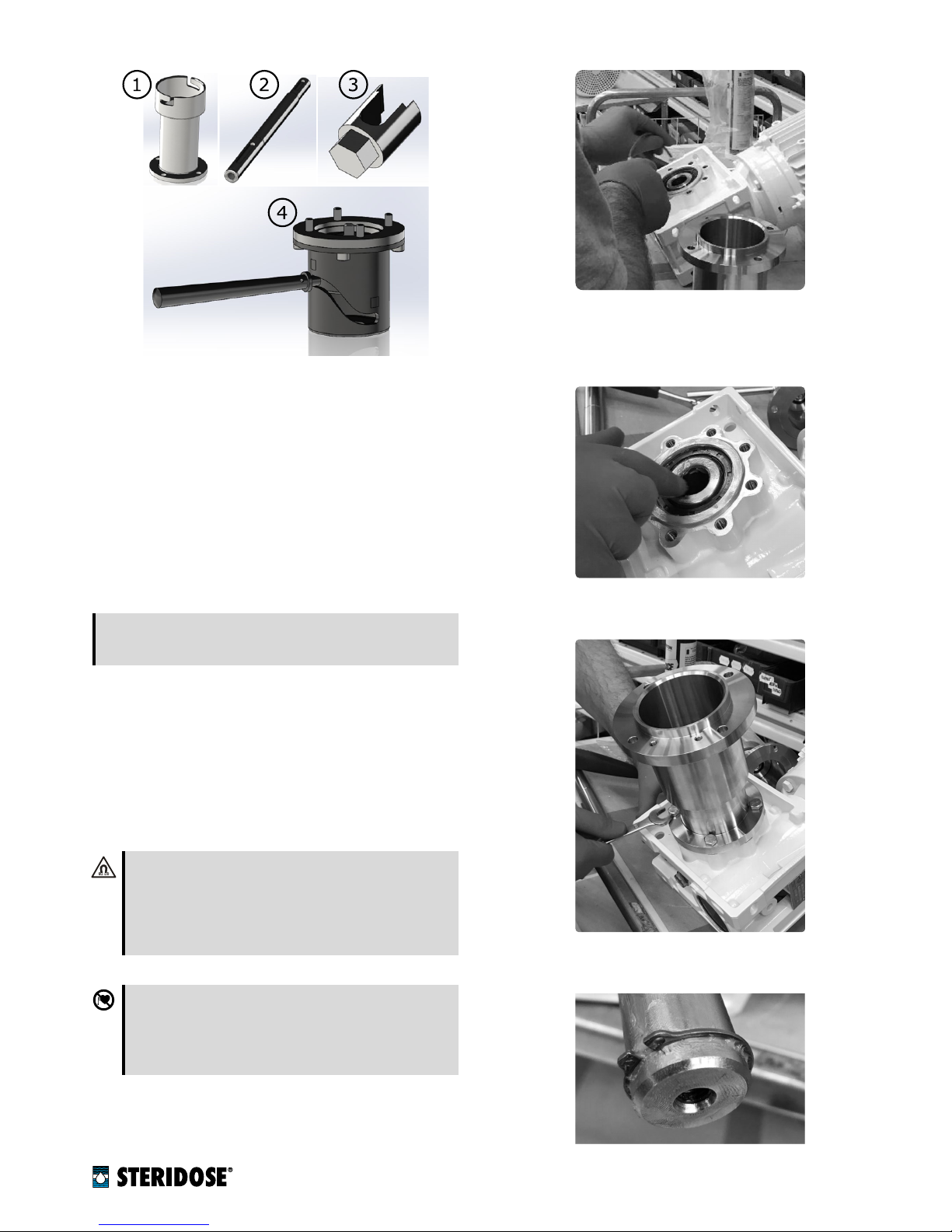

nFigure 3

Upgrade kit contents: 1. extended drive unit

flange, 2. extended shaft, 3 mounting tool, 4. the lowering

device.

DU LD KIT:

This kit is intended to be used when up-

grading drive units delivered in or after 2018. Since

the standard drive unit with cooling extension deliv-

ered in or after 2018 are already equipped with the

modified drive unit flange and shafts with bottom

thread (please consult factory), this kit only contains

the mounting tool and the lowering device (items 3

and 4 in figure 3).

+NOTICE:

Due to international shipping regulations

grease required for successful retrofit of the lowering

device is NOT included in the kits.

7.1. Steps for assembling the Magnet Lowering Device.

1. Clean the drive unit and especially the gearbox thor-

oughly.

2.

Remove the drive unit flange from the gearbox by

loosening the screws that fix it to the gearbox.

3. Remove the shaft from the gearbox’s hollow-shaft.

4.

Remove the magnet rotor from the shaft.

STRONG MAGNETIC FIELDS HAZARD:

The

Sterimixer impeller and magnetic rotor include

strong magnets with the associated risk of pinching

fingers and permanently damaging magnetic cards

(e.g. credit cards) if being close to these compo-

nents.

HAZARD FOR WEARERS OF CARDIAC PACE-

MAKER:

The Sterimixer impeller and magnetic

rotor include strong magnets thus personnel

equipped with pacemaker shall not handle these

components.

5.

Check the gearbox mounting frame for damage and

remove any paint, leaving the surface of interface

between flange and gearbox clean, even and smooth.

6.

Apply a suitable grease (e.g. Chesterton 630 SXCF)

to the gearbox’s hollow-shaft and the frame interface.

This will facilitate movement of the shaft and protect

against corrosion.

7.

Fit the extended drive unit flange to the gearbox and

tighten the screws.

8.

Fit the bottom circlip on the shaft (use protective eye-

wear when fitting circlips).

www.steridose.com Installation & Operation | 5

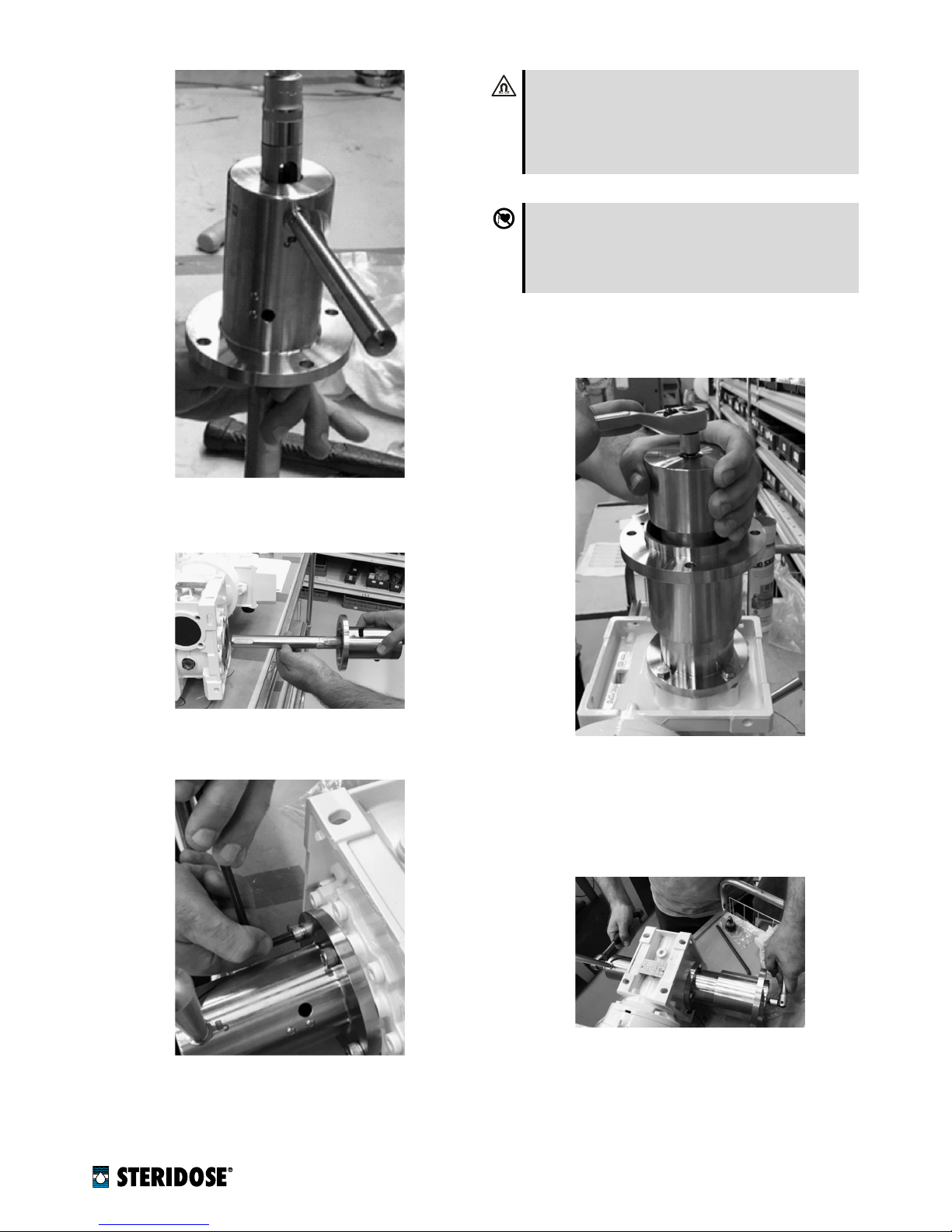

9.

Fit the keys in the keyways on the extended shaft and

apply grease (e.g. Chesterton 630 SXCF).

10.

Put the drive unit on a flat surface. Verify that the

gearbox’s hollow shaft is completely free of deforma-

tions or burrs. A common file can be used for this

purpose.

11.

Verify that the shaft can move smoothly up and down

the gearbox, all the way to the stop provided by the

bottom circlip. If necessary use a file to de-burr and

straighten the hollow-shaft keyway and/or the bot-

tom shaft key.

12.

Once the shaft runs smoothly up and down the gear-

box, apply additional grease to the gearbox’s hollow

shaft.

13.

Apply a suitable thread-sealant/locking liquid (e.g.

Loctite 243, Loctite 2400) to the Magnet Lowering

Device screw.

14.

Screw the Magnet Lowering Device mounting screw

into the bottom end of the shaft and tighten to 17 Nm

(150 in-lb) with assistance of the mounting tool.

6 | © Steridose www.steridose.com

15.

Insert the shaft and Magnet Lowering Device in the

gearbox hollow-shaft.

16.

Screw the Magnet Lowering Device into the gearbox

frame.

17.

Put the drive unit upright (use care and appropriate

lifting devices where required) and raise the shaft by

operating the Magnet Lowering Device.

STRONG MAGNETIC FIELDS HAZARD:

The

Sterimixer impeller and magnetic rotor include

strong magnets with the associated risk of pinching

fingers and permanently damaging magnetic cards

(e.g. credit cards) if being close to these compo-

nents.

HAZARD FOR WEARERS OF CARDIAC PACE-

MAKER:

The Sterimixer impeller and magnetic

rotor include strong magnets thus personnel

equipped with pacemaker shall not handle these

components.

Fix the magnet rotor on the shaft with the magnet

rotor screw.

18.

For final tightening of the magnet rotor and Magnet

Lowering Device mounting screw, put the drive unit

on its side (use care and appropriate lifting devices

where required) and tighten as shown in the picture

below.

8. FITTING THE OPTIONAL SENSOR KIT TO

THE MAGNET LOWERING DEVICE

1.

Remove the M3x3 screws from the Magnet Lowering

Device housing.

www.steridose.com Installation & Operation | 7

2.

Re-use the M3x3 screws to fix the sensor bracket to

the housing.

3.

Mount the sensor on the sensor bracket using the 2

provided M3x14 screws and nuts.

4.

Verify that the sensor works as intended. Since the

magnetic sensing range might pick up interference

from other moving parts in the Magnet Lowering

Device the sensor bracket has a slotted hole to allow

for adjustment of the sensor position to eliminate

interference.

Sensor technical data can be obtained from the sensor

supplier’s product information.

8 | © Steridose www.steridose.com

www.steridose.com Installation & Operation | 9

About us

Steridose is a global company and our world head-

quarters are located in Tumba, Sweden. We are highly

specialized in the design, development and manufactur-

ing of magnetic coupled mixers and radial diaphragm

valves.

Steridose is part of the Velcora group, with regional

offices in key locations around the world.

Steridose is represented in important certifying and

standards organizations, most notably and relevant to

the pharmaceutical industry, ASME BioProcessing Equip-

ment standards committee (BPE). We help develop the

standards and Good Manufacturing Practices that mini-

mize risk for process interference.

Steridose partners with the best distributors and repre-

sentatives in the industry all over the world. Together we

become the perfect mix; a premium product with global

references combined with local presence for product and

application support.

Steridose AB

Himmelsbodavägen 7

SE 147 39 Tumba, Sweden

Phone: +46 8 449 9900

www.steridose.com

Steridose Inc.

5020 World Dairy Drive

Madison, WI 53718, U.S.A.

Phone: +1 608 229 5225

www.steridose.com

Visit our website for the latest version of this document. The original instruction is in English, all non-English

instructions are translations of the original instruction. © Steridose AB

STD0023EN00 Revision en-1.0.0 - 20180831

Other manuals for sterimixer

1

Table of contents