Steris Basil 3600 User manual

UNCRATING/INSTALLATION INSTRUCTIONS

Basil®3600 Bedding Dispenser

(2009-03-31) P122997-217

i

Introduction Uncrating/Installation Instructions 122997-217

Follow each step of the UNCRATING/INSTALLATION INSTRUCTIONS in the

order presented. Open the carton carefully to avoid damage to the

equipment inside. If you find any indication of damage to the equip-

ment, no matter how slight, show it to your supervisor.

To properly install this Basil®3600 Bedding Dispenser, you need the

equipment drawing (previously furnished) showing all utility service

and space requirements. If the equipment drawing cannot be

located, contact STERIS for a replacement copy, providing the serial

and model numbers of the bedding dispenser.

Once installed, equipment operation should be tested by a qualified

service technician prior to use.

If STERIS supervision is desired for installing and starting up this

equipment, contact STERIS for pricing and availability of this service

in your region.

Advisory IMPORTANT: A listing of the Safety Precautions to be observed

when uncrating/installing and testing this bedding dispenser can be

found in SECTION 1 of this manual. Do not begin uncrating/installing

the equipment until you have become familiar with this information.

Any alteration of this equipment not authorized or performed by

STERIS will void the warranty. Alteration of equipment which could

adversely affect its operation and efficacy and may violate national,

state and local laws or regulations.

IMPORTANT: Refer to local occupational health and safety regula-

tions, as well as electric and plumbing codes, for any special require-

ments that may pertain to installation of this bedding dispenser.

Indications For Use The Basil 3600 Bedding Dispenser is an automatic, conveyorized

unit designed to dispense bedding into animal cages as they pass

through the unit. The bedding dispenser is capable of handling most

solid bedding used in the care of laboratory animals.

A WORD FROM STERIS CORPORATION

©2009, STERIS Corporation. All rights reserved. Printed in Canada.

ii

122997-217 Uncrating/Installation Instructions Introduction

Service Information A thorough preventive maintenance program is essential to help

ensure safe and proper equipment operation. Customers are

encouraged to contact STERIS concerning our comprehensive

annual maintenance program. Under the terms of the program, pre-

ventive maintenance, adjustments and replacement of worn parts

are performed on a scheduled basis to help ensure equipment per-

formance at peak capability and to help avoid untimely or costly

interruptions.

STERIS maintains a global staff of well-equipped, qualified service

technicians to provide this service, as well as expert repair services.

Please contact STERIS for details.

STERIS carries a complete line of accessories for use in this equip-

ment. A STERIS representative will gladly review these with you.

Manufactured by:

Corporation STERIS Canada

490, boulevard Armand-Paris

Québec, Qc,

G1C 8A3

CANADA

The base language of this document is

ENGLISH. Any translation must be made

from the base language document.

STERIS Limited

STERIS House

Jays Close

Viables

Basingstoke

Hampshire

RG22 4AX

United Kingdom

Sales and Service:

STERIS Corporation

5960 Heisley Road

Mentor, Ohio 44060

440-354-2600 • 800-444-9009

www.steris.com

iii

Table of Contents Uncrating/Installation Instructions 122997-217

A WORD FROM STERIS CORPORATION ................................................................ I

Advisory ........................................................................................................................................................... i

Indications For Use .......................................................................................................................................... i

Service Information ..........................................................................................................................................ii

1 SAFETY PRECAUTIONS .....................................................................................1-1

2 UNCRATING INSTRUCTIONS .............................................................................2-1

2.1 Open Crates .......................................................................................................................................... 2-1

2.2 Move Sections and Remove Skids ........................................................................................................ 2-2

2.3 Prepare Bedding Dispenser For Installation ......................................................................................... 2-3

3 INSTALLATION INSTRUCTIONS ........................................................................3-1

3.1 Before Installing Bedding Dispenser ..................................................................................................... 3-1

3.2 Technical Specifications ........................................................................................................................ 3-2

3.2.1 Voltage, Amperage and Power Consumption ................................................................................ 3-2

3.2.2 Permissible Environmental Conditions ........................................................................................... 3-2

3.2.3 Seismic Anchorage System ........................................................................................................... 3-2

3.3 Installing Conveyor ................................................................................................................................ 3-3

3.4 Installing Dust Collection System .......................................................................................................... 3-4

3.5 Connect Utilities ..................................................................................................................................... 3-5

3.6 Cleanup ................................................................................................................................................. 3-6

4 INSTALLATION CHECKLIST ...............................................................................4-1

5 OPERATIONAL TEST ..........................................................................................5-1

5.1 Start-Up Test Procedures ...................................................................................................................... 5-1

5.2 Transfer Plates For Different Bedding Types ........................................................................................ 5-3

5.2.1 Curved Transfer Plate With Bedding Fall Guide ............................................................................5-4

5.2.2 Flat Transfer Plate ........................................................................................................................... 5-6

TABLE OF CONTENTS

Section

Number Description Page

v

List of Illustrations Uncrating/Installation Instructions 122997-217

Section 2: Uncrating Instructions

2-1 Crates .............................................................................................................................................. 2-2

Section 3: Installation Instructions

3-1 Disconnect Switch For Electrical Supply ........................................................................................ 3-1

3-2 Installing Conveyor .......................................................................................................................... 3-3

3-3 Dust Collection System ................................................................................................................... 3-4

3-4 Conveyor Motor Wiring .................................................................................................................... 3-5

Section 5: Operational Test

5-1 Adjust Cage Size For Flip-Over Rotation ........................................................................................ 5-2

5-2 Bedding Types and Transfer Plates ................................................................................................ 5-3

5-3 Installing Curved Transfer Plate and Bedding Fall Guide ............................................................... 5-5

5-4 Installing Flat Transfer Plate ............................................................................................................ 5-6

LIST OF ILLUSTRATIONS

Figure Description Page

1-1

Safety Precautions Uncrating/Installation Instructions 122997-217

1

The following Safety Precautions must be observed when uncrating/installing, operating or servicing this Basil®

3600 Bedding Dispenser. WARNING indicates the potential for personal injury and CAUTION indicates the

potential for damage to equipment. For emphasis, certain Safety Precautions are repeated throughout the manual.

It is important to review ALL Safety Precautions before operating or servicing the bedding dispenser.

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

WARNING – ELECTRIC SHOCK AND/OR BURN HAZARD:

WARNING – LACERATION AND/OR EYE INJURY HAZARD:

WARNING – LACERATION HAZARD:

WARNING – HEALTH HAZARD:

Fans and motors have rotating parts and pinch points. When operating a unit equipped with dust collec-

tion system, ensure exhaust guard, elbow and dust bag are securely in place.

Repairs and adjustments to this equipment must be made only by STERIS or STERIS-trained service

personnel. Non-routine maintenance performed by unqualified personnel or installation of unauthorized

parts could cause personal injury, result in improper equipment performance, void the warranty or result

in costly damage. Contact STERIS regarding service options.

When moving the unit, use a forklift.

Disconnect all utilities to dispenser before servicing. Do not service dispenser unless all utilities have

been properly locked out. Always follow local lockout-tagout and electrical safety-related work practice

standards.

Fasteners and star washers are used to ensure protective bonding continuity. Always reinstall any star

washer which may have been removed during installation or servicing.

When removing bands, wear appropriate Personal Protective Equipment (PPE) and always use a tool

specifically designed to cut bands. Bands used to secure this carton can cause personal injury when

cut and tension is released.

When removing bolts, wear gloves to protect your hands.

Vapors from solvents can be harmful. Use with adequate ventilation. Follow directions on the container.

SAFETY PRECAUTIONS

1-2

122997-217 Uncrating/Installation Instructions Safety Precautions

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

IMPORTANT: Refer to the local occupational health and safety regulations, as well as electric and plumbing

codes, for any special requirements that may pertain to installation of this unit.

After utilities are connected to equipment, slowly remove the protective adhesive paper from the exte-

rior cabinet panels to reduce the level of static discharge.

Ensure a cooling fan is attached to rear motor shaft. Verify fan blades are positioned to send airflow to

motor. Motor will overheat without a cooling fan.

Once electrical power is connected, verify each motor for correct rotation. Incorrect motor rotation may

result in equipment damage and improper equipment operation.

When removing adhesives from stainless steel, use a solvent specially formulated for that purpose. Rub

in a back-and-forth motion (in same direction as surface grain). Solvent rubbed in a circular motion or

applied with a wire brush or steel wool on bedding dispenser assemblies can be harmful to stainless

steel. Do not use solvents on painted surfaces.

1-3

Safety Precautions Uncrating/Installation Instructions 122997-217

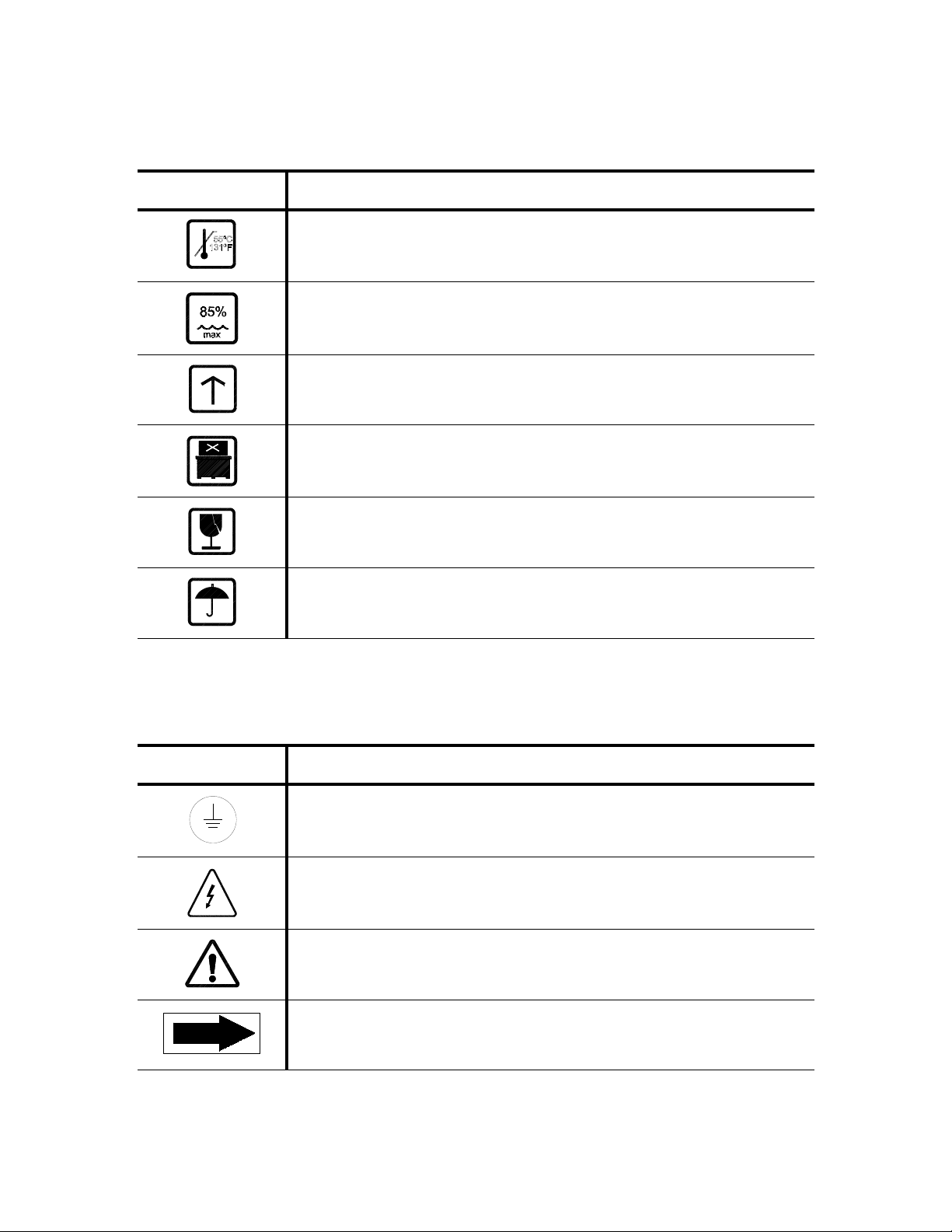

The table below contains symbols which may be on the crate of your Basil 3600 Bedding Dispenser:

The table below contains symbols which may be on your Basil 3600 Bedding Dispenser components:

Table 1-1. Definition of Symbols

Symbol Definition

Maximum Shipping and Storing Temperature.

Maximum Humidity Level.

This Way Up.

Do Not Stack.

Fragile.

Keep Dry.

Table 1-2. Definition of Symbols

Symbol Definition

Protective Earth (Ground).

Warning! Risk of Electrical Shock.

Warning. Refer to Manual For Further Information.

Rotation Direction.

1-4

122997-217 Uncrating/Installation Instructions Safety Precautions

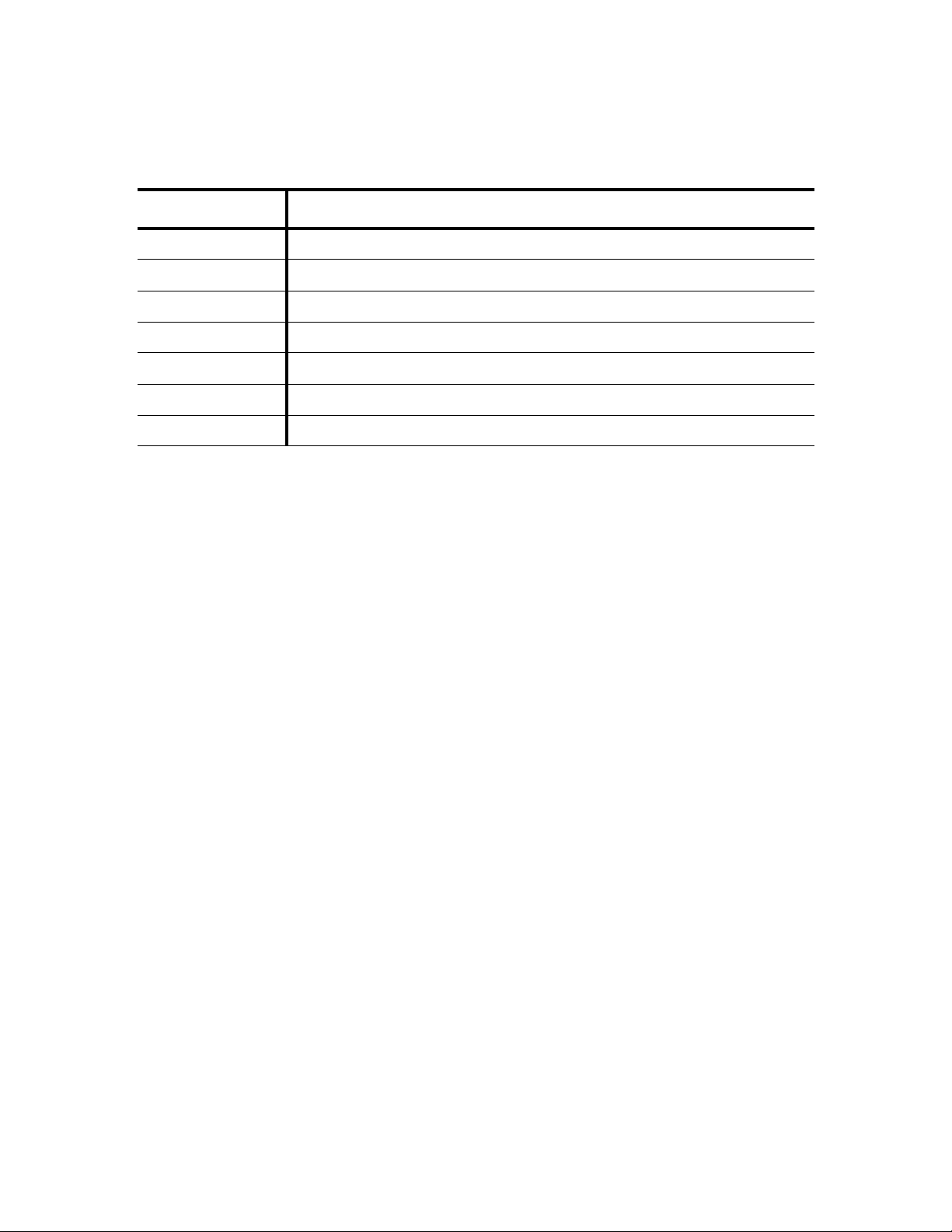

The table below contains symbols which may be on the identification nameplate of your Basil 3600 Bedding

Dispenser:

Table 1-3. Definition of Symbols

Symbol Definition

MOD. Model Number of Bedding Dispenser.

SER. Serial Number of Bedding Dispenser.

kW Power Rating of Bedding Dispenser.

VVoltage Rating of Bedding Dispenser.

AAmperage Rating of Bedding Dispenser.

PH/Hz Phase of Bedding Dispenser/Hertz – Frequency of Bedding Dispenser.

WIRE X + PE Number of Wires [X] in the Electrical Cable and Protective Ground Wire.

2

2-1

Uncrating Instructions Uncrating/Installation Instructions 122997-217

2.1 Open Crates NOTE: Before opening any crates, note the following:

1) Unit weighs approximately 1,800 lb (816 kg). Use a forklift to move

the unit.

2) Uncrate on level floor as close to installation site as possible.

3) Verify each crate for identification sticker indicating crate number

(see Figure 2-1).

1. Ensure crates are positoned so they open from top. Provide a

clear work area on all sides.

•Crate 1 contains conveyor base and pans for dust collection

system.

•Crate 2 contains load/unload conveyor.

2. Carefully cut and remove bands from Crate 1. Discard bands

before continuing.

3. Using a nail puller, remove and discard top wooden panel.

4. Using a nail puller, remove and discard side wooden panels.

5. Using a nail puller, remove and discard wooden frame from con-

veyors.

6. Remove and discard polystyrene wrap from around unit.

7. Take out two «V» shaped pans from crate and put safely aside.

8. Repeat Steps 1 to 7 for Crate 2.

IMPORTANT: A listing of the Safety Precautions to be observed when uncrating/installing and testing this

bedding dispenser can be found in SECTION 1 of this manual. Do not begin uncrating/installing the

equipment until you have become familiar with this information.

WARNING – PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: When moving the

unit, use a forklift.

WARNING – LACERATION AND/

OR EYE INJURY HAZARD:

When removing bands, wear

appropriate Personal Protec-

tive Equipment (PPE) and

always use a tool specifically

designed to cut bands. Bands

used to secure this carton can

cause personal injury when cut

and tension is released.

UNCRATING INSTRUCTIONS

2-2

122997-217 Uncrating/Installation Instructions Uncrating Instructions

2.2 Move Sections and

Remove Skids

1. With units still mounted on skids, use a forklift to move both sec-

tions to installation site.

2. Remove six lag bolts securing each section base to skid.

3. Remove and discard skid from under each section. If necessary,

use a piece of plywood as a small ramp to slide each section

from skid to floor.

Figure 2-1. Crates

WARNING – PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: When moving the

unit, use a forklift.

WARNING – LACERATION HAZ-

ARD: When removing bolts,

wear gloves to protect your

hands.

2-3

Uncrating Instructions Uncrating/Installation Instructions 122997-217

2.3 Prepare Bedding

Dispenser For

Installation

NOTE: Do not remove protective adhesive paper from the exterior

cabinet panels until after utilities are connected.

1. Remove all tape from bedding dispenser.

2. Locate electrical box compartment keys located in an envelope

taped on bedding dispenser electrical box.

3. Remove envelope labeled «Customer Information» containing

Operator Manual (P122996-163) taped on bedding dispenser

electrical box. Ensure appropriate person receives Operator

Manual. Give keys to department supervisor.

IMPORTANT: Items needed to assemble bedding dispenser are

enclosed in a box labeled "Hardware" included inside Crate 1

(see number on sticker affixed on crate). "Hardware" box

contains spare bolts, washers, nuts and other items.

4. Discard all packing material removed during uncrating proce-

dures.

CAUTION – POSSIBLE EQUIP-

MENT HAZARD:

• After utilities are connected

to equipment, slowly remove

the protective adhesive

paper from the exterior cabi-

net panels to reduce the

level of static discharge.

• When removing adhesives

from stainless steel, use a

solvent specially formulated

for that purpose. Rub in a

back-and-forth motion (in

same direction as surface

grain). Solvent rubbed in a

circular motion or applied

with a wire brush or steel

wool on bedding dispenser

assemblies can be harmful

to stainless steel. Do not use

solvents on painted sur-

faces.

3

3-1

Installation Instructions Uncrating/Installation Instructions 122997-217

3.1 Before Installing

Bedding Dispenser

See Figure 3-1.

1. Review installation requirements:

a. Clearance – clearance space shown on equipment drawing

(122-998-267 or 122-998-283) indicates space necessary

for easy installation and proper operation and maintenance

of Basil®3600 Bedding Dispenser.

For best results, tunnel cage washer conveyor should be 10-

3/4 to 11" (273 to 279 mm) higher than bedding dispenser

conveyor.

Tunnel cage washer conveyor opening must be aligned

within 1/8" to ensure functionality of chute conveyor safety

device.

Bedding dispenser and tunnel washer can be welded

together; however, placing them next to each other without a

gap is sufficient.

b. Utility service lines:

• Disconnect switch (not provided by STERIS) must be

installed in electric supply line near bedding dispenser

(see Figure 3-1). Disconnect switch must be capable of

being locked in OFF position only.

• If bedding dispenser is installed next to other equipment,

disconnect switch should be located so service can be

shut off to one piece of equipment at a time.

• Utility service requirements are as shown on equipment

drawing. Verify equipment drawing or identification plate

(located over electrical box cover) for proper voltage.

2. Ensure bedding dispenser is placed, as shown on equipment

drawing (122-998-267 or 122-998-283), in correct relation to

building supply lines.

NOTE: If bedding dispenser is not at installation site, see

SECTION 2.2, MOVE SECTIONS AND REMOVE SKIDS, for proper

moving instructions.

3. Verify bedding dispenser is level.

a. Place a spirit level on top of each conveyor.

b. If necessary, level bedding dispenser, end-to-end and side-

to-side, by adjusting leveling legs.

IMPORTANT: A listing of the Safety Precautions to be observed when uncrating/installing and testing this

bedding dispenser can be found in SECTION 1 of this manual. Do not begin uncrating/installing the

equipment until you have become familiar with this information.

WARNING – PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: Repairs and adjust-

ments to this equipment must be

made only by STERIS or STERIS-

trained service personnel. Non-

routine maintenance performed

by unqualified personnel or

installation of unauthorized parts

could cause personal injury,

result in improper equipment

performance, void the warranty

or result in costly damage. Con-

tact STERIS regarding service

options.

Figure 3-1. Disconnect Switch For

Electrical Supply

INSTALLATION INSTRUCTIONS

3-2

122997-217 Uncrating/Installation Instructions Installation Instructions

3.2 Technical

Specifications

These specifications are intended to describe the technical informa-

tion given on the identification nameplate of your bedding dispenser

and to state other relevant information. Verify equipment drawing or

identification nameplate, located in chemical storage compartment,

for proper voltage and amperage.

3.2.1 Voltage, Amperage and

Power Consumption

The Basil 3600 Bedding Dispenser operates on:

• 208 V, 60 Hz, three-phase, neutral, four-wire

• 480 V, 60 Hz, three-phase, three-wire

Maximum current and power consumptions are:

Amp kW

• 208 V 13.9 2.6

• 480 V 5.6 2.7

See SECTION 3.5, CONNECT UTILITIES, for proper connection.

3.2.2 Permissible

Environmental Conditions

This equipment is designed to give optimal results in an environment

where maximum relative humidity is 80% for temperatures up to 88°F

(31°C), decreasing linearly to 50% relative humidity at 104°F (40°C).

3.2.3 Seismic Anchorage

System

A seismic anchorage system is available for high-risk seismic zones.

3-3

Installation Instructions Uncrating/Installation Instructions 122997-217

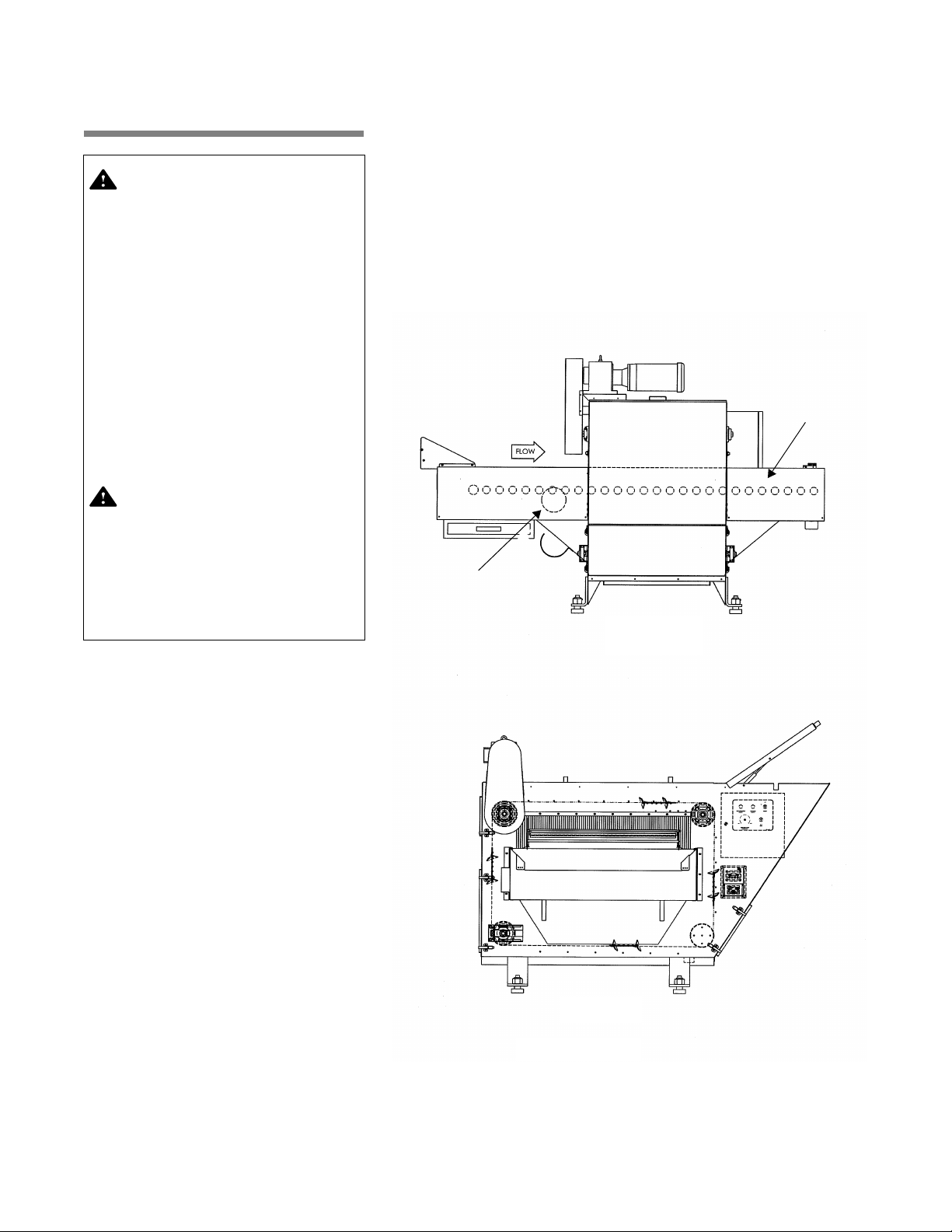

3.3 Installing Conveyor See Figure 3-2.

1. Insert load/unload conveyor into bedding dispenser using four

provided lag bolts.

2. Install base conveyor inlet and base conveyor outlet using 1/4-

20 x 3/4" bolts.

3. Install dust deflectors.

WARNING – PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: Repairs and adjust-

ments to this equipment must

be made only by STERIS or

STERIS-trained service person-

nel. Non-routine maintenance

performed by unqualified per-

sonnel or installation of unau-

thorized parts could cause

personal injury, result in

improper equipment perfor-

mance, void the warranty or

result in costly damage. Contact

STERIS regarding service

options.

WARNING – ELECTRIC SHOCK

AND/OR BURN HAZARD: Fas-

teners and star washers are

used to ensure protective bond-

ing continuity. Always reinstall

any star washer which may have

been removed during installa-

tion or servicing.

SIDE VIEW

Ventilation System

FRONT VIEW

(Load Side)

Load/Unload

Conveyor

Figure 3-2. Installing Conveyor

3-4

122997-217 Uncrating/Installation Instructions Installation Instructions

3.4 Installing Dust

Collection System

See Figure 3-3.

1. Connect 6" (152 mm) diameter black hose and reducer to inlet

elbow using two provided clamps.

2. Connect other end of hose to exhaust filter using provided

clamp.

3. Ensure black hose does not hang or form humps below suction

system inlet level to avoid a loss of suction or hose being

clogged.

4. Unscrew metal setscrews located over dust collection system

exhaust.

5. Connect 6" (152 mm) galvanized steel elbow over dust collection

system blower discharge guard.

6. Insert sleeve inside dust collection bag.

7. Large lip must be inserted so it holds bag tightly.

8. Secure sleeve to bag with provided clamp.

9. Slide sleeve over elbow and secure with provided clamps.

10. Secure elbow over dust collection system exhaust with previ-

ously removed setscrews.

WARNING – PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: Repairs and adjust-

ments to this equipment must be

made only by STERIS or STERIS-

trained service personnel. Non-

routine maintenance performed

by unqualified personnel or

installation of unauthorized parts

could cause personal injury,

result in improper equipment

performance, void the warranty

or result in costly damage. Con-

tact STERIS regarding service

options.

WARNING – ELECTRIC SHOCK

AND/OR BURN HAZARD: Fas-

teners and star washers are used

to ensure protective bonding

continuity. Always reinstall any

star washer which may have

been removed during installa-

tion or servicing.

Figure 3-3. Dust Collection System

Dust Collection

System Blower

Reducer

Setscrews

6" Galvanized

Steel Elbow

Sleeve

Hose

Dust Collection

Bag

Bag

Clamp

IMPORTANT: Avoid hose hangs

below dust collector inlet.

3-5

Installation Instructions Uncrating/Installation Instructions 122997-217

3.5 Connect Utilities See Figure 3-4.

1. Connect conveyor motor as per Figure 3-4.

2. Connect dust collection system electrical supply line from unit to

dust collection motor, securing connections with wire nuts:

• Red wire with T1

• Black wire with T2

• Blue wire with T3

3. If bedding dispenser is to be used with a Basil®6700 Tunnel

Cage Washer, make following wire connections:

a. Secure wire conduit located at unload end of Basil 6700

Tunnel Cage Washer in bedding dispenser electrical box.

b. Connect wires to their corresponding (numbered) terminal in

bedding dispenser electrical box.

4. Knocked-down shipment and photoelectric conveyor stop:

a. Secure wire conduit of photoelectric sensor in bedding

dispenser electrical box.

b. Connect wires to their corresponding (numbered) terminals

in bedding dispenser electrical box.

WARNING – PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: Repairs and adjust-

ments to this equipment must be

made only by STERIS or

STERIS-trained service person-

nel. Non-routine maintenance

performed by unqualified per-

sonnel or installation of unau-

thorized parts could cause

personal injury, result in

improper equipment perfor-

mance, void the warranty or

result in costly damage. Contact

STERIS regarding service

options.

WARNING – ELECTRIC SHOCK

AND/OR BURN HAZARD: Fas-

teners and star washers are

used to ensure protective bond-

ing continuity. Always reinstall

any star washer which may have

been removed during installa-

tion or servicing.

Figure 3-4. Conveyor Motor Wiring

3-6

122997-217 Uncrating/Installation Instructions Installation Instructions

3.6 Cleanup 1. Remove any adhesive found on panels with a small amount of

nonflammable cleaning solvent. Keep solvents away from all

painted surfaces or damage may result.

2. Remove all protective paper from unit cabinet panels. Slowly

peel paper away from stainless steel to reduce level of static dis-

charge.

3. Inspect dispenser and work area to ensure all materials used

during installation have been removed.

THIS COMPLETES THE INSTALLATION. Before operating bedding

dispenser, confirm all items on installation checklist (SECTION 4) have

been satisfactorily implemented and operational test (SECTION 5) is

conducted by a qualified service technician.

WARNING – HEALTH HAZARD:

Vapors from solvents can be

harmful. Use with adequate

ventilation. Follow directions

on the container.

CAUTION – POSSIBLE EQUIP-

MENT HAZARD:

• After utilities are connected

to equipment, slowly remove

the protective adhesive

paper from the exterior cabi-

net panels to reduce the

level of static discharge.

• When removing adhesives

from stainless steel, use a

solvent specially formulated

for that purpose. Rub in a

back-and-forth motion (in

same direction as surface

grain). Solvent rubbed in a

circular motion or applied

with a wire brush or steel

wool on bedding dispenser

assemblies can be harmful

to stainless steel. Do not use

solvents on painted sur-

faces.

4

4-1

Installation Checklist Uncrating/Installation Instructions 122997-217

Installation checklist must be completed after Basil®3600 Bedding

Dispenser is installed and prior to performing operational test to help

ensure complete and correct installation.

NOTE: Contact STERIS to schedule a technician to test your installa-

tion and demonstrate proper equipment operation.

❑Disconnect switch (not provided by STERIS), capable of being

locked in OFF position only, is installed in electrical supply line in

same room as bedding dispenser and within 10 feet (3 m) of

electrical control box and in compliance with local occupational

health and safety regulations, as well as electric codes for any

special requirements that may pertain to installation of this bed-

ding dispenser.

NOTE: If bedding dispenser is installed next to other equipment,

disconnect switches should be located so service can be shut off

to one piece of equipment at a time.

❑Bedding dispenser is positioned as shown on equipment drawing

(122-998-267 or 122-998-283), with required clearance space

and in relation to building supply lines.

❑Electrical supply for bedding dispenser is as specified on equip-

ment drawing.

❑Both conveyor motors (load/unload drive motor and bedding

conveyor motor) rotate in same direction shown by arrow.

❑Exhaust guard, elbow and dust collection bag are in position.

❑Verify cage flip-over system is firmly installed and in proper posi-

tion.

❑Verify photoelectric switch is properly installed at end of unload

conveyor.

IMPORTANT: A listing of the Safety Precautions to be observed when uncrating/installing and testing this

bedding dispenser can be found in SECTION 1 of this manual. Do not begin uncrating/installing the

equipment until you have become familiar with this information.

INSTALLATION CHECKLIST

5

5-1

Operational Test Uncrating/Installation Instructions 122997-217

5.1 Start-Up Test

Procedures

See Figure 5-1.

1. Ensure storage hopper is filled with bedding.

2. Position Power ON/OFF selector switch to ON.

3. Pull Unit STOP pushbutton (red) to start conveyor.

4. After pulling Unit STOP pushbutton, wait two seconds and push

Dispenser ON/OFF pushbutton to activate bedding dispenser

system.

5. Press Dust Collector ON/OFF pushbutton to activate dust col-

lection system.

6. If necessary, adjust amount of bedding desired in cages using

Dispenser Adjustment knob to increase/decrease bedding flow.

7. Position a few cages top side up on load-end conveyor.

NOTE: Cages of cage flip-over system are automatically flipped

from inverted position to top side up position when exiting Basil®

6700 Tunnel Cage Washer.

8. Let bedding dispenser run for a few minutes.

9. Verify rotation of conveyor motors. Motors should turn in direc-

tion shown by arrow. If motors are rotating in wrong direction,

disconnect main power, reverse any two three-phase wires and

verify shaft rotation again.

10. Verify rotation of dust collection motor fan. Fan should rotate

clockwise (in same direction as outlet of blower casing). If fan

motor is rotating in wrong direction, disconnect main power,

reverse any two three-phase wires and verify shaft rotation

again.

11. Adjust cage size for cage flip-over system as follows:

a. Remove two 10-32 screws.

b. Move adjustment rod to one of the four positions available

(see Figure 5-1).

IMPORTANT: Adjustment rod must be installed in the same

position on each side of cage flip-over module.

12. Position Power ON/OFF selector switch to OFF position. Verify

bedding dispenser conveyor operation stops.

IMPORTANT: A listing of the Safety Precautions to be observed when uncrating/installing and testing this

bedding dispenser can be found in SECTION 1 of this manual. Do not begin uncrating/installing the

equipment until you have become familiar with this information.

WARNING – PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: Fans and motors

have rotating parts and pinch

points. When operating a unit

equipped with dust collection

system, ensure exhaust guard,

elbow and dust bag are

securely in place.

WARNING – ELECTRIC SHOCK

AND/OR BURN HAZARD: Dis-

connect all utilities to dis-

penser before servicing. Do not

service dispenser unless all

utilities have been properly

locked out. Always follow local

lockout-tagout and electrical

safety-related work practice

standards.

CAUTION – POSSIBLE EQUIP-

MENT HAZARD: Once electri-

cal power is connected, verify

each motor for correct rota-

tion. Incorrect motor rotation

may result in equipment dam-

age and improper equipment

operation.

OPERATIONAL TEST

Table of contents

Popular Dispenser manuals by other brands

Bunn

Bunn VPR-VPS 10053.0000 Installation & operating guide

Bunn

Bunn BUNN-O-MATIC ULTRA-1 Installation & operating guide

Nordson

Nordson Asymtek X-1000 Series Training guide

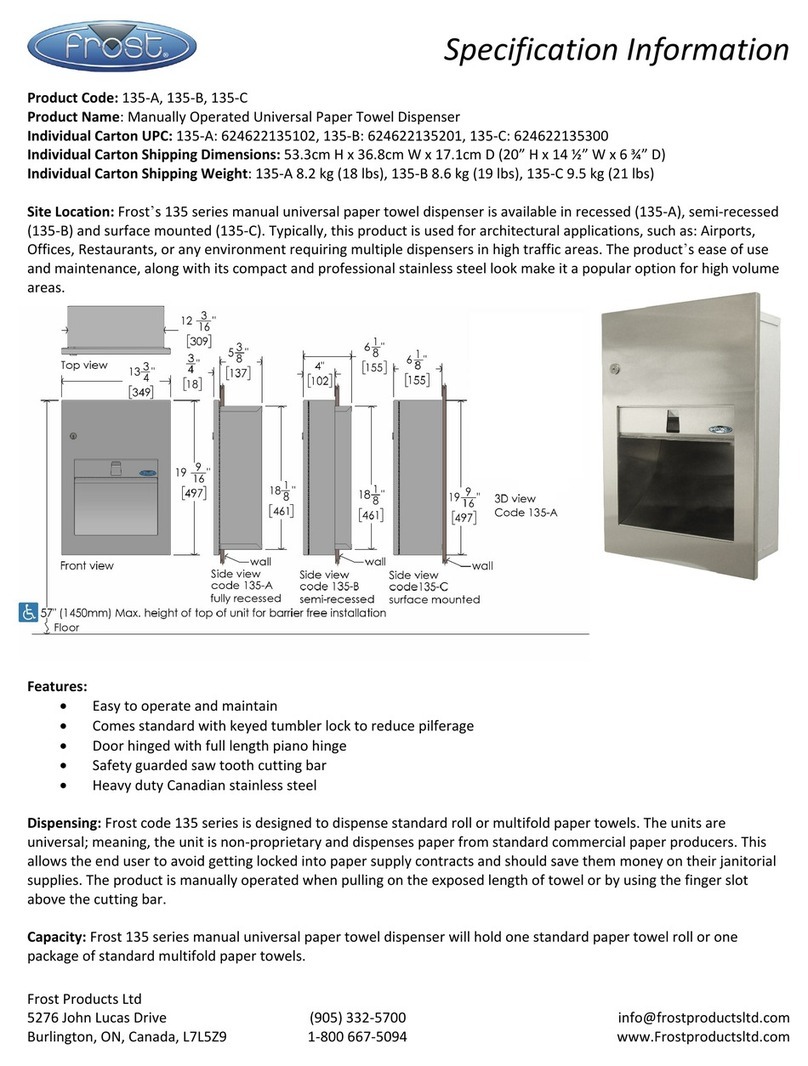

FROST

FROST 135 Series specification

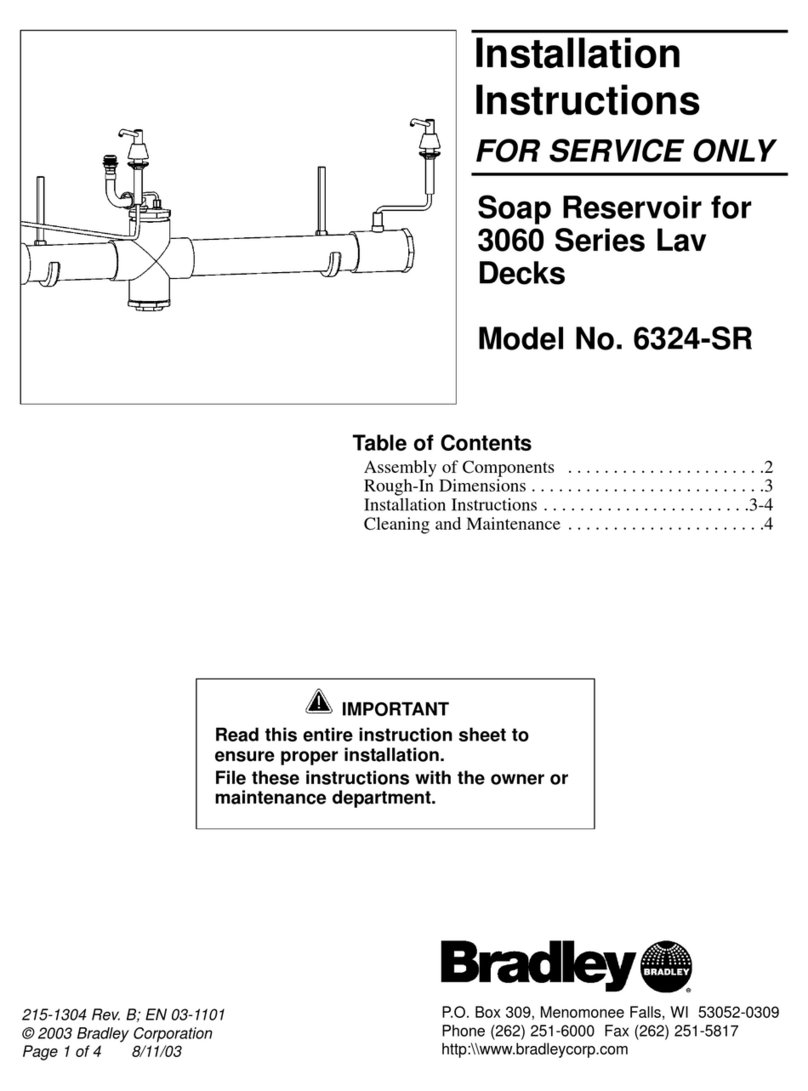

Bradley

Bradley 6324-SR installation instructions

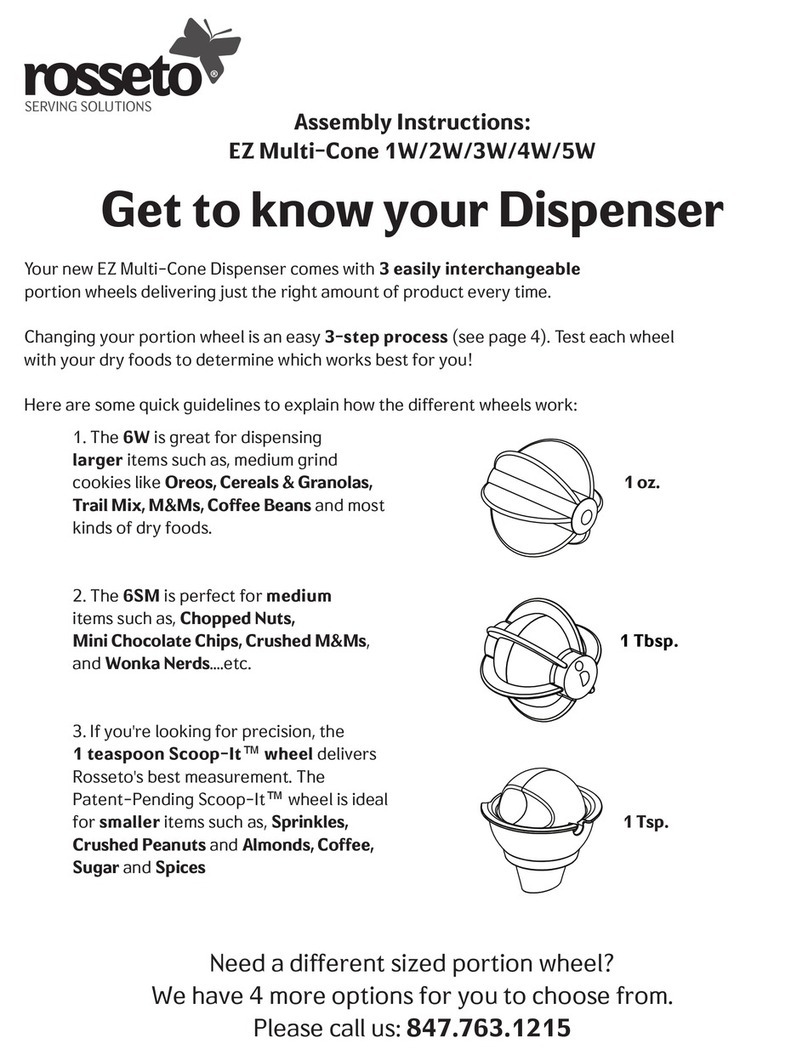

rosseto

rosseto EZ Multi-Cone 1W Assembly instructions